Zoe Gladstone Tarigan

Contents

[hide]Introduction

Perkenalkan saya Zoe Gladstone Tarigan, lahir di Kabanjahe 14 Juli 2003. Saya suka bermain bulu tangkis

Kelas 26/05/2023

Resume Perkuliahan:

Pertemuan pertama berisikan perkenalan dan introduksi dari Pak DAI.

Pak Dai menjelaskan cara mengajarnya yaitu mengenai teori consciousness (kesadaran) dimana jika individu menilai dirinya atau berlaku secara tidak sesuai berarti individu tersebut tidak sadar, sehingga kesadaran itu sendiri merupakan suatu realita yang ada. Hati itu merupakan sumber dari perintah dan otak yang meberikan perintahnya ke anggota tubuh untuk dilaksanakan,

Kemudian, beliau juga menceritakan teori/hal lainnya, seperti toleransi, ketuhanan, dan penilaian terhadap suatu hal yang memiliki banyak solusi melalui banyak pandangan atau perspektif.

Design & Optimization of Pressurized Hydrogen Storage

Objective:

- Design and Optimization

Specification:

- Capacity: 1 L

- Pressure Level: 8 bar

- Limitation: Cost should not exceed Rp. 500 K

Week 1 Progress

Knowing that I need to create something for this project, I consciously think that I need some assistance to provide me with some information about elements and procedures for designing and optimizing hydrogen storage. I chose ChatGPT to provide me assistance in this project because of its vast knowledge, exceptional language skills, and ability to understand and respond to a wide range of topics effectively and efficiently. "Could you offer an in-depth explanation of the elements and procedures involved in the design and optimization of a cost-effective compact pressurized hydrogen storage system?" I used this prompt in ChatGPT.

ChatGPT Response

Certainly! Designing and optimizing a cost-effective compact pressurized hydrogen storage system involves considering several key elements and following specific procedures. Here's an in-depth explanation of the process:

System Requirements: Begin by identifying the specific requirements for the hydrogen storage system, such as the desired storage capacity, operating pressure, weight, dimensions, and safety considerations. These requirements will guide the design process.

Storage Method: Determine the storage method based on the application and requirements. In this case, we'll focus on pressurized hydrogen storage. Other methods include cryogenic storage, solid-state storage, and chemical storage.

Material Selection: Selecting appropriate materials is crucial for safety, cost-effectiveness, and efficiency. The storage vessel should have high strength, be compatible with hydrogen, and possess low permeability to prevent hydrogen leakage. Common materials include high-strength steel, carbon fiber composites, or polymer-based liners with carbon fiber wrapping.

System Design: Develop a detailed design for the storage system, considering factors such as vessel shape, internal volume, structural integrity, valve and fitting placement, thermal management, and pressure relief mechanisms. Computer-aided design (CAD) software can assist in creating accurate models.

Safety Measures: Implement safety features to prevent accidents and ensure reliable operation. This may include pressure relief devices, burst disks, pressure sensors, and fire suppression systems. Adhering to relevant safety standards, such as ISO 16111 or ASME Boiler and Pressure Vessel Code, is crucial.

Optimization Techniques: Optimize the design for cost-effectiveness and compactness. This can involve various techniques, including structural analysis, computational fluid dynamics (CFD) simulations, and optimization algorithms. These methods help identify the most efficient shapes, materials, and manufacturing techniques to reduce cost and maximize storage capacity.

Manufacturing Process: Choose an appropriate manufacturing process that balances cost, quality, and scalability. Common methods for hydrogen storage vessels include filament winding for composite materials and deep-drawing or forging for metal containers. Continually improve the manufacturing process to reduce costs and enhance reliability.

Performance Testing: Conduct thorough performance tests to ensure the system meets the desired specifications and safety requirements. This may involve pressure cycling, leak testing, burst tests, and other relevant evaluations. Real-world conditions should be simulated as accurately as possible.

Regulatory Compliance: Ensure compliance with relevant regulations and standards for hydrogen storage systems. This may include certifications from regulatory bodies such as the International Organization for Standardization (ISO), the U.S. Department of Transportation (DOT), or local regulatory agencies. Compliance is essential for market acceptance and safety.

Lifecycle Considerations: Evaluate the lifecycle impact of the storage system, considering factors such as material sourcing, manufacturing energy consumption, maintenance requirements, and end-of-life considerations. Aim for sustainability and minimize environmental impact.

Continuous Improvement: As new technologies and materials emerge, continue to monitor advancements in hydrogen storage systems. Look for opportunities to enhance the system's efficiency, reduce costs, and improve safety through ongoing research and development efforts.

Final Report of Design & Optimization Hydrogen Storage

Intro

Compressed Gas Hydrogen Storage: To design a compressed gas hydrogen storage system, there are a few factors such as the type of storage vessel and the safety measures involved. Here's a basic outline for designing the system:

1. Storage Vessel Selection: Choose a suitable high-pressure storage vessel capable of withstanding the desired pressure of 8 bar. Common options include composite overwrapped pressure vessels (COPVs) made of lightweight materials like carbon fiber reinforced composites.

2. Volume Calculation: Given that the required storage volume is 1 liter, ensure that the selected storage vessel has a capacity of at least 1 liter.

3.Safety Considerations: Hydrogen is a highly flammable gas, so safety precautions are crucial. Ensure the storage vessel is designed and manufactured to meet the necessary safety standards. It should include features such as pressure relief devices, burst disks, and proper venting mechanisms to prevent overpressure situations.

4.Valve and Fittings: Install suitable valves and fittings on the storage vessel to control the flow of hydrogen during filling and dispensing processes. Use high-quality components compatible with hydrogen gas.

5.Material Compatibility: Ensure that all materials in contact with hydrogen gas, including the storage vessel, valves, and fittings, are compatible with hydrogen to prevent any degradation or safety risks.

6.Handling and Transport: Follow proper handling and transport protocols for hydrogen gas, including proper labeling, storage in well-ventilated areas, and adherence to relevant safety regulations.

Requirements :

-Pressure = 8 bar

-capacity = 1 liter

-budget = not more than Rp 500.000

Optimization variable :

-Geometry size

-Material selection

-Material strength

-Budget

Geometry Size

First we have to find the most optimized size for the hydrogen storage. Below are the example code to find that:

import math

def calculate_surface_area(x):

radius, height = x

surface_area = 2 * math.pi * radius * (radius + height)

return surface_area

def calculate_optimized_dimensions(volume):

volume_cm3 = volume * 1000

objective = lambda x: calculate_surface_area(x)

constraint = lambda x: volume_cm3 - (math.pi * x[0]**2 * x[1])

x0 = [1, 1]

bounds = ((0, None), (0, None))

volume_constraint = {'type': 'eq', 'fun': constraint}

result = minimize(objective, x0, method='SLSQP', bounds=bounds, constraints=volume_constraint)

optimized_radius = result.x[0]

optimized_height = result.x[1]

optimized_surface_area = result.fun

return optimized_radius, optimized_height, optimized_surface_area

volume = 1

radius, height, surface_area = calculate_optimized_dimensions(volume)

print(f"Optimal Radius: {optimal_radius} cm")

print(f"Optimal Height: {optimal_height} cm")

print(f"Surface Area: {surface_area} cm^2")

Results:

Optimal Radius: 5.419259622871326 cm Optimal Height: 10.838525719677232 cm Surface Area: 553.5810446887042 cm^2

Now we have the optimal radius, height, and the surface area for the hydrogen storage

Material Strength

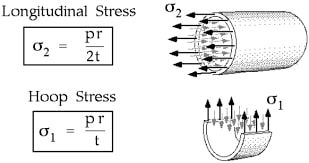

There are so many factors that affect the material strength of an object. One of the aspects that affect the material strength of a pressure container is material thickness. Thickness of the material contributes to the circumferential (hoop) and longitudinal stress. Circumferential stress is a type of stress that occurs in a cylindrical or spherical structure and longitudinal stress is a type of stress that occurs along the longitudinal or axial direction of a structural component Below is the equation to calculate hoop and longitudinal stress:

To find the thickness, we will use a code to find several thickness and circumferential stress. Wy only circumferential stress? because its very affecting thin wall tube.

Below are the code:

r = 5.42e-2

p = 800000

t = 1e-3

mylist = []

while t < 3e-3:

circumferential = (r * p)/(t)

t += 0.1e-3

mylist.append((t,circumferential))

print('(Thickness, Pressure):',mylist)

Results:

[(0.0011, 43360000.0), (0.0012, 39418181.8182), (0.0013, 36133333.3333), (0.0014, 33353846.1538), (0.0015, 30971428.5714), (0.0016, 28906666.6666), (0.0017, 27099999.9999), (0.0018, 25505882.3529), (0.0019, 24088888.8888), (0.0020, 22821052.6315), (0.0021, 21679999.9999), (0.0022, 20647619.0476), (0.0023, 19709090.9090), (0.0024, 18852173.9130), (0.0024, 18066666.6666), (0.0025, 17344000.0), (0.0026, 16676923.0769), (0.0027, 16059259.2592), (0.0028, 15485714.2857), (0.0029, 14951724.1379), (0.0031, 14453333.3333)]

From the results, we can say that the greater the thickness, the smaller the required material strength needed.

Material Selection

When it comes to selecting the best material for hydrogen storage, it is crucial to consider the material's properties, such as its resistance to hydrogen embrittlement and permeability. Stainless steels from the austenitic family, specifically those with high nickel content, are commonly used for hydrogen storage applications due to their favorable properties.

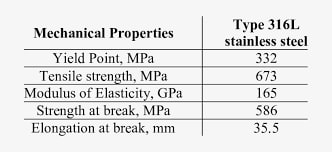

One of the most widely used stainless steels for hydrogen storage is type 316L stainless steel. Type 316L stainless steel has good mechanical properties and is relatively resistant to hydrogen embrittlement.

Below is the mechanical properties of 316L stainless steel:

Yield Strength of the material is 332 MPa and the general safety factor of the pressurized storage is 10, so the pressure times safety material should be lower than the selected material yield strength (332 MPa). If we see the thickness and pressure iteration before, the fulfiled thickness must be greater than 1.4 mm.

Budget

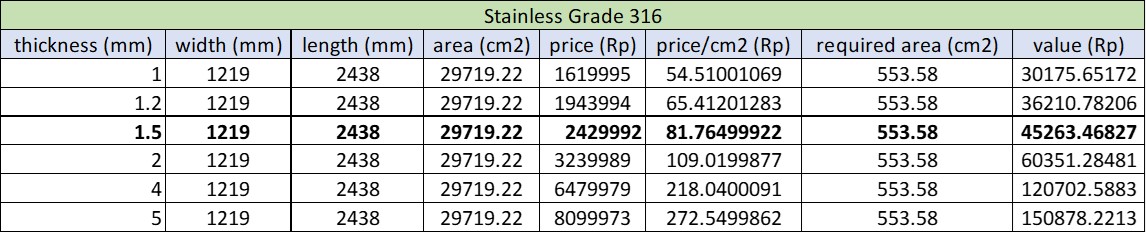

Below is the pricelist from one company that sells 316L stainless steel

And below is the specific price by area

If we see the list, all the price provided is under Rp500.000. So we will find the thickness that can withstand the safety pressure and also the cheapest one. 1.5 mm thickness stainless steel will be the best option to choose for the hydrogen storage that only cost Rp45.263,468.

My Consciousness in Numerical Method and Designing an Optimum Hydrogen Tube

link youtube: metode numerik