Tugas Besar Metode Numerik - Josiah Enrico S

Contents

Abstract

Introduction

Objective

- Membuat program analisis truss dan optimasi sederhana dengan Modelica

- Mengoptimasi harga pembuatan rangka truss sederhana dengan memvariasi dimensi dan elastisitas material.

Methodology

- Metode Optimasi Golden Section (univariabel)

- Metode Optimasi Golden Section (multivariabel)

Procedure

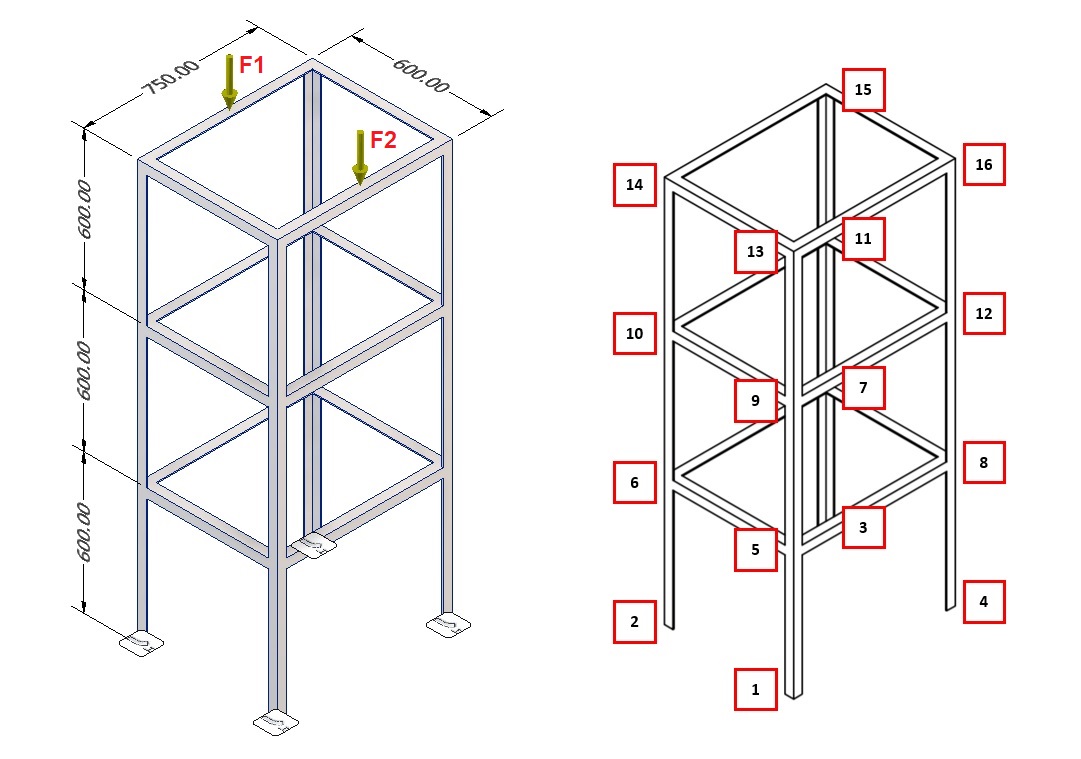

Geometri dan Load

| F1 | 2000 |

|---|---|

| F2 | 1000 |

Constraint:

- Spesifikasi L (Panjang) dan geometri rangka truss

- Gaya beban terhadap struktur (1000 N dan 2000 N)

Asumsi:

- Beban akan terdistribusi hanya pada point penghubung dan semua gaya yang dipengaruhi moment diamggap tidak ada karena sistem bersifat truss

Koleksi Data

Data Proceessing

Truss Structure Analysis Model

Pada tahap pertama, dilakukanka simulasi menggunakan Modelica untuk mengetahui pengaruh beban gaya yang diberikan terhadap struktur truss. Pengaruh ini direpresantasikan oleh 4 nilai yaitu displacement/perpindahan, gaya reaksi, tekanan di setiap truss dan faktor keamanan di setiap truss. Keempat nilai ini diperoleh dengan menggunakan operasi tranformasi matriks untuk pembebanan truss dalam Finite Element Analysis. Operasi ini diterjemahkan ke dalam bahasa C dalam pemrograman Modelica. Berikut ini adalah hasil simulasi Modelica dan program tertulisnya:

model Truss_3D_Tugas_Besar_Safety

// Base Code by Josiah Enrico S. 1906356286

// Editing and Testing by Ahmad M. Fahmi 1806181836

// Commenting and Cleaning by Christopher S. Erwin 1806201056

// === DEFINITION PHASE ===

// Define the properties of the truss arrangement

parameter Integer Nodes = size(node_points,1); // Number of Nodes

parameter Integer Members = size(node_pairs,1); // Number of Members

// Define the properties of the truss material

parameter Real Yield = 215e6; // Yield Strength (Pa)

parameter Real Area = 0.000224; // Area L Profile [Dimension=0.03, Thickness=0,004] (m^2)

parameter Real Elas = 193e9; // Elasticity of material [SS 304] (Pa)

// Define connections; list pair of nodes joined by a member

parameter Integer node_pairs[:,2]=[1,5; 2,6; 3,7; 4,8; // Lowest vertical members

5,6; 6,7; 7,8; 5,8; // 1st shelf

5,9; 6,10; 7,11; 8,12; // Middle vertical members

9,10; 10,11; 11,12; 9,12; // 2nd shelf

9,13; 10,14; 11,15; 12,16; // Top vertical members

13,14; 14,15; 15,16; 13,16];// 3rd shelf

// Define coordinates and boundaries of each node

// [x, y, z, boundary_x, boundary_y, boundary_z]

// If the node is bound (stationary) along that axis, then boundary_axis = 1

// otherwise the node is free and boundary_axis = 0

parameter Real node_points[:,6]=[0.3,-0.375,0,1,1,1; // Node 1

-0.3,-0.375,0,1,1,1; // Node 2

-0.3,0.375,0,1,1,1; // Node 3

0.3,0.375,0,1,1,1; // Node 4

0.3,-0.375,0.6,0,0,0; // Node 5

-0.3,-0.375,0.6,0,0,0; // Node 6

-0.3,0.375,0.6,0,0,0; // Node 7

0.3,0.375,0.6,0,0,0; // Node 8

0.3,-0.375,1.2,0,0,0; // Node 9

-0.3,-0.375,1.2,0,0,0; // Node 10

-0.3,0.375,1.2,0,0,0; // Node 11

0.3,0.375,1.2,0,0,0; // Node 12

0.3,-0.375,1.8,0,0,0; // Node 13

-0.3,-0.375,1.8,0,0,0; // Node 14

-0.3,0.375,1.8,0,0,0; // Node 15

0.3,0.375,1.8,0,0,0]; // Node 16

// Define external forces in Newtons on each node

// [Fx, Fy, Fz]

parameter Real Forces[nodes_xyz]={0,0,0, // Node 1

0,0,0, // Node 2

0,0,0, // Node 3

0,0,0, // Node 4

0,0,0, // Node 5

0,0,0, // Node 6

0,0,0, // Node 7

0,0,0, // Node 8

0,0,0, // Node 9

0,0,0, // Node 10

0,0,0, // Node 11

0,0,0, // Node 12

0,0,-500, // Node 13

0,0,-1000, // Node 14

0,0,-1000, // Node 15

0,0,-500}; // Node 16

// === SOLUTION PHASE ===

Real displacement[nodes_xyz], reaction[nodes_xyz];

Real check[3]; // To check if forces in xyz directions sum to zero (structure is static)

Real safety[Members]; // Safety Factor of each member (based on stress experienced)

Real mem_dis[3]; // Displacement in xyz directions experienced by member

Real stress_vector[3]; // Stress experienced by member in xyz directions

Real stress_mag[Members]; // Magnitude of stress experienced by member

protected

parameter Integer nodes_xyz = 3 * Nodes; // Size of vector of {node_#_x, node_#_y, node_#_z} containing all nodes

Real node_i[3], node_j[3]; // Coordinates in xyz for member's node pairs

// Global Stiffness Matrix construction

Real G_element[nodes_xyz, nodes_xyz], G_total[nodes_xyz, nodes_xyz], G_total_new[nodes_xyz, nodes_xyz];

// Transformation Matrix construction

Real cos_x, cos_y, cos_z, L, T[3,3];

// Limits to eliminate Float Errors

Real err_solve = 10e-10, err_check = 10e-4;

algorithm

//Creating Global Matrix

G_total := identity(nodes_xyz);

for mem in 1:Members loop

// Get coordinates of member's nodes

for i in 1:3 loop

node_i[i] := node_points[node_pairs[mem,1],i];

node_j[i] := node_points[node_pairs[mem,2],i];

end for;

// Finding the Stiffness Matrix [Ke]

// {F} = [Ke]{U}

// [Ke] = k[T]

L := Modelica.Math.Vectors.length(node_j - node_i);

cos_x := (node_j[1]-node_i[1])/L;

cos_y := (node_j[2]-node_i[2])/L;

cos_z := (node_j[3]-node_i[3])/L;

T := (Area * Elas / L)*[cos_x^2,cos_x*cos_y,cos_x*cos_z;

cos_y*cos_x,cos_y^2,cos_y*cos_z;

cos_z*cos_x,cos_z*cos_y,cos_z^2];

// Transforming to Global Matrix

G_element := zeros(nodes_xyz,nodes_xyz);

for m,n in 1:3 loop

G_element[3*(node_pairs[mem,1]-1)+m, 3*(node_pairs[mem,1]-1)+n] := T[m,n];

G_element[3*(node_pairs[mem,2]-1)+m, 3*(node_pairs[mem,2]-1)+n] := T[m,n];

G_element[3*(node_pairs[mem,2]-1)+m, 3*(node_pairs[mem,1]-1)+n] := -T[m,n];

G_element[3*(node_pairs[mem,1]-1)+m, 3*(node_pairs[mem,2]-1)+n] := -T[m,n];

end for;

// Adding to total Global Matrix

G_total_new := G_total + G_element;

G_total := G_total_new;

end for;

//Implementing boundary conditions to Global Matrix

for nod in 1:Nodes loop

// Boundary x-axis

if node_points[nod,4] <> 0 then

for i in 1:Nodes*3 loop

G_total[(nod*3)-2,i] := 0;

G_total[(nod*3)-2,(nod*3)-2] := 1;

end for;

end if;

// Boundary y-axis

if node_points[nod,5] <> 0 then

for i in 1:Nodes*3 loop

G_total[(nod*3)-1,i] := 0;

G_total[(nod*3)-1,(nod*3)-1] := 1;

end for;

end if;

// Boundary z-axis

if node_points[nod,6] <> 0 then

for i in 1:Nodes*3 loop

G_total[nod*3,i] := 0;

G_total[nod*3,nod*3] := 1;

end for;

end if;

end for;

// Solving displacement (U)

// [G_total]{U} = {F}

displacement := Modelica.Math.Matrices.solve(G_total, Forces);

// Solving reaction (R)

// {R} = [G_total]{U} - {F}

reaction := (G_total_new * displacement) - Forces;

// Eliminating float errors

for i in 1:nodes_xyz loop

reaction[i] := if abs(reaction[i])<= err_solve then 0 else reaction[i];

displacement[i] := if abs(displacement[i])<= err_solve then 0 else displacement[i];

end for;

// Checking Sum of Forces

// For static structures, should add up to 0

check[1]:=sum({reaction[i] for i in (1:3:(nodes_xyz-2))}) + sum({Forces[i] for i in (1:3:(nodes_xyz-2))});

check[2]:=sum({reaction[i] for i in (2:3:(nodes_xyz-1))}) + sum({Forces[i] for i in (2:3:(nodes_xyz-1))});

check[3]:=sum({reaction[i] for i in (3:3:(nodes_xyz))}) + sum({Forces[i] for i in (3:3:(nodes_xyz))});

// Eliminating float errors

for i in 1:3 loop

check[i] := if abs(check[i])<= err_check then 0 else check[i];

end for;

// === POSTPROCESSING PHASE ===

//Calculating stress in each truss

for mem in 1:Members loop

// Getting node coordinate data and displacement for current member

for i in 1:3 loop

node_i[i] := node_points[node_pairs[mem,1],i];

node_j[i] := node_points[node_pairs[mem,2],i];

mem_dis[i] := abs(displacement[3*(node_pairs[mem,1]-1)+i] - displacement[3*(node_pairs[mem,2]-1)+i]);

end for;

// Solving the Displacement Matrix for current member

// Stress = F/A = (E/L) * [dL]

L:=Modelica.Math.Vectors.length(node_j-node_i);

cos_x:=(node_j[1]- node_i[1])/L;

cos_y:=(node_j[2]- node_i[2])/L;

cos_z:=(node_j[3]- node_i[3])/L;

T := (Elas/L)*[cos_x^2,cos_x*cos_y,cos_x*cos_z;

cos_y*cos_x,cos_y^2,cos_y*cos_z;

cos_z*cos_x,cos_z*cos_y,cos_z^2];

stress_vector:=(T*mem_dis); // The stress in vector components {stress_x, stress_y, stress_z}

stress_mag[mem]:=Modelica.Math.Vectors.length(stress_vector); // Magnitude/length of the stress vectors for each member

end for;

// Safety Factor

// Factor of Safety = (Yield Strength of material) / (Stress experienced by Member)

for mem in 1:Members loop

if stress_mag[mem]>0 then

safety[mem] := Yield / stress_mag[mem];

else

safety[mem] := 0;

end if;

end for;

end Truss_3D_Tugas_Besar_Safety;

|

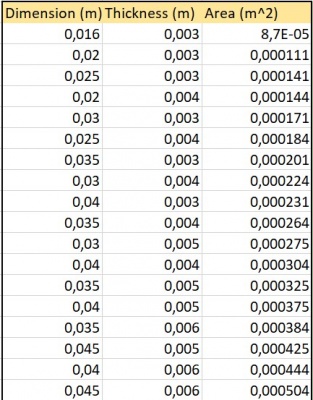

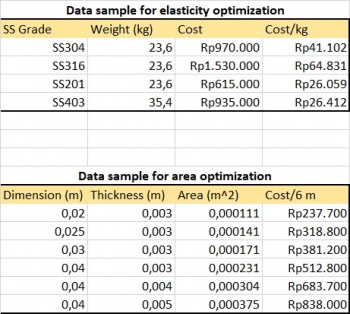

Cost and Cost Efficiency of Area Variation and Constrained Elasticity

Berdasarkan hasil analisis dari struktur truss sebelumnya, pada bagian ini parameter area cross-section dari setiap truss dalam struktur tesebut divariasi dengan menggunakan yann standar ukuran yang tertera pada prosedur. Data perbedaan Area dalam material yang sama tersebut diproses menjadi variasi harga (cost) dan efisiensi harga (safaty factor/cost) agar dapat diproses di akhir dengan optimisasi metode Powell. Dalam Prosesnya, data harga material yang terbatas di pasar akan di-regresi orde 2 untuk mendapatkan nilai harga pada ukuran-ukuran yang tidak memilik harga. Berikut adalah tabel hasil proses data dan grafik yang dihasilkan:

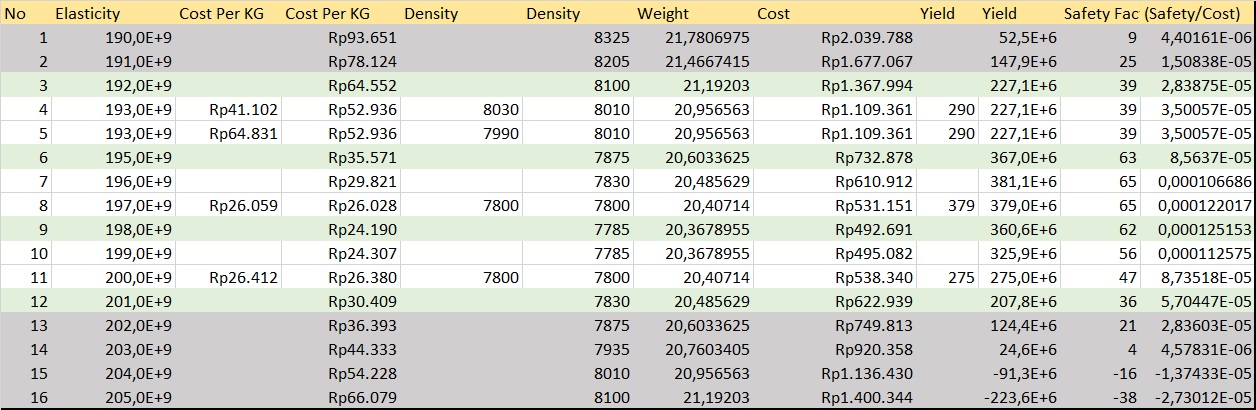

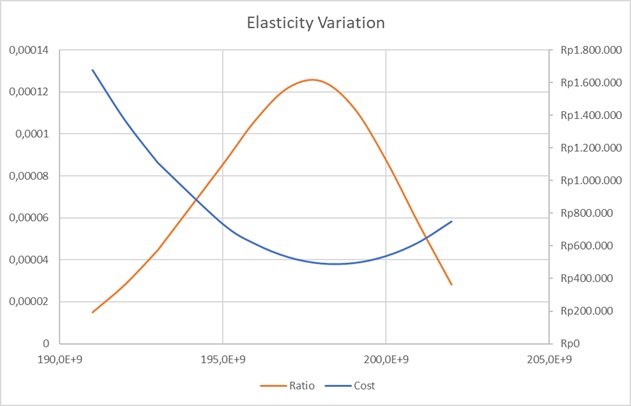

Cost and Cost Efficiency of Elasticity Variation and Constrained Area

Result and Analysis

|

Powell Method model Powell_Method_Opt_Jos_Ratio

parameter Integer order=2; //order of regression

parameter Integer GoldN=15; //maximum iteration of linear gold optimization

parameter Integer N=10; //maximum iteration

parameter Real maxerror=1e-50; //maximum error

//Assumed to be X function

parameter Real RatioArea[size(Area,1)]={3.6534e-5, 3.75348e-5, 3.79639e-5, 3.79507e-05, 3.74821e-05};

parameter Real CostArea[size(Area,1)]={829776,1053955,1308215,1722235,2202651};

parameter Real Area[:]={141e-6, 184e-6, 231e-6, 304e-6, 384e-6};

Real CoeArea[order+1];

Real CoeAreaCost[order+1];

//Assumed to be Y function

parameter Real RatioElas[size(Elas,1)]={2.83875e-5, 8.5637e-5, 12.5153e-5, 5.70447e-5};

parameter Real CostElas[size(Elas,1)]={1367994,732878,492691,622939};

parameter Real Elas[:]={192e9, 195e9, 198e9, 201e+9};

Real CoeElas[order+1];

Real CoeElasCost[order+1];

//Guessing Start (1 point, 2 vector) - the second vector will be auto-generated

parameter Real StartPoint[2]={171e-6,195e9};

parameter Real VectorPoint[2]={205e-6,200e9};

//Solution

Real RatioZ[N]; //Optimum result

Real CostZ; //Cost Optimum result

Real x3[2]; //Optimum point coordinate (x,y)

Real error[N]; //Error

protected

Real jos;

Real RatioZX;

Real RatioZY;

Real CostZX;

Real CostZY;

Real x0tes[2];

Real x0[2];

Real x1[2];

Real x2[2];

Real grad1;

Real grad2;

Real grad3;

//Checking approach

Real cek0[N];

Real cek1[N];

Real cek2[N];

Real cek3[N];

Real yek0[N];

Real yek1[N];

Real yek2[N];

Real yek3[N];

algorithm

//Creating function at both

CoeArea:=Curve_Fitting(Area,RatioArea,order);

CoeElas:=Curve_Fitting(Elas,RatioElas,order);

CoeAreaCost:=Curve_Fitting(Area,CostArea,order);

CoeElasCost:=Curve_Fitting(Elas,CostElas,order);

//Creating 2 vector defined in 2 gradient (grad1,grad2)

x0:=StartPoint;

x0tes:=VectorPoint;

grad1:=(x0tes[2]-x0[2])/(x0tes[1]-x0[1]);

grad2:=-0.5*grad1;

//Provide error variable

RatioZX:=CoeArea[1]*x0[1]^2+CoeArea[2]*x0[1]+CoeArea[3];

RatioZY:=CoeElas[1]*x0[2]^2+CoeElas[2]*x0[2]+CoeElas[3];

jos:=(RatioZX+RatioZY)/2;

//Computing approach

for i in 1:N loop

cek0[i]:=x0[1];

yek0[i]:=x0[2];

x1:=Gold_Opt_Func_2D_Vector(x0,grad1,GoldN,CoeArea,CoeElas);

cek1[i]:=x1[1];

yek1[i]:=x1[2];

x2:=Gold_Opt_Func_2D_Vector(x1,grad2,GoldN,CoeArea,CoeElas);

cek2[i]:=x2[1];

yek2[i]:=x2[2];

if (x0[1]==x2[1]) and (x0[2]<>x2[2]) then

grad3:=1/0; //divergent gradient, please subtitute vector

x3:=Gold_Opt_Func_2D_Vector_1(x2,1,GoldN,CoeArea,CoeElas);

else

grad3:=(x2[2]-x0[2])/(x2[1]-x0[1]);

x3:=Gold_Opt_Func_2D_Vector(x0,grad3,GoldN,CoeArea,CoeElas);

end if;

cek3[i]:=x3[1];

yek3[i]:=x3[2];

grad1:=grad2;

grad2:=grad3;

//Function Created

RatioZX:=CoeArea[1]*x3[1]^2+CoeArea[2]*x3[1]+CoeArea[3];

RatioZY:=CoeElas[1]*x3[2]^2+CoeElas[2]*x3[2]+CoeElas[3];

RatioZ[i]:=(RatioZX+RatioZY)/2;

CostZX:=CoeAreaCost[1]*x3[1]^2+CoeAreaCost[2]*x3[1]+CoeAreaCost[3];

CostZY:=CoeElasCost[1]*x3[2]^2+CoeElasCost[2]*x3[2]+CoeElasCost[3];

CostZ:=(CostZX+CostZY)/2;

x0:=x3;

error[i]:=abs(1-jos/RatioZ[i]);

jos:=RatioZ[i];

if error[i]<maxerror then

break;

end if;

end for;

end Powell_Method_Opt_Jos_Ratio;

|