Tri Aji Setyawan

Contents

Biodata

Tri Aji Setyawan 1906301324

Saya merupakan mahasiswa teknik mesin UI angkatan 2019. saya menyukai teknik mesin karena tertarik pada bidang manufaktur dan karena teknik mesin sendiri memiliki prospek kerja yang luas. hal yang saya pelajari sebelum uts ini adalah mengenai turunan numerik, deret mclaurin , interpolasi, regresi, pengertian dari metode numerik, pseucode.

MINGGU KE 1

- Tujuan mempelajari metode numerik

- 1. matching dengan tujuan belajar: memahami konsep dan prinsip dasar di dalam metnum. contoh persamaan aljabar, algorithma, pencocokan kurva, persamaan diferensial parsial.

- 2. dapat menerapkan pemahaman terhadap konsep di dalam permodelan numerik ( pengaplikasian metode numerik )

- 3. mampu menerapkan metnum di dalam persoalan keteknikan.

- 4. untuk mencapai poin 1,2,3, yaitu dengan cara moral value (adab). untuk menambah nilai tambah / adabsehingga kita menjadi orang yang lebih beradab

TUGAS 1

Pada pertemuan sebelumnya , saya mendapatkan tugas untuk membuat video terkait penggunaan aplikasi open modelica

MINGGU KE 2

perbedaan openmodelica dengan python , open modelicca lebih ke bahasa permodelan sedangkan python hanya bahasa cpoding. kelebihan dari open modelicca yaitu :

- menggunakan bahasa permodelan yang cocok untuk seorang engineer

- proses perhitungan lebih cepat

- pengguna aplikasi openmodelica cukup banyak penggunanya, dan termasuk open teknologi (free).

pada minggu kedua, saya mempelajari mengenai cara memanggil fungsi dalam suatu kelas tertentu

Tugas 2

mengaplikasikan penggunaan fitur function dan class pada open modelica. Membuat sebuah fungsi berupa persamaan aljabar simultan dengan variabel array kemudian membuat class untuk memanggil fungsi tersebut. Persamaan aljabar simultan adalah sebuah persoalan matematika yang kompleks sehingga penyelesaian perlu dengan menggunakan tools, agar dapat dibuat lebih sederhana.

pada tugas kali ini saya mencoba menyelesaikan suatu soal sistem persamaan linier menggunakan metode gauss

MINGGU KE 3

Pada pertemuan ketiga, Pak Dai menjelaskan mengenai tiga aplikasi metode numerik yang sering digunakan dalam menyelesaikan permasalahan teknik

- 1. Computation Fluid Dynamics (CFD)

- 2. Finite Element Analysis

- 3. Metode Stokastik.

Pak Dai kemudian menugaskan untuk membuat fungsi mengenai gauss jordan. kemudian dijelaskan oleh cristo dengan fungsi sebagai berikut :

// Gauss-Jordan Algorithm // Transforms input matrix A into reduced row echelon form matrix B // Christopher S.E. November 2020 input Real [:,:] A; // An augmented matrix of m*n output Real [:,:] B; // Output matrix in reduced row echelon form // Local variables

protected Integer h = 1; // Initialize pivot row Integer k = 1; // Initialize pivot column Integer m = size(A,1); // Number of rows in matrix Integer n = size(A,2); // Number of columns in matrix Integer c = 0; // Index counter Integer max_row; // Row index of max number in pivot column

Real [:] pivot_column; // Vector containing pivot column data Real [:] pivot_row; // Vector containing backwards pivot row data Real [:,:] temp_array; // Stores matrix data when switching rows Real r; // Ratio value used for row operations

// Limit to handle floating point errors Real float_error = 10e-10;

algorithm

// Transfer input matrix A into variable B B := A;

while h <= m and k <= n loop

// Dealing with floating point errors

for i in 1:m loop

for j in 1:n loop

if abs(B[i,j]) <= float_error then

B[i,j] := 0;

end if;

end for;

end for;

// Finding the pivot

pivot_column := {B[i,h] for i in h:m};

// Get position index of lowest row with greatest pivot number

c:= h-1;

for element in pivot_column loop

c := c+1;

if abs(element) == max(abs(pivot_column)) then

max_row := c;

end if;

end for;

// No pivot in this column, move on to next column

if B[max_row, k] == 0 then

k := k+1;

else

// Swap Rows h <-> max_row

temp_array := B;

temp_array[h] := B[max_row];

temp_array[max_row] := B[h];

B:= temp_array;

// Divide pivot row by pivot number

B[h] := B[h]/B[h,k];

// For all rows below the pivot

for i in (h+1):m loop

// Store the ratio of the row to the pivot

r := B[i,k] / B[h,k];

// Set lower part of pivot column to zero

B[i,k] := 0;

// Operations on the remaining row elements

for j in (k+1):n loop

B[i,j] := B[i,j] - B[h,j] * r;

end for;

end for;

// Move on to next pivot row and column

h := h+1;

k := k+1;

end if;

end while;

// The matrix is now in row echelon form

// Set values of (h,k) to (m,n) h := m; k := n;

while h >= 1 and k >=1 loop

// Dealing with floating point errors

for i in 1:m loop

for j in 1:n loop

if abs(B[i,j]) <= float_error then

B[i,j] := 0;

end if;

end for;

end for;

// Finding the pivot

pivot_row := {B[h,i] for i in 1:k};

// Get position index k of pivot

c := 0;

for element in pivot_row loop

c := c+1;

if element <> 0 then

break;

end if;

end for;

k := c;

// No pivot in this row, move on to next row

if B[h, k] == 0 then

h := h-1;

else

// Perform row operations

for i in 1:(h-1) loop

r := B[i,k];

B[i] := B[i] - B[h] * r;

end for;

// Move on to next pivot row and column

h := h-1;

k := k-1;

end if;

end while;

// The matrix is now in reduced row echelon form

end GaussJordan;

PR 3

menyelesaikan 2 soal dengan open modelica yang berhubungan dengan engineering

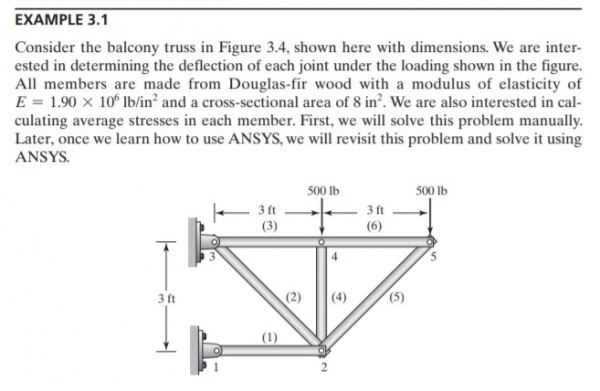

problem 1 ( pada example 3.1)

*model Trusses

parameter Integer N=10; //Global matrice = 2*points connected

parameter Real A=8;

parameter Real E=1.9e6;

Real G[N,N]; //global

Real Ginitial[N,N]; //global

Real Sol[N]; //global dispplacement

Real X[N]={0,0,0,0,0,0,0,-500,0,-500};

Real R[N]; //global reaction force

Real SolMat[N,1];

Real XMat[N,1];

//boundary coundition

Integer b1=1;

Integer b2=3;

//truss 1

parameter Real X1=0; //degree between truss

Real k1=A*E/36;

Real K1[4,4]; //stiffness matrice

Integer p1a=1;

Integer p1b=2;

Real G1[N,N];

//truss 2

parameter Real X2=135; //degree between truss

Real k2=A*E/50.912;

Real K2[4,4]; //stiffness matrice

Integer p2a=2;

Integer p2b=3;

Real G2[N,N];

//truss 3

parameter Real X3=0; //degree between truss

Real k3=A*E/36;

Real K3[4,4]; //stiffness matrice

Integer p3a=3;

Integer p3b=4;

Real G3[N,N];

//truss 4

parameter Real X4=90; //degree between truss

Real k4=A*E/36;

Real K4[4,4]; //stiffness matrice

Integer p4a=2;

Integer p4b=4;

Real G4[N,N];

//truss 5

parameter Real X5=45; //degree between truss

Real k5=A*E/50.912;

Real K5[4,4]; //stiffness matrice

Integer p5a=2;

Integer p5b=5;

Real G5[N,N];

//truss 6

parameter Real X6=0; //degree between truss

Real k6=A*E/36;

Real K6[4,4]; //stiffness matrice

Integer p6a=4;

Integer p6b=5;

Real G6[N,N];

/*

for each truss, please ensure pXa is lower then pXb (X represents truss element number)

*/

algorithm

//creating global matrice

K1:=Stiffness_Matrices(X1);

G1:=k1*Local_Global(K1,N,p1a,p1b);

K2:=Stiffness_Matrices(X2);

G2:=k2*Local_Global(K2,N,p2a,p2b);

K3:=Stiffness_Matrices(X3);

G3:=k3*Local_Global(K3,N,p3a,p3b);

K4:=Stiffness_Matrices(X4);

G4:=k4*Local_Global(K4,N,p4a,p4b);

K5:=Stiffness_Matrices(X5);

G5:=k5*Local_Global(K5,N,p5a,p5b);

K6:=Stiffness_Matrices(X6);

G6:=k6*Local_Global(K6,N,p6a,p6b);

G:=G1+G2+G3+G4+G5+G6;

Ginitial:=G;

//implementing boundary condition

for i in 1:N loop

G[2*b1-1,i]:=0;

G[2*b1,i]:=0;

G[2*b2-1,i]:=0;

G[2*b2,i]:=0;

end for;

G[2*b1-1,2*b1-1]:=1;

G[2*b1,2*b1]:=1;

G[2*b2-1,2*b2-1]:=1;

G[2*b2,2*b2]:=1;

//solving displacement

Sol:=Gauss_Jordan(N,G,X);

//solving reaction force

SolMat:=matrix(Sol);

XMat:=matrix(X);

R:=Reaction_Trusses(N,Ginitial,SolMat,XMat);

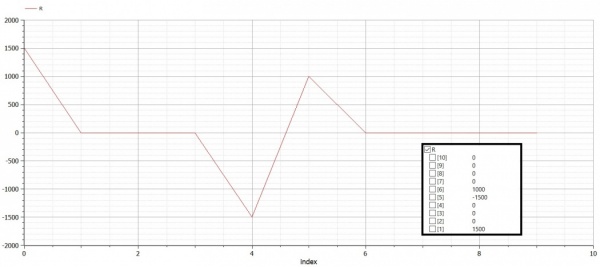

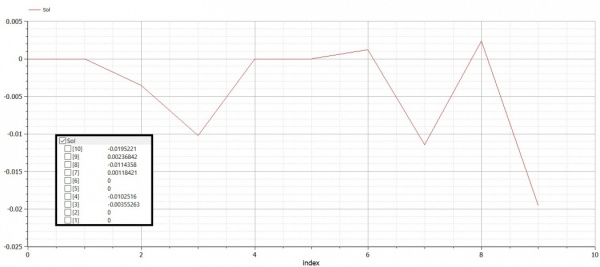

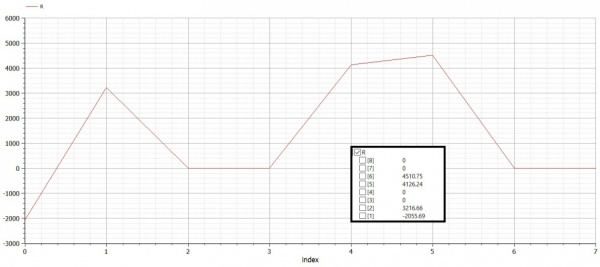

end Trusses;Grafik Reaction forces

Grafik Diplacement

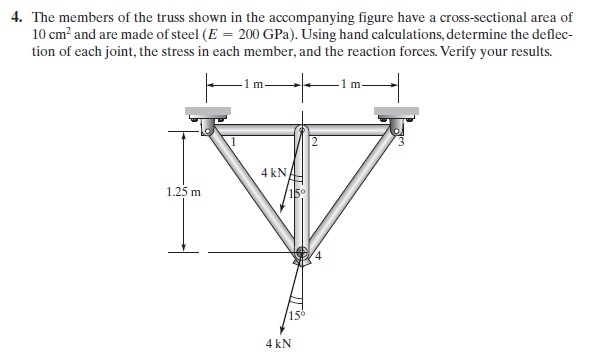

problem 2 ( PR NO 4 )

*class MetodeTrusses

parameter Integer N=8; //Global matrice = 2*points connected

parameter Real A=0.001; //Area m2

parameter Real E=200e9; //Pa

Real G[N,N]; //global

Real Ginitial[N,N]; //global

Real Sol[N]; //global dispplacement

Real X[N]={0,0,-1035.2762,-3863.7033,0,0,-1035.2762,-3863.7033};

Real R[N]; //global reaction force

Real SolMat[N,1];

Real XMat[N,1];

//boundary condition

Integer b1=1;

Integer b2=3;

//truss 1

parameter Real X1=0; //degree between truss

Real k1=A*E/1;

Real K1[4,4]; //stiffness matrice

Integer p1a=1;

Integer p1b=2;

Real G1[N,N];

//truss 2

parameter Real X2=0; //degree between truss

Real k2=A*E/1;

Real K2[4,4]; //stiffness matrice

Integer p2a=2;

Integer p2b=3;

Real G2[N,N];

//truss 3

parameter Real X3=90; //degree between truss

Real k3=A*E/1.25;

Real K3[4,4]; //stiffness matrice

Integer p3a=2;

Integer p3b=4;

Real G3[N,N];

//truss 4

parameter Real X4=90+38.6598; //degree between truss

Real k4=A*E/1.6;

Real K4[4,4]; //stiffness matrice

Integer p4a=1;

Integer p4b=4;

Real G4[N,N];

//truss 5

parameter Real X5=90-38.6598; //degree between truss

Real k5=A*E/1.6;

Real K5[4,4]; //stiffness matrice

Integer p5a=3;

Integer p5b=4;

Real G5[N,N];

/*

for each truss, please ensure pXa is lower then pXb (X represents truss element number)

*/

algorithm

//creating global matrice

K1:=Stiffness_Matrices(X1);

G1:=k1*Local_Global(K1,N,p1a,p1b);

K2:=Stiffness_Matrices(X2);

G2:=k2*Local_Global(K2,N,p2a,p2b);

K3:=Stiffness_Matrices(X3);

G3:=k3*Local_Global(K3,N,p3a,p3b);

K4:=Stiffness_Matrices(X4);

G4:=k4*Local_Global(K4,N,p4a,p4b);

K5:=Stiffness_Matrices(X5);

G5:=k5*Local_Global(K5,N,p5a,p5b);

G:=G1+G2+G3+G4+G5;

Ginitial:=G;

//implementing boundary condition

for i in 1:N loop

G[2*b1-1,i]:=0;

G[2*b1,i]:=0;

G[2*b2-1,i]:=0;

G[2*b2,i]:=0;

end for;

G[2*b1-1,2*b1-1]:=1;

G[2*b1,2*b1]:=1;

G[2*b2-1,2*b2-1]:=1;

G[2*b2,2*b2]:=1;

//solving displacement

Sol:=Gauss_Jordan(N,G,X);

//solving reaction force

SolMat:=matrix(Sol);

XMat:=matrix(X);

R:=Reaction_Trusses(N,Ginitial,SolMat,XMat);

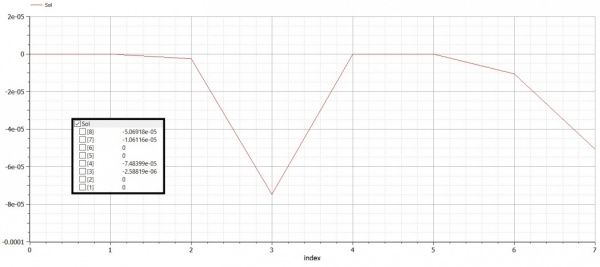

end MetodeTrusses;Grafik Reaction Process

Grafik Diplacement

Transformasi Matriks

function Stiffness_Matrices

input Real A;

Real Y;

output Real X[4,4];

Real float_error = 10e-10;

final constant Real pi=2*Modelica.Math.asin(1.0);

algorithm

Y:=A/180*pi;

X:=[(Modelica.Math.cos(Y))^2,Modelica.Math.cos(Y)*Modelica.Math.sin(Y),-(Modelica.Math.cos(Y))^2,-Modelica.Math.cos(Y)*Modelica.Math.sin(Y);

Modelica.Math.cos(Y)*Modelica.Math.sin(Y),(Modelica.Math.sin(Y))^2,-Modelica.Math.cos(Y)*Modelica.Math.sin(Y),-(Modelica.Math.sin(Y))^2;

-(Modelica.Math.cos(Y))^2,-Modelica.Math.cos(Y)*Modelica.Math.sin(Y),(Modelica.Math.cos(Y))^2,Modelica.Math.cos(Y)*Modelica.Math.sin(Y);

-Modelica.Math.cos(Y)*Modelica.Math.sin(Y),-(Modelica.Math.sin(Y))^2,Modelica.Math.cos(Y)*Modelica.Math.sin(Y),(Modelica.Math.sin(Y))^2];

for i in 1:4 loop

for j in 1:4 loop

if abs(X[i,j]) <= float_error then

X[i,j] := 0;

end if;

end for;

end for;

end Stiffness_Matrices;Global Element Matrice

function Local_Global

input Real Y[4,4];

input Integer B;

input Integer p1;

input Integer p2;

output Real G[B,B];

algorithm

for i in 1:B loop

for j in 1:B loop

G[i,j]:=0;

end for;

end for;

G[2*p1,2*p1]:=Y[2,2];

G[2*p1-1,2*p1-1]:=Y[1,1];

G[2*p1,2*p1-1]:=Y[2,1];

G[2*p1-1,2*p1]:=Y[1,2];

G[2*p2,2*p2]:=Y[4,4];

G[2*p2-1,2*p2-1]:=Y[3,3];

G[2*p2,2*p2-1]:=Y[4,3];

G[2*p2-1,2*p2]:=Y[3,4];

G[2*p2,2*p1]:=Y[4,2];

G[2*p2-1,2*p1-1]:=Y[3,1];

G[2*p2,2*p1-1]:=Y[4,1];

G[2*p2-1,2*p1]:=Y[3,2];

G[2*p1,2*p2]:=Y[2,4];

G[2*p1-1,2*p2-1]:=Y[1,3];

G[2*p1,2*p2-1]:=Y[2,3];

G[2*p1-1,2*p2]:=Y[1,4];

end Local_Global;

Reaction Matrice Equation

function Reaction_Trusses

input Integer N;

input Real A[N,N];

input Real B[N,1];

input Real C[N,1];

Real X[N,1];

output Real Sol[N];

Real float_error = 10e-10;

algorithm

X:=A*B-C;

for i in 1:N loop

if abs(X[i,1]) <= float_error then

X[i,1] := 0;

end if;

end for;

for i in 1:N loop

Sol[i]:=X[i,1];

end for;

end Reaction_Trusses;Gauss Jordan

function Gauss_Jordan

input Integer N;

input Real A[N,N];

input Real B[N];

output Real X[N];

Real float_error = 10e-10;

algorithm

X:=Modelica.Math.Matrices.solve(A,B);

for i in 1:N loop

if abs(X[i]) <= float_error then

X[i] := 0;

end if;

end for;

end Gauss_Jordan;MINGGU KE 4

Kuis pada hari rabu tanggal 2 desember 2020

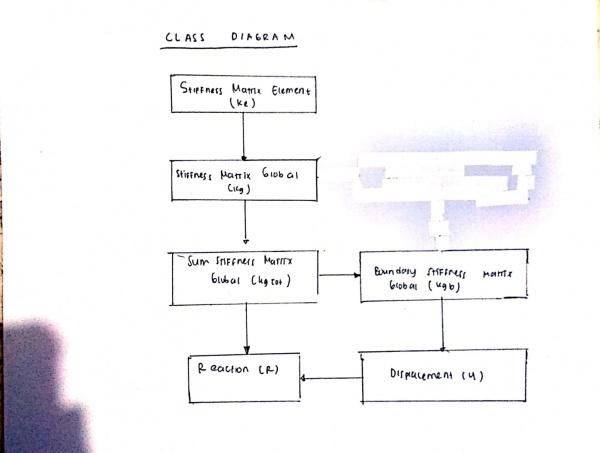

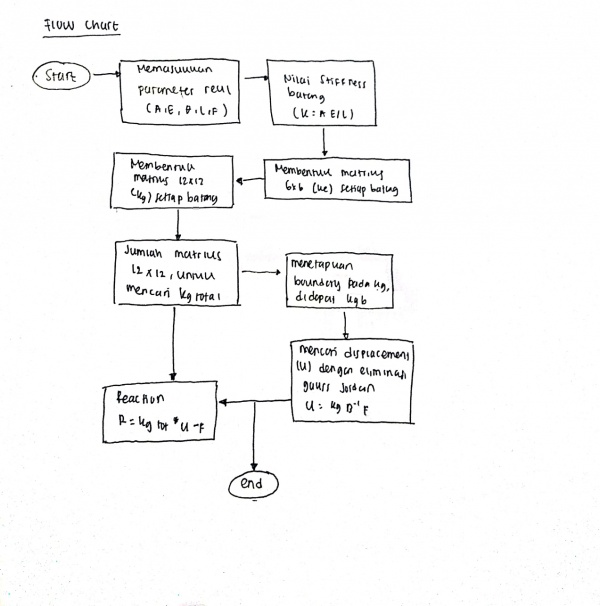

membuat diagram class dan flowchart dari fungsi yang telah dibuat josiah

KUIS DIAGRAM CLASS DAN FLOWCHART

Tugas Minggu ke 4

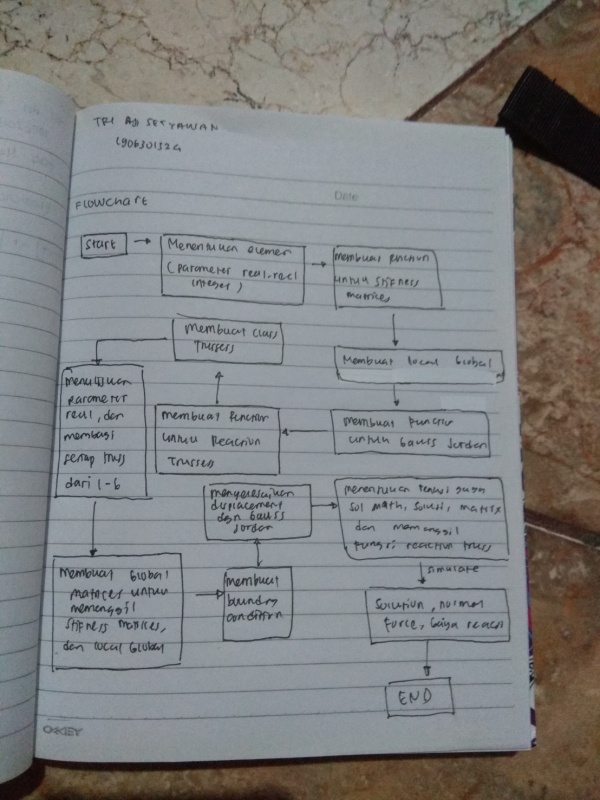

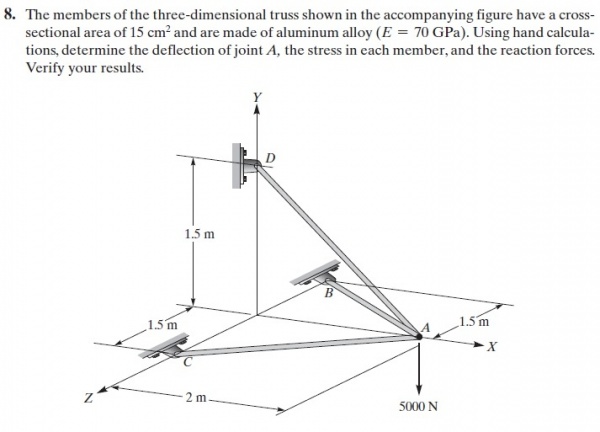

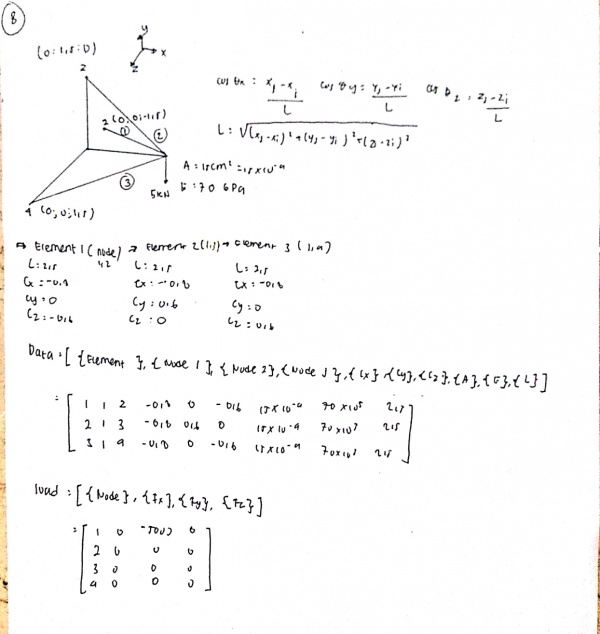

Pada tugas ke 4 kali ini , kami diberikan soal untuk menyelesaikan sebuah permasalahan mengenai space truss dengan membuat flowchart, diagram class, dan coding modelicanya.

jawab :

Pertama tama saya membuat flowchart dan diagram class. lalu saya membuat free body diagram dari sistem dan mencari data-data yang dibutuhkan.

Class Diagram

Flowchart

Setelah data-data sudah didapatkan lalu diproses ke dalam OpenModelica menggunakan referensi coding A. M. Fahmi.

Saya mencari k tiap element terlebih dahulu menggunakan rumus k=AE/L. Setelah itu bisa mencari nilai Ke.

function StiffnessMatrixElement

input Real [:,9] inisiasi_mat;

output Real [size(inisiasi_mat,1),6,6] Ke_mat;

protected

Real cos_x;

Real cos_y;

Real cos_z;

Real [6] StiffTrig;

Real [6,6] StiffTrans;

Real [size(inisiasi_mat,1)] k_vec;

algorithm

k_vec := {(inisiasi_mat[i,7] * inisiasi_mat[i,8] / inisiasi_mat[i,9]) for i in 1:size(inisiasi_mat,1)};

// Finding stiffness matrix of each element member

for i in 1:size(inisiasi_mat,1) loop

// Clearing the matrices

StiffTrig := zeros(6);

StiffTrans := zeros(6,6);

// Converting degrees to radians

cos_x := inisiasi_mat[i,4];

cos_y := inisiasi_mat[i,5];

cos_z := inisiasi_mat[i,6];

// {cos^2, sin^2, sincos}

StiffTrig := {(cos_x)^2,

(cos_y)^2,

(cos_z)^2,

(cos_x*cos_y),

(cos_x*cos_z),

(cos_y*cos_z)};

// Construct stiffness transformation matrix

StiffTrans := [ StiffTrig[1], StiffTrig[4], StiffTrig[5], -1*StiffTrig[1], -1*StiffTrig[4], -1*StiffTrig[5];

StiffTrig[4], StiffTrig[2], StiffTrig[6], -1*StiffTrig[4], -1*StiffTrig[2], -1*StiffTrig[6];

StiffTrig[5], StiffTrig[6], StiffTrig[3], -1*StiffTrig[5], -1*StiffTrig[6], -1*StiffTrig[3];

-1*StiffTrig[1], -1*StiffTrig[4], -1*StiffTrig[5], StiffTrig[1], StiffTrig[4], StiffTrig[5];

-1*StiffTrig[4], -1*StiffTrig[2], -1*StiffTrig[6], StiffTrig[4], StiffTrig[2], StiffTrig[6];

-1*StiffTrig[5], -1*StiffTrig[6], -1*StiffTrig[3], StiffTrig[5], StiffTrig[6], StiffTrig[3]];

// Multiply in stiffness constant of element, add final stiffness matrix to Ke_mat

for m in 1:6 loop

for n in 1:6 loop

Ke_mat[i,m,n] := k_vec[i] * StiffTrans[m,n];

end for;

end for;

end for;

end StiffnessMatrixElement;Membuat stiffness matrix global

function StiffnessMatrixGlobal

input Integer [:,2] n;

input Integer x;

input Integer y;

input Real [y,6,6] Ke_mat;

output Real [y,x,x] Kg_mat;

algorithm

for i in 1:y loop

for a in 1:x loop

for b in 1:x loop

Kg_mat[i,a,b]:=0;

end for;

end for;

end for;

for i in 1:y loop

Kg_mat[i,3*n[i,1],3*n[i,1]]:=Ke_mat[i,3,3];

Kg_mat[i,3*n[i,1],3*n[i,1]-1]:=Ke_mat[i,3,2];

Kg_mat[i,3*n[i,1],3*n[i,1]-2]:=Ke_mat[i,3,1];

Kg_mat[i,3*n[i,1]-1,3*n[i,1]]:=Ke_mat[i,2,3];

Kg_mat[i,3*n[i,1]-1,3*n[i,1]-1]:=Ke_mat[i,2,2];

Kg_mat[i,3*n[i,1]-1,3*n[i,1]-2]:=Ke_mat[i,2,1];

Kg_mat[i,3*n[i,1]-2,3*n[i,1]]:=Ke_mat[i,1,3];

Kg_mat[i,3*n[i,1]-2,3*n[i,1]-1]:=Ke_mat[i,1,2];

Kg_mat[i,3*n[i,1]-2,3*n[i,1]-2]:=Ke_mat[i,1,1];

Kg_mat[i,3*n[i,2],3*n[i,2]]:=Ke_mat[i,6,6];

Kg_mat[i,3*n[i,2],3*n[i,2]-1]:=Ke_mat[i,6,5];

Kg_mat[i,3*n[i,2],3*n[i,2]-2]:=Ke_mat[i,6,4];

Kg_mat[i,3*n[i,2]-1,3*n[i,2]]:=Ke_mat[i,5,6];

Kg_mat[i,3*n[i,2]-1,3*n[i,2]-1]:=Ke_mat[i,5,5];

Kg_mat[i,3*n[i,2]-1,3*n[i,2]-2]:=Ke_mat[i,5,4];

Kg_mat[i,3*n[i,2]-2,3*n[i,2]]:=Ke_mat[i,4,6];

Kg_mat[i,3*n[i,2]-2,3*n[i,2]-1]:=Ke_mat[i,4,5];

Kg_mat[i,3*n[i,2]-2,3*n[i,2]-2]:=Ke_mat[i,4,4];

Kg_mat[i,3*n[i,2],3*n[i,1]]:=Ke_mat[i,6,3];

Kg_mat[i,3*n[i,2],3*n[i,1]-1]:=Ke_mat[i,6,2];

Kg_mat[i,3*n[i,2],3*n[i,1]-2]:=Ke_mat[i,6,1];

Kg_mat[i,3*n[i,2]-1,3*n[i,1]]:=Ke_mat[i,5,3];

Kg_mat[i,3*n[i,2]-1,3*n[i,1]-1]:=Ke_mat[i,5,2];

Kg_mat[i,3*n[i,2]-1,3*n[i,1]-2]:=Ke_mat[i,5,1];

Kg_mat[i,3*n[i,2]-2,3*n[i,1]]:=Ke_mat[i,4,3];

Kg_mat[i,3*n[i,2]-2,3*n[i,1]-1]:=Ke_mat[i,4,2];

Kg_mat[i,3*n[i,2]-2,3*n[i,1]-2]:=Ke_mat[i,4,1];

Kg_mat[i,3*n[i,1],3*n[i,2]]:=Ke_mat[i,3,6];

Kg_mat[i,3*n[i,1],3*n[i,2]-1]:=Ke_mat[i,3,5];

Kg_mat[i,3*n[i,1],3*n[i,2]-2]:=Ke_mat[i,3,4];

Kg_mat[i,3*n[i,1]-1,3*n[i,2]]:=Ke_mat[i,2,6];

Kg_mat[i,3*n[i,1]-1,3*n[i,2]-1]:=Ke_mat[i,2,5];

Kg_mat[i,3*n[i,1]-1,3*n[i,2]-2]:=Ke_mat[i,2,4];

Kg_mat[i,3*n[i,1]-2,3*n[i,2]]:=Ke_mat[i,1,6];

Kg_mat[i,3*n[i,1]-2,3*n[i,2]-1]:=Ke_mat[i,1,5];

Kg_mat[i,3*n[i,1]-2,3*n[i,2]-2]:=Ke_mat[i,1,4];

end for;

end StiffnessMatrixGlobal;Semua stiffness matrix global dijumlahkan dan didapatkan sum stiffness matrix global.

function SumStiffnessMatrixGlobal

input Integer x;

input Integer y;

input Real [y,x,x] Kg_mat;

output Real [x,x] KgTot_mat;

algorithm

for a in 1:x loop

for b in 1:x loop

KgTot_mat[a,b] := sum(Kg_mat [:,a,b]);

end for;

end for;

end SumStiffnessMatrixGlobal;menentukan boundaries pada sum stiffness matrix global.

function BoundaryStiffnessMatrixGlobal

input Integer x;

input Integer z;

input Real [x,x] KgTot_met;

input Integer[z] Boundary_met;

output Real [x,x] KgB_met;

algorithm

for a in 1:x loop

for b in 1:x loop

KgB_met[a,b] := KgTot_met [a,b];

end for;

end for;

for i in 1:x loop

for a in 1:z loop

for b in 0:2 loop

KgB_met[3*(Boundary_met[a])-b,i]:=0;

end for;

end for;

end for;

for a in 1:z loop

for b in 0:2 loop

KgB_met[3*Boundary_met[a]-b,3*Boundary_met[a]-b]:=1;

end for;

end for;

end BoundaryStiffnessMatrixGlobal;

Untuk mencari nilai displacement (U) lainnya digunakan eliminasi Gauss Jordan dengan persamaan XU=F. Dimana X adalah stiffness matrix global yang sudah ditentukan boundarynya.

function GaussJordan

input Integer x;

input Real [x,x] KgB_met;

input Real [x] load_met;

output Real [x] U_met;

protected

Real float_error = 10e-10;

algorithm

U_met:=Modelica.Math.Matrices.solve(KgB_met,load_met);

for i in 1:x loop

if abs(U_met[i]) <= float_error then

U_met[i] := 0;

end if;

end for;

end GaussJordan;kemudian mencari reaction menggunakan persamaan R=Kg*U - F.

function ReactionForce

input Integer x;

input Real [x,x] KgTot_met;

input Real [x] U_met;

input Real [x] load_met;

output Real [x] R_met;

algorithm

R_met := (KgTot_met*U_met)-load_met;

end ReactionForce;Selanjutnya, membuat sebuah Class untuk memanggil fungsi-fungsi diatas agar bisa melihat nilai U dan R.

class truss

parameter Real [:,9] inisiasi = [1, 1, 2, -0.8, 0, -0.6, 15e-4, 70e9, 2.5;

2, 1, 3, -0.8, -0.6, 0, 15e-4, 70e9, 2.5;

3, 1, 4, -0.8, 0, 0.6, 15e-4, 70e9, 2.5];

parameter Integer [:,2] node = [1, 2;

1, 3;

1, 4];

parameter Integer y = size(node,1);

parameter Integer x = 3*(size(node_load,1));

parameter Integer z = size(Boundary,1);

parameter Integer [:] Boundary = {2,3,4};

parameter Real [:,4] node_load = [1, 0, -5000, 0;

2, 0, 0, 0;

3, 0, 0, 0;

4, 0, 0, 0];

parameter Real [x] load = {0,-5000, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0};

Real [y] k;

Real [y,6,6] Ke;

Real [y,x,x] Kg;

Real [x,x] KgTot;

Real [x,x] KgB;

Real [x] U;

Real [x] R;

equation

k = {(inisiasi[i,7] * inisiasi[i,8] / inisiasi[i,9]) for i in 1:y};

Ke = StiffnessMatrixElement(inisiasi);

Kg = StiffnessMatrixGlobal(node, x, y, Ke);

KgTot = SumStiffnessMatrixGlobal(x, y, Kg);

KgB = BoundaryStiffnessMatrixGlobal(x, z, KgTot, Boundary);

U = GaussJordan(x, KgB, load);

R = ReactionForce(x, KgTot, U, load);

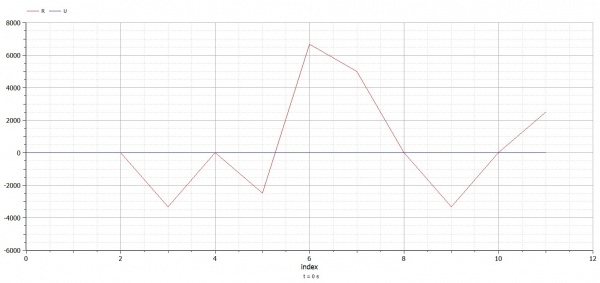

end truss;hasil dari U dan R

grafik

video penjelasan terkait penyelesaian soal no 8

Aplikasi Metode Numerik dalam Kasus Optimasi

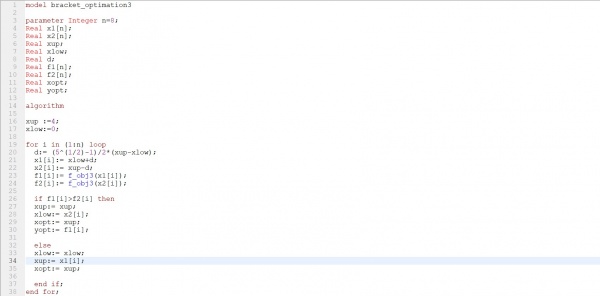

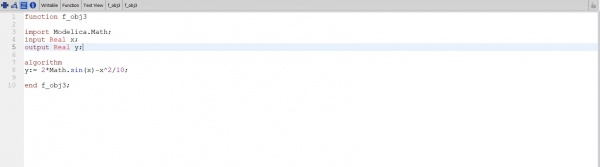

Pada minggu ke 6 , kami mempelajari mengenai optimasi. sebelum kuliah dimulai, bu chandra memberikan penjelasan singkat mengenai optimasi dengan menggunakan bracket. Di akhir video , kami diperintahkan untuk mencoba perhitungan optimasi yang ada di video.

Membuat model untuk memanggil fungsi

Fungsi yang akan di panggil

Hasil yang diperoleh

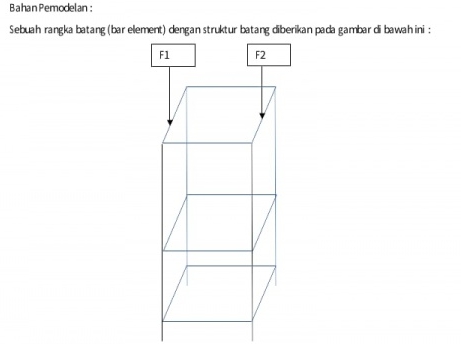

TUGAS BESAR METNUM

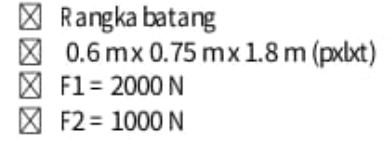

Pada tugas besar ini, kami diperimtahkan untuk mendesain rangka dengan menggunakan optimasi.

Dari soal tersebut kita diperintahkan untuk mendesain rangka batang dengan harga terjangkau dan optimal untuk fungsinya.

Yang perlu kita cari adalah Harga, Material yang digunakan, cross section Dilakukan dengan metode optimasi dan membentuk curve fitting pada variabel harga

Asumsi yang digunakan dalam perhitungan ini :

- Beban akan terdistribusi hanya pada node (karena bersifat trusses).

- Safety factor minimal bernilai 2.

- Batas displacement 0,001 m sebelum buckling (pada truss paling atas).

- Ketinggian trusses pada tiap lantai sama yaitu 0,6 m.

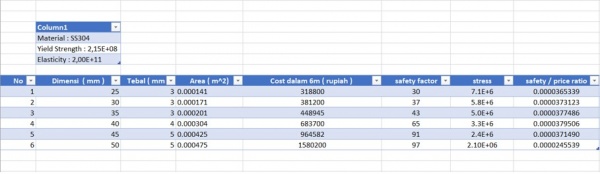

Untuk jenis material yang sama:

- Mencari harga untuk 6 ukuran batang dengan material yang sama yaitu SS304 .

- Mengitung nilai safety factor pada 6 ukuran batang dengan coding awal.

- Membuat rasio antara safety factor dengan harga total.

- Membuat persamaan antara rasio (safe/harga) dengan area dengan metode curve fitting.

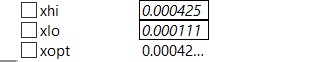

- Melakukan optimasi menggunakan metode golden section.

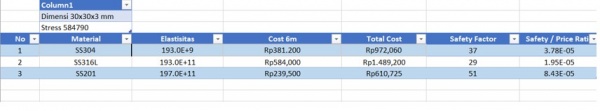

Untuk area penampang yang sama:

- Mencari harga untuk 3 jenis material dengan area penampang yang sama yaitu 171 mm^2.

- Mengitung nilai safety factor pada 3 jenis batang dengan coding awal.

- Membuat rasio antara safety factor dengan harga total.

- Membuat persamaan antara rasio (safe/harga) dengan jenis material dengan metode curve fitting.

- Melakukan optimasi menggunakan metode golden section.

Kemudian , saya akan menggunakan coding sebagai berikut untuk melakukan perhitugnan sehingga didapatkan reaction force , stress , displacement , dan safety factor ( yield / stress ).

Coding Yang akan digunakan

model Trusses_3D_Tugas_Besar_Safety

//define initial variable

parameter Integer Points=size(P,1); //Number of Points

parameter Integer Trusses=size(C,1); //Number of Trusses

parameter Real Yield=215e6; //Yield Strength (Pa)

parameter Real Area=0.000201; //Area L Profile (Dimension=0.03, Thickness=0,004) (m2)

parameter Real Elas=200e9; //Elasticity SS304 Stainless Steel (Pa)

//define connection

parameter Integer C[:,2]=[1,5;

2,6;

3,7;

4,8;

5,6; //1st floor

6,7; //1st floor

7,8; //1st floor

5,8; //1st floor

5,9;

6,10;

7,11;

8,12;

9,10; //2nd floor

10,11;//2nd floor

11,12;//2nd floor

9,12; //2nd floor

9,13;

10,14;

11,15;

12,16;

13,14;//3rd floor

14,15;//3rd floor

15,16;//3rd floor

13,16];//3rd floor

//define coordinates (please put orderly)

parameter Real P[:,6]=[0.3,-0.375,0,1,1,1; //1

-0.3,-0.375,0,1,1,1; //2

-0.3,0.375,0,1,1,1; //3

0.3,0.375,0,1,1,1; //4

0.3,-0.375,0.6,0,0,0; //5

-0.3,-0.375,0.6,0,0,0; //6

-0.3,0.375,0.6,0,0,0; //7

0.3,0.375,0.6,0,0,0; //8

0.3,-0.375,1.2,0,0,0; //9

-0.3,-0.375,1.2,0,0,0; //10

-0.3,0.375,1.2,0,0,0; //11

0.3,0.375,1.2,0,0,0; //12

0.3,-0.375,1.8,0,0,0; //13

-0.3,-0.375,1.8,0,0,0; //14

-0.3,0.375,1.8,0,0,0; //15

0.3,0.375,1.8,0,0,0]; //16

//define external force (please put orderly)

parameter Real F[Points*3]={0,0,0,

0,0,0,

0,0,0,

0,0,0,

0,0,0,

0,0,0,

0,0,0,

0,0,0,

0,0,0,

0,0,0,

0,0,0,

0,0,0,

0,0,-500,

0,0,-1000,

0,0,-1000,

0,0,-500};

//solution

Real displacement[N], reaction[N];

Real check[3];

Real stress1[Trusses];

Real safety[Trusses];

Real dis[3];

Real Str[3];

protected

parameter Integer N=3*Points;

Real q1[3], q2[3], g[N,N], G[N,N], G_star[N,N], id[N,N]=identity(N), cx, cy, cz, L, X[3,3];

Real err=10e-10, ers=10e-4;

algorithm

//Creating Global Matrix

G:=id;

for i in 1:Trusses loop

for j in 1:3 loop

q1[j]:=P[C[i,1],j];

q2[j]:=P[C[i,2],j];

end for;

//Solving Matrix

L:=Modelica.Math.Vectors.length(q2-q1);

cx:=(q2[1]-q1[1])/L;

cy:=(q2[2]-q1[2])/L;

cz:=(q2[3]-q1[3])/L;

X:=(Area*Elas/L)*[cx^2,cx*cy,cx*cz;

cy*cx,cy^2,cy*cz;

cz*cx,cz*cy,cz^2];

//Transforming to global matrix

g:=zeros(N,N);

for m,n in 1:3 loop

g[3*(C[i,1]-1)+m,3*(C[i,1]-1)+n]:=X[m,n];

g[3*(C[i,2]-1)+m,3*(C[i,2]-1)+n]:=X[m,n];

g[3*(C[i,2]-1)+m,3*(C[i,1]-1)+n]:=-X[m,n];

g[3*(C[i,1]-1)+m,3*(C[i,2]-1)+n]:=-X[m,n];

end for;

G_star:=G+g;

G:=G_star;

end for;

//Implementing boundary

for x in 1:Points loop

if P[x,4] <> 0 then

for a in 1:Points*3 loop

G[(x*3)-2,a]:=0;

G[(x*3)-2,(x*3)-2]:=1;

end for;

end if;

if P[x,5] <> 0 then

for a in 1:Points*3 loop

G[(x*3)-1,a]:=0;

G[(x*3)-1,(x*3)-1]:=1;

end for;

end if;

if P[x,6] <> 0 then

for a in 1:Points*3 loop

G[x*3,a]:=0;

G[x*3,x*3]:=1;

end for;

end if;

end for;

//Solving displacement

displacement:=Modelica.Math.Matrices.solve(G,F);

//Solving reaction

reaction:=(G_star*displacement)-F;

//Eliminating float error

for i in 1:N loop

reaction[i]:=if abs(reaction[i])<=err then 0 else reaction[i];

displacement[i]:=if abs(displacement[i])<=err then 0 else displacement[i];

end for;

//Checking Force

check[1]:=sum({reaction[i] for i in (1:3:(N-2))})+sum({F[i] for i in (1:3:(N-2))});

check[2]:=sum({reaction[i] for i in (2:3:(N-1))})+sum({F[i] for i in (2:3:(N-1))});

check[3]:=sum({reaction[i] for i in (3:3:N)})+sum({F[i] for i in (3:3:N)});

for i in 1:3 loop

check[i] := if abs(check[i])<=ers then 0 else check[i];

end for;

//Calculating stress in each truss

for i in 1:Trusses loop

for j in 1:3 loop

q1[j]:=P[C[i,1],j];

q2[j]:=P[C[i,2],j];

dis[j]:=abs(displacement[3*(C[i,1]-1)+j]-displacement[3*(C[i,2]-1)+j]);

end for;

//Solving Matrix

L:=Modelica.Math.Vectors.length(q2-q1);

cx:=(q2[1]-q1[1])/L;

cy:=(q2[2]-q1[2])/L;

cz:=(q2[3]-q1[3])/L;

X:=(Elas/L)*[cx^2,cx*cy,cx*cz;

cy*cx,cy^2,cy*cz;

cz*cx,cz*cy,cz^2];

Str:=(X*dis);

stress1[i]:=Modelica.Math.Vectors.length(Str);

end for;

//Safety factor

for i in 1:Trusses loop

if stress1[i]>0 then

safety[i]:=Yield/stress1[i];

else

safety[i]:=0;

end if;

end for;

end Trusses_3D_Tugas_Besar_Safety;Membuat Kurva Curve Fitting

function Curve_Fitting

input Real X[:];

input Real Y[size(X,1)];

input Integer order=2;

output Real Coe[order+1];

protected

Real Z[size(X,1),order+1];

Real ZTr[order+1,size(X,1)];

Real A[order+1,order+1];

Real B[order+1];

algorithm

for i in 1:size(X,1) loop

for j in 1:(order+1) loop

Z[i,j]:=X[i]^(order+1-j);

end for;

end for;

ZTr:=transpose(Z);

A:=ZTr*Z;

B:=ZTr*Y;

Coe:=Modelica.Math.Matrices.solve(A,B);

end Curve_Fitting;Untuk Optimasi Golden Section

model Opt_Gold

parameter Real xd[:];

parameter Real yd[size(xd,1)];

parameter Real xlo=87e-6;

parameter Real xhi=504e-6;

parameter Integer N=10; // maximum iteration

parameter Real es=0.0001; // maximum error

Real f1[N], f2[N], x1[N], x2[N], ea[N], y[3];

Real xopt, fx;

protected

Real d, xl, xu, xint, R=(5^(1/2)-1)/2;

algorithm

xl := xlo;

xu := xhi;

y := Curve_Fitting(xd,yd);

for i in 1:N loop

d:= R*(xu-xl);

x1[i]:=xl+d;

x2[i]:=xu-d;

f1[i]:=y[1]*x1[i]^2+y[2]*x1[i]+y[3];

f2[i]:=y[1]*x2[i]^2+y[2]*x2[i]+y[3];

xint:=xu-xl;

if f1[i]>f2[i] then

xl:=x2[i];

xopt:=x1[i];

fx:=f1[i];

else

xu:=x1[i];

xopt:=x2[i];

fx:=f2[i];

end if;

ea[i]:=(1-R)*abs((xint)/xopt);

if ea[i]<es then

break;

end if;

end for;

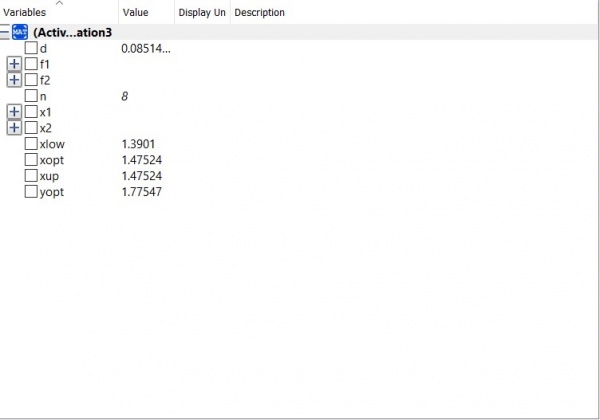

end Opt_Gold;Material Tetap

Hasil Optimasi :

Nilai luas area penampang optimum untuk material SS304 adalah 0.000423422m^2.

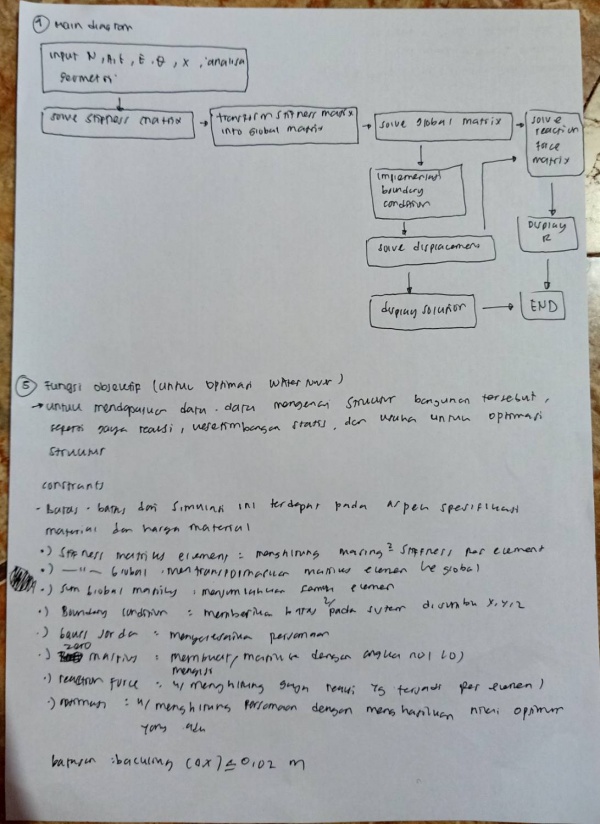

Luas Truss Tetap

Hasil Optimasi :

Material optimum yang dapat digunakan untuk luas penampang 171mm^2 adalah material dengan nilai elastisitas sebesar 1.9697x10^11Pa, yaitu material SS304.

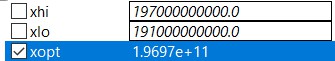

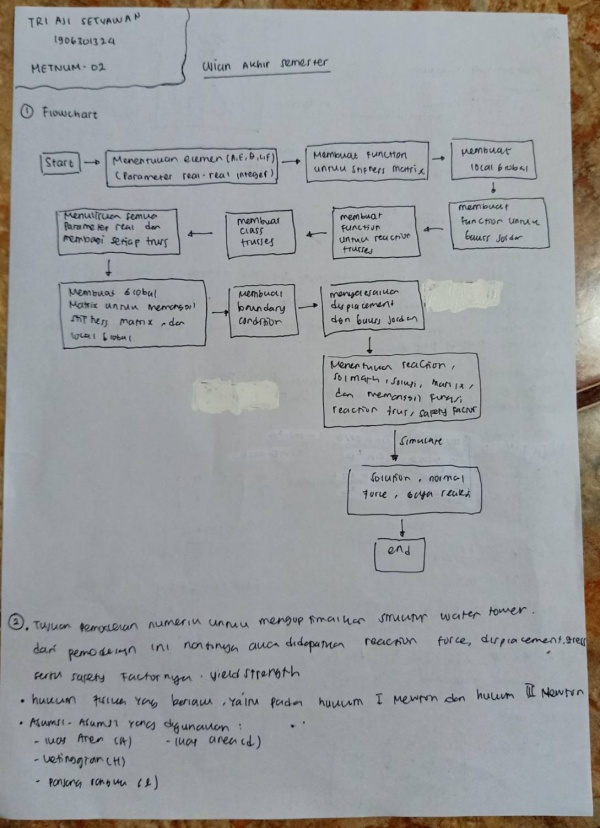

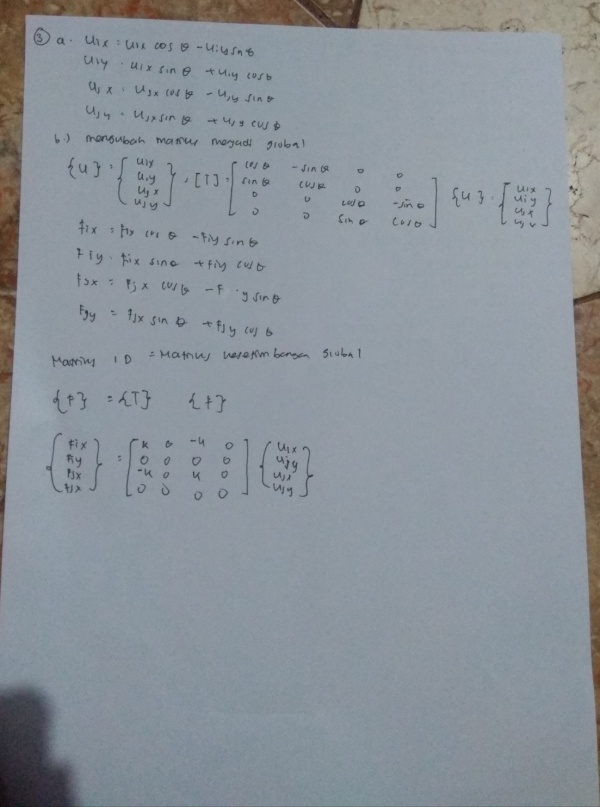

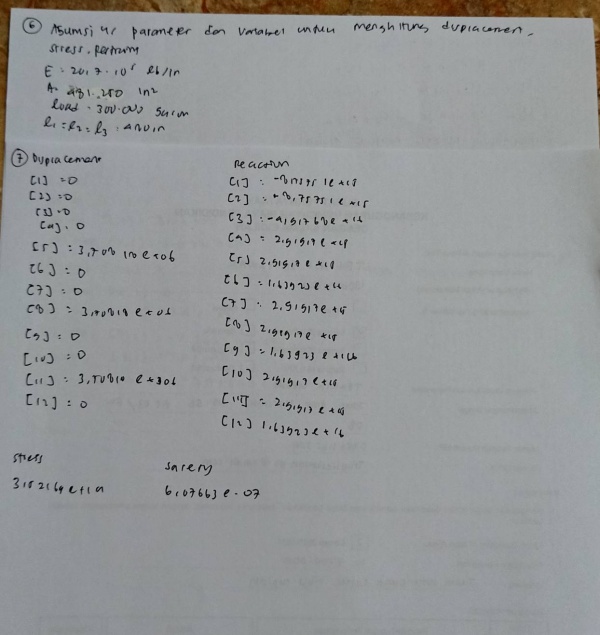

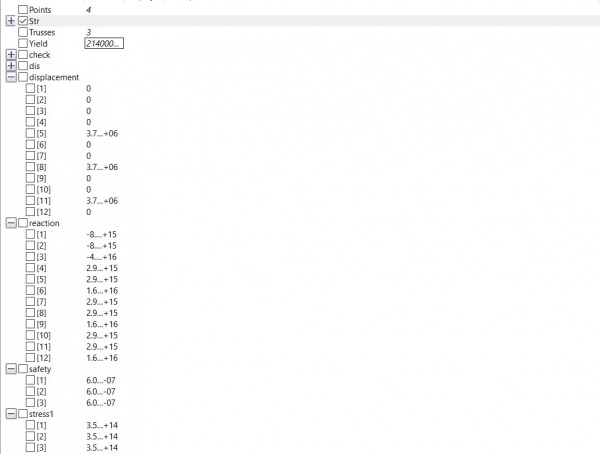

UJIAN AKHIR SEMESTER

Jawaban Uas

coding yang akan digunakan

model Uas_MetodeNumerik

//define initial variable

parameter Integer Points=4; //Number of Points

parameter Integer Trusses=3; //Number of Trusses

parameter Real Yield=214e6; //Yield Strength (Pa)

parameter Real Area=0.16; //Area Block Profile (0.4 * 0.4) (m2)

parameter Real Elas=207e9; //Elasticity SS 304 (Pa)

parameter Real Volume=1135; //m3 from 200000 gallons

parameter Real rho=1000; //kg/m3

parameter Real W=Volume*rho*9.81;

//define connection

parameter Integer C[Trusses,2]=[1,2;

2,3;

2,4];

//define coordinates (please put orderly)

parameter Real P[Points,3]=[0,37,0;

0,12,0;

-16,0,0;

16,0,0];

//define external force (please put orderly)

parameter Real F[Points*3]={0,-W,0,

0,0,0,

0,0,0,

0,0,0};

//define boundary

parameter Integer b[:]={3,4};

//solution

Real displacement[N], reaction[N];

Real check[3];

Real stress1[Trusses];

Real safety[Trusses];

Real dis[3];

Real Str[3];

protected

parameter Integer N=3*Points;

Integer boundary[3*size(b,1)]=cat(1,(3*b).-2,(3*b).-1,3*b);

Real q1[3], q2[3], g[N,N], G[N,N], G_star[N,N], id[N,N]=identity(N), cx, cy, cz, L, X[3,3];

Real err=10e-10, ers=10e-4;

algorithm

//Creating Global Matrix

G:=id;

for i in 1:Trusses loop

for j in 1:3 loop

q1[j]:=P[C[i,1],j];

q2[j]:=P[C[i,2],j];

end for;

//Solving Matrix

L:=Modelica.Math.Vectors.length(q2-q1);

cx:=(q2[1]-q1[1])/L;

cy:=(q2[2]-q1[2])/L;

cz:=(q2[3]-q1[3])/L;

X:=(Area*Elas/L)*[cx^2,cx*cy,cx*cz;

cy*cx,cy^2,cy*cz;

cz*cx,cz*cy,cz^2];

//Transforming to global matrix

g:=zeros(N,N);

for m,n in 1:3 loop

g[3*(C[i,1]-1)+m,3*(C[i,1]-1)+n]:=X[m,n];

g[3*(C[i,2]-1)+m,3*(C[i,2]-1)+n]:=X[m,n];

g[3*(C[i,2]-1)+m,3*(C[i,1]-1)+n]:=-X[m,n];

g[3*(C[i,1]-1)+m,3*(C[i,2]-1)+n]:=-X[m,n];

end for;

G_star:=G+g;

G:=G_star;

end for;

//Implementing boundary

for i in boundary loop

for j in 1:N loop

G[i,j]:=id[i,j];

end for;

end for;

//Solving displacement

displacement:=Modelica.Math.Matrices.solve(G,F);

//Solving reaction

reaction:=(G_star*displacement)-F;

//Eliminating float error

for i in 1:N loop

reaction[i]:=if abs(reaction[i])<=err then 0 else reaction[i];

displacement[i]:=if abs(displacement[i])<=err then 0 else displacement[i];

end for;

//Checking Force

check[1]:=sum({reaction[i] for i in (1:3:(N-2))})+sum({F[i] for i in (1:3:(N-2))});

check[2]:=sum({reaction[i] for i in (2:3:(N-1))})+sum({F[i] for i in (2:3:(N-1))});

check[3]:=sum({reaction[i] for i in (3:3:N)})+sum({F[i] for i in (3:3:N)});

for i in 1:3 loop

check[i] := if abs(check[i])<=ers then 0 else check[i];

end for;

//Calculating stress in each truss

for i in 1:Trusses loop

for j in 1:3 loop

q1[j]:=P[C[i,1],j];

q2[j]:=P[C[i,2],j];

dis[j]:=abs(displacement[3*(C[i,1]-1)+j]-displacement[3*(C[i,2]-1)+j]);

end for;

//Solving Matrix

L:=Modelica.Math.Vectors.length(q2-q1);

cx:=(q2[1]-q1[1])/L;

cy:=(q2[2]-q1[2])/L;

cz:=(q2[3]-q1[3])/L;

X:=(Elas/L)*[cx^2,cx*cy,cx*cz;

cy*cx,cy^2,cy*cz;

cz*cx,cz*cy,cz^2];

Str:=(X*dis);

stress1[i]:=Modelica.Math.Vectors.length(Str);

end for;

//Safety factor

for i in 1:Trusses loop

if stress1[i]>0 then

safety[i]:=Yield/stress1[i];

else

safety[i]:=0;

end if;

end for;

end Uas_MetodeNumerik;