Tanveer khan

Hello! Welcome to my Wiki page.

I am Tanveer Khan, a dedicated student from Pakistan, currently pursuing my studies at the Faculty of Engineering, Universitas Indonesia (FTUI). My major is Mechanical Engineering, with a specialization in Manufacturing and Automation Systems. My academic journey has been marked by a passion for innovation, a keen eye for detail, and a persistent drive to solve complex engineering challenges.

To broaden my expertise and enhance my skills, I have enrolled in the Finite Element and Multiphysics course. My goal is to gain a deeper understanding of the fundamental principles and practical applications of the Finite Element Method (FEM). This course allows me to explore various types of simulations, which are essential for analyzing and optimizing engineering designs in manufacturing and automation systems. I am particularly interested in the interplay of multiple physical phenomena, as it provides a comprehensive approach to problem-solving.

As a highly motivated and diligent learner, I strive for excellence in my academic and professional pursuits. My strong analytical skills, combined with my ability to adapt and collaborate in diverse environments, have enabled me to excel in challenging projects. I am committed to using the knowledge and insights gained from this course to contribute meaningfully to the field of mechanical engineering.

Contents

[hide]- 1 Predicting Static Stress in One-Dimensional Bar Elements Using Artificial Neural Networks coupled with DAI5 Framework-by-TanveeKhan

- 2 The 33 DAI5 Implementation Evaluation Criteria for Final project

- 3 Final_Term_Predicting Static Stress in One-Dimensional S275 J0 Bar Elements Using Artificial Neural Networks Coupled with DAI5 Framework

- 4 Video_Mid_Term_Optimization of 2D Element Mesh in plane stress analysis of Polycarbonate Shell Structures Using the DAI5 Framework

- 5 Writing_Mid_Term_Optimization of 2D Element Mesh in plane stress analysis of Polycarbonate Shell Structures Using the DAI5 Framework

- 6 DAI5 Framework:

- 7 Total deformation analysis of a bar using 1D elements and Ansys 2021R2:

- 8 2D plane stress analysis using Ansys 2021R2:

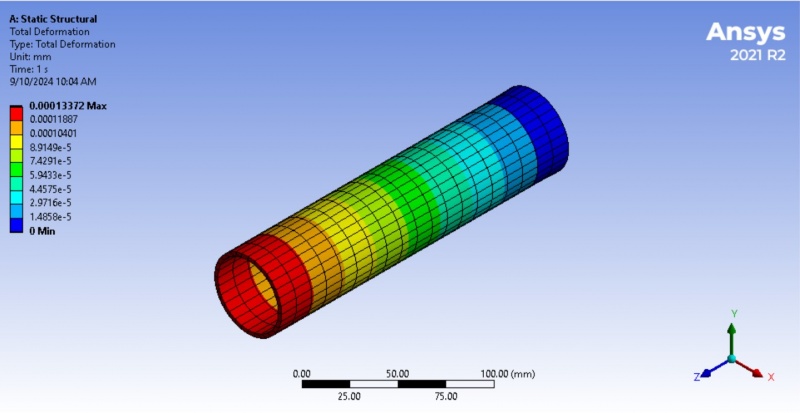

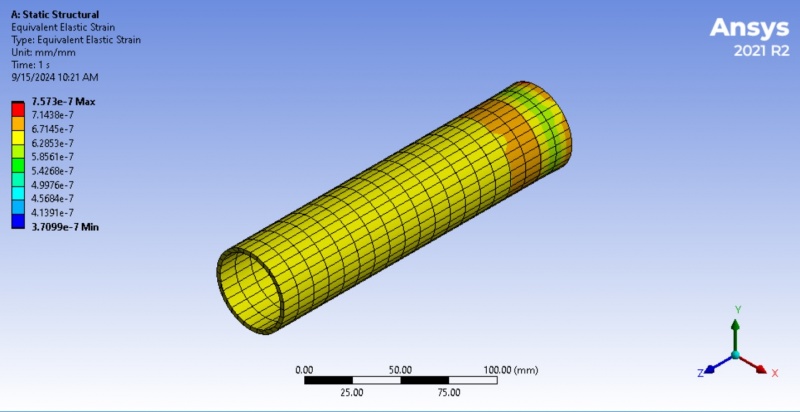

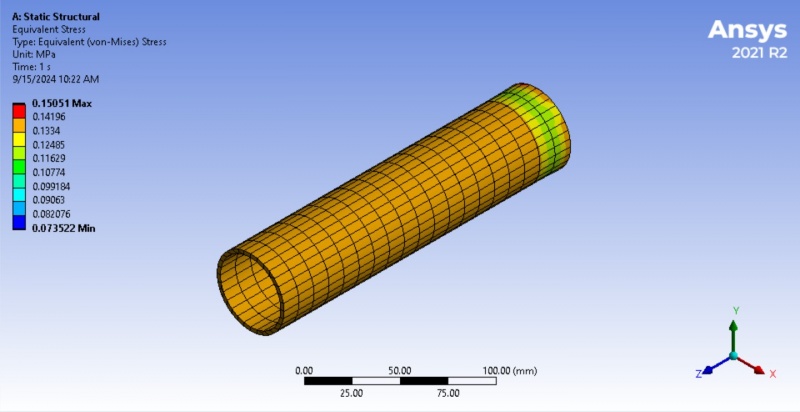

- 9 Pipe stress analysis using Ansys 2021R2:

- 10 Basic questions:

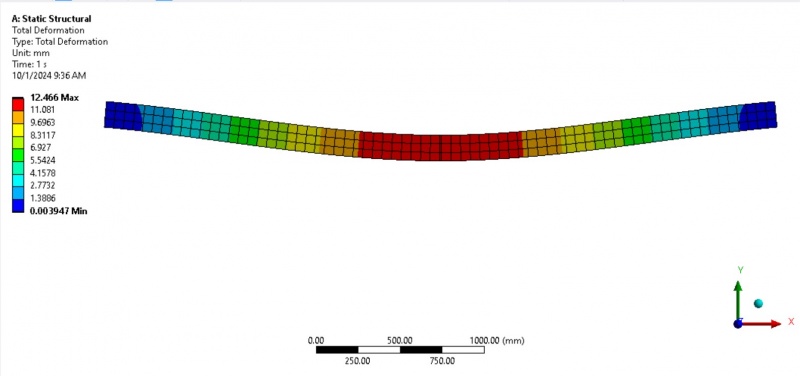

- 11 2D_beam stress_strain analysis using Ansys 2021R2:

- 12 shell plain stress_strain analysis using Ansys 2021R2:

- 13 Interpretation of Post-Processing Results:

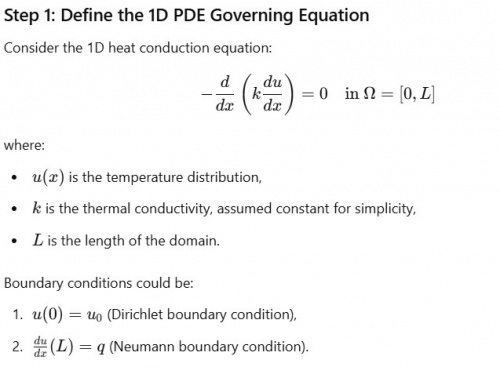

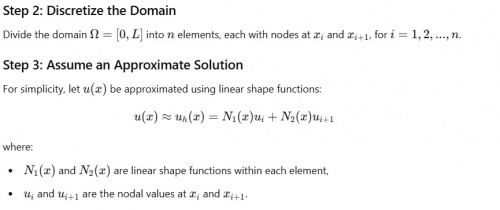

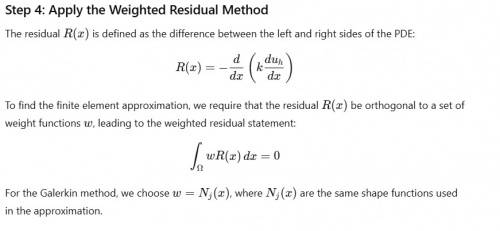

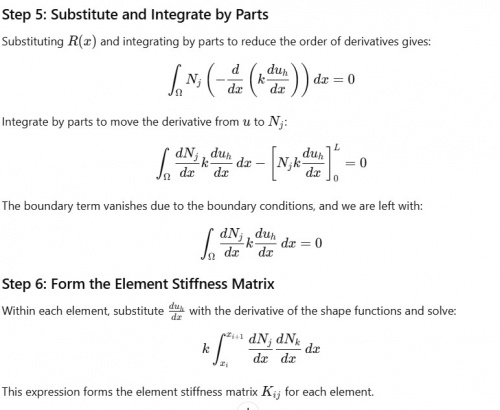

- 14 Finite element equations from a 1D Partial Differential Equation (PDE) using the weighted residual method:

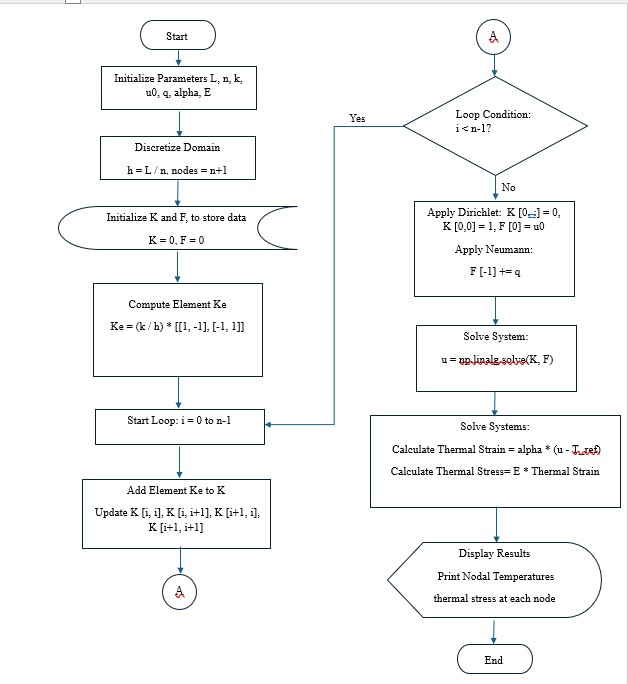

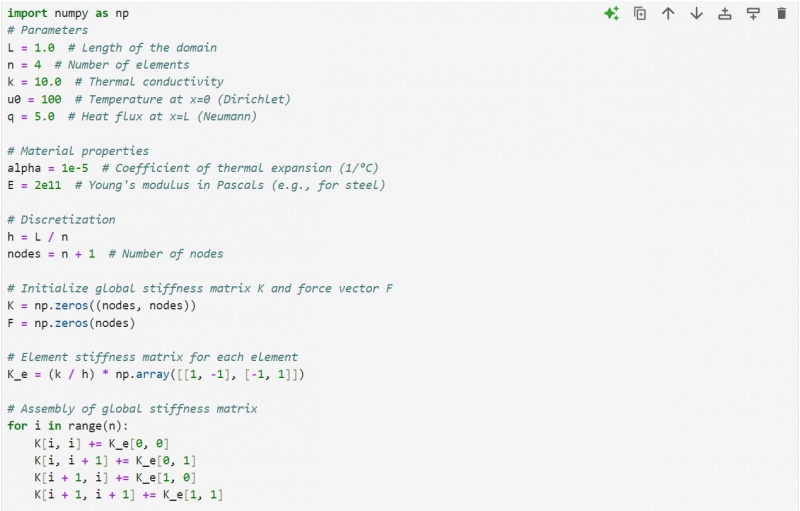

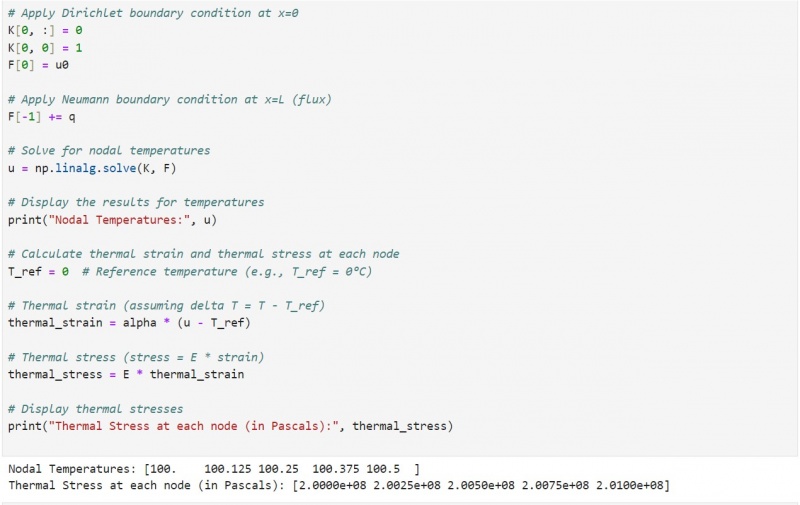

- 15 Algorithm, Flow chart, and python code for a 1D FEM:

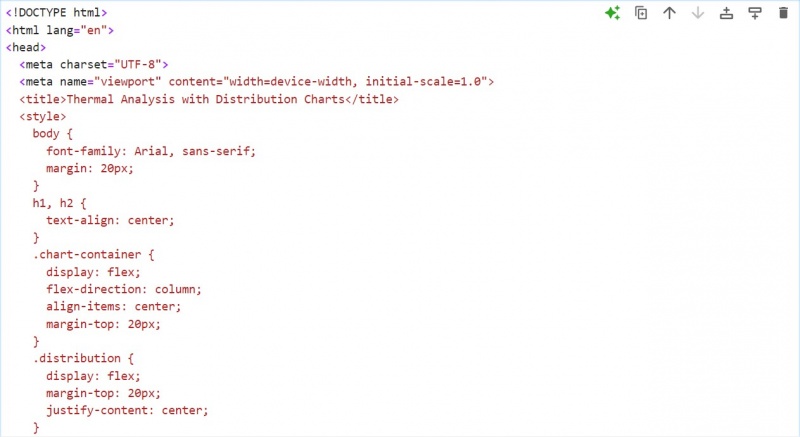

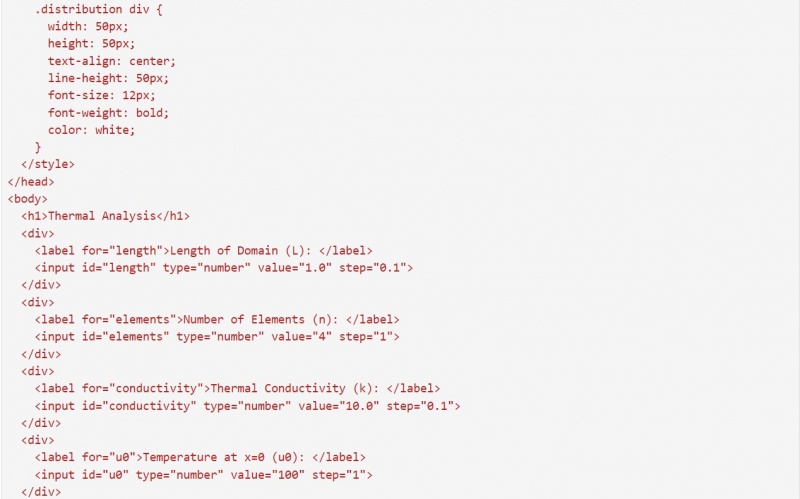

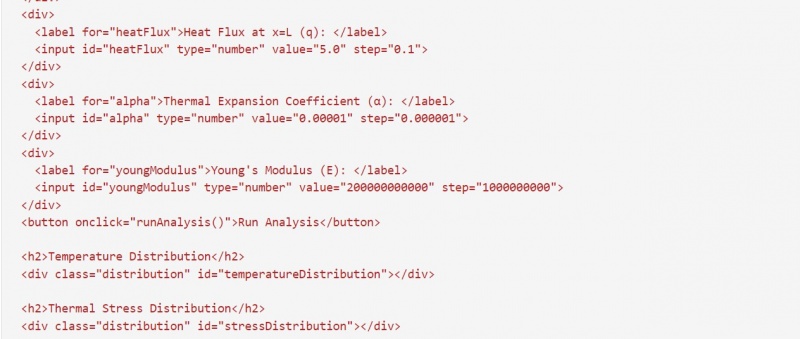

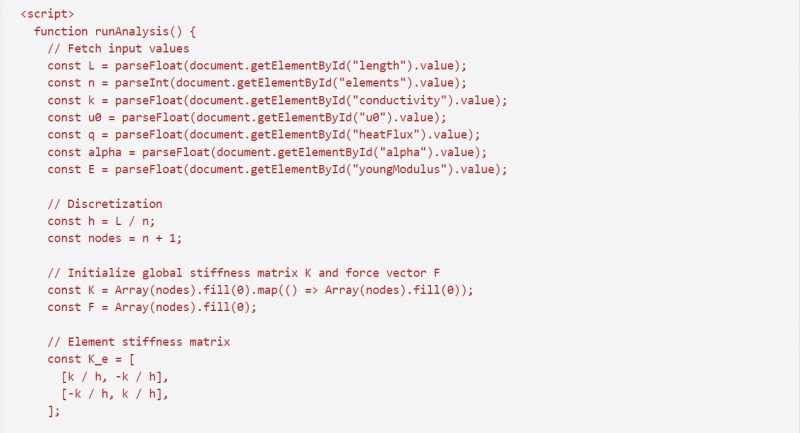

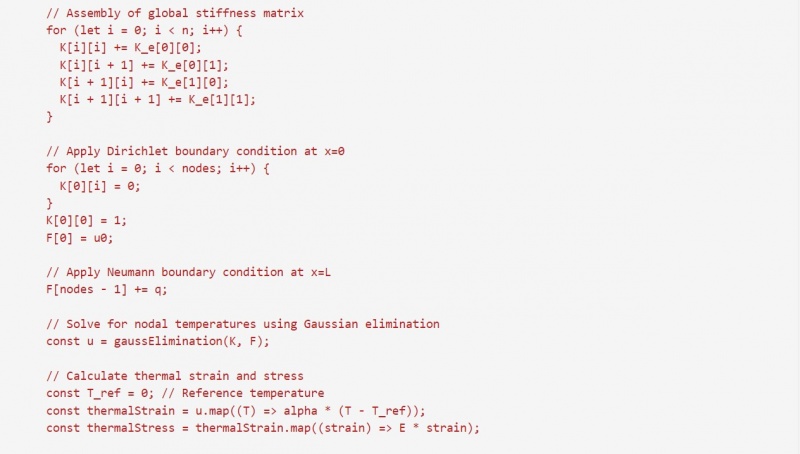

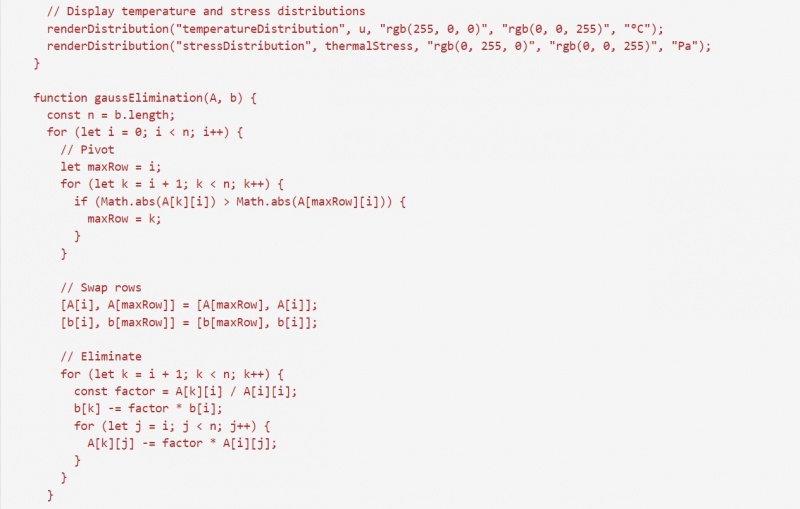

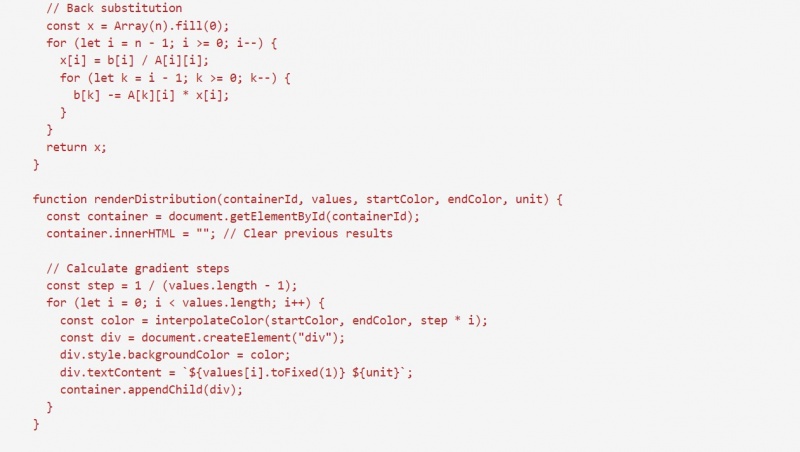

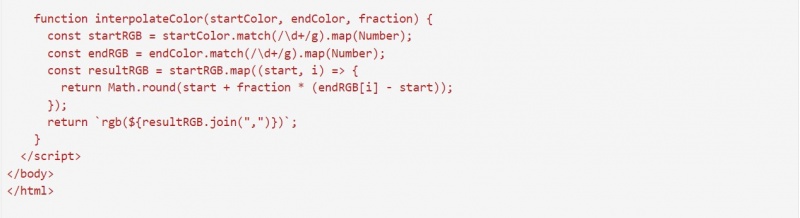

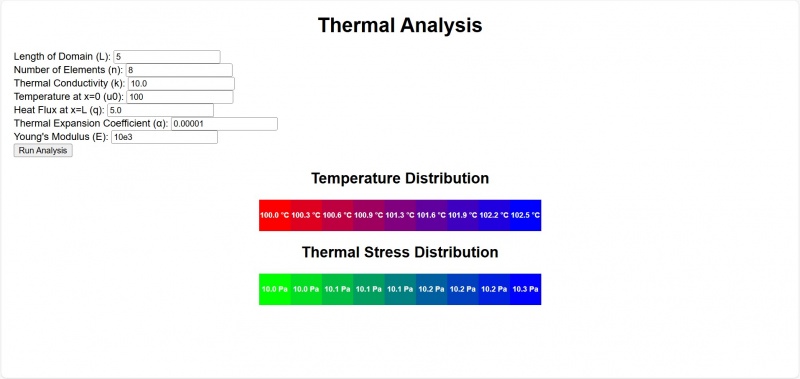

- 16 1D Thermal analysis using web based Java script:

- 17 The 33 DAI5 Implementation Evaluation Criteria

Predicting Static Stress in One-Dimensional Bar Elements Using Artificial Neural Networks coupled with DAI5 Framework-by-TanveeKhan

The given video is the part-1

The given video is the part-2

The 33 DAI5 Implementation Evaluation Criteria for Final project

Final_Term_Predicting Static Stress in One-Dimensional S275 J0 Bar Elements Using Artificial Neural Networks Coupled with DAI5 Framework

Tanveer Khan

Department of Mechanical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, 16424, Indonesia

Abstract

This study introduces a novel approach for static stress prediction in one-dimensional bar elements having material composition S275 J0 by applying Artificial Neural Networks (ANNs) integrated with the Deep Awareness of I (DAI5) framework. The research focuses on developing a computationally efficient ANN model trained on FEM-generated data to predict stress under static loading conditions. The ANN architecture consists of two inputs (force and cross-sectional area), a single hidden layer with eight neurons, and one output layer to predict tensile stress. The 'logsig' activation function and Bayesian regularization were utilized to optimize model performance. Results indicate that the ANN predictions closely approximate FEM outcomes, with minimal error percentages across multiple test cases, validating the model's accuracy and reliability. Regression analysis demonstrates a high correlation coefficient (R=0.99998), confirming the ANN's robustness in generalizing patterns. The proposed ANN model offers significant advantages over traditional FEM in terms of computational speed and efficiency, making it suitable for real-time engineering applications and iterative simulations. Future extensions of this research include multi-dimensional stress analysis and applications to complex structural geometries.

Keywords: Static stress prediction, Artificial Neural Network (ANN), Deep Awareness of I (DAI5), One-dimensional bar elements, Finite Element Method (FEM), Tensile stress analysis, Computational efficiency

1. Author Declaration

1.1 Deep Awareness (of) I

The author’s conscious understanding of the role of self-awareness in this study is deeply rooted in the concept of Deep Awareness (of) I, which emphasizes a continuous remembrance of The One and Only, The Creator. This foundational principle highlights the interconnectedness of self-awareness and purposeful action. By fostering an awareness of the soul, the author aligns the research process with a higher intent serving not only technical goals but also fulfilling a spiritual purpose. In this context, the development of the ANN model and its integration with the DAI5 framework reflect a conscious pursuit of knowledge and truth, grounded in the remembrance of the Creator. The study becomes an act of alignment between intellectual exploration and spiritual understanding, ensuring that innovation is guided by ethical reflection and recognition of divine purpose.

1.2 Intention of Project Activity

The primary objective of this research is to develop and validate an advanced ANN model, augmented by the capabilities of the DAI5 framework, specifically tailored for predicting static stress within one-dimensional bar elements. This model aims to achieve a balance between accuracy and computational speed, thereby overcoming the inherent constraints associated with traditional finite element method (FEM) while ensuring consistency and reliability across diverse structural conditions. The study will focus on enhancing the ANN model's predictive capabilities by inputting critical parameters such as the magnitude and direction of applied loads, essential material property like Young’s modulus, geometric details including the bar's length and cross-sectional area, number of elements over the entire length of the bar, and one fixed node. Out of them, only the two inputs are variables such as cross-sectional area and applied force; the others are constant. Additionally, the integration of domain-specific insights through the DAI5 framework aims to significantly refine the model’s performance. Ultimately, this research endeavors to develop a reliable, efficient, and scalable predictive tool that seamlessly integrates into existing engineering processes, reducing the resources and time required for static stress analysis in one-dimensional bar elements. This innovation is poised to not only benefit professionals in the engineering field but also provide substantial advantages to local communities by enhancing the safety and durability of structural designs. This ultimately reduces costs and time for both local communities and the government. A well-designed structure is sustainable and requires less frequent maintenance and repairs, thereby saving time and money while also minimizing the risk of injuries and other hazards.

2. Introduction

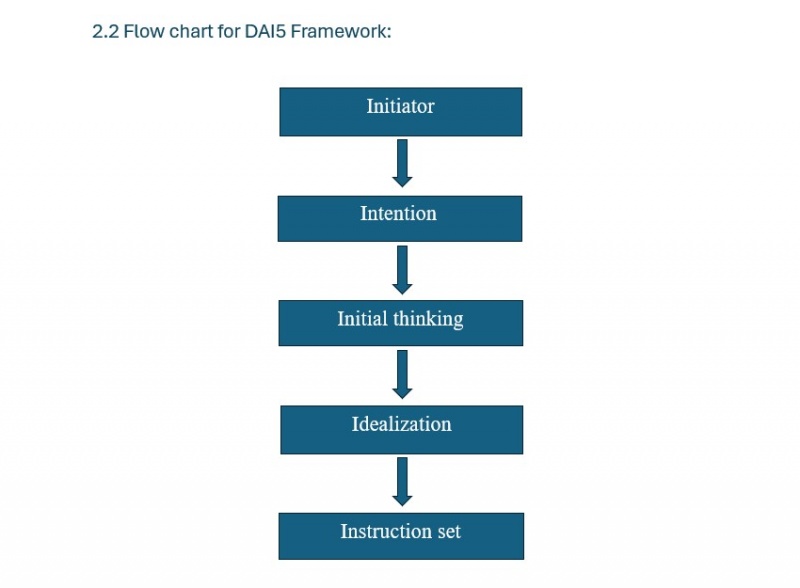

There are various ways to approach the problem, however, Deep Awareness (of) I (DAI5) conscious thinking framework integrates philosophical self-awareness and intentional thinking into problem-solving, beginning with Dr. Ahmad Indra's concept of "I am My Consciousness." Unlike traditional methods that focus primarily on logical, step-by-step approaches, DAI5 emphasizes reflective consciousness at each stage: Intention (purpose) both technical and non-technical, Initial thinking about the problem (open brainstorming), Idealization (envisioning the best outcomes) simply the problem, and Instruction set (actionable steps). This approach differs by promoting deep self-awareness, ethical reflection, and holistic engagement, fostering solutions that align personal values with practical execution, rather than focusing solely on technical or analytical solutions. The first three I’s cover the author declaration and introduction of the manuscript and the remaining two I’s cover the methodology[1].

2.1 Initial thinking

There are various ways to perform stress analysis in FEM such as 1D elements analysis, 2D elements analysis, and 3D elements analysis. 1D elements are simpler and computationally less intensive compared to 2D and 3D elements. They are particularly useful for structures that can be approximated as beam-like, such as vehicle frames or I-beam[2]. These elements are often used in scenarios where the geometry of the structure is relatively simple, and the primary interest is in the overall behavior rather than detailed local effects. For example, they are commonly used in the automotive industry for simplified vehicle structure models[3]. Simplified 1D models, such as 1D-bar and 1D-beam models, are used for stress analysis in bonded joints. These models assume a linear elastic adhesive material and can simulate the entire bonded overlap using a four-node macro-element. These models can be extended to include elasto-plastic adhesive material behavior, providing results comparable to more complex 3D models[4]. Low-order displacement-based finite elements, such as 3-node and 4-node elements, are computationally efficient and can achieve good stress convergence in 1D solutions and a novel procedure improves stress predictions by ensuring that stress convergence is quadratic, matching the order of displacement convergence[5]. A method for steady-state viscoelastic stress analysis using FEM is described, which includes a one-dimensional case. This method is effective for calculating stress distribution and deformation in viscoelastic materials[6]. Classical 6-DOF beam theories, such as Euler-Bernoulli and Timoshenko, are evaluated for their accuracy in predicting higher-order phenomena like elastic bending/shear coupling and torsional warping. These theories are often used in 1D finite element models[7]. A refined 1D formulation for fiber-reinforced laminated composites allows for detailed stress/strain field descriptions by increasing the order of the 1D model. This approach provides accurate displacement/stress fields with low computational costs[8].

A 1D round bar, commonly referred to as a cylindrical or round bar, is a long, solid cylindrical piece of metal or alloy used in various industrial applications. These bars are integral in numerous sectors due to their mechanical properties and versatility. Round bars are used in the manufacturing of various components due to their strength and durability[9]. They serve as reinforcement in concrete structures and are used in the production of steel rebar[10]. Round bars are essential in producing machine parts, mechanical equipment, and seamless pipes for the oil and gas industry[11]. They are used in the production of components requiring high dimensional accuracy and specific mechanical properties[12]. They are made from various materials such as steel, aluminum, and alloys etc. Steel known for its excellent corrosion resistance and strength, steel round bars are widely used in construction and mechanical engineering[11]. Aluminum bars are preferred for applications requiring lightweight and nearly straight bars with minimal deformation[9]. Various alloys, such as 32CrB4 steel and AA 2219, are used for specific applications requiring high strength and specific mechanical properties[13, 14]. The mechanical properties of round bars, such as yield strength, tensile strength, and hardness, vary depending on the material and manufacturing process. For instance, AA 2219 alloy bars exhibit yield strengths of 288–304 MPa and tensile strengths of 410–428 MPa after T6 temper heat treatment[14]. Shape Memory Alloys (SMAs) round bars are designed to replace conventional steel bars in structural applications, offering super elasticity and shape memory effects[15]. Moreover, the strength of a round bar is affected by its diameter, with larger diameters generally showing different mechanical properties compared to smaller ones. For instance, larger diameter bars may exhibit higher tensile strength due to the increased volume of material resisting deformation[16, 17]. The mechanical properties of round bars, including yield strength, can be influenced by processing conditions such as drawing and straightening. Larger diameter bars may experience more significant changes in yield strength due to these processes[18, 19]. The bending stiffness of a round bar is directly related to its diameter. Larger diameter bars are stiffer and less prone to bending under load, whereas smaller diameter bars are more flexible and can bend more easily[20, 21]. The bending strength of round bars can be affected by the presence of defects or initial damage, which is more pronounced in larger diameter bars due to the higher stress concentrations[21, 22]. Residual stresses within the bar, which can be compressive or tensile, vary with diameter. Smaller diameter bars tend to have compressive stresses, while larger diameter bars may exhibit tensile stresses, impacting their overall strength[23].

S275 J0 is a grade of structural steel that falls under the S275 category, which is a popular low carbon steel used in various engineering and structural applications. This type of steel is widely utilized in construction, maintenance, machinery, and manufacturing industries due to its favorable mechanical properties and weldability. It exhibits a combination of mechanical properties that make it suitable for structural applications such as the yield strength typically around 275 MPa, which is a standard requirement for this grade of steel, and the tensile strength ranges from 410 to 560 MPa, providing adequate strength for various structural applications[24]. The steel's properties make it suitable for use in bridge construction, where it can handle significant loads and stresses, besides that the 'J0' designation indicates that the steel has been tested for impact resistance at 0°C, ensuring its performance in moderately cold environments[25]. Its good weldability makes it an excellent choice for welded beams and columns in various structural applications, and it is relatively inexpensive compared to higher-grade steels, making it a cost-effective choice for many construction projects [26]

Artificial Neural Networks (ANNs) have emerged as powerful tools for structural stress analysis, offering efficient alternatives to traditional methods like finite element analysis (FEA). These models leverage machine learning techniques to predict stress distributions and responses under various loading conditions, significantly reducing computational costs and time, Machine learning (ML) has shown significant promise in the field of structural stress analysis, offering innovative solutions to traditional challenges, ML techniques have been employed to expedite the multiscale analysis of composite materials. By learning the relationships between different scales, ML models can significantly reduce computation times while maintaining high accuracy in stress predictions[27]. Artificial Neural Networks (ANNs) have been applied to improve stress recovery in FEA. Traditional FEA often provides accurate stress values only at specific points (super-convergent points. ANNs can map the stress field across the entire domain, enhancing accuracy and efficiency[28]. ML algorithms have been used to estimate axial stress in CWR by analyzing vibration data. By training ML models with data from finite element models, researchers can predict stress from vibration frequencies, demonstrating ML's viability in real-world applications[29]. Various ML models, including Gaussian Process Regression (GPR), Neural Networks (NN), and Boosted Trees (BST), have been used to predict stress-strain curves for materials like aluminum alloys. These models have shown high accuracy, with NNs achieving a coefficient of determination (R²) of 0.998[30]. ML models can provide highly accurate predictions, often surpassing traditional empirical models. For example, gradient boosting models have shown superior prediction accuracy for flow stress in high entropy alloys[31]. An Artificial Neural Network (ANN) is utilized to establish the relationship between selected feature elements and correlation elements for structural stress analysis. This approach enhances accuracy in measuring global stress in marine structures, achieving 93.6% accuracy in real-scale model tests[32].

Prediction, also known as forecasting, is a fundamental task across various scientific and engineering disciplines. It involves estimating outcomes based on past data and observed patterns. There are various models to predict the outcomes. Firstly, statistical methods including; Linear Regression used to predict values based on the relationship between dependent and independent variables[33], Logistic Regression commonly used for binary classification tasks[34], Naïve Bayes a probabilistic classifier based on Bayes' theorem[34], and Decision Trees a model that splits data into branches to make predictions[34]. Secondly, machine learning algorithms such as; Support Vector Machines (SVM) effective for classification and regression tasks[35], Artificial Neural Networks (ANN) used for complex pattern recognition and prediction tasks[36], and K-Nearest Neighbors (KNN) a simple, instance-based learning algorithm[34]. Lastly, Deep Learning Methods comprise of; Multilayer Perceptron (MLP) a type of neural network used for time series prediction and other tasks[37], and Deep Learning Models employed for handling large datasets and complex prediction tasks[38]. In the context of stress prediction, FEA is widely used to predict static stress by simulating the stress-strain response of materials under various loading conditions. This method can be enhanced by data-driven models to improve accuracy[39]. ANNs can be trained using displacement and force data to predict the stress state of materials. This method leverages synthetic data from virtual experiments to enhance prediction accuracy[40].

2.2 Problem statement

The prediction of static stress in structural elements, such as one-dimensional bar elements, remains a computationally intensive task when relying on traditional Finite Element Methods (FEM). While FEM offers precise stress distribution analysis, its high computational cost and time requirements pose significant limitations, especially for large-scale or iterative simulations in real-time engineering applications. Additionally, the simplification of geometric configurations, like one-dimensional bar elements, often leads to challenges in balancing accuracy and efficiency. The need for a scalable, accurate, and computationally efficient alternative has become increasingly critical in structural analysis to optimize resources and enhance engineering workflows. This study addresses the gap by proposing an Artificial Neural Network (ANN) model, augmented with the Deep Awareness of I (DAI5) framework, as a surrogate to FEM. This innovative approach aims to overcome the computational challenges while ensuring robust and accurate predictions of static tensile stress under varying input conditions, thus providing a cost-effective and time-saving solution for engineers and designers.

3. Methodology

3.1 Idealization

3.1.1 Material

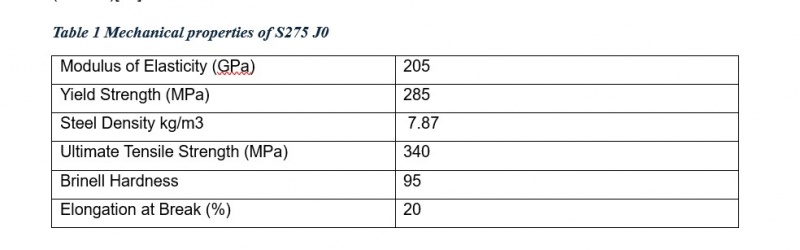

Mild steel is widely used in structural applications due to its favorable mechanical properties, affordability, and versatility. Among its various grades, S275 J0 is extensively employed in structural components, offering an optimal combination of strength, ductility, and weldability. This study focuses on predicting the static tensile stress of S275 J0 under static loading conditions using an Artificial Neural Network (ANN). To train the ANN's, the Finite Element Method (FEM) is incorporated for generating reliable training data to feed the ANN. This integration ensures to avoid experiments data collection. The mechanical properties of S275 J0 are presented in (Table 1)[41].

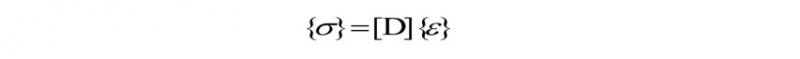

2.1.2 Finite Element Method (FEM)

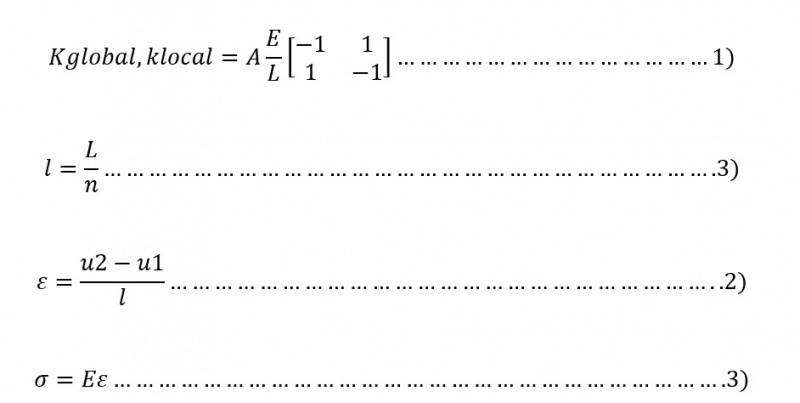

The Finite Element Method (FEM) is a powerful numerical technique used to obtain approximate solutions to a wide range of engineering problems, and is used to solve partial differential equations (PDEs) with specific boundary conditions by discretizing the solution region into smaller, simpler parts called finite elements, which can be assembled in various ways to represent complex shapes[42]. There are various ways to conduct finite element analysis to predict stress in a bar such as 1D, 2D, and 3D. However, 1D is simpler one, and the discrete elements are typically line segments[43]. Using one-dimensional elements allows for a straightforward mathematical description, making it easier to understand the principles and assumptions of mechanical modeling without complex mathematics[44]. The following 1D equations (1,2,3)[45] we used in our study for the predict of static stress in the bar.

Where:

K= Stiffness matrix.

E = Young's modulus of the material (Pa).

A = Cross-sectional area of the bar (m^2).

L =Length of the bar (m).

n= number of elements to divide the bar into.

l= element length (m).

u2-u1= change in length of the element (m).

ε= strain (m).

σ= stress (Pa).

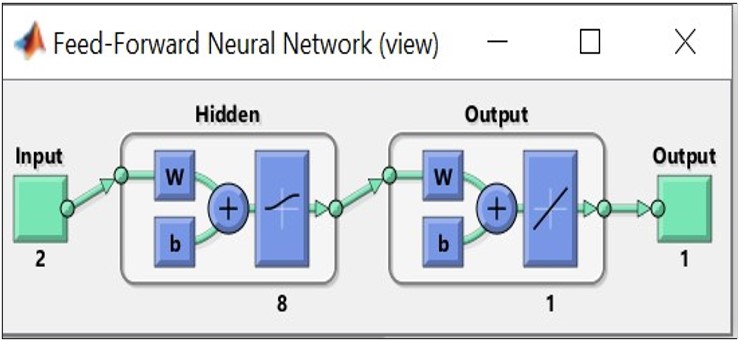

2.1.3 Artificial neural network (ANN)

The architecture of an ANN typically includes an input layer, one or more hidden layers, and an output layer. The number of hidden layers and the number of neurons in each layer are crucial parameters. An optimal configuration balances complexity and performance, avoiding underfitting or overfitting[46]. The choice of activation function (e.g. ReLU, logsig) affects how the network learns and processes information. Different functions can be applied to different layers to enhance performance[47]. Based on simplicity and performance considerations, the following Artificial Neural Network (ANN) configuration was applied using MATLAB to predict the static tensile stress in a bar. The ANN model utilized two inputs (the cross-sectional area and the applied force) both of which are critical parameters influencing tensile stress. A single hidden layer with 8 neurons was chosen to balance computational efficiency and model accuracy. The output layer predicted the tensile stress of the bar, which serves as the primary objective of this analysis. To ensure optimal performance, the ‘logsig’ activation function was used. This activation function demonstrated superior results in comparison to other alternatives based on a trial-and-error method, where the primary evaluation criteria included computational time, performance (mean squared error), and the correlation coefficient (R) between predicted and actual values. The ‘logsig’ activation function is advantageous for its smooth, nonlinear properties, which allow the ANN to approximate complex relationships between inputs and outputs effectively. This configuration strikes a balance between model simplicity and prediction accuracy, making it suitable for real-time applications and structural analysis tasks. The study demonstrates that integrating this ANN configuration can provide reliable predictions of tensile stress, thereby offering an efficient alternative to traditional methods like direct FEM simulations.

2.2 Instructure set

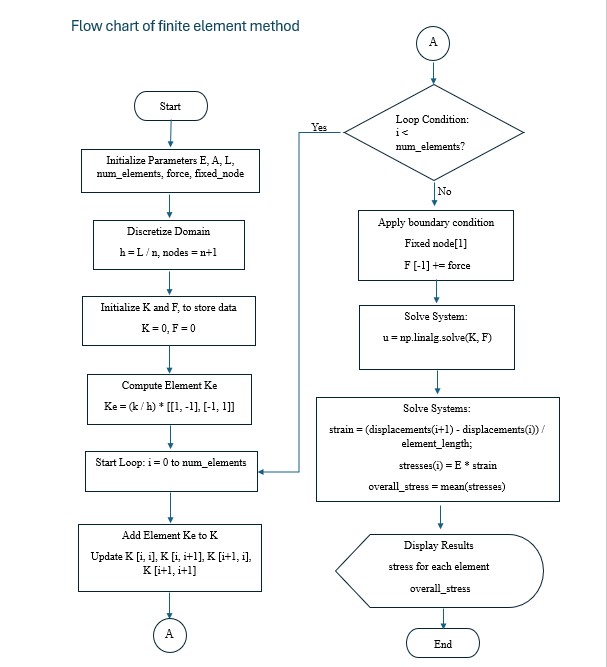

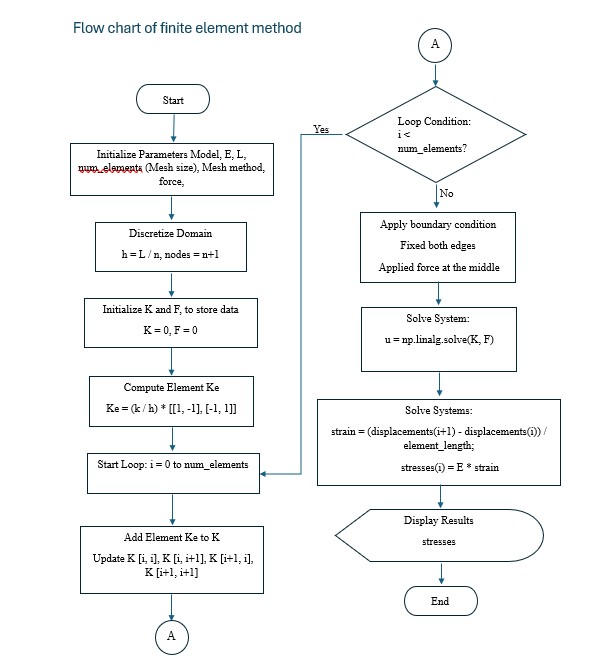

2.2.1 Finite element method

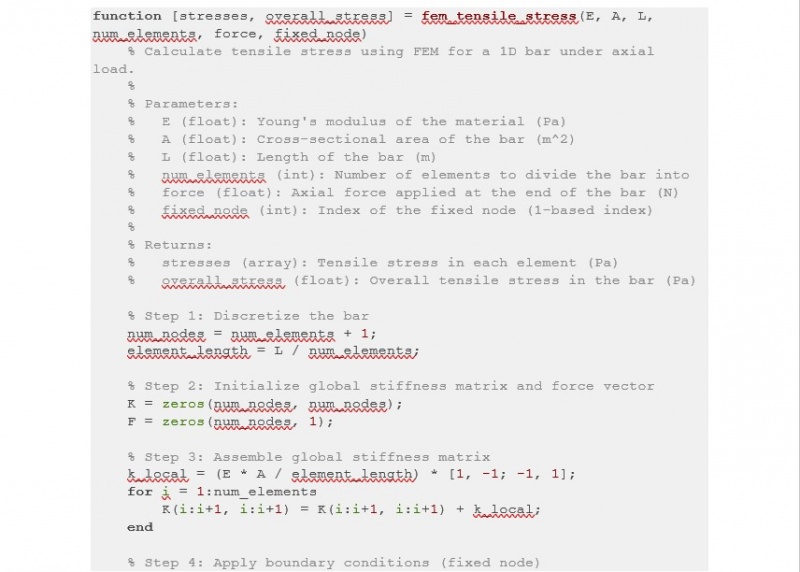

Step 1: Input Data to the model using MATLAB R2018a

Provide material properties, geometry, and load.

E =Young's modulus (Pa).

A=Cross-sectional area (m²).

L=Total bar length (m).

num_elements=Number of finite elements.

force=Axial force applied at the free end (N).

fixed_node=Fixed node index.

Step 2: Discretization

Divide the bar into num_elements segments.

Calculate the length of each element form the equation l=L/n.

Define the number of nodes from the equation num_nodes=num_elements+1.

Step 3: Global Stiffness Matrix Assembly

Initialize a global stiffness matrix K of size (num_nodes x num_nodes).

Define the local stiffness matrix for an element k(local)=A E/L [[-1 1]; [1 -1]].

Loop over each element and add the local stiffness matrix to the global stiffness matrix K.

Step 4: Apply Boundary Conditions

Fix the specified node (fixed_node) by eliminating the corresponding row and column in K.

Apply the force at the last node such as 𝐹end=force. Modify the system to exclude the fixed node.

Step 5: Solve for Displacements

Solve the reduced system of equations: K (reduced) x u (free)=F (reduced)where u (free) are the unknown displacements at free nodes.

Add the solved displacements back into the displacement vector u, including a zero displacement for the fixed node.

Step 6: Calculate Element Stresses

Compute strain in each element using ε=(u2-u1)/l.

Calculate element stress using Hooke's law as σ=Eε.

Store stresses for all elements.

Step 7: Compute Overall Stress and Display Results

Average the element stresses to find the overall tensile stress as overall_stress=mean(stresses)

Print the stress for each element and the overall tensile stress.

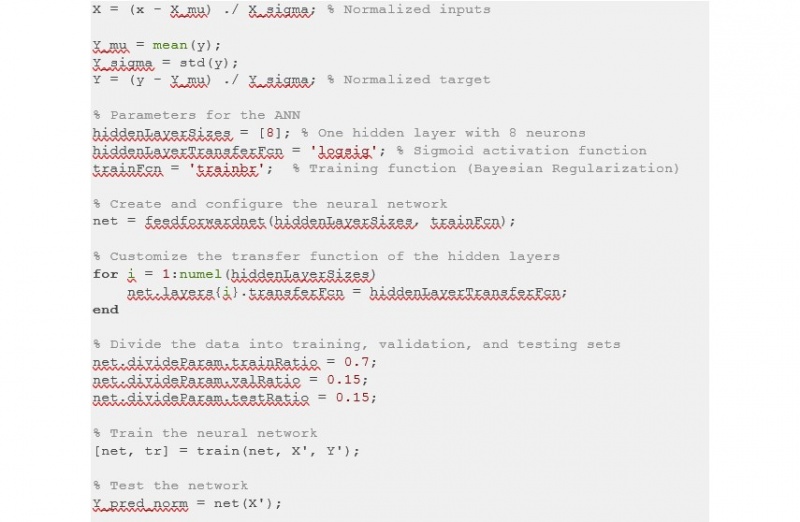

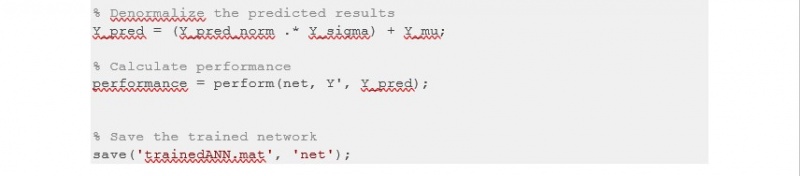

2.2.2 Artificial neural network ANN

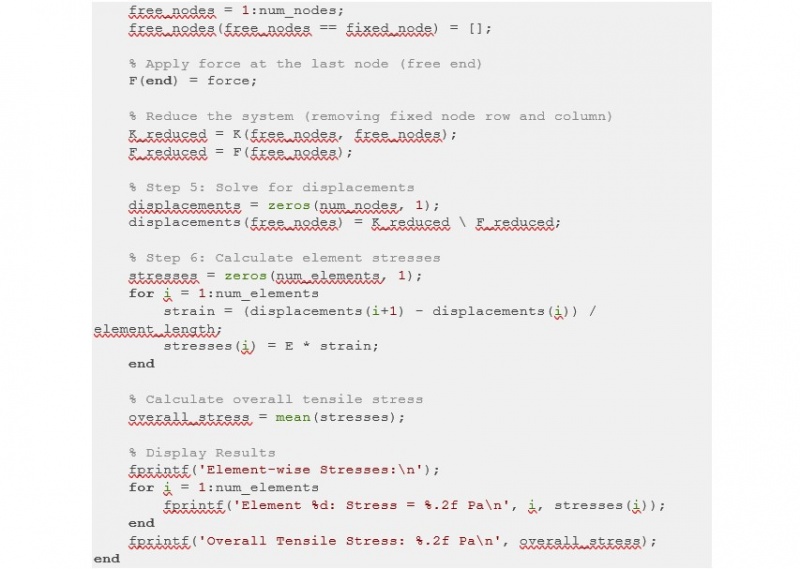

Step 1: Load Data to the MATLAB R2018a

Load data from a CSV file ().

Extract X as Features (input data) from columns and Y as Target values (output data) from column.

Step 2: Normalize Data

Normalize the inputs X and targets Y using mean (μ) and standard deviation (σ).

Step 3: Define Neural Network Architecture

Choose parameters for the ANN such as number of layers (One hidden layer with 8 neurons).

Activation function like logsig for the hidden layer.

Training function using Bayesian Regularization (trainbr).

Create the neural network using net=feedforwardnet(hiddenLayerSizes, trainFcn).

Step 4: Configure Neural Network

Update the transfer function for hidden layers using Matlab code net.layers{i}.transferFcn = 'logsig';

Divide data into. Such as 70% Training, 15% Validation, and 15% for Testing.

Step 5: Train the Neural Network

Use the training function to train the network using the code line [net,tr]=train(net, X’, Y’).

Step 6: Test the Network

Predict normalized outputs using the trained network such as Y pred_norm=net(Xt ).

Denormalize predictions back to the original scale by using the code line Y pred=(Y pred_norm *Yσ)+Yμ.

Step 7: Calculate Performance

Evaluate network performance using the performance function=perform(net, Y’, Y_pred).

Step 8: Save Trained Network

Save the trained network to a .mat file using code save('trainedANN.mat', 'net')

4. Results and discussion

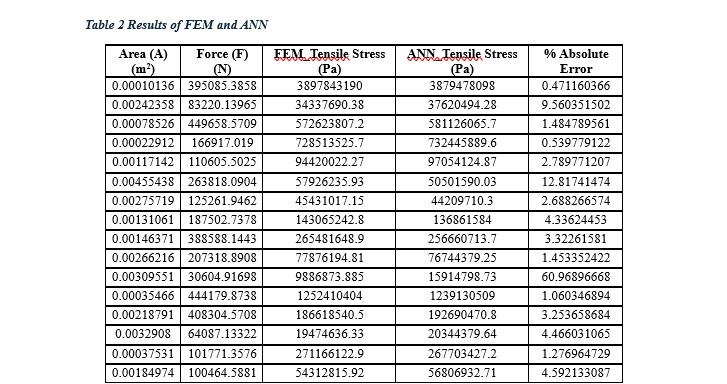

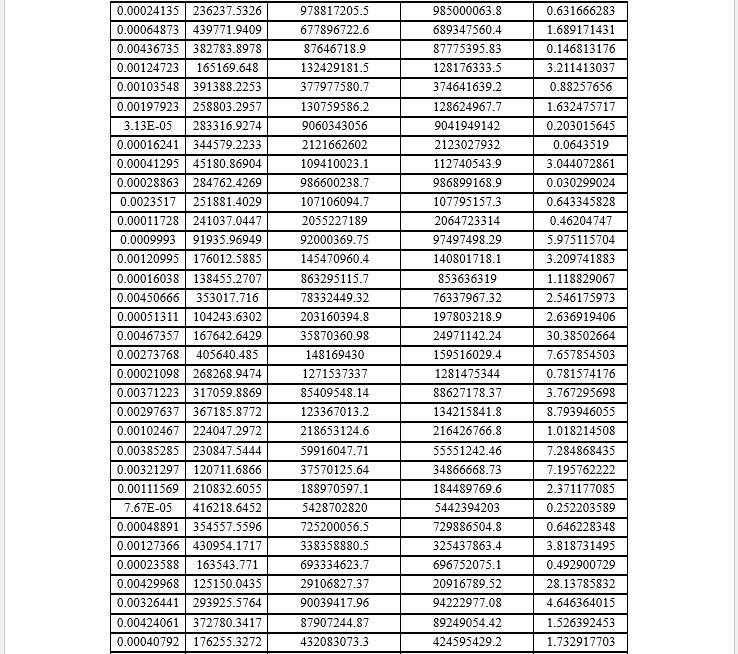

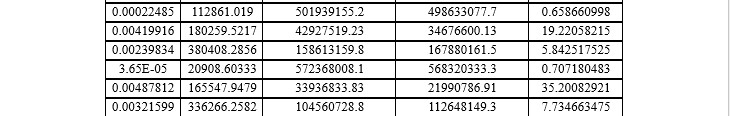

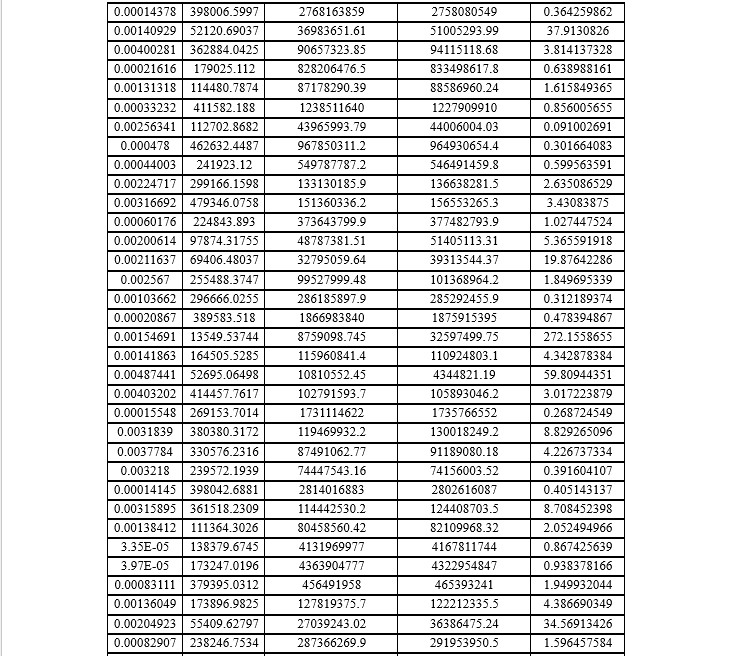

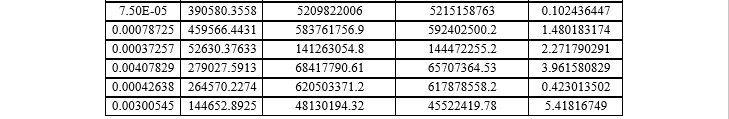

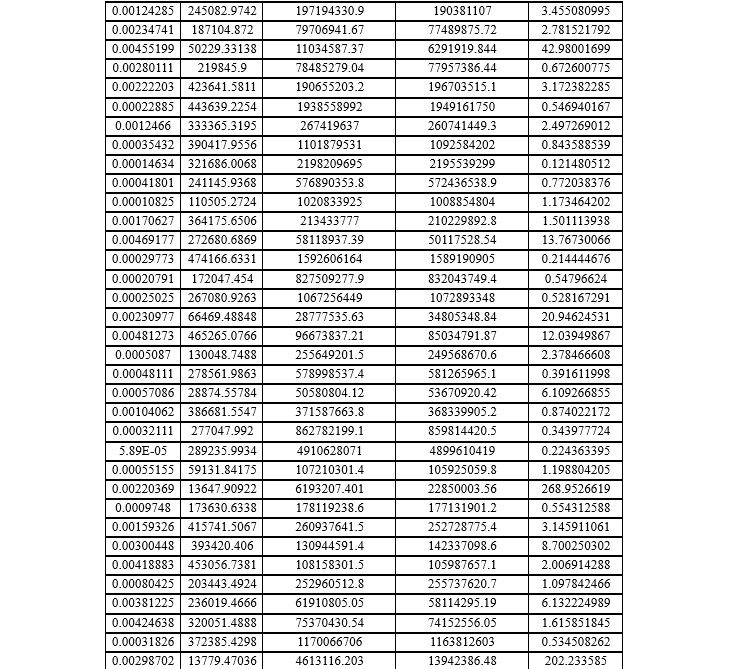

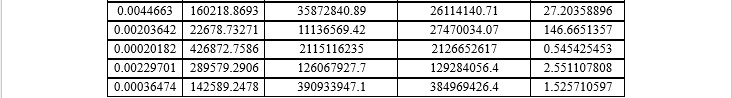

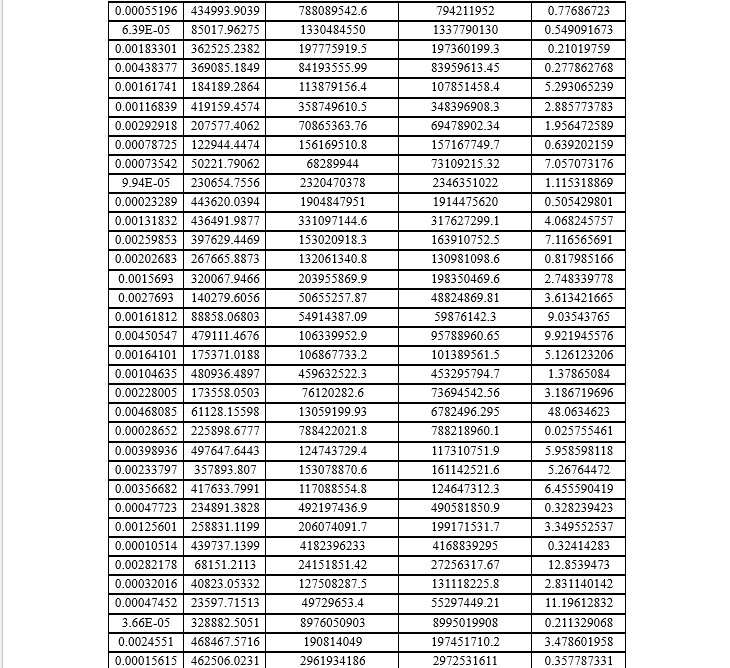

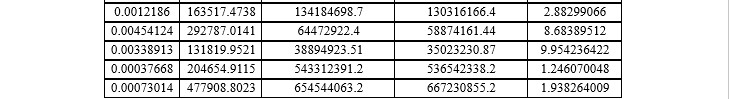

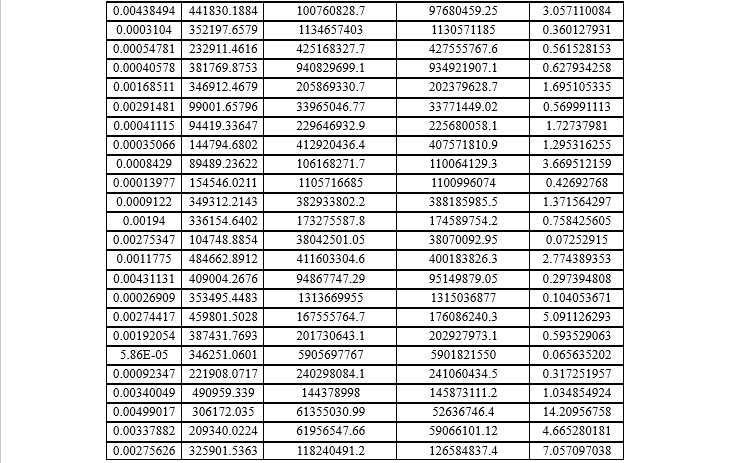

The (Table 2) presents predicted tensile stress values from the ANN model alongside FEM results. It also includes the absolute percent error of ANN predictions, highlighting their accuracy. This comparison demonstrates the ANN's ability to approximate FEM outcomes, with minor deviations indicating the model's reliability for tensile stress prediction in engineering applications. The key parameters include the cross-sectional area A, applied force F, FEM-predicted tensile stress, ANN-predicted tensile stress, and the absolute percentage error between ANN and FEM results. The FEM results serve as a benchmark for tensile stress prediction, while ANN results approximate these values based on training and generalization capabilities. The absolute percentage error varies across the cases. For instance, in the first case, the error is minimal at 0.47%, indicating high alignment between ANN and FEM predictions. The second case exhibits a larger error of 9.56%, suggesting some deviation, likely due to nonlinearities or ANN training limitations. For the remaining cases, errors generally stay within a small range (0.5%-2.8%), demonstrating that ANN predictions are close to FEM results. Smaller errors (0.47%, 0.54%) suggest that the ANN effectively learns from the input-output relationships for tensile stress. Larger deviations, as seen in case 2, may arise when input values fall outside the ANN’s training range or involve variations that the model could not fully capture. The ANN model achieves reasonably accurate predictions of tensile stress, with absolute errors mostly below 3%. These small deviations validate the ANN’s reliability for estimating FEM results, offering computational efficiency and reduced processing time compared to FEM, particularly for iterative simulations. The findings demonstrate that ANN models can effectively approximate FEM results in tensile stress prediction, making them valuable tools for engineering applications where rapid predictions are required.

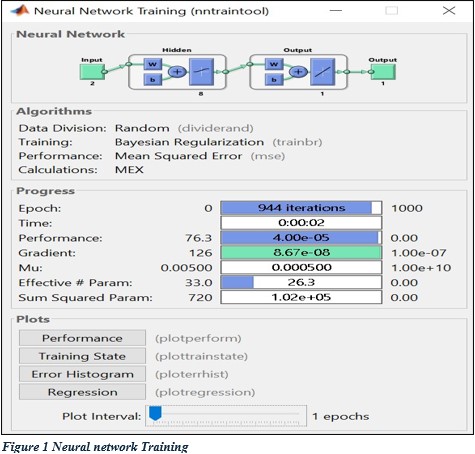

The (Figure 1) shows the Neural Network Training (nntraintool) interface for an Artificial Neural Network (ANN) model trained using Bayesian Regularization (trainbr). The neural network comprises 2 inputs, 1 hidden layer with 8 neurons, and 1 output. The network completed 944 iterations out of the 1000 iterations allowed, showing it approached convergence early. Training lasted 2 seconds, demonstrating computational efficiency due to the network’s simple architecture. The performance achieved is 4.00e-05, which is a very small error. This indicates that the network closely approximates the target values, confirming high accuracy. The gradient value is 8.67e-08, which is near zero. A low gradient suggests that the training process has reached an optimal solution where weight adjustments are minimal.The parameter μ remains constant at 0.005, indicating stable Bayesian regularization without divergence or instability. The network uses approximately 26.3 effective parameters out of 33, demonstrating efficiency in parameter utilization and avoiding overfitting.

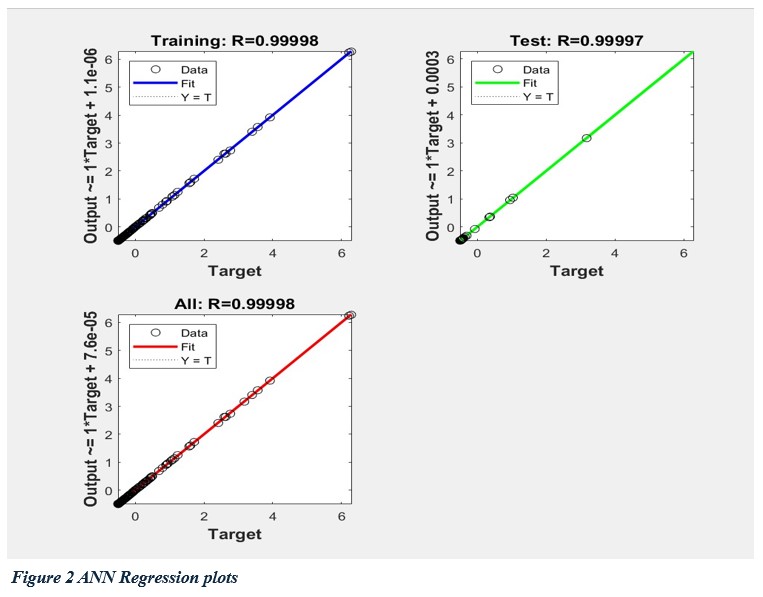

The (Figure 2) presents regression plots for the training, testing, and overall performance of the Artificial Neural Network (ANN) used to predict tensile stress. These plots demonstrate the relationship between the target values (actual data) and the network outputs (predicted values) for different phases of training. The regression coefficient R, which indicates the linear correlation between the ANN outputs and targets, is provided for each phase. In the top-left plot, the regression coefficient for the training set is R=0.99998, indicating an almost perfect correlation between the ANN predictions and the actual target values. The blue line, representing the best fit, closely aligns with the diagonal line Y=T, where the output equals the target. The very slight offset (1.1 × 10-6) confirms minimal prediction error. This near-perfect regression demonstrates that the network effectively learned the underlying patterns in the training data, achieving high accuracy. The clustering of data points along the ideal line further supports the strong generalization of the model within the training phase. The top-right plot shows the performance of the ANN on the testing set, with R=0.99997. The regression coefficient remains close to 1.0, indicating excellent agreement between predictions and actual targets for unseen data. The green fitting line also aligns well with the Y=T line, with a minor offset of 0.0003. This small deviation highlights the ANN’s robustness and ability to generalize its learned patterns to new, unseen data. The consistency between training and testing results suggests that overfitting has been avoided, a notable achievement given the complexity of neural network training. The bottom plot combines all the data (training, validation, and testing) and reports an overall regression coefficient of R=0.99998. The red fit line closely follows the Y=T line, with an extremely small offset of 7.6×10-5 .This result further confirms the model's excellent performance across the entire dataset. The high R-value indicates a strong linear correlation between the predicted and actual tensile stress values, underscoring the ANN's reliability and precision.

The regression results collectively demonstrate the high predictive accuracy of the ANN model. The near-perfect R-values across training, testing, and overall phases confirm the network’s ability to approximate the FEM results with minimal errors. The consistency of performance across the subsets of data is particularly significant, as it indicates that the network has successfully generalized its predictions without overfitting or underfitting. From a practical perspective, the results highlight the ANN's capability to serve as a reliable surrogate model for tensile stress prediction. Traditional methods such as Finite Element Analysis (FEA) are computationally expensive and time-consuming, especially for large-scale or iterative simulations. The ANN model, on the other hand, provides rapid and accurate predictions, making it highly suitable for real-time engineering applications where efficiency is paramount. Furthermore, the minimal offsets observed in the regression lines suggest that the ANN is capable of handling noise or variations in input data without significant loss of accuracy. This robustness is a critical factor in practical implementations where real-world data often contains inherent variability.

5. Conclusion

The integration of Artificial Neural Networks (ANN) with the Finite Element Method (FEM) has proven to be a highly effective approach for static stress prediction in one-dimensional bar elements. By leveraging the DAI5 framework, this study has successfully demonstrated a novel methodology that balances computational efficiency with predictive accuracy. The ANN model showcased high alignment with FEM results, achieving minimal prediction errors, which underscores its potential as a reliable surrogate for FEM in engineering applications. Moreover, the ANN's ability to generalize across diverse input scenarios highlights its robustness and adaptability for real-world use. These findings validate the ANN's applicability in reducing computational costs and expediting stress analysis processes, particularly in iterative simulations and large-scale engineering tasks.

Future research should explore applying this ANN-based framework to multi-dimensional stress analysis and more complex geometries, broadening its usability across various structural engineering scenarios.

6. Acknowledgments

The author gratefully acknowledges the support and contributions provided by Universitas Indonesia for facilitating this research. Special thanks are extended to the Department of Mechanical Engineering, Faculty of Engineering, for their resources and guidance throughout the study. The author also wishes to express gratitude to mentors whose insights and encouragement have significantly enriched the research process.

7. References

[1] D. A. Indra. "Deep Awareness (of) I (DAI5) Framework." https://air.eng.ui.ac.id/index.php?title=Main_Page (accessed.

[2] C. M. Wai, A. Rivai, and O. Bapokutty, "Modelling optimization involving different types of elements in finite element analysis," in IOP Conference Series: Materials Science and Engineering, 2013, vol. 50, 1 ed., doi: 10.1088/1757-899X/50/1/012036. [Online]. Available: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84893574266&doi=10.1088%2f1757-899X%2f50%2f1%2f012036&partnerID=40&md5=f1f018e49b16a62d4e13fc279deb1527

[3] P. Mihaylova, N. Baldanzini, and M. Pierini, "Considerations on 1D beam concept modelling for the vehicle structure," in International Conference on Noise and Vibration Engineering 2012, ISMA 2012, including USD 2012: International Conference on Uncertainty in Structure Dynamics, 2012, vol. 5, pp. 3793-3808. [Online]. Available: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84906330927&partnerID=40&md5=14669964066ea29b3d1fdf60b455df5b. [Online]. Available: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84906330927&partnerID=40&md5=14669964066ea29b3d1fdf60b455df5b

[4] E. Paroissien, F. Gaubert, A. Da Veiga, and F. Lachaud, "Elasto-plastic analysis of bonded joints with macro-elements," Journal of Adhesion Science and Technology, Article vol. 27, no. 13, pp. 1464-1498, 2013, doi: 10.1080/01694243.2012.745053.

[5] D. J. Payen and K. J. Bathe, "A stress improvement procedure," Computers and Structures, Article vol. 112-113, pp. 311-326, 2012, doi: 10.1016/j.compstruc.2012.07.006.

[6] F. Qin, Y. Yu, and T. Rudolphi, "Finite element modeling of viscoelastic stress analysis under moving loads," World Academy of Science, Engineering and Technology, Article vol. 50, pp. 941-948, 2011. [Online]. Available: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84871277457&partnerID=40&md5=2cad14132cbf04614b57759b670dbbef.

[7] E. Carrera and A. Pagani, "Evaluation of the accuracy of classical beam FE models via locking-free hierarchically refined elements," International Journal of Mechanical Sciences, Article vol. 100, pp. 169-179, 2015, doi: 10.1016/j.ijmecsci.2015.06.021.

[8] E. Carrera, M. Maiarú, M. Petrolo, and G. Giunta, "A refined 1D element for the structural analysis of single and multiple fiber/matrix cells," Composite Structures, Article vol. 96, pp. 455-468, 2013, doi: 10.1016/j.compstruct.2012.09.012.

[9] S. Roy and A. K. Pal, "A novel approach for study of straightness in commercially produced round metal bars based on deflection measurements," Applications in Engineering Science, Article vol. 16, 2023, Art no. 100161, doi: 10.1016/j.apples.2023.100161.

[10] V. N. Shinkin, "Elastoplastic Flexure of Round Steel Beams. 1. Springback Coefficient," Steel in Translation, Article vol. 48, no. 3, pp. 149-153, 2018, doi: 10.3103/S0967091218030117.

[11] V. N. Shinkin, "Elastoplastic bend of round steel beam. Report 1. springback coefficient," Izvestiya Ferrous Metallurgy, Article vol. 61, no. 3, pp. 194-200, 2018, doi: 10.17073/0368-0797-2018-3-194-200.

[12] M. Asakawa, "Part 1: Trends in drawing technology for bars and wires," Wire Journal International, Article vol. 47, no. 8, pp. 60-66, 2014. [Online]. Available: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84940307389&partnerID=40&md5=583a4dbbc1bc0dd040b183bc2f2e527a.

[13] A. Stepanov, A. Koldaev, N. Arutyunyan, and A. Zaitsev, "Evolution of the Structural State and Properties of 32CrB4 Steel during the Production of High-Strength Fasteners," Metals, Article vol. 12, no. 2, 2022, Art no. 366, doi: 10.3390/met12020366.

[14] T. R. Prabhu, "Effects of ageing time on the mechanical and conductivity properties for various round bar diameters of AA 2219 Al alloy," Engineering Science and Technology, an International Journal, Article vol. 20, no. 1, pp. 133-142, 2017, doi: 10.1016/j.jestch.2016.06.003.

[15] M. K. Song, E. Choi, and J. H. Lee, "Development and Performance Evaluation of a Mechanical Connection for Steel and Shape Memory Alloy Bars," Metals, Article vol. 14, no. 3, 2024, Art no. 300, doi: 10.3390/met14030300.

[16] J. Gu, "Approach to mechanical properties of die casting components," Tezhong Zhuzao Ji Youse Hejin/Special Casting and Nonferrous Alloys, Article vol. 25, no. 8, pp. 482-484, 2005. [Online]. Available: https://www.scopus.com/inward/record.uri?eid=2-s2.0-24744466912&partnerID=40&md5=6ca5341ac775ffbfc7c593a004369d63.

[17] "Experimental investigation on bond of largediameter reinforcing bars," in fib Bulletins, vol. 2022, 2022, pp. 98-109.

[18] B. Rivolta, G. Silva, M. Rota, and M. Cusolito, "Drawn bars: Influence of straightening conditions," Wire Journal International, Article vol. 37, no. 5, pp. 77-81, 2004. [Online]. Available: https://www.scopus.com/inward/record.uri?eid=2-s2.0-2542513096&partnerID=40&md5=713de22f81aadc388850dbc1795be450.

[19] Y. Tanaka, M. Asakawa, R. Komami, and H. Kubota, "Effect of mechanical properties on diameter of drawn bars," Wire Journal International, Article vol. 42, no. 11, pp. 66-71, 2009. [Online]. Available: https://www.scopus.com/inward/record.uri?eid=2-s2.0-71949101522&partnerID=40&md5=21558bbad821a3a1f816b6015e90056d.

[20] Y. Song, Z. Guan, Y. Nie, and X. Guan, "The analysis of the bending stiffness and intensity of cylindrical tubes," Science in China, Series E: Technological Sciences, Article vol. 50, no. 3, pp. 268-278, 2007, doi: 10.1007/s11431-007-0031-3.

[21] Y. L. Zheng, Y. T. Sun, H. R. Lin, J. Q. Wang, X. Liu, and C. H. Lu, "Experimental study of initial damage to steel bars due to bending process and the resulting performance deterioration," Construction and Building Materials, Article vol. 411, 2024, Art no. 134326, doi: 10.1016/j.conbuildmat.2023.134326.

[22] Y. Zheng, X. Liu, C. Lu, S. Bu, and K. Kosa, "Incipient Damage When Bending Stirrup and Its Influence on Mechanical Properties," Cailiao Daobao/Materials Reports, Article vol. 36, no. 23, 2022, Art no. 21110130, doi: 10.11896/cldb.21110130.

[23] G. Roy and K. Sennah, "Residual stress in axisymmetric rods," in AES-ATEMA International Conference Series - Advances and Trends in Engineering Materials and their Applications, 2009, pp. 111-117. [Online]. Available: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84856622647&partnerID=40&md5=e2570fdb937b225a08b45d08a56e2bd7. [Online]. Available: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84856622647&partnerID=40&md5=e2570fdb937b225a08b45d08a56e2bd7

[24] B. Çevik, "Effect of welding processes on mechanical and microstructural properties of S275 structural steel joints," Materialpruefung/Materials Testing, Article vol. 60, no. 9, pp. 863-868, 2018, doi: 10.3139/120.111225.

[25] J. Brnic, G. Turkalj, J. Niu, M. Canadija, and D. Lanc, "Analysis of experimental data on the behavior of steel S275JR - Reliability of modern design," Materials and Design, Article vol. 47, pp. 497-504, 2013, doi: 10.1016/j.matdes.2012.12.037.

[26] T. Lipiński, "Corrosion of S235JR steel in NaCL environment at 3 °c," in METAL 2017 - 26th International Conference on Metallurgy and Materials, Conference Proceedings, 2017, vol. 2017-January, pp. 660-665. [Online]. Available: https://www.scopus.com/inward/record.uri?eid=2-s2.0-85043327383&partnerID=40&md5=bbfb99a56487675d5bce750b42101320. [Online]. Available: https://www.scopus.com/inward/record.uri?eid=2-s2.0-85043327383&partnerID=40&md5=bbfb99a56487675d5bce750b42101320

[27] W. Kuś, W. Mucha, and I. T. Jiregna, "Multiscale Analysis of Composite Structures with Artificial Neural Network Support for Micromodel Stress Determination," Materials, Article vol. 17, no. 1, 2024, Art no. 154, doi: 10.3390/ma17010154.

[28] B. B. Saikia, D. Nath, and S. S. Gautam, "Application of machine learning in efficient stress recovery in finite element analysis," in Materials Today: Proceedings, 2023, vol. 78, pp. 359-363, doi: 10.1016/j.matpr.2022.10.100. [Online]. Available: https://www.scopus.com/inward/record.uri?eid=2-s2.0-85141385166&doi=10.1016%2fj.matpr.2022.10.100&partnerID=40&md5=175dba8b506c4c8801ab5e7ff3c87e2b

[29] M. Belding, A. Enshaeian, and P. Rizzo, "A Machine learning-based approach to determining stress in rails," Structural Health Monitoring, Article vol. 22, no. 1, pp. 639-656, 2023, doi: 10.1177/14759217221085658.

[30] A. Dorbane, F. Harrou, D. C. Anghel, and Y. Sun, "Machine Learning Prediction of Aluminum Alloy Stress–Strain Curves at Variable Temperatures with Failure Analysis," Journal of Failure Analysis and Prevention, Article vol. 24, no. 1, pp. 229-244, 2024, doi: 10.1007/s11668-023-01833-2.

[31] S. K. Dewangan et al., "Enhancing flow stress predictions in CoCrFeNiV high entropy alloy with conventional and machine learning techniques," Journal of Materials Research and Technology, Article vol. 30, pp. 2377-2387, 2024, doi: 10.1016/j.jmrt.2024.03.164.

[32] T. Zhang et al., "Reconstructing the Global Stress of Marine Structures Based on Artificial-Intelligence-Generated Content," Applied Sciences, vol. 13, no. 14, doi: 10.3390/app13148196.

[33] Y. Mishra, S. Mishra, and P. K. Mallick, "A Regression Approach Towards Climate Forecasting Analysis in India," in Lecture Notes in Networks and Systems, 2022, vol. 375, pp. 457-465, doi: 10.1007/978-981-16-8763-1_37. [Online]. Available: https://www.scopus.com/inward/record.uri?eid=2-s2.0-85132028355&doi=10.1007%2f978-981-16-8763-1_37&partnerID=40&md5=296facd8681f403b4c78711986db19f2

[34] T. Goswami, "Machine learning behind classification tasks in various engineering and science domains," in Cognitive Informatics, Computer Modelling, and Cognitive Science: Volume 1: Theory, Case Studies, and Applications, 2020, pp. 339-356.

[35] D. Liu, Y. Peng, and X. Peng, "Online adaptive status prediction strategy for data-driven fault prognostics of complex systems," in 2011 Prognostics and System Health Management Conference, PHM-Shenzhen 2011, 2011, doi: 10.1109/PHM.2011.5939530. [Online]. Available: https://www.scopus.com/inward/record.uri?eid=2-s2.0-79960910267&doi=10.1109%2fPHM.2011.5939530&partnerID=40&md5=774d6ca54d55e118a78e63f216d0a1ee

[36] S. Han, T. Hong, G. Kim, and S. Lee, "Technical comparisons of simulation-based productivity prediction methodologies by means of estimation tools focusing on conventional earthmovings," Journal of Civil Engineering and Management, Article vol. 17, no. 2, pp. 265-277, 2011, doi: 10.3846/13923730.2011.574381.

[37] K. N. Myint and M. Khaing, "Time Series Forecasting System for Stock Market Data," in IEEE International Conference on Control and Automation, ICCA, 2023, vol. 2023-February, pp. 56-61, doi: 10.1109/ICCA51723.2023.10181945. [Online]. Available: https://www.scopus.com/inward/record.uri?eid=2-s2.0-85166283979&doi=10.1109%2fICCA51723.2023.10181945&partnerID=40&md5=f22632502068119381e416e3f453587a

[38] B. U. Maheswari, S. Kirubakaran, P. Saravanan, M. Jeyalaxmi, A. Ramesh, and R. G. Vidhya, "Implementation and Prediction of Accurate Data Forecasting Detection with Different Approaches," in Proceedings of the 4th International Conference on Smart Electronics and Communication, ICOSEC 2023, 2023, pp. 891-897, doi: 10.1109/ICOSEC58147.2023.10276331. [Online]. Available: https://www.scopus.com/inward/record.uri?eid=2-s2.0-85175695713&doi=10.1109%2fICOSEC58147.2023.10276331&partnerID=40&md5=fb8be12ce3e577f41c15d76b48ec9cc5

[39] X. Li, Z. Li, Y. Chen, and C. Zhang, "An enhanced data-driven constitutive model for predicting strain-rate and temperature dependent mechanical response of elastoplastic materials," European Journal of Mechanics, A/Solids, Article vol. 100, 2023, Art no. 104996, doi: 10.1016/j.euromechsol.2023.104996.

[40] R. Lourenço, A. Andrade-Campos, and P. Georgieva, "The Virtual Fields Method to Indirectly Train Artificial Neural Networks for Implicit Constitutive Modelling," in Key Engineering Materials, 2022, vol. 926 KEM, pp. 2060-2068, doi: 10.4028/p-gy2di7. [Online]. Available: https://www.scopus.com/inward/record.uri?eid=2-s2.0-85140455747&doi=10.4028%2fp-gy2di7&partnerID=40&md5=c1a33ebfdba66e5f99a233db5ff4e9a6

[41] D. McClements. "All About Mild Steel." https://www.xometry.com/resources/materials/mild-steel/ (accessed.

[42] V. Jagota, A. P. S. Sethi, and K. Kumar, "Finite element method: An overview," Walailak Journal of Science and Technology, Review vol. 10, no. 1, pp. 1-8, 2013. [Online]. Available: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84884232632&partnerID=40&md5=978bc7ff76751fb4aadd81c407653ca2.

[43] A. Quarteroni, "Generation of 1D and 2D grids," in Modeling, Simulation and Applications, vol. 16, 2017, pp. 141-160.

[44] A. Öchsner and M. Merkel, One-dimensional finite elements: An introduction to the FE method (One-Dimensional Finite Elements: An Introduction to the FE Method). 2013, pp. 1-398.

[45] Y. Charles, "A finite element formulation to model extrinsic interfacial behavior," 2014, doi: 10.1016/j.finel.2014.05.008.

[46] W. Fink, "Autonomous self-configuration of artificial neural networks for data classification or system control," in Proceedings of SPIE - The International Society for Optical Engineering, 2009, vol. 7331, doi: 10.1117/12.821836. [Online]. Available: https://www.scopus.com/inward/record.uri?eid=2-s2.0-69949172844&doi=10.1117%2f12.821836&partnerID=40&md5=1a2160eec0d56383c7efc38b3368c127

[47] M. R. Shaeri, A. M. Randriambololona, and S. Sarabi, "Prediction Accuracy of Artificial Neural Networks in Thermal Management Applications Subject to Neural Network Architectures," in Proceedings of the World Congress on Mechanical, Chemical, and Material Engineering, 2022, doi: 10.11159/htff22.175. [Online]. Available: https://www.scopus.com/inward/record.uri?eid=2-s2.0-85145297886&doi=10.11159%2fhtff22.175&partnerID=40&md5=dad358820386a0405180e02837363f17

8. Appendices

8.1 Finite element method algorithm

8.2 Artificial neural network algorithm

End of Final Term

Video_Mid_Term_Optimization of 2D Element Mesh in plane stress analysis of Polycarbonate Shell Structures Using the DAI5 Framework

Writing_Mid_Term_Optimization of 2D Element Mesh in plane stress analysis of Polycarbonate Shell Structures Using the DAI5 Framework

Tanveer Khan

Department of Mechanical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, 16424, Indonesia

Abstract

This study investigates the optimization of 2D element mesh configurations in polycarbonate shell structures using the DAI5 conscious thinking Framework. Finite Element Analysis (FEA) methods were applied to analyze stress distributions in shell structures under static loading conditions. The goal is to identify the optimal mesh size and method for accurate stress analysis under plane stress conditions, focusing on three meshing techniques: Multizone Quad/Tri, Quadrilateral Dominant, and Triangle. Each technique was evaluated at varying mesh sizes (1 mm, 2 mm, and 3 mm) using ANSYS simulation software. Results indicate that the Multizone Quad/Tri method provides a balanced approach with high accuracy and computational efficiency at 2 mm mesh size. The Quadrilateral Dominant method demonstrated consistent accuracy across different mesh sizes but with slightly longer computation times. The Triangle method yielded the most detailed stress analysis but at a higher computational cost. This study highlights that smaller mesh sizes increase accuracy but at the expense of computational time, with the DAI5 framework promoting a reflective and intentional approach to optimization.

Keywords:Finite Element Method (FEM), 2D Element Mesh, Polycarbonate, Stress Analysis, DAI5 Framework, Multizone Quad/Tri, Quadrilateral Dominant, Triangle Method.

1. Introduction

The Finite Element Method (FEM) is one of the most powerful tools used in engineering and applied sciences to solve complex structural problems. FEM is widely used for static analysis, enabling optimal design by combining mathematical optimization and computer technology. This method helps achieve better design parameters efficiently compared to traditional trial-and-error approaches[1].There are various ways to perform the stress anlysis in FEM such as; 1D elements analysis, 2D elements anlysis, and 3D elements analysis. 1D elements are simpler and computationally less intensive compared to 2D and 3D elements. They are particularly useful for structures that can be approximated as beam-like, such as vehicle frames or I-beams[2]. These elements are often used in scenarios where the geometry of the structure is relatively simple, and the primary interest is in the overall behavior rather than detailed local effects. For example, they are commonly used in the automotive industry for simplified vehicle structure models. However they have limitations in modeling complex geometries and capturing detailed stress distributions. This can lead to modeling errors influenced by factors such as cross-section deformations and discontinuities[3]. Static analysis of 2D elements involves evaluating structures under steady loads to determine displacements, stresses, strains, and forces without considering inertia and damping effects. Common 2D elements used in static analysis include quadrilateral elements such as four-node (Q4), eight-node (Q8), and nine-node (Q9) elements. These are particularly useful in plane stress problems where the thickness is small compared to other dimensions[4]. This method reduces memory requirements and simplifies the assembly of elements with internal nodes. It transforms stiffness matrices and force vectors for more efficient post-processing[5]. A full 3D finite element model was used to analyze the structural response of the CAREM-25 nuclear power plant under design basis accident and seismic loads. This model included over 2 million solid elements and incorporated foundation flexibility through linear springs[6]. This approach uses 3D solid elements to model the role of shear reinforcement in flat slabs, accurately capturing the gradual decrease in concrete contribution to shear resistance with increasing slab rotation[7]. For a continuous steel truss bridge, a mixed-element approach was used, where cracked cross-beams were modeled as solid elements, and other members as 3D-beam elements. This method effectively captured the static analysis results[8].

Polycarbonate is a versatile, high-performance material widely used in roofing sheets and various building products. Its applications span windows, lights, wall panels, roof towers, and external LED lighting. Known for being lightweight, offering excellent clarity, high impact resistance, and flame retardance, polycarbonate is a reliable choice for many construction and manufacturing needs[9]. It is employed in roof and wall glazing, offering durability and good optical properties. Its use in high-rise buildings and machine construction is valued for its thermal stability and toughness[10].

Optimization in stress primarily involves techniques and methodologies aimed at minimizing stress in structural engineering, Several studies focus on optimizing structural designs to minimize stress. Techniques like the bi-directional evolutionary structural optimization (BESO) method and p-norm stress minimization are used to reduce maximum stress in structures like beams and brackets[11, 12]. Techniques like Interior Value Extrapolation (IVE) improve stress evaluation accuracy in jagged structures, which is crucial for effective stress minimization in topology optimization[13]. To improve computational efficiency, a first-order approximation of internal force is used to express stress constraints explicitly. This method has shown better performance compared to zero-order approximations and reciprocal variable methods[14].

There are are verious ways to approach to the problem ,however, the DAI5 conscious thinking framework integrates philosophical self-awareness and intentional thinking into problem-solving, beginning with Dr. Ahmad Indra's concept of "I am My Consciousness." Unlike traditional methods that focus primarily on logical, step-by-step approaches, DAI5 emphasizes reflective consciousness at each stage: intention (purpose), initial thinking (open brainstorming), idealization (envisioning the best outcomes), and instruction set (actionable steps). This approach differs by promoting deep self-awareness, ethical reflection, and holistic engagement, fostering solutions that align personal values with practical execution, rather than focusing solely on technical or analytical solutions[15].

Among its various elements analysis method, 2D shell elements, plane stress model play a pivotal role in simplifying three-dimensional (3D) problems into two-dimensional (2D) approximations. These simplifications allow for the efficient analysis of structures like plates, thin shells, and pressure vessels without the need to model the entire 3D geometry[16]. 2D shell elements reduce computational complexity, making them an appealing choice for analyzing mechanical systems and complex structures that include plate and shell components, 2D shell elements offer significant computational advantages, their limitations necessitate advanced methods to ensure accurate simulations, particularly in complex or localized scenarios[17]. Shell elements are widely used in various industries, including aerospace, energy, chemical, and civil engineering. They are essential for designing structures like aircraft fuselages, pipelines, and reactor compartments, where stability and strength are critical[18]. The use of finite element procedures is common in analyzing shell structures. There are different approaches to shell finite elements, including those derived from shell models and those based on 3D formulations with kinematical assumptions[19]. Traditional 2D shell theories may fail to capture the full range of physical behaviors, particularly in scenarios requiring rich 3D representations. This limitation can compromise the accuracy of simulations[20].

In this article, we will explore the 2D element analysis of shell structures under various mesh element sizes and mesh methods, focusing on Triangles, Quadrilateral Dominant, and Multizone Quad/Tri. The objective is to search for the optimal mesh element size and mesh method that provide accurate results for plane stress while maintaining constant shell thickness, length, and boundary conditions in a polycarbonate shell structure.

The problem statement addresses the challenge of finding the ideal mesh configuration to enhance the accuracy of stress calculations. Key factors include selecting the appropriate mesh size and type, which significantly influence the stress within the polycarbonate shell. By applying the DAI5 conscious thinking framework, this study aims to determine the optimal combination of mesh methods and sizes to achieve the best balance computational efficiency and accuracy, which alternatively decrease the energy consumption and time while maintaining the structural parameters (thickness, length, and boundary conditions) constant. Reduced computational time not only enhances the speed of analysis but also directly contributes to lower energy usage, as less processing power is required to reach convergence in the solution. This reduction in energy consumption is particularly beneficial in resource-constrained environments, contributing to cost savings and environmental sustainability. Additionally, minimizing energy use aligns with sustainable engineering practices, as it decreases the overall carbon footprint associated with computational tasks. Therefore, the optimized mesh configuration ultimately provides a solution that is not only precise and efficient but also environmentally responsible, offering practical benefits to local communities by reducing energy demands and associated costs.

2. Methodology

2.1 DAI5 Framework:

We followed this framework to find the good solution for the problem which is totally different from the conventional approaches, this approach more focused on subjective experience is about how each person perceives and interprets the world in their own unique way. It's based on individual feelings, thoughts, and personal experiences rather than objective facts. This framework consist of 5 Is which we followed to achive our objectives as;

2.1.1 Initiator:

In this study, the author play role of the initiator, anchoring this process through his philosophical insight: "I am My Consciousness" This concept underscores the intrinsic connection between personal identity and self-awareness, proposing that our consciousness and thoughts not only shape our actions but also influence how we perceive reality. By integrating this perspective, Dr. Indra introduces crucial philosophical, psychological, and ethical dimensions into the framework, which in turn fosters reflective thinking. By fostering an awareness of the soul, the author aligns the research process with a higher intent serving not only technical goals but also fulfilling a spiritual purpose. In this context, the Optimization of 2D Element Mesh in plane stress and its integration with the DAI5 framework reflect a conscious seeking of knowledge and truth, grounded in the remembrance of the Creator.

2.1.2 Intention:

In the context of the DAI5 framework, intention plays a pivotal role in defining the purpose and desired outcome of the thought process. This aligns with the philosophy of consciousness, where intentionality guides mental engagement with precision and focus. Throughout this study, having a clear understanding of the intention allowed us to maintain focus on the primary objective: conducting a 2D element plane stress analysis of a shell structure. The goal of this analysis was to determine the optimal combination of mesh methods and mesh sizes that would achieve the best accuracy, while maintaining constant structural parameters such as thickness, length, and boundary conditions. This clear intention shaped every step of the research, ensuring that each decision, from mesh generation to boundary condition application, was aligned with the objective of producing precise and reliable results within an efficient computational framework. By emphasizing intentional thinking, we were able to approach the problem methodically and with mindfulness, ensuring that each phase of the analysis was coherent with the broader aim of optimizing the mesh configuration. This clarity helped mitigate distractions, streamline the process, and foster a structured analysis focused on optimizing the 2D element mesh for the shell structure which will help the local community in term of energy reduction and time saving and hence the cost.

The deliberate focus on intention throughout the study not only ensured that the research remained aligned with its core objectives but also facilitated the development of an efficient analytical approach. By maintaining the structural parameters constant, we were able to isolate the impact of different mesh configurations and ultimately identify the combination that provided the optimal balance of accuracy and computational efficiency.

2.1.3 Initial Thinking:

The initial thinking phase of the DAI5 framework serves as an exploratory stage where ideas and information are gathered without the constraints of immediate judgment or decision-making. During this phase, participants are encouraged to brainstorm, reflect, and contemplate multiple facets of the problem at hand. The freedom to explore various ideas fosters a holistic approach, allowing intuition and past experiences to guide the generation of creative insights. The aim is to gather as much relevant information as possible before narrowing down to more focused solutions. While applying this concept to the 2D element stress analysis of a shell structure, the nature of the problem becomes the primary focus: the shell is subjected to specific boundary conditions and external uniform force, and the goal is to evaluate the resulting stress field. In particular, the problem centers on understanding how external forces and boundary constraints influence the structural integrity of the polycarbonate shell under static loading conditions. This involve the following;

1) Information Search:

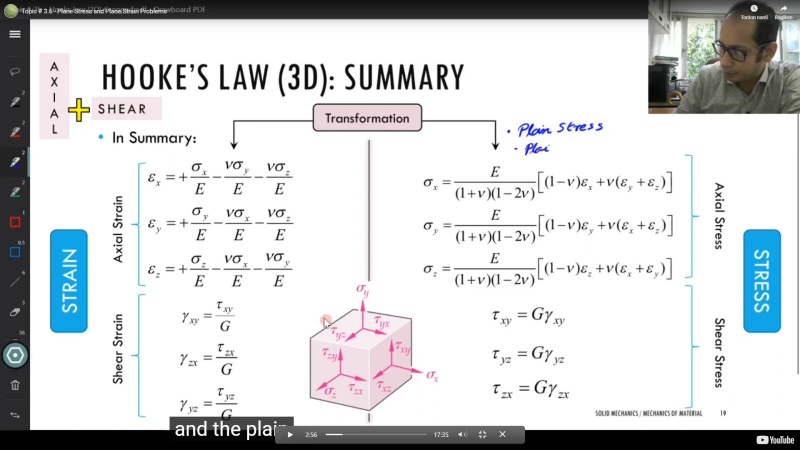

At this stage, a 2D element analysis is being conducted on a cylindrical shell made of polycarbonate, a thermoplastic known for its toughness, impact resistance, and thermal stability. Polycarbonate is frequently chosen in engineering applications for its ability to withstand applied loads while maintaining structural integrity. This makes it a suitable material for pressure-bearing applications, such as cylindrical shells, where the structure must resist deformation under various loading conditions.The focus of this analysis is on the 2D element approach, which is especially effective for structures like cylindrical shells. This method simplifies computation while still delivering accurate results. By using 2D plane stress assumptions, the complexity of a full 3D analysis is reduced, concentrating only on the significant stress components within the shell’s plane. This approach is suitable when the shell's thickness is relatively small compared to its length and radius, as is the case here. Underlying principles for stress analysis are; Hooke’s Law provides the foundational relationship between stress and strain in elastic materials, while the stress equilibrium equations ensure that forces within a structure are balanced under static loading. Together, these principles are essential for accurately analyzing the behavior of materials and structures in engineering applications, particularly when using methods such as Finite Element Analysis (FEA). In the context of a cylindrical polycarbonate shell, understanding these principles is crucial for determining how the material will respond to applied forces and ensuring that it maintains structural integrity under load.

2) Nature of the Problem:

The focus of this analysis is on the behavior of a cylindrical shell under external uniform force, with the aim of understanding how the material responds under static loading conditions. The shell in question is made of polycarbonate, with mechanical properties that include a modulus of elasticity and Poisson's ratio specific to polycarbonate's behavior under loading conditions. Moreover, polycarbonate a versatile thermoplastic material widely used in engineering and industrial applications due to its mechanical properties such as high impact resistance, toughness, and thermal stability. These properties make polycarbonate an ideal choice for applications requiring structural integrity under various loads, including pressure vessels, piping systems, and storage tanks etc. In additon we are searching for the appropriate mesh configuration that balanced the accuracy and computational time.

3) Stress Analysis:

To evaluate the stress field within the shell using 2D element analysis. The primary focus is on understanding how the plane stress is distributed within the shell structure. Specifically, the goal is to assess how the polycarbonate material responds to the applied forces, considering both the radial force loading and the fixed boundary conditions. Normal Stress in the x and y directions; The analysis involves calculating the stresses acting on the material’s plane, which are critical for determining how the shell will deform under load. When a uniform radial force is applied, these stresses help identify regions of potential failure or deformation.

2.1.4 idealization:

Idealization involves envisioning the best possible scenarios and solutions while transcending present limitations. This stage encourages creative thinking and prompts individuals to consider solutions beyond the immediate constraints. In scientific and engineering analysis, idealization plays a critical role in simplifying complex problems by making certain assumptions that allow for more focused and efficient modeling, without losing sight of the ultimate goal of accuracy and precision. In this analysis, the assumptions reflect an idealization of the shell's behavior under given loading conditions are given by;

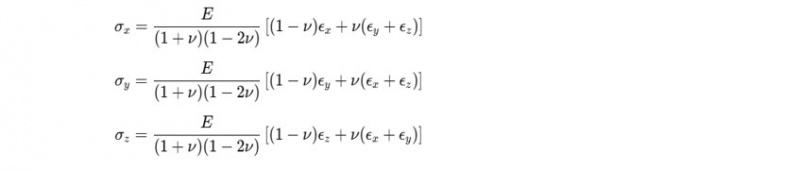

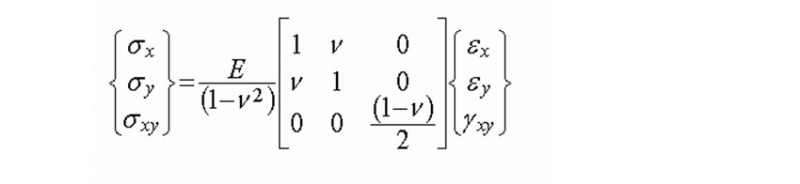

1) By assuming linear elastic behavior for the polycarbonate material, the analysis focuses on the portion of the material’s behavior that is predictable and consistent with Hooke's Law, while disregarding complexities such as plastic deformation or fracture. This assumption simplifies the problem, enabling the analysis to stay within the elastic regime where stress is proportional to strain[21]. By governing the stress-strain relationships with Hooke's Law, the analysis leverages the linear relationship between stress and strain in elastic materials, which is well understood and easily modeled. This idealization reflects a best-case scenario where the material behaves predictably within its elastic limit, allowing for precise calculation of stress and strain distributions without the need for more complex nonlinear models for 2d element analysis of shell. The required equations are[18, 19] as shown in the Hook’s law matrix equation;

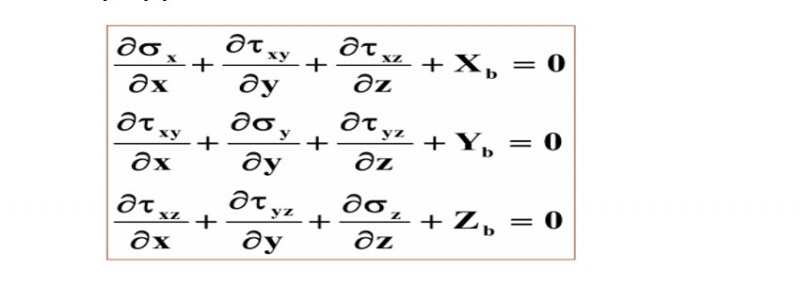

2) The application of plane stress conditions is another idealization that allows the problem to be reduced from three dimensions to two, thus enhancing computational efficiency while maintaining accuracy for structures where the thickness is much smaller than the length and radius. This approach is not about ignoring the z-axis stress but recognizing that, for the purposes of this analysis, the deformation in the z-direction is negligible and will not significantly affect the in-plane stress and strain behavior. Similarly, excluding z-axis terms (σz=0, and τxz=τyz=0 in the following equations) from the governing equations aligns with the assumption of plane stress and emphasizes the in-plane behavior of the shell. This idealization ensures that the model remains efficient and tractable while still capturing the essential behavior of the shell under pressure loading.

Axial Stress for Transformation (Plane Stress):

Plane stress matrix equation[22]:

Stress equibrium equations by putting Xb=0, Yb=0, Zb=0, σz=0, τxz=0, and τyz=0 to get plane stress equation[22]:

3) By applying 2D plane stress assumptions, the need for a full 3D analysis is simplified, focusing primarily on the key stress components that occur within the plane of the shell. This approach reduces computational complexity while capturing the most relevant stress behavior.

4) The shell is made of polycarbonate becaause of exceptional applications in real world.

5) Dimensions:

Length: 500 mm

Outer radius: 50 mm

Inner radius: 45 mm

Wall thickness: 5 mm

The shell's geometry is representative of thin-walled cylindrical structures commonly found in engineering applications, where the ratio of the shell's thickness to its radius is small enough to justify the assumption of plane stress condition. The wall thickness of 5 mm, relative to the shell's overall dimensions, suggests that the shell's structural response will primarily involve in-plane stresses, with negligible out-of-plane deformations.

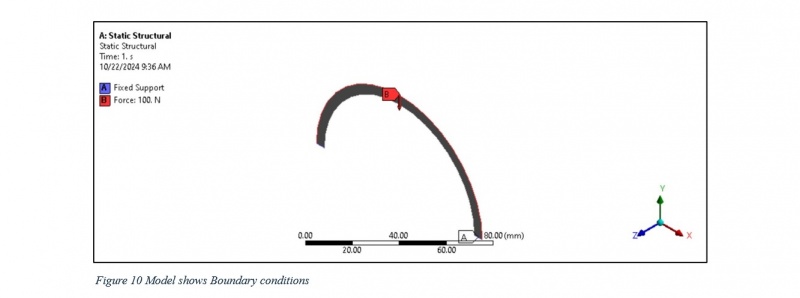

6) Boundary Conditions:

For this analysis, the following boundary conditions have been applied: Force: A uniform force of 100 N is applied in the negative y-direction. This force simulates real-world conditions where cylindrical shells, such as pressure vessels or pipes, are subjected to forces that deform the structure. Fixed Support: The shell is fixed at two edges, ensuring no displacement occurs at these points. This boundary condition restricts movement at the support locations and focuses the analysis on the stress response of the material elsewhere. These boundary conditions are appropriate for static structural problems, where the shell is subjected to continuous force loading. Understanding how these forces affect the stress field within the shell is crucial for ensuring the material’s structural integrity under load.

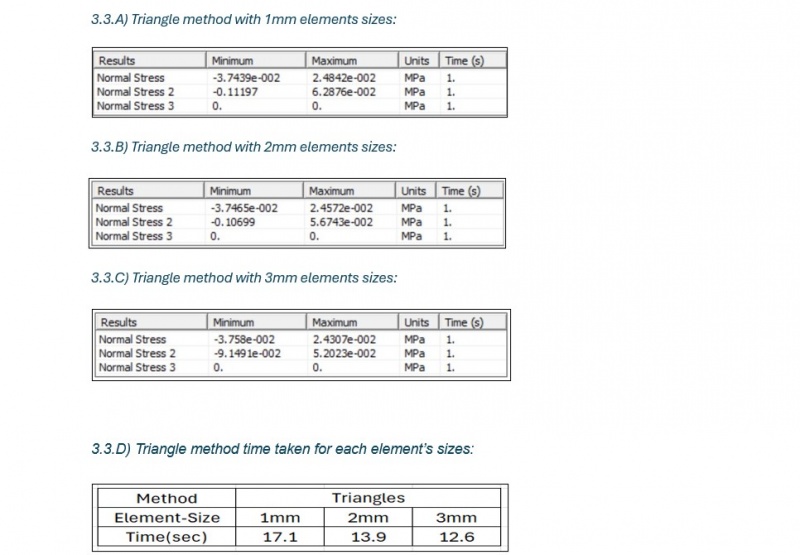

7) Constraints:

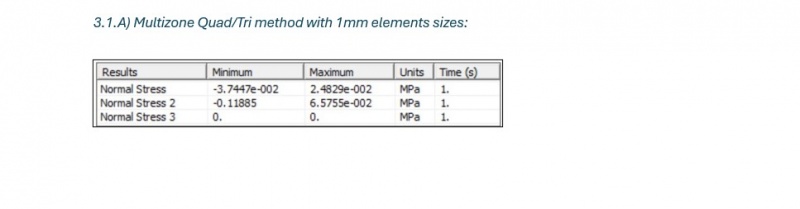

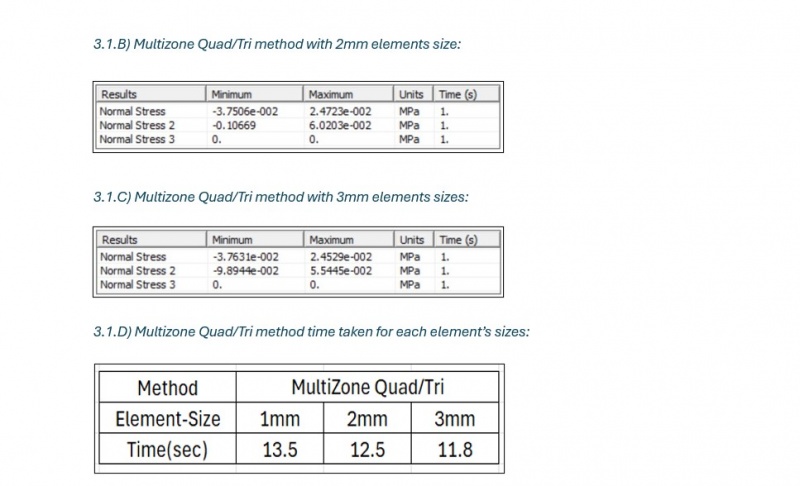

In this study, a reference value of 0.03 MPa was selected to calculate the error in normal stress in the x-direction, serving as the benchmark for evaluating accuracy across different mesh configurations. Additionally, a computational time constraint of 13.0 seconds was established to identify the minimum time required for each solution run, ensuring that the selected configurations meet both accuracy and efficiency criteria. These constraints provide a structured basis for assessing the performance of various mesh methods and element sizes under consistent conditions.

2.1.5 Instruction set:

The instruction set phase of the DAI5 framework bridges the gap between theoretical ideals and practical implementation. It involves translating abstract concepts and objectives into clear, actionable steps that can be carried out to achieve the desired outcomes. In engineering and computational analysis, this stage ensures that the ideas and assumptions made during the idealization phase are effectively operationalized through a systematic approach. In this analysis, a structured instruction set is developed to translate the idealized solutions and assumptions into concrete, actionable steps. The aim is to ensure that the methodology aligns with the theoretical framework established in the earlier phases while focusing on practical implementation using ANSYS 2021R2. The analysis involves a shell structure made from polycarbonate, a common thermoplastic known for its toughness and elasticity, under specific boundary conditions, while varying the mesh element size and method. The shell dimensions are kept constant, and we examine the effect of changing mesh configurations on the stress distribution within the shell.

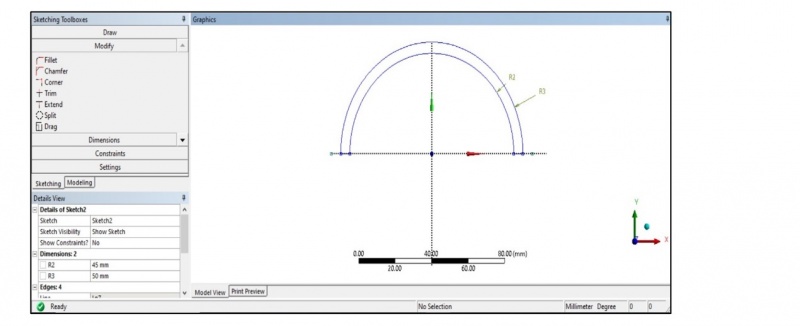

2.1.5a Model Setup:

The initial phase of the analysis involved creating the geometric model of the shell using DesignModeler in ANSYS 2021R2. The geometry was modeled as a shell structure, reflecting a typical cross-section of pressure vessels or pipelines subjected to uniform force. The following dimensions were applied:

Length: 500 mm

Outer radius: 50 mm

Inner radius: 45 mm

Wall thickness: 5 mm

This shell structure model was selected due to its practical application in various industrial fields, where cylindrical shells are subjected to various loads from fluids or gases. Given the small thickness of the shell relative to its other dimensions, the model was simplified using 2D element analysis under plane stress condition. This assumption is valid since the deformation along the z-axis (out-of-plane) is negligible when the thickness is small in comparison to the shell’s length and radius.The shell geometry allows for efficient simulation of the stress distribution in the shell, while the 2D analysis approach simplifies the model without compromising on accuracy. The geometry was carefully defined to reflect real-world applications and to ensure that the results could be generalized to other pressure-bearing structures made from polycarbonate or similar materials.

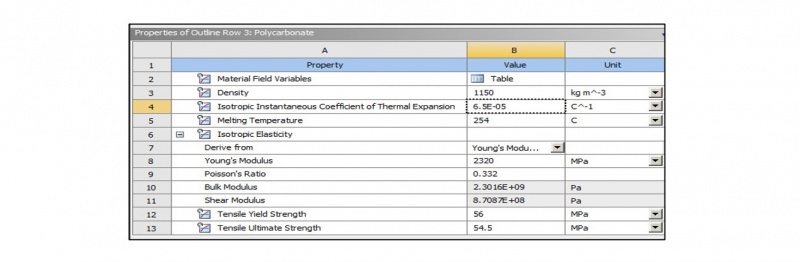

2.1.5b Material Properties:

The material chosen for this analysis was polycarbonate, a well-known thermoplastic that exhibits excellent toughness and resilience, making it ideal for use in pressure-bearing structures such as pipelines, pressure vessels, and protective coverings. Polycarbonate is favored for its high impact resistance and ability to retain structural integrity under varying loading conditions. The following material properties were assigned in the ANSYS material library:

These material properties are critical in defining the linear elastic behavior of the polycarbonate shell, allowing the use of Hooke’s Law to model the stress-strain relationship within the material. By assuming linear elasticity, the analysis remains within the elastic regime of the material, focusing on the behavior of polycarbonate without considering plastic deformation or failure. This simplification streamlines the calculations while providing an accurate representation of the material’s response to internal pressure.

2.1.5c Meshing: (Varying the Mesh Element Size and Method)

The key variable in this analysis was the mesh configuration, which was systematically varied to examine the impact of different mesh element sizes and meshing methods on the accuracy and computational efficiency of the results. The following meshing methods were tested in ANSYS:

Multizone Quad/Tri method: This method combines quadrilateral and triangular elements to generate a structured mesh that adapts well to the complex geometry of the cylindrical shell. The multizone approach provides a balance between element accuracy (quadrilateral elements) and flexibility (triangular elements).

Quadrilateral Dominant method: This method prioritizes the use of quadrilateral elements, which are known to provide higher accuracy for structural analysis. Quadrilateral elements are particularly effective at capturing stress and strain distributions in flat and curved regions of the shell.

Triangle method: A purely triangular element mesh was applied to evaluate the performance of this simpler meshing method. Triangular elements are commonly used in FEA due to their flexibility in conforming to complex geometries, but they tend to be less accurate than quadrilateral elements.

For each meshing method, the element size was varied as follows: 1 mm, 2 mm, and 3 mm. Smaller element sizes were expected to yield more accurate results by capturing finer details in the stress and strain distributions, particularly in areas with high stress concentrations. However, smaller element sizes increase the computational cost. Larger element sizes, on the other hand, reduce the computational time but may lead to a loss of accuracy in critical regions of the shell.By systematically testing these mesh sizes and methods, the goal was to identify the optimal combination that provided the best accuracy. This step is crucial for determining the most effective meshing strategy for future simulations of similar structures.

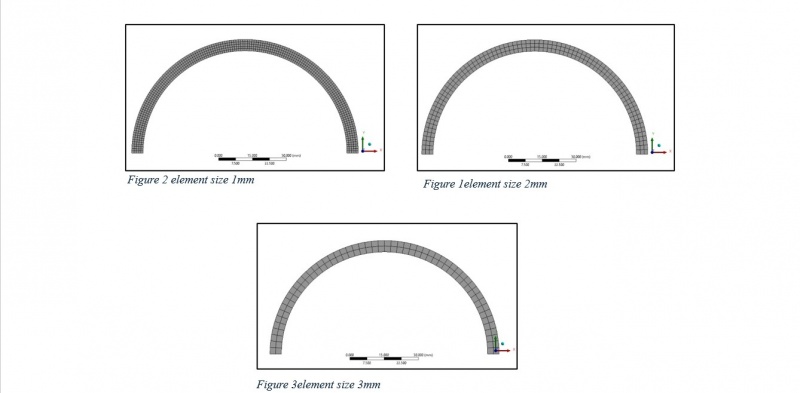

A) Multizone Quad/Tri method with varying elements sizes:

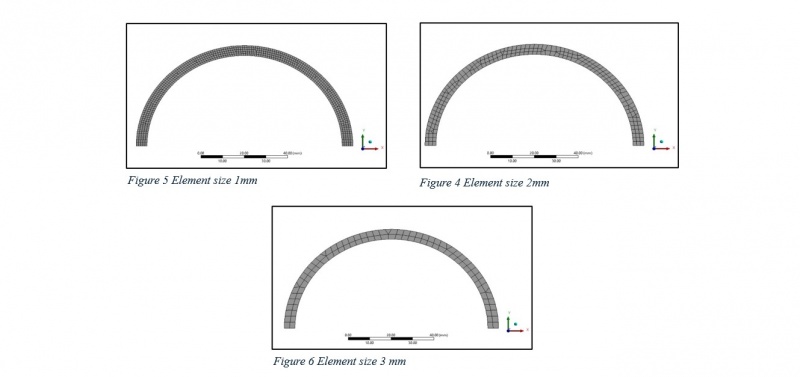

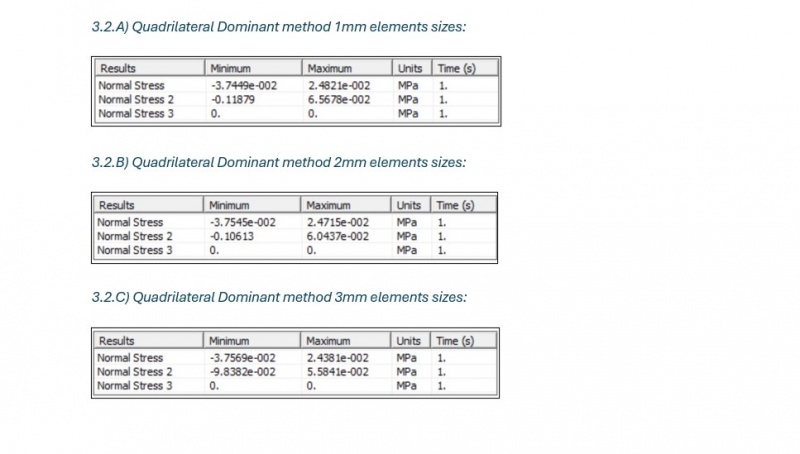

B) Quadrilateral Dominant method with varying elements sizes:

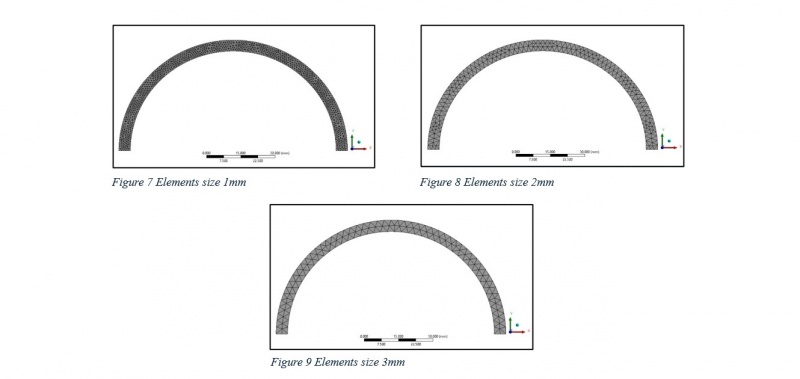

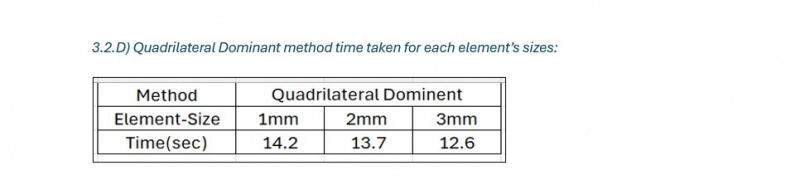

C) Triangle method with varying elements sizes:

2.1.5d Boundary Conditions:

To simulate real-world loading scenarios, the following boundary conditions were applied to the polycarbonate shell: Fixed Support: The shell was fixed at both ends along the axial direction (x-direction). This boundary condition ensured that no displacement occurred in the axial direction, simulating a scenario where the ends of the shell are constrained or anchored, as in pressure vessels or pipes supported at both ends.

External force: A constant external force of 100 N was applied uniformly to the the shell. This force simulated typical internal loading conditions experienced by cylindrical shells in real-world applications. These boundary conditions were designed to simulate the most realistic loading conditions for the polycarbonate shell, allowing for accurate analysis of the shell’s response to external force.

2.1.5e Solver and Stress-Strain Analysis:

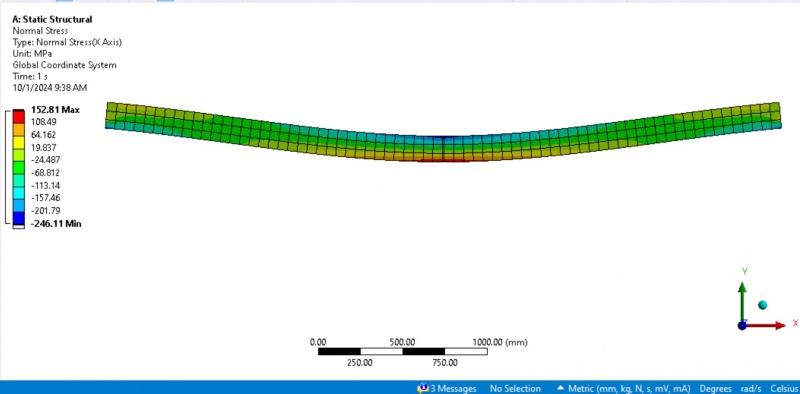

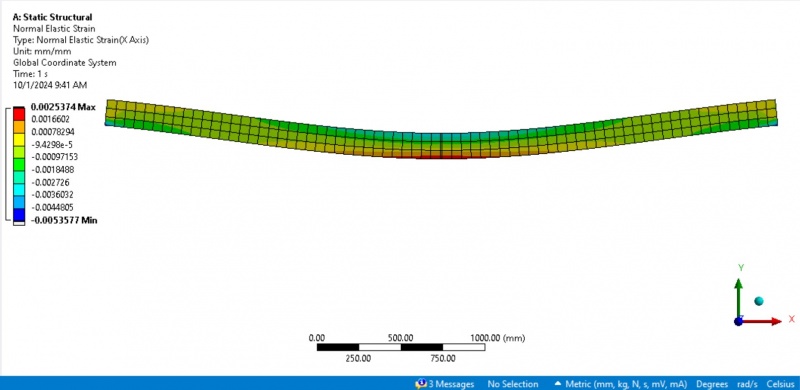

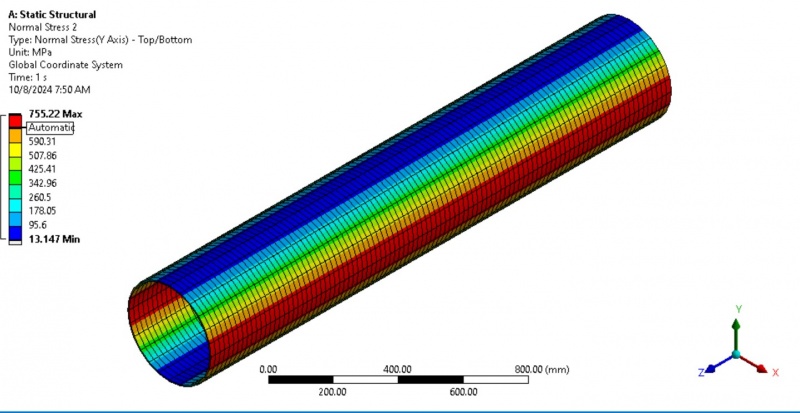

With the geometry, material properties, mesh configurations, and boundary conditions defined, the static structural solver in ANSYS was used to compute the stress distribution across the shell. The solver focused on the following key aspects of the shell’s behavior: