Rithwik Nathani

Name: Rithwik Chandur Nathani

NPM: 1806228070

Place, Date of Birth: Jakarta, 18 April 2000

I am a student in the Department of Mechanical Engineering Faculty of Engineering University of Indonesia. Currently, in my 6th semester in this university. I have always had a great passion for renewable energy generation and that is the reason behind my admission to this major.

Date 23/2/2021

I am fine today and I feel good.

Justice for me is something different from fairness. When something is said to be just it can't be described as fair and when something is fair it can't be said as just. Taking an example of a picture we have seen many times. If three kids with different height is trying to see off a wall and there is a box. Fairness would mean each kid gets a box to boost their height. But Justice means that the shortest kid would get more boxes and the tallest kid the least. So all of them could equally see beyond the wall.

Discussing energy with a small kid. Energy is the ability to do work. How do we explain to them in simple language? We speak about the energy required for learning. Is there a special energy for learning? Can someone be forced to learn? To realize something you need to be moved by something. Fundamentals of Physics is this realization. Realization that we can't study if we don't think.

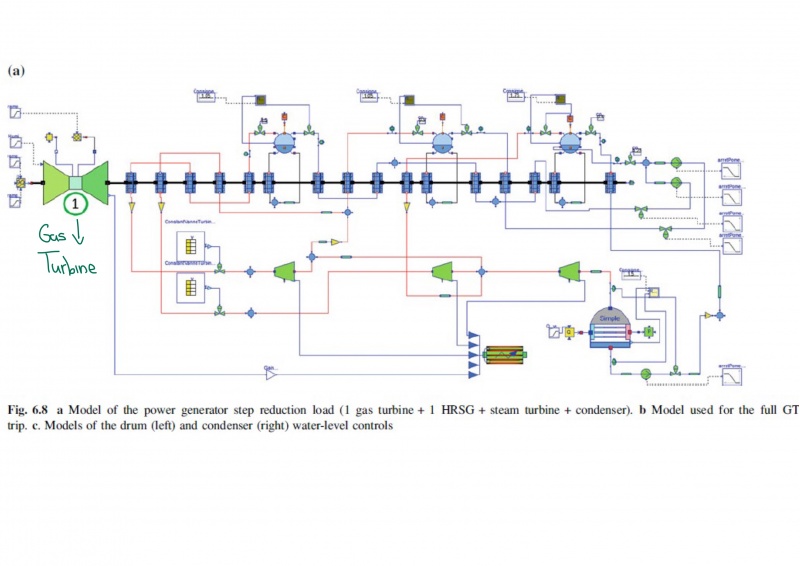

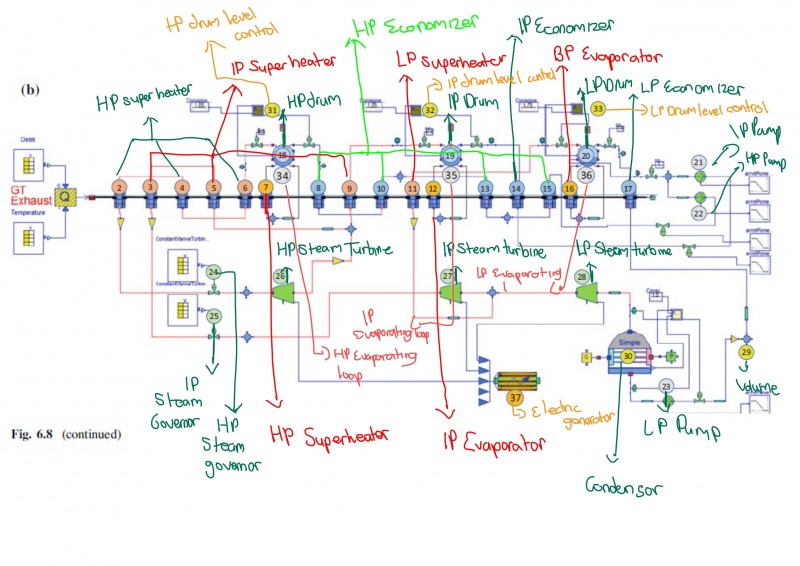

Homework: Go to the pictures given and name all the components

Date 24/2/2021

We begin by a short presentation by each of the students about the materials learned in the previous class. Discussing a bit about the homework given in the previous class and getting a small introduction to OpenModelica software that is used to model systems in real life.

Homework: Learn and get a feel about the OpenModelica software

In this matter we should first understand the system that we would like to create and get a good feel and understanding on the symbols that represent the different parts of the energy conversion system. To understand OpenModelica better we should use a simple system to get a clear understanding of the software.

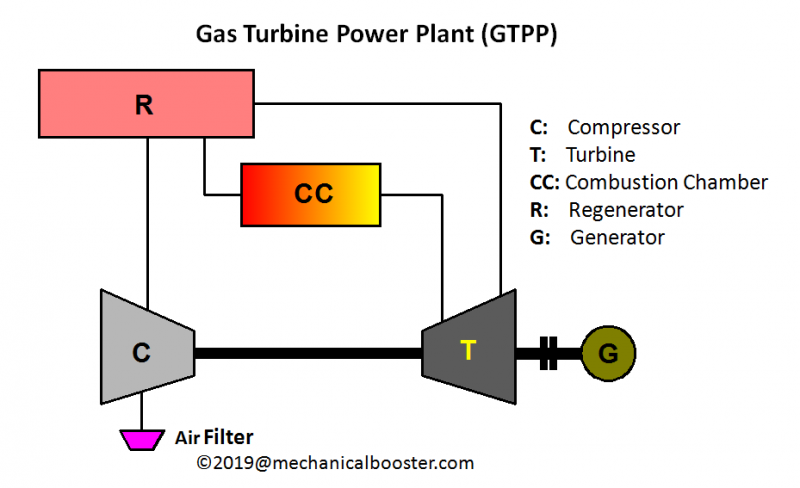

1. We should first understand the system that we want to develop in this case 'Simple Power Plant'

2. Interpret the system in open modelica using the symbols given in the software

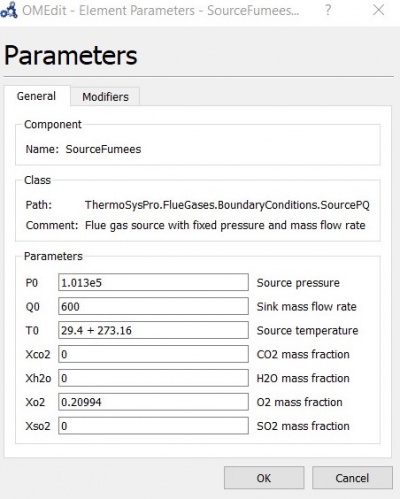

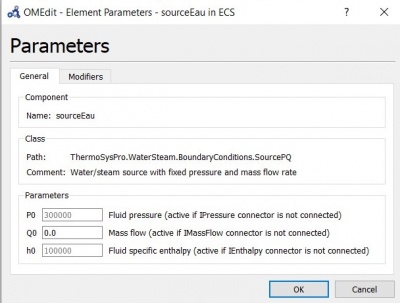

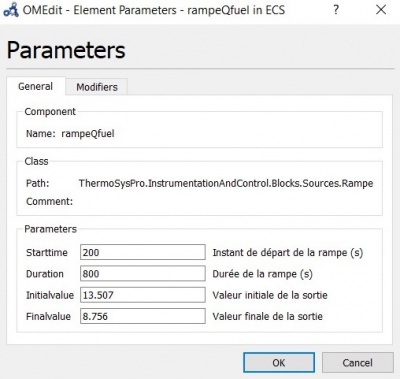

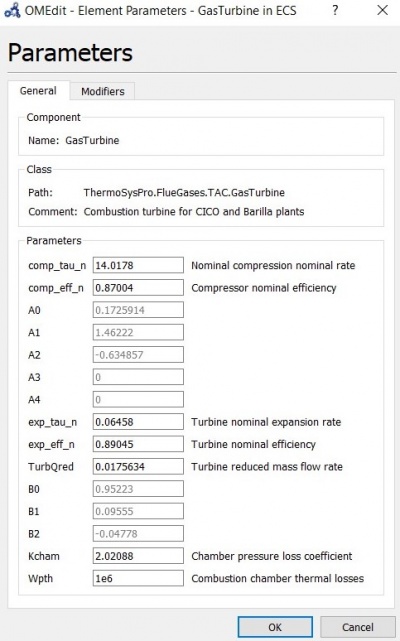

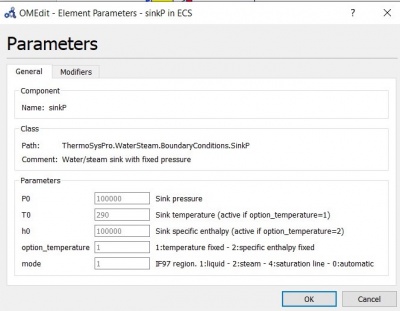

3. Input the parameters in each part that is required for the operation and simulation of the Gas Power Plant System

4. Finally we can run the simulation according the various parameters set

Date 3/3/2021

Today, we discussed more regarding the topic and designing a simple system. We had a discussion regarding the meaning of a system and practiced how to explain a system in a very simple way. We ended the day by an explanation by our friend Zakaria regarding the design of a simple system.

Date 9/3/2021

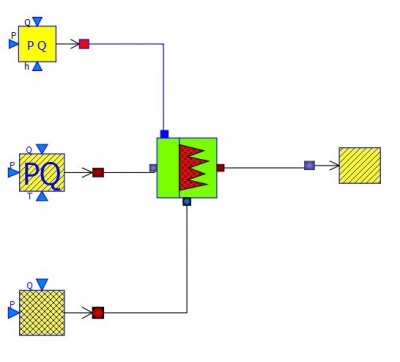

Today we learned a simple design simulation. In the class we were explained to set up a simple furnace or gas burner system with a few inputs and a sink output. The design is then tested with a few parameter.

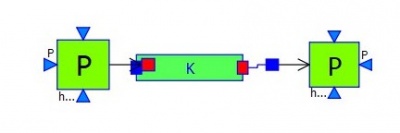

However, the simulation could not run in my computer so we tried testing a simpler system in Open Modelica that is a Pressure Drop system pipe to test the problem where this did not work as well so I decided to reinstall a different version and try my luck with the same system.

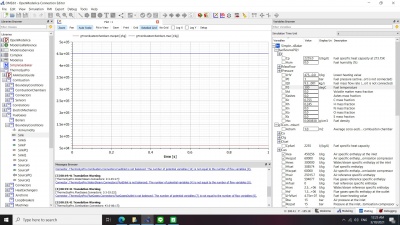

After finally changing the version of my OpenModelica application the simulation finally worked and I tried a few parameters to understand its impact on the graph and simulation result. However, not much could be understood yet from this different parameters because I could not find any difference

Date 10/3/2021

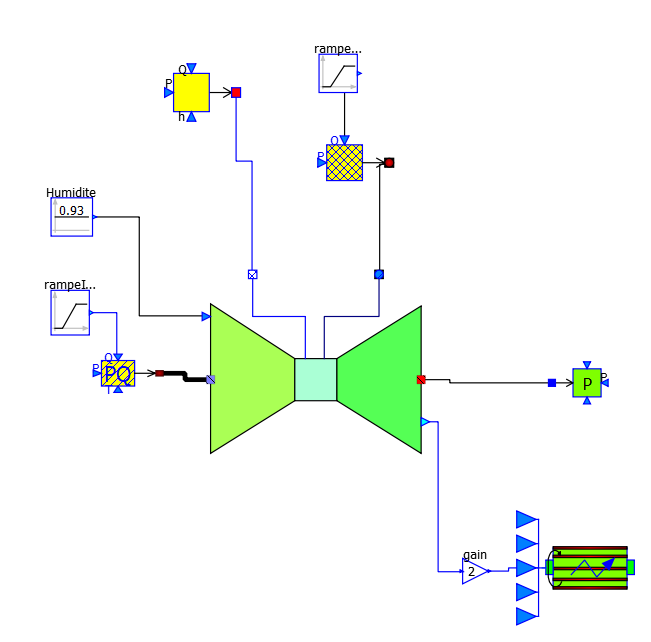

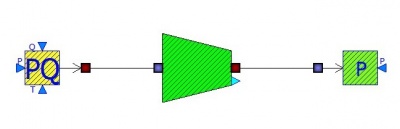

Today we tested again our Compressor design simply by applying basic parameters and observing changes in the sink while doing so. We input standard parameters into the source of the compressor and observed result in the sink of the Compressor by observing the Temperature. Here is what we designed

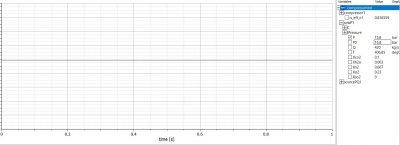

From this compressor we simulated the result of the given temperature in the sink after the simulation. The first simulation did not work well for me However, this worked well and obtained a good result.

The result gave a temperature of 406 degree celcius with an input of around 30 degree celcius which shows that the temperature has increased and that would be the trend expected from the output of this compressor that does air compression and naturally temperature increases.