Review pekan 3

ditulis oleh Muhammad Fajri Shiddiq

Pengamatan Video

Video Pertama Pada video ini dijelaskan bahwa suatu sistem terbuka yang memiliki 2 katup di berikan tekanan awal melalui alat vacuum cleaner. Alat tersebut berfungsi untuk meniupkan fluida berupa gas. Pada ilustrasi berikut, percobaan dilakukan untuk menghitung perbedaan pada pangkal dan ujung rangkaian, serta pengaruh dari sebelum dan setelah katup 2 dibuka. Pengukuran tekananan pada video pertama dilakukan dengan memakai manometer analog.

Hasil dari pengamatan di dapat, sebelum katup 2 dibuka

P1 = 10 milibar P2 = 1.5 milibar

setelah katup 2 dibuka

P1' = 8.5 milibar P2' = 1.5 milibar

Video Kedua Rangkaian dan jenis percobaan yang dilakukan pada video kedua sama dengan yang pertama, namun perhitungan tekanan dilakukan dengan memakai pipa U

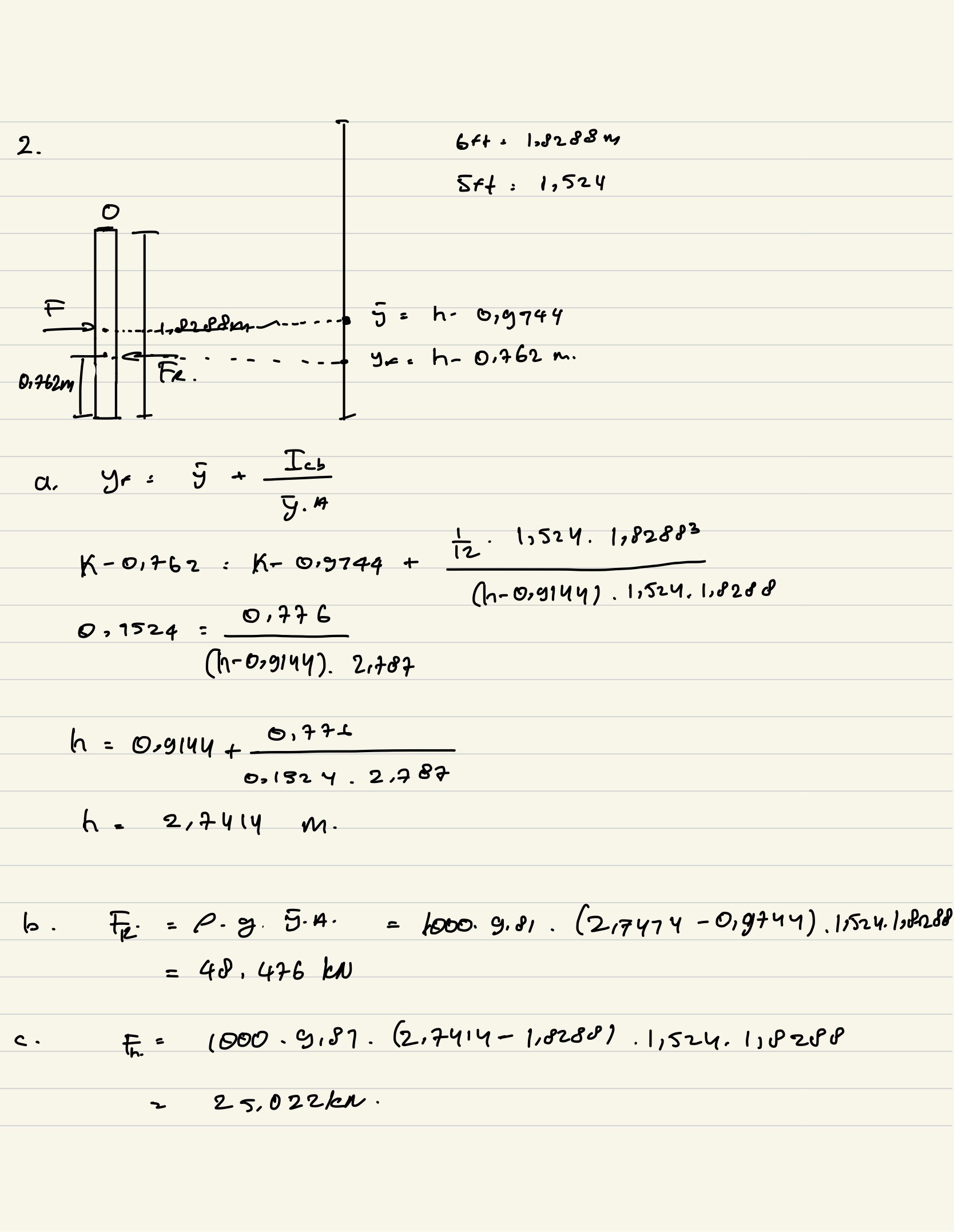

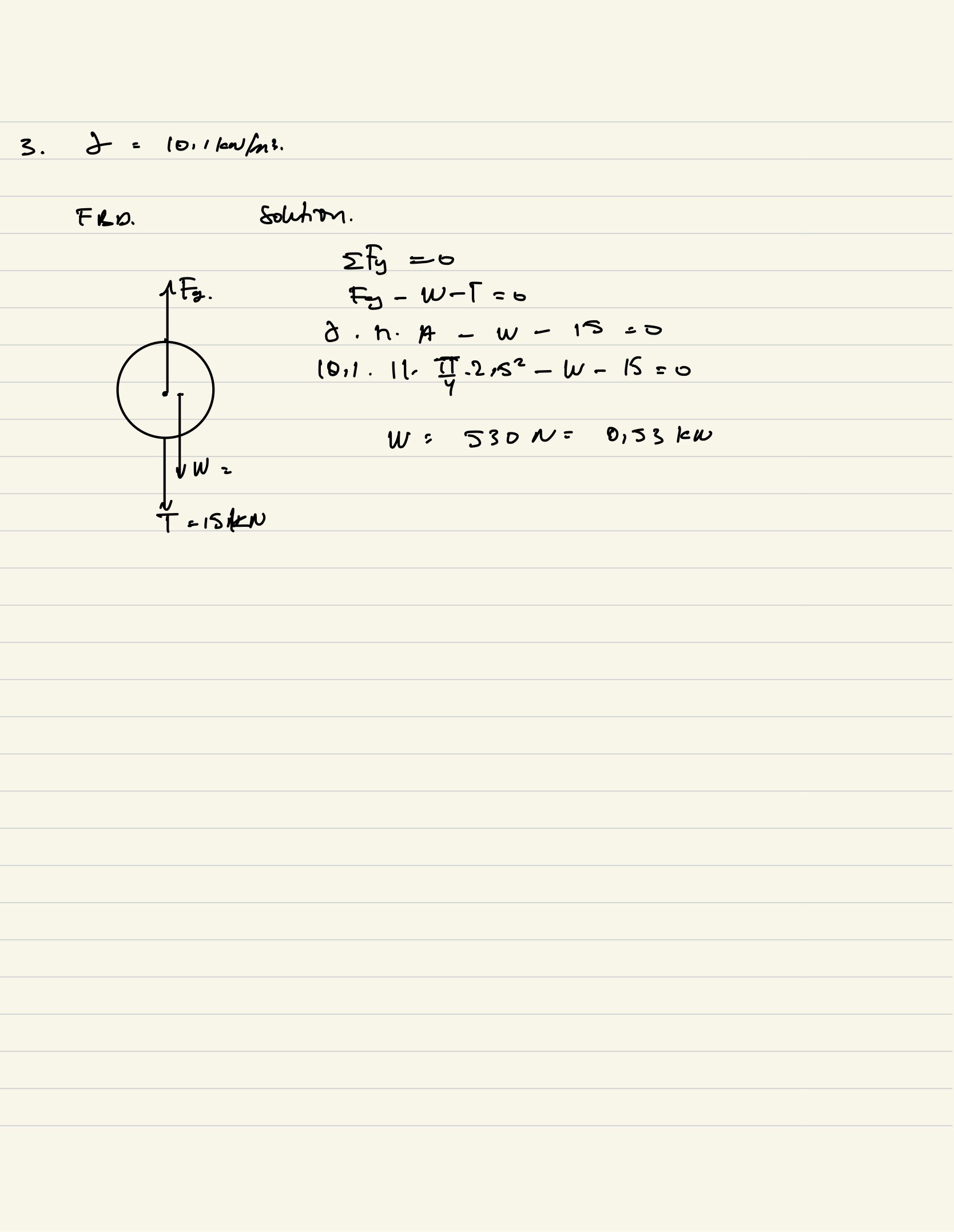

Tugas Manometer

1. Manometer analog menggunakan mekanisme sederhana dan akurat untuk menentukan tekanan udara yang melibatkan perpindahan fluida. Air atau merkuri adalah zat alternatif yang dipilih untuk mengisi sebagian tabung berbentuk "U" yang dibiarkan terbuka di salah satu atau kedua ujungnya (tergantung jenisnya). Salah satu ujung tabung terhubung ke saluran gas untuk memasukkan tekanan. Saat diterapkan, tekanan memindahkan cairan, sekaligus memaksanya naik ke sisi lain 'U.' Hasilnya diukur pada skala, dan tingkat tekanan ditentukan.

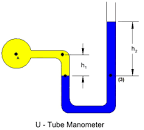

2. Manometer tabung-U adalah alat pengukur tekanan yang paling sederhana. Namanya berasal dari bentuk U yang terbentuk ketika kedua ujung tabung fleksibel berisi cairan dinaikkan agar cairan tidak keluar dari ujungnya. Manometer tabung-U adalah keseimbangan 'cair'.

Neraca pegas yang digunakan di dapur menimbang beban dengan mencocokkan gaya yang dihasilkan oleh berat beban dengan gaya yang dihasilkan dari tegangan pegas keseimbangan. Perubahan panjang pegas adalah ukuran berat beban dan ditunjukkan pada skala bertahap dengan penunjuk yang terpasang pada pegas. Demikian pula, manometer tabung-U digunakan untuk menyeimbangkan berat cairan di satu kaki 'U' terhadap tekanan yang dimasukkan ke kaki lainnya. Perbedaan ketinggian antara kedua kaki cairan menunjukkan tekanan yang mendorong cairan ke bawah satu kaki dan ke atas kaki lainnya. Perbedaan ketinggian diukur pada skala bertingkat.

3. P1 = 10 milibar P2 = 1,5 milibar

4. Beberapa faktor yang memengaruhi besarnya tekanan adalah - ketinggian - temperatur - volume - gravitasi - komposisi gas dan liduid - kecepatan fluida - gaya eksternal

5. Satuan tekanan udara pada manometer = milibar = 100 Pa

Sehingga jika dilakukan konversi, 1 milibar = 100 Pa

6. Dari pengamatan, perbandingan antara sebelum dan setelah katup 2 terbuka adalah P1 = 10 mbar dan P2 = 1.5 mbar ----- Skala tekanan P1 : P2 = 10 : 1,5 = 20 : 3

P1' = 8,5 mbar menjadi 1,5 mbar ---- Skala = 8.5 : 1,5 = 17 : 3

Pertanyaan dengan chat gpt seputar manometer

what is the most effective manometer The effectiveness of a manometer depends on the specific application and the requirements of the measurement. However, some common types of manometers and their effectiveness in different scenarios are:

U-tube manometer: This is a simple and inexpensive manometer that is effective for measuring small pressure differences in low-pressure applications. However, it may not be suitable for high-pressure applications as it can be difficult to read accurately.

Inclined manometer: This type of manometer is effective for measuring pressure differences in pipes and ducts where space is limited. It uses a tube that is inclined at a specific angle, which makes it easier to read the pressure difference compared to a U-tube manometer.

Digital manometer: Digital manometers are highly accurate and provide precise readings of pressure differences. They are easy to read and offer a range of units of measure. They are suitable for both low-pressure and high-pressure applications and are often used in laboratory settings.

Differential pressure transducer: This is a highly accurate and reliable manometer that is suitable for measuring pressure differences in critical applications. It uses advanced sensors and electronics to provide precise and stable measurements, and can be configured for a wide range of pressure ranges and output signals. It is often used in industrial applications and in the process control industry.

Overall, the most effective manometer for a specific application depends on factors such as the required accuracy, pressure range, type of fluid being measured, and the available space for the instrument.

when should we use manometer or barometer

Manometers and barometers are both devices used to measure pressure, but they are used for different purposes.

A manometer is typically used to measure the pressure difference between two points in a fluid system, such as the pressure drop across a filter or the pressure difference between two rooms in a building. Manometers can be simple, inexpensive devices such as a U-tube manometer or more complex, digital instruments that offer greater accuracy and precision.

On the other hand, a barometer is used to measure atmospheric pressure. It is commonly used in weather forecasting and to determine altitude. Barometers are usually designed to be highly sensitive and accurate to detect even small changes in atmospheric pressure.

So, when deciding whether to use a manometer or barometer, it is important to consider what type of pressure is being measured. If you need to measure the pressure difference between two points in a fluid system, a manometer is the appropriate instrument. If you need to measure atmospheric pressure, a barometer is the appropriate instrument.

what is the most effective instrument for fluid pressure measurement The most effective instrument for fluid pressure measurement depends on the specific requirements of the application. However, some commonly used instruments for fluid pressure measurement are:

Bourdon tube pressure gauge: This is a widely used instrument for measuring fluid pressure in various industries. It is simple, reliable, and suitable for measuring pressure ranges from vacuum to high pressure.

Diaphragm pressure gauge: This type of pressure gauge uses a flexible diaphragm to measure fluid pressure. It is suitable for measuring low to medium pressure and can handle corrosive and viscous fluids.

Differential pressure transducer: This is a highly accurate instrument that is commonly used in critical applications. It uses advanced sensors and electronics to measure pressure differences in fluid systems, and can be configured for a wide range of pressure ranges and output signals.

Digital pressure gauge: This type of gauge provides precise and accurate measurements of fluid pressure. It can be used to measure both low and high pressures, and can be configured to provide a range of output signals and units of measure.

Overall, the choice of the most effective instrument for fluid pressure measurement depends on factors such as the required accuracy, pressure range, type of fluid being measured, and the specific application requirements. It is important to carefully consider these factors when selecting an instrument for fluid pressure measurement.

what is the most effective instrument of pressure measurement for each application? The most effective instrument of pressure measurement for each application depends on various factors, such as the required accuracy, pressure range, type of fluid, and the specific application requirements. However, here are some examples of commonly used pressure measuring instruments for different applications:

Industrial applications: Bourdon tube pressure gauges are commonly used for measuring fluid pressure in industrial applications due to their durability, reliability, and wide range of pressure measurement capability.

Medical applications: Electronic pressure transducers are commonly used in medical applications, such as blood pressure measurement, due to their high accuracy and precision.

Laboratory applications: Digital pressure gauges are widely used in laboratory applications due to their accuracy, ease of use, and ability to provide a range of output signals and units of measure.

Aerospace applications: Piezoresistive pressure sensors are commonly used in aerospace applications due to their ability to operate at high temperatures and high pressures.

HVAC applications: Diaphragm pressure gauges are commonly used in HVAC applications, such as measuring pressure drop across filters and ductwork, due to their ability to handle corrosive and viscous fluids.

Automotive applications: Strain gauge pressure sensors are commonly used in automotive applications, such as measuring fuel and oil pressure, due to their high accuracy and reliability.

Overall, it is important to consider the specific requirements of the application when selecting the most effective instrument for pressure measurement.

Tugas Praktikum Pengukuran Tekanan

Penjelasan mengenai cara kerja dari tiap alat ukur

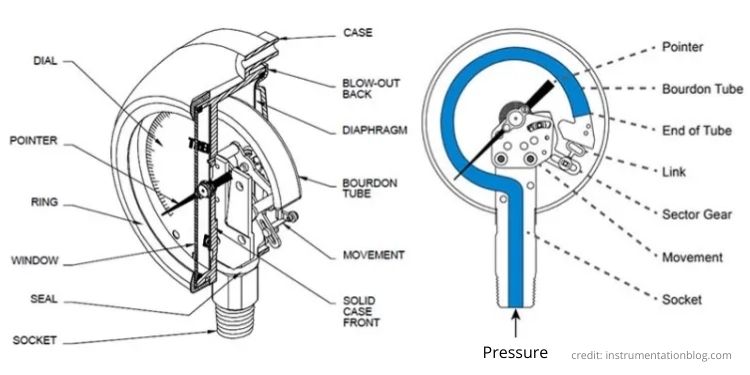

Pengukuran tekananan dengan Bourdon Tube. Pengukur tekanan bekerja melalui tabung Bourdon, sepotong logam berongga. Ketika gas atau cairan memasuki tabung, itu mengembang dan mendorong tuas. Jarak tuas bergerak sebanding dengan tekanan gas atau cairan di dalam tabung berongga.

Serangkaian roda gigi dan pegas menghubungkan tuas ke jarum di muka pengukur tekanan. Dengan mengalibrasi mekanisme ini, kita dapat mengonversi gerakan tuas menjadi tekanan gas yang diketahui.

Muka pengukur memiliki skala bertahap di belakang jarum yang menunjukkan tekanan. Anda akan sering melihat satuan tekanan yang berbeda (psi, bar, dll.), tetapi kami perlahan-lahan menggantinya dengan satuan SI—Pascal.

Pengukuran tekananan dengan manometer U. Manometer analog menggunakan mekanisme sederhana dan akurat untuk menentukan tekanan udara yang melibatkan perpindahan fluida. Air atau merkuri adalah zat alternatif yang dipilih untuk mengisi sebagian tabung berbentuk "U" yang dibiarkan terbuka di salah satu atau kedua ujungnya (tergantung jenisnya). Salah satu ujung tabung terhubung ke saluran gas untuk memasukkan tekanan. Saat diterapkan, tekanan memindahkan cairan, sekaligus memaksanya naik ke sisi lain 'U.' Hasilnya diukur pada skala, dan tingkat tekanan ditentukan.

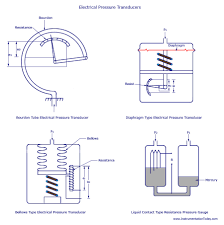

Pengukuran tekananan dengan manometer U. Transduser tekanan mengukur tekanan. Ini menggunakan sensor yang mampu mengubah tekanan yang bekerja padanya menjadi sinyal listrik. Sinyal-sinyal listrik ini kemudian diteruskan ke pengontrol atau PLC yang kemudian diproses dan direkam.

Transduser tekanan memiliki elemen penerima input dan merespons gaya yang diterapkan ke area ini oleh tekanan fluida. Gaya ini membelokkan tabung Bourdon. Pada gilirannya, defleksi, regangan, atau tegangan ini diubah menjadi keluaran listrik melalui salah satu dari berbagai metode transduksi yang berbeda. Transduser tekanan menggunakan pengukur regangan untuk mengukur gaya yang bekerja padanya. Pengukur regangan menahan deformasi, dan deformasi ini menghasilkan variasi dalam tegangan yang ditimbulkannya. Pengukuran tekanan didasarkan pada tingkat variasi terdeteksi dalam tegangan.

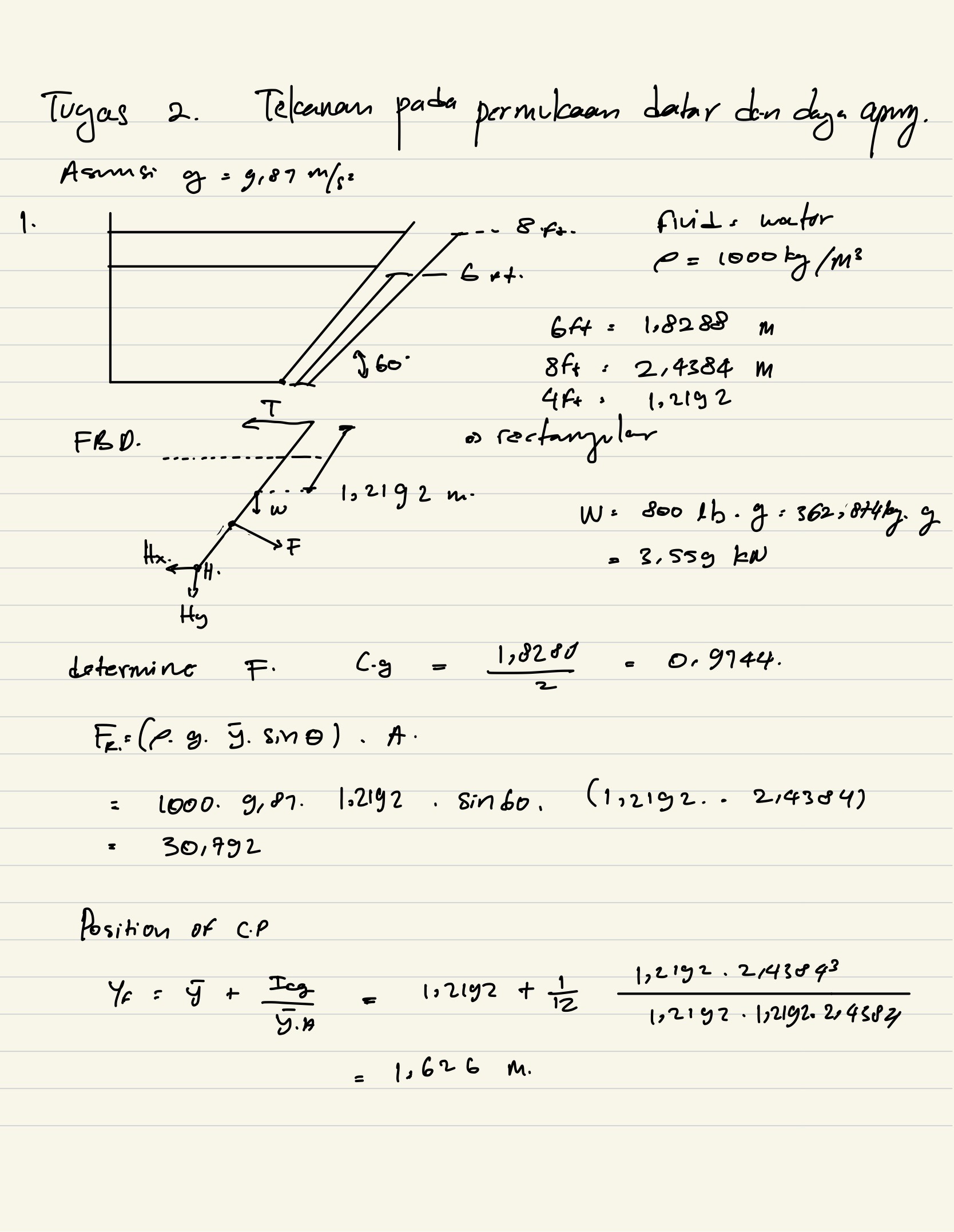

Studi kasus manometer U dengan tekanan 300 Pa

Jika diambil asumsi percepatan gravitasi (g) adalah 9.8 m/s^2. Dalam persamaan tekanan hidrostatis :

P = ρgh

P adalah tekanan, rho adalah massa jenis fluida, g adalah percepatan gravitasi, dan h adalah perbedaan ketinggian fluida pada titik di ketinggian yang sama pada manometer, maka ketinggian fluida dapat dihitung sebagai berikut:

h = P / (ρ * g)

I. Pada kasus air dengan ρ = 1000 kg/m^3, maka h = 300 / (1000 * 9.8) = 0.0306 m

II. Pada kasus minyak dengan ρ = 800 kg/m^3, maka h = 300 / (800 * 9.8) = 0.0382 m

III. Pada kasus raksa dengan ρ = 13.600 kg/m^3, maka h = 300 / (13.600 * 9.8) = 0.00225 m

Chat GPT seputar eksperimen

how accurate is pressure tranducer

The accuracy of a pressure transducer depends on various factors such as its design, the quality of materials used, calibration, and environmental conditions. In general, pressure transducers can be very accurate, with some models having accuracies of +/- 0.1% of full scale or better.

However, it's important to note that accuracy is not the same as precision. Accuracy refers to how close the measured value is to the actual value, while precision refers to how consistently the measurement can be reproduced. Therefore, even if a pressure transducer has high accuracy, it may not be precise if it has a lot of variability in its measurements.

Additionally, the accuracy of a pressure transducer may degrade over time due to factors such as wear and tear, environmental conditions, and aging of its components. Regular calibration and maintenance can help to ensure that a pressure transducer remains accurate over time.

Overall, pressure transducers can be very accurate, but their accuracy depends on many factors, and it's important to use them appropriately and to regularly calibrate and maintain them to ensure accurate and consistent measurements.

so, what do we do to overcome the precision problem in pressure transducer?

To improve the precision of a pressure transducer, there are several steps that can be taken:

Choose a transducer with high resolution: The resolution of a transducer determines the smallest change in pressure that it can detect. Choosing a transducer with high resolution can help to improve its precision.

Use averaging or filtering techniques: Averaging or filtering the measurements taken by a transducer can help to reduce random variations in the measurements and improve their precision.

Use a stable and controlled environment: Environmental factors such as temperature and humidity can affect the accuracy and precision of a pressure transducer. Using a stable and controlled environment can help to reduce variability in the measurements.

Perform regular calibration and maintenance: Regular calibration and maintenance of a pressure transducer can help to ensure that it remains accurate and precise over time.

Use a suitable signal conditioner: Signal conditioning is the process of amplifying, filtering, and processing the electrical signal output from a transducer. Using a suitable signal conditioner can help to improve the precision of a pressure transducer.

By implementing these steps, it is possible to improve the precision of a pressure transducer and obtain more consistent and reliable measurements.

how to use pressure transducer?

Using a pressure transducer involves several steps, which can vary depending on the specific transducer and the application. Here are some general steps to follow:

Connect the pressure transducer to your measurement system: This involves physically connecting the transducer to the appropriate hardware, such as a data acquisition system or signal conditioner, using the appropriate cables or connectors. Follow the manufacturer's instructions for connecting the transducer.

Power up the transducer and any associated equipment: Ensure that the transducer is properly powered and any associated equipment, such as a data acquisition system, is also powered up and functioning properly.

Calibrate the pressure transducer: Before taking any measurements, it's important to calibrate the pressure transducer to ensure its accuracy. Follow the manufacturer's instructions for calibrating the transducer, which typically involves applying known pressure levels to the transducer and verifying that the output corresponds to the expected values.

Configure the measurement system: Depending on the hardware and software you are using, you may need to configure the measurement system to read the output from the transducer. This may involve setting up the appropriate channels and parameters in the data acquisition software.

Take pressure measurements: Once the transducer is calibrated and the measurement system is configured, you can take pressure measurements by applying pressure to the transducer and recording the output. Follow the manufacturer's instructions for applying pressure to the transducer and ensure that the pressure is within the range of the transducer's capabilities.

Record and analyze the measurements: After taking pressure measurements, record the data and analyze it as needed. This may involve converting the output signal to the appropriate units and performing calculations to derive useful parameters, such as mean or peak pressure.

Repeat as needed: Depending on the application, you may need to repeat the measurement process multiple times to obtain a sufficient amount of data. Ensure that the transducer remains calibrated and the measurement system is functioning properly for each measurement.

It's important to follow the manufacturer's instructions for using the pressure transducer and any associated hardware and software, as well as any applicable safety guidelines. Proper use and maintenance of the pressure transducer can help ensure accurate and reliable measurements.