Patrick Ray Samperuru

Contents

[hide]Introduction

- NAME: Patrick Ray Samperuru

- NPM: 2106718306

- EMAIL: patrick.ray@ui.ac.id

Greetings!

My name is Patrick Ray Samperuru, I am an undergraduate mechanical engineering student from batch 2021 at Universitas Indonesia. Currently, my passion and interests revolve around manufacturing engineering ranging from automation to supply chain management, as I seek to one day revolutionize the manufacturing industry in Indonesia. In the Numerical Method course, I hope to learn many new things that would help open my consciousness towards the real world!

Class Recaps

23 May 2023

The first class of Numerical Method with our lecturer, Pak Dr. Ahmad Indra Siswantara, involved the introduction to the concept of his base teaching regarding consciousness and his theory of "I'm my consciousness". According to Pak DAI, our consciousness plays a pivotal role in the way we grasp things in life as demonstrated by how we are able to comprehend numerical mathematical problems of 1/0 which equals infinity and (x^2-1)/(x-1). He explains how our consciousness is a gift from God that separates us from other living beings in which Pak DAI introduces the concept of CCIT or Cara Cerdas Ingat Tuhan. Here, we are invited to discuss the importance of consciousness and how it relates to using numerical method. Finally, Pak DAI assigned us our project for the remainder of the semester.

30 May 2023

In todays class of Numerical Method, Pak DAI asked us to discuss the Hydrogen Tank Design and Optimization project within the class with every class member to gain better knowledge on developing our overall results. Throughout the class, I moderated the discussion as a replacement for the class coordinator, M. Jiddan Walta, who was at the time absent due to exchange matters. In this discussion, we started by making an outline on the project objective function which was to create a functional hydrogen tank design that is optimized following the constraint parameters of pressure at 8 bars, a capacity of 1 liter, and a maximum budget of 500,000 IDR. To achieve this budget, we discussed several potential materials that could be used in the design based on the different types of tanks (type I, type II, etc.) such as all metal, composite with non-metal liner, and so forth.

We conversed the 3 main points needed in our optimization. This include the design variable, objective function, constraint which can be different for every class member. I personally started by explaining that my objective function is to accommodate the usage of hydrogen tanks in environments that are more complex and dynamic meaning it would need a constraint of a high strength and wear fatigue so that is can used for long term. I continue by adding that this can be achieved by choosing an all metal tank for the material as it has a high value for strength while also being within the allocated budget. Afterwards, I also listened some of others' ideas to further brainstorm and gain inspiration. According to Vegantra Siaga, he wanted a pressure constraint because hydrogen storage systems often have pressure limits to ensure safe operation, where pressure constraints can be defined as upper and lower bounds on the hydrogen storage pressure that prevent the storage system from operating outside the desired pressure range. For Faris Pasya, space and weight constraints can be used as well depending on the application, there may be limitations on the available space or weight of the pressurized hydrogen system. These constraints can influence the choice of tank size, material selection, and system layout. This gave me insights to think more on my personal project and find other perspectives.

Pak DAI stated that we need to discuss the next steps to take because the deadline for the project is next week on Tuesday, 6 June 2023. Thus, I began the discussion again regarding the points needed for completing the project which is first to find the constraints based on the objective function, then to conduct research on different materials and dimensions that could potentially be used, followed by finalizing the chosen design variables based on the constraints, and creating the code whether it is on Python or MATLAB to calculate the design following the constraints numerically. Finally, with everything in order the discussion was ended.

Hydrogen Tank Design and Optimization Project

Project Overview and Case Study

The individual project for the Numerical Method course with Pak Dr. Ahmad Indra Siswantara is the design and optimization of a pressurized hydrogen tank with constraints we need to consider being the gas pressurized at 8 bars, a required volume of 1 liter, and a maximum budget of 500,000 IDR. In this case study, we are asked to create the hydrogen tank design while also being within the set parameters. The details of our design is free to our choice, ranging from the material selection to the dimensions of the diameter as well as length of the tank.

Hydrogen tanks, also known as hydrogen cartridges or cylinders, refer to containers that are used for storing hydrogen may it be in a gaseous or liquid state. The chemical element of hydrogen (H) is a non-metal that has an atomic number of 1, which is gas at room temperature making it the lightest element. Hydrogen is highly utilized in various industries used in fuel cells for generating power, refining petroleum, as well as producing fertilizer. Despite its many uses, hydrogen is a highly combustible energy carrier which can diffuse with certain materials, meaning there are risks that come with its storage. Several important aspects that need to be considered when creating a storage for hydrogen as following:

- Fatigue Resistance: As the tank will be filled and refilled after usage often, it will go through a cycling of load which in time will deteriorate the condition of the tank. Additionally, hydrogen can embrittle certain materials made of metal causing further wear in the container. With this, it is crucial that the hydrogen tank has a high fatigue resistance to withstand wear over time.

- Leak Tightness: Leaks in the tank can cause serious damage due to the nature of the hydrogen. As a fuel, this element is highly flammable making it prone to causing fires when exposed to potential sparks/ignition. Given hydrogen tanks are stored in a cluster, a leakage can result in explosions endangering operations as well as human life. Thus, it is important for tanks to always retain its hydrogen and only be released under controlled conditions.

- Adequate Weight: The weight of hydrogen tanks while not light still need to be considered for the application of transportation. The storage of hydrogen tanks are usually in accumulation meaning in quantities more than one. Given this condition, it is important to consider the weight of the tanks to ensure that more tanks can be transported in one time, thus cutting costs and creating more profit.

- Effective Construction: The design of hydrogen tanks need to be optimized in a sense that there is a optimized amount of room for the tank to store the hydrogen element. In an effective construction, the tank has enough thickness to prevent leakage and have a high resistance to fatigue while also maximizing the area for the hydrogen to be stored. This would lower the cost for manufacturing as well as maintenance as the material usage is optimal while being able to bring the most amount of hydrogen.

Objective Function: Hydrogen Tank Project

The objective function of this project refers to the quantity that is to be optimized in the design variables with the restrictions of the constraints. For my project, the main goal is to achieve a high ultimate tensile strength and being able to have a long life (or withstand a significant amount of wear) while following the given conditions and being within the manufacturing budget range of 500,000 IDR. This is because my aim for the project is for the tank to be able to be utilized in any working environment, meaning it must be able to withstand forces exerted on the tank to maintain safety of the hydrogen inside.

Design Variables: Dimensions of Hydrogen Tank Design

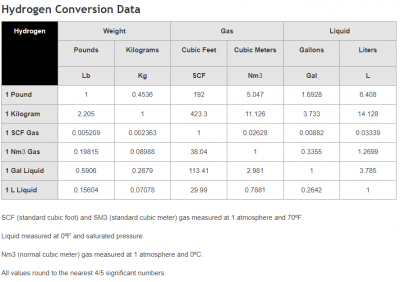

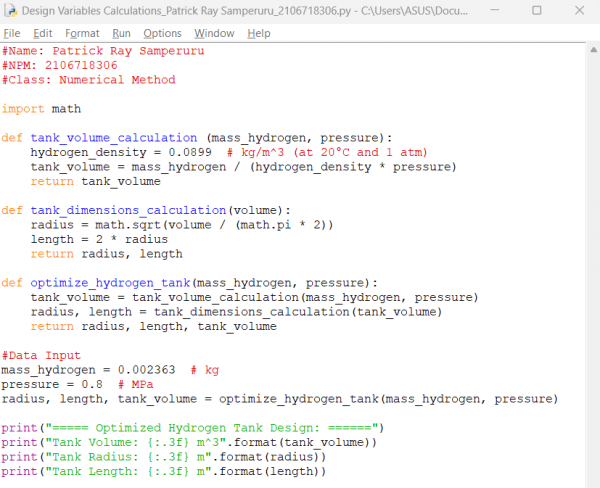

To be able to achieve the objective function of the Hydrogen Tank project, the design variables must be optimized while also following the specifications of the constraints given. These design variables will be tested to the upper limit to maximize the quantities that is within the objective function in order to be able to set best results possible in achieving the set goals. In creating the design variable, multiple factors need to be considered which includes the dimensions and volume of the hydrogen tank. To create an optimized design, coding plays a pivotal role in computing the ideal dimensions based on the desired quantities to be inputted. Here, I use the Python programming language to calculate the dimensions of the hydrogen tank design based on density, mass, and pressure of the hydrogen. To gain the appropriate data, I used the conversion data table for hydrogen using the given information for the constraint of 1 liter of hydrogen pressurized at 8 bar. The table can be observed on the left hand side below:

From this table, I used the data of 1 liter of liquid hydrogen and converting it into kilograms to be input to the data, in which I obtained 0.002363 kg for the mass of the hydrogen. Additionally, I also obtained data for the hydrogen density which is assumed to be kept at a temperature of 20°C and an atmospheric pressure of 1 atm, being 0.0899 kg/m^3. Finally, I converted the pressure of 8 bar given as a condition to MPa which is 0.8 MPa.

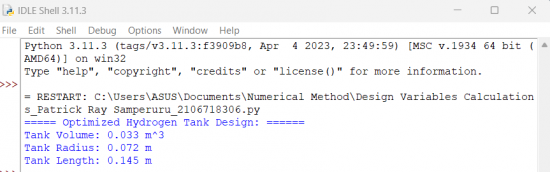

With all the data obtained, I inputted the information into the the Python coding. The utilized data will be the hydrogen's density, mass, and pressure as acquired previously. For my code, I use three main functions to compute the hydrogen tank volume, hydrogen tank dimension, and hydrogen tank optimized dimensions. The first function (tank_volume_calculation) uses the mass of the hydrogen along with the given pressure for the input to compute the required tank volume by using the ideal gas law. The next function (tank_dimensions_calculation) utilizes the previously obtained tank volume to calculate the dimensions of the tank (radius and length) with the assumption that the hydrogen tank is cylindrical in shape. The third and final function combines the tank volume and tank dimension functions to create an optimized design for the volume, radius, and length. The hydrogen mass (mass_hydrogen) and pressure (pressure) inputs can be changed according to specific requirements as necessary. As the output, the dimensions of the tank can be obtained for the three factors of the volume, radius, and length. The obtained result is Volume: 0.033m^3, Radius: 0.072m, Length: 0.145m.

Constraints: Strength of Hydrogen Tank Design

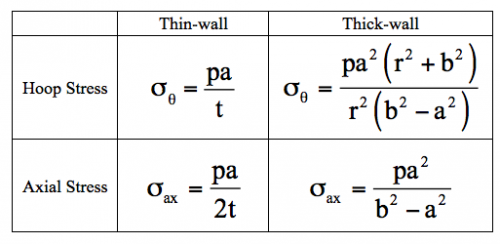

With the design variables obtained, the main constraint of the high number of strength for the Hydrogen Tank design can be considered. To find the strength for the Hydrogen Tank, we need to consider the thickness of the object in accordance with the amount of stress that would be exerted on its tube entrance. Within the the walls of the cylindrical tank, there are two stresses that occurs: circumferential stress and longitudinal stress. The equation for both quantities is as following:

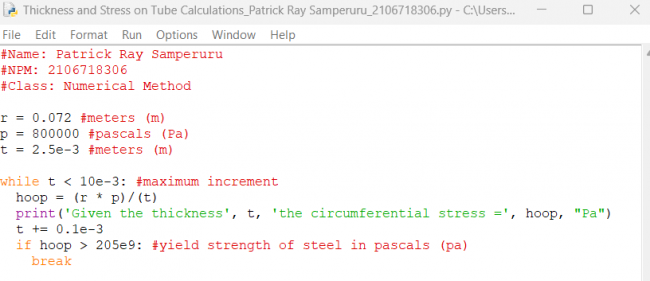

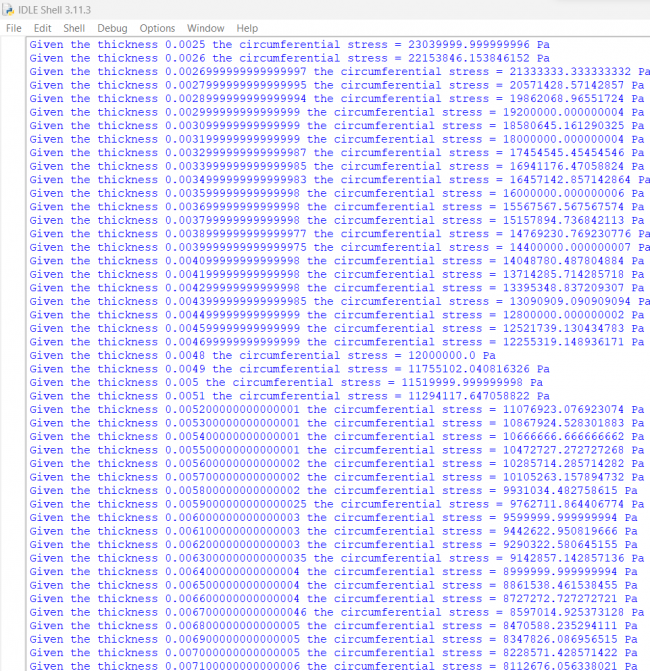

In this case, we are going to use the thin-walled equations as the Hydrogen Tank fits into said description. With the design variables already obtained in the previous coding, we can input the data into the formula of the circumferential stress of thin-wall to calculate the stress in accordance to the thickness that is set to be at a minimum of 2.5mm for safety. Given for this project, the stainless steel grade 304 is to be used, the maximum stress will be set to 205 MPa following the yield strength of the steel. The set stress will determine the thickness used based on the experienced stress on the hoop of the hydrogen tank. With this, the data will be input into the Python coding to determine the right thickness of the object in accordance with the stress exerted on the hoop of the tank. The coding and its result is as follows:

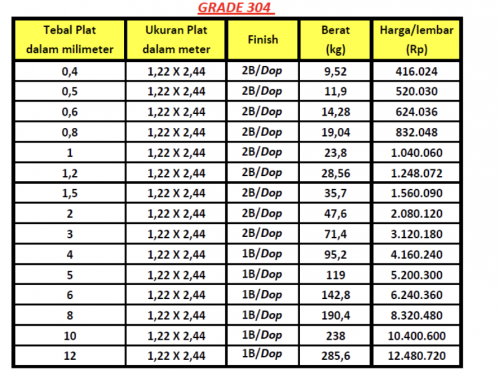

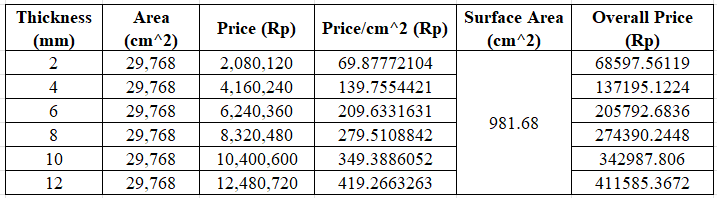

Constraints: Cost of Hydrogen Tank Design

With the data on thickness according to stresses already obtained, we can now decide the final thickness for the hydrogen tank design based on the last constraint of the cost, which is a maximum of 500,000 IDR. The surface area of the hydrogen tank = 2πrh+2πr^2 = 2·π·7.2·14.5+2·π·7.2^2 = 981.68 cm^2. Following the prices on PT. Citra Anggun Lestari, the stainless steel grade 304 that is falls within the budget constraint while following the dimensions of the surface area would have a maximum thickness of 12cm which would withstand a stress of 4800000 Pa (4.8 MPa).

Evaluation and Conclusion of Results

In conclusion, the application of numerical methods enabled the calculation of the dimensions of the hydrogen tank variables accordingly to the strength and cost of the design. Here, the utilization of coding from the programming language, Python, became the facilitator for computing various quantities that are based on different other quantities as well as qualities. From the coding of the design variable of dimensions, the obtained dimensions of the hydrogen tank design is:

- Volume: 0.033m^3

- Radius: 0.072m

- Length: 0.145m

- Surface Area: 981.68 cm^2

This enabled the computation of the thickness of the cylinder tank in accordance to the stress that is exerted on the hoop of the product. The chosen material is the stainless steel grade 304 which has an ultimate tensile strength of 205 MPa. When compared to the cost of grade 304 stainless steel sheets (dimension-wise), the chosen thickness was 12cm which would withstand a stress of 4800000 Pa (4.8 MPa). This would enable it to have a higher wear resistance which results in a longer life, thus achieving the objective function I have set in the start.

Final Case Study Report Video

The video link to my final report of the Hydrogen Design and Optimization Project can be found as following:

To conclude this project, I would like to state that I've learned a lot regarding the concept of consciousness and how my personal consciousness is used throughout my studying process and my life as a whole. I believe Pak DAI's theory of "I'm my consciousness" gives me new insights on the importance of using my consciousness appropriately as it defines who I am and what I do in life. In the class of Numerical Method, I realized that only with consciousness I am able to understand the topics and apply it accordingly to the project. I hope moving forward in life, I become a more conscious human being through my thoughts, actions, and words.