Muhammad Alif Wahab Adhicahya

Assalamu'alaikum Warahmatullahi Wabarakatuh, Salam Sejahtera untuk kita semua. Perkenalkan, saya Muhammad Alif Wahab Adhicahya, Mahasiswa Pascasarjana Departemen Teknik Mesin Universitas Indonesia Angkatan 2023.

Sewaktu menempuh pendidikan sarjana di Universitas Hasanuddin, saya juga mengambil Program Studi yang linear dengan jenjang Magister saat ini. Saya tertarik untuk mendalami bidang konversi energi, tentang fluid mechanics, concept and its application in life.

Computational Fluid Dynamics (CFD) didasari oleh Hukum Kesetimbangan (Conservation), yaitu : 1. Conservation of Mass, 2. Conservation of Momentum, 3. Conservation of Energy. Ketiga Hukum kesetimbangan diatas, dibentuk dalam Differential Partial Equation yang dikenal sebagai Navier-Stokes Equation.

Salah satu parameter penting dalam kajian fluida adalah viskositas, yang dalam masyarakat disebut sebagai kekentalan. Viskositas adalah ukuran kemampuan fluida melawan deformasi akibat tegangan geser [1]. Ditinjau dari hubungan fluida dengan tegangan geser dan viskositasnya, maka fluida dikelompokkan menjadi dua, yaitu Newtonian Fluid dan Non-newtonian fluid.

Newtonian fluid atau fluida newtonian adalah fluida yang hubungan antara viskositas dan tegangan gesernya linear, contohnya air, udara, bensin, dll. sedangkan non-newtonian fluid atau fluida non newtonian adalah fluida yang hubungan viskositas dan tegangan gesernya tidak linear/tidak berbanding lurus, dengan kata lain, apabila fluida non newtonian diberikan tegangan geser, maka viskositasnya akan berubah. Contoh fluida non newtonian, misalnya darah, crude oil, dll. Berdasarkan sifat itulah maka fluida non newtonian diklasifikasikan menjadi dilatant, pseudoplastic, dan bingham plastic.

Thesis Topic: STUDI OPTIMASI DUAL ENCAPSULATIONS MICROFLUIDICS UNTUK APLIKASI HIGH THROUGHPUT

Literature Review: Microfluidics is a technology that deals with the manipulation of small volumes of fluids in microscale channels. Single-cell encapsulation and dual encapsulation microfluidics are two types of microfluidic techniques used for the isolation and analysis of individual cells. Encapsulation microfluidics is a technique that involves the formation of droplets or particles of one fluid within another fluid, which can be used for various applications such as drug delivery, cell encapsulation, and material synthesis. There are different types of encapsulation microfluidics, including double emulsion and dual encapsulation microfluidics.

-Single-Cell Encapsulation Microfluidics, technique involves the generation of picoliter-sized microdroplets to encapsulate individual cells for further analysis -Dual Encapsulation Microfluidics, This technique involves the encapsulation of two different fluids in a single droplet, which can be used for various applications such as drug delivery and cell-cell interaction studies. The double emulsion production method is commonly used for dual encapsulation, which involves the formation of an oil-water-oil emulsion.

Double Emulsion Microfluidics: This technique involves the formation of droplets within droplets, resulting in a structure that resembles a miniature droplet-in-droplet-in-droplet structure. Double emulsion microfluidics can be used for various applications such as drug delivery, material synthesis, and cell encapsulation. Dual Encapsulation Microfluidics: This technique involves the formation of two layers of droplets, with one layer encapsulating the other. Dual encapsulation microfluidics can be used for various applications such as stem cell encapsulation and drug delivery.

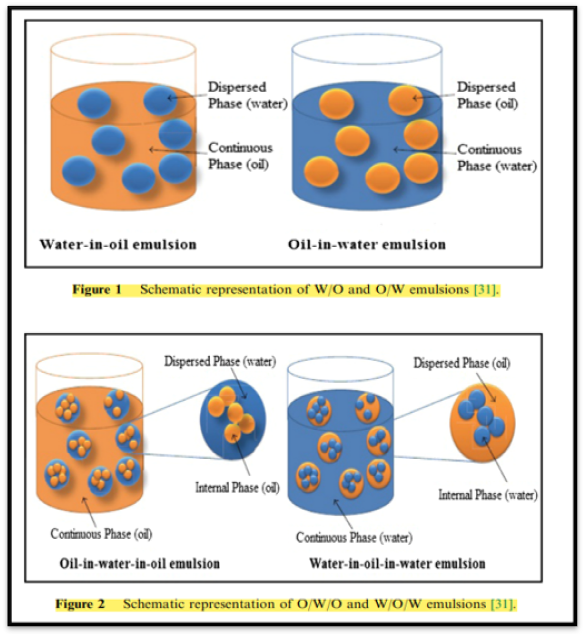

In general, there are two types of emulsification techniques, namely, two-phase and three-phase emulsion.

The formation of three-phase emulsion is in need of two-stages of emulsification process with different surfactant and a result of increases in process cost. The two-phase emulsion comprises one continuous phase and one dispersed phase while The three-phase comprises one continuous phase and two are dispersed phases.

There are generally two distinct forms of two-phase emulsion: (i) water-in-oil (W/O) (ii) oil-in-water (O/W). An emulsion that consists of water droplets dispersed in an oil phase is known as W/O emulsion.

Multiple emulsions comprise three phases such that the inner and outer phases are separated by a dispersed phase. O/W/O emulsions are recommended for fuel preparation and W/O/W emulsions are recommended for pharmaceutical applications.

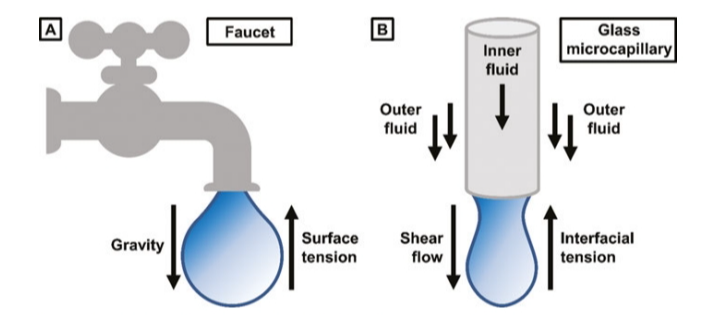

Just like a faucet, when operated at a low flow rate, a microfluidic device can produce fluid droplets one at a time. There are largely three differences to the faucet case. First, in a microfluidic system, the external phase is not air like in our faucet example, but a flowing liquid in a microchannel; this fluid necessarily contains a small portion (typically approximately 1%, w/w) of a surfactant to stabilize the droplets that form from undergoing coalescence. Second, whereas a faucet operates at droplet production rates up to just a few Hertz, a microfluidic dropmaker can produce droplets at rates much higher, up to kilohertz. Third, whereas a faucet produces drops with sizes in the millimeter range, microfluidic devices do so in the range below, typically with tens to hundreds of micrometers in diameter.

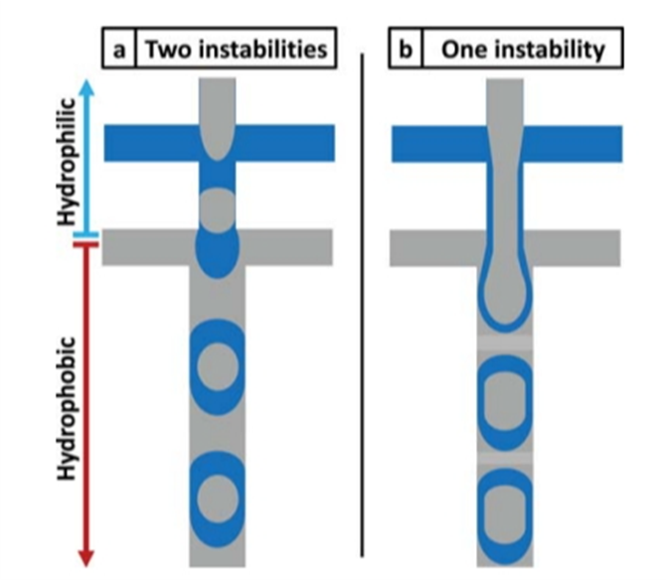

The capillary number relates the shear force on a liquid jet exerted by an outer continuous phase to its surface tension, whereas the Weber number reflects the balance between inertial forces of the inner liquid pushing the drop downstream and again the surface tension forces resisting the flow. We also find, that for f {Ca, We} > 1, the dispersed phase does not break into single droplets, whereas for f {Ca, We} < 1, the liquid stream breaks into droplets due to a dripping instability.

The double Emulsion is a method to produce emulsion products with liquid-liquid-liquid which consist of the inner phase, middle phase, and outer phase. Nowadays, the development of these double emulsion leads to high-throughput product. A high-throughput double emulsion product can produce higher droplet intensity in a certain time droplet production. This arrangement will provide better efficiency in droplet production.