Difference between revisions of "Metode Numerik - Josiah Enrico S (1906356286)"

JosiahEnrico (talk | contribs) (→Tugas Besar Metode Numerik - Metode Numerik/23 Desember 2020) |

JosiahEnrico (talk | contribs) (→Jawaban UAS 2021 - Josiah Enrico S) |

||

| (66 intermediate revisions by the same user not shown) | |||

| Line 1,000: | Line 1,000: | ||

| − | == Tugas Besar Metode Numerik - Metode Numerik/23 Desember 2020 == | + | == [[Tugas Besar Metode Numerik (Latihan)- Metode Numerik/23 Desember 2020]] == |

| + | ==[[Tugas Besar Metode Numerik - Josiah Enrico S]]== | ||

| − | |||

| − | - | + | ==Jawaban UAS 2021 - Josiah Enrico S== |

| + | <gallery mode="slideshow"> | ||

| + | UAS Metnum02 Josiah Enrico S-01.jpg | ||

| + | UAS Metnum02 Josiah Enrico S-02.jpg | ||

| + | UAS Metnum02 Josiah Enrico S-03.jpg | ||

| + | UAS Metnum02 Josiah Enrico S-04.jpg | ||

| + | UAS Metnum02 Josiah Enrico S-05.jpg | ||

| + | UAS Metnum02 Josiah Enrico S-06.jpg | ||

| + | UAS Metnum02 Josiah Enrico S-07.jpg | ||

| + | UAS Metnum02 Josiah Enrico S-08.jpg | ||

| + | UAS Metnum02 Josiah Enrico S-09.jpg | ||

| + | UAS Metnum02 Josiah Enrico S-10.jpg | ||

| + | </gallery> | ||

| − | + | Revisi dan Narasi | |

| + | === No 1 === | ||

| − | + | Langkah-langkah optimasi | |

| − | + | # Tentukan tujuan optimasi lalu definisikan semua parameter yang ada. | |

| + | # Menentukan boundary dan constraint pada struktur | ||

| + | # Menentukan asumsi dalam permodelan struktur | ||

| + | # Melakukan analisa struktur (komputasi) | ||

| + | # Setelah mendapat persamaan utama, variasikan nilai objektif yang akan dioptimasi | ||

| + | # Gunakan metode optimasi yang sesuai | ||

| + | # Setelah mendapatakan nilai optimasi, lakukan pengujian variabel dengan analisa | ||

| + | # Jika hasilnya memuaskan, optimasi selesai. Jika hasilnya belum memuaskan, ulangi dari langkah 6 | ||

| − | + | === No 2 === | |

| − | - | + | {| class="wikitable" style="margin-left: auto; margin-right: auto; border: none;" |

| + | |- | ||

| + | | '''Tujuan Optimasi:''' | ||

| + | | | ||

| + | * Mengoptimasi kekuatan material struktur dan dinding water tank | ||

| + | |- | ||

| + | | '''Asumsi:''' | ||

| + | | | ||

| + | * Fluida Statis | ||

| + | * Gravitasi: 9,81 m/s2 | ||

| + | * Fluida: air murni (rho = 1000 kg/m3) | ||

| + | |- | ||

| + | | '''Dalil Fisika:''' | ||

| + | | | ||

| + | * Gaya Hidrostatis F = rho*g*V | ||

| + | * Stress = E*Strain | ||

| + | |} | ||

| − | + | === No 3 === | |

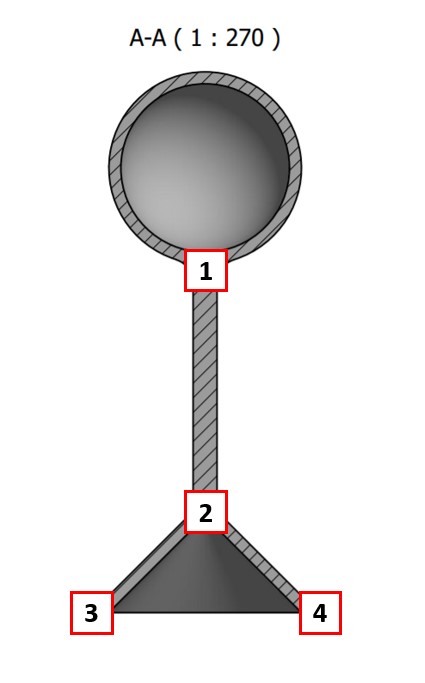

| − | + | [[File:UAS Metnum Water Tower.jpg|thumb|600px|right|'''Nomor 3''' Ilustrasi struktur truss water tower (3 elemen)]] | |

| + | {| class="wikitable" style="margin-left: auto; margin-right: auto; border: none;" | ||

| + | |+ Matriks Persamaan Aljabar | ||

| + | |- | ||

| + | | Persamaan aljabar lokal tiap elemen | ||

| + | | Persamaan aljabar global tiap elemen | ||

| + | |- | ||

| + | | style='border-style: none right none left;' | | ||

| − | + | Truss A (1 to 2) | |

| − | - | + | [ 0 0 0 0 ] (1x) |

| + | k = (A*E/L) [ 0 1 0 1 ] (1y) | ||

| + | [ 0 0 0 0 ] (2x) | ||

| + | [ 0 -1 0 -1 ] (2y) | ||

| − | - | + | | style='border-style: none right none left;' | |

| − | + | Truss A (1 to 2) | |

| + | [ 0 0 0 0 0 0 0 0 ] (1x) | ||

| + | [ 0 1 0 1 0 0 0 0 ] (1y) | ||

| + | [ 0 0 0 0 0 0 0 0 ] (2x) | ||

| + | k = (A*E/L) [ 0 -1 0 -1 0 0 0 0 ] (2y) | ||

| + | [ 0 0 0 0 0 0 0 0 ] (3x) | ||

| + | [ 0 0 0 0 0 0 0 0 ] (3y) | ||

| + | [ 0 0 0 0 0 0 0 0 ] (4x) | ||

| + | [ 0 0 0 0 0 0 0 0 ] (4y) | ||

| + | |- | ||

| + | | style='border-style: none right none left;' | | ||

| − | + | Truss B (2 to 3) | |

| − | [[ | + | [ 0.5 0.5 -0.5 -0.5 ] (2x) |

| + | k = (A*E/L) [ 0.5 0.5 -0.5 -0.5 ] (2y) | ||

| + | [-0.5 -0.5 0.5 0.5 ] (3x) | ||

| + | [-0.5 -0.5 0.5 0.5 ] (3y) | ||

| − | + | | style='border-style: none right none left;' | | |

| + | Truss B (2 to 3) | ||

| + | [ 0 0 0 0 0 0 0 0 ] (1x) | ||

| + | [ 0 0 0 0 0 0 0 0 ] (1y) | ||

| + | [ 0 0 0.5 0.5 -0.5 -0.5 0 0 ] (2x) | ||

| + | k = (A*E/L) [ 0 0 0.5 0.5 -0.5 -0.5 0 0 ] (2y) | ||

| + | [ 0 0 -0.5 -0.5 0.5 0.5 0 0 ] (3x) | ||

| + | [ 0 0 -0.5 -0.5 0.5 0.5 0 0 ] (3y) | ||

| + | [ 0 0 0 0 0 0 0 0 ] (4x) | ||

| + | [ 0 0 0 0 0 0 0 0 ] (4y) | ||

| + | |- | ||

| + | | style='border-style: none right none left;' | | ||

| − | + | Truss C (2 to 4) | |

| − | + | [ 0.5 -0.5 -0.5 0.5 ] (2x) | |

| + | k = (A*E/L) [-0.5 0.5 0.5 -0.5 ] (2y) | ||

| + | [-0.5 0.5 0.5 -0.5 ] (4x) | ||

| + | [ 0.5 -0.5 -0.5 0.5 ] (4y) | ||

| − | + | | style='border-style: none right none left;' | | |

| − | + | Truss C (2 to 4) | |

| − | + | [ 0 0 0 0 0 0 0 0 ] (1x) | |

| + | [ 0 0 0 0 0 0 0 0 ] (1y) | ||

| + | [ 0 0 0.5 -0.5 0 0 -0.5 0.5 ] (2x) | ||

| + | k = (A*E/L) [ 0 0 -0.5 0.5 0 0 0.5 -0.5 ] (2y) | ||

| + | [ 0 0 0 0 0 0 0 0 ] (3x) | ||

| + | [ 0 0 0 0 0 0 0 0 ] (3y) | ||

| + | [ 0 0 -0.5 0.5 0 0 0.5 -0.5 ] (4x) | ||

| + | [ 0 0 0.5 -0.5 0 0 -0.5 0.5 ] (4y) | ||

| − | + | |} | |

| + | |||

| + | === No 4 === | ||

| + | |||

| + | <gallery mode=packed heights=500px> | ||

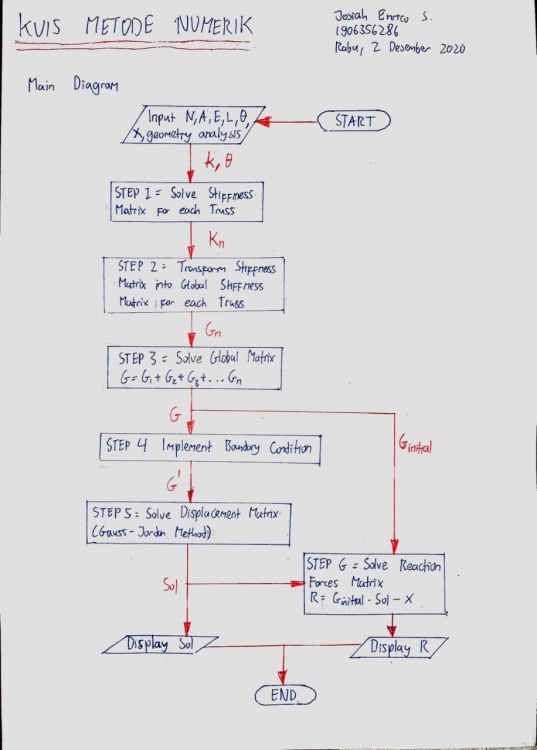

| + | Kuis Metnum1 Jos.jpeg|'''Nomor 4''' Flowchart Analisa Struktur | ||

| + | Verifikasi Metnum Jos.jpeg|'''Nomor 4''' Verifikasi Gaya Reaksi | ||

| + | </gallery> | ||

| + | |||

| + | === No 5 === | ||

| + | |||

| + | Fungsi Objektif | ||

| + | |||

| + | {| class="wikitable" style="margin-left: auto; margin-right: auto; border: none;" | ||

| + | |- | ||

| + | | displacement= | ||

| + | | [A*E/L][Uglobal]* '''deltaL''' = [F] | ||

| + | |- | ||

| + | | Reaction Force= | ||

| + | | '''R''' = [A*E/L][Uglobal]*deltaL - [F] | ||

| + | |- | ||

| + | | Stress= | ||

| + | | '''Stress''' = E*(deltaL)/A | ||

| + | |} | ||

| + | |||

| + | Constraint/Boundary | ||

| + | |||

| + | *Berdasarkan struktur di nomor 3, boundary condition terdapat pada titik 3 dan 4 | ||

| + | |||

| + | === No 6 === | ||

| + | |||

| + | Asumsi: | ||

| + | |||

| + | *Area: 0.16 (Persegi 0.4 x 0.4 meter) | ||

| + | *Elastisitas: 193 GPa (SS 304) | ||

| + | *Yield: 215 MPa (SS 304) | ||

| + | *rho air murni: 1000 kg/m3 | ||

| + | *Gravitasi: 9,81 m/s2 | ||

| + | *Volume air: 200000 gallon / 1136 m3 | ||

| + | |||

| + | === No 7 === | ||

| + | |||

| + | <gallery mode=packed heights=300px> | ||

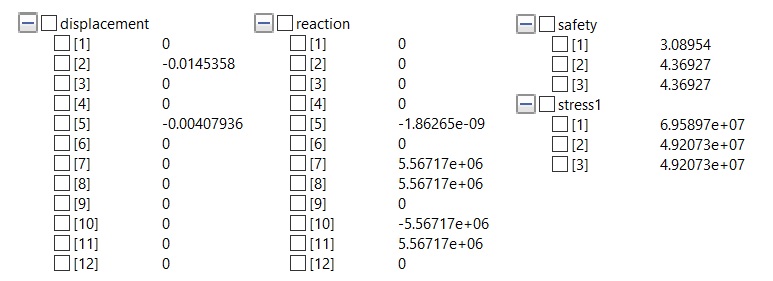

| + | UAS Metnum Result.jpg|'''Nomor 7''' Hasil Simulasi Modelica | ||

| + | </gallery> | ||

| + | |||

| + | {| class="wikitable" style="margin-left: auto; margin-right: auto; border: none;" | ||

| + | |- | ||

| + | | | ||

| + | '''Kode Modelica''' | ||

| + | |||

| + | model UAS_METNUM | ||

| + | |||

| + | //define initial variable | ||

| + | parameter Integer Points=4; //Number of Points | ||

| + | parameter Integer Trusses=3; //Number of Trusses | ||

| + | parameter Real Yield=215e6; //Yield Strength (Pa) | ||

| + | parameter Real Area=0.16; //Area Block Profile (0.4 * 0.4) (m2) | ||

| + | parameter Real Elas=193e9; //Elasticity SS 304 (Pa) | ||

| + | parameter Real Volume=1135; //m3 from 200000 gallons | ||

| + | parameter Real rho=1000; //kg/m3 | ||

| + | |||

| + | parameter Real W=Volume*rho*9.81; | ||

| + | |||

| + | //define connection | ||

| + | parameter Integer C[Trusses,2]=[1,2; | ||

| + | 2,3; | ||

| + | 2,4]; | ||

| + | |||

| + | //define coordinates (please put orderly) | ||

| + | parameter Real P[Points,3]=[0,37,0; | ||

| + | 0,8,0; | ||

| + | -8,0,0; | ||

| + | 8,0,0]; | ||

| + | |||

| + | //define external force (please put orderly) | ||

| + | parameter Real F[Points*3]={0,-W,0, | ||

| + | 0,0,0, | ||

| + | 0,0,0, | ||

| + | 0,0,0}; | ||

| + | |||

| + | //define boundary | ||

| + | parameter Integer b[:]={3,4}; | ||

| + | |||

| + | //solution | ||

| + | Real displacement[N], reaction[N]; | ||

| + | Real check[3]; | ||

| + | |||

| + | Real stress1[Trusses]; | ||

| + | Real safety[Trusses]; | ||

| + | Real dis[3]; | ||

| + | Real Str[3]; | ||

| + | |||

| + | protected | ||

| + | parameter Integer N=3*Points; | ||

| + | Integer boundary[3*size(b,1)]=cat(1,(3*b).-2,(3*b).-1,3*b); | ||

| + | Real q1[3], q2[3], g[N,N], G[N,N], G_star[N,N], id[N,N]=identity(N), cx, cy, cz, L, X[3,3]; | ||

| + | Real err=10e-10, ers=10e-4; | ||

| + | |||

| + | algorithm | ||

| + | //Creating Global Matrix | ||

| + | G:=id; | ||

| + | for i in 1:Trusses loop | ||

| + | for j in 1:3 loop | ||

| + | q1[j]:=P[C[i,1],j]; | ||

| + | q2[j]:=P[C[i,2],j]; | ||

| + | end for; | ||

| + | |||

| + | //Solving Matrix | ||

| + | L:=Modelica.Math.Vectors.length(q2-q1); | ||

| + | cx:=(q2[1]-q1[1])/L; | ||

| + | cy:=(q2[2]-q1[2])/L; | ||

| + | cz:=(q2[3]-q1[3])/L; | ||

| + | X:=(Area*Elas/L)*[cx^2,cx*cy,cx*cz; | ||

| + | cy*cx,cy^2,cy*cz; | ||

| + | cz*cx,cz*cy,cz^2]; | ||

| + | |||

| + | //Transforming to global matrix | ||

| + | g:=zeros(N,N); | ||

| + | for m,n in 1:3 loop | ||

| + | g[3*(C[i,1]-1)+m,3*(C[i,1]-1)+n]:=X[m,n]; | ||

| + | g[3*(C[i,2]-1)+m,3*(C[i,2]-1)+n]:=X[m,n]; | ||

| + | g[3*(C[i,2]-1)+m,3*(C[i,1]-1)+n]:=-X[m,n]; | ||

| + | g[3*(C[i,1]-1)+m,3*(C[i,2]-1)+n]:=-X[m,n]; | ||

| + | end for; | ||

| + | |||

| + | G_star:=G+g; | ||

| + | G:=G_star; | ||

| + | end for; | ||

| + | |||

| + | //Implementing boundary | ||

| + | for i in boundary loop | ||

| + | for j in 1:N loop | ||

| + | G[i,j]:=id[i,j]; | ||

| + | end for; | ||

| + | end for; | ||

| + | |||

| + | //Solving displacement | ||

| + | displacement:=Modelica.Math.Matrices.solve(G,F); | ||

| + | |||

| + | //Solving reaction | ||

| + | reaction:=(G_star*displacement)-F; | ||

| + | |||

| + | //Eliminating float error | ||

| + | for i in 1:N loop | ||

| + | reaction[i]:=if abs(reaction[i])<=err then 0 else reaction[i]; | ||

| + | displacement[i]:=if abs(displacement[i])<=err then 0 else displacement[i]; | ||

| + | end for; | ||

| + | |||

| + | //Checking Force | ||

| + | check[1]:=sum({reaction[i] for i in (1:3:(N-2))})+sum({F[i] for i in (1:3:(N-2))}); | ||

| + | check[2]:=sum({reaction[i] for i in (2:3:(N-1))})+sum({F[i] for i in (2:3:(N-1))}); | ||

| + | check[3]:=sum({reaction[i] for i in (3:3:N)})+sum({F[i] for i in (3:3:N)}); | ||

| + | |||

| + | for i in 1:3 loop | ||

| + | check[i] := if abs(check[i])<=ers then 0 else check[i]; | ||

| + | end for; | ||

| + | |||

| + | //Calculating stress in each truss | ||

| + | for i in 1:Trusses loop | ||

| + | for j in 1:3 loop | ||

| + | q1[j]:=P[C[i,1],j]; | ||

| + | q2[j]:=P[C[i,2],j]; | ||

| + | dis[j]:=abs(displacement[3*(C[i,1]-1)+j]-displacement[3*(C[i,2]-1)+j]); | ||

| + | end for; | ||

| + | |||

| + | //Solving Matrix | ||

| + | L:=Modelica.Math.Vectors.length(q2-q1); | ||

| + | cx:=(q2[1]-q1[1])/L; | ||

| + | cy:=(q2[2]-q1[2])/L; | ||

| + | cz:=(q2[3]-q1[3])/L; | ||

| + | X:=(Elas/L)*[cx^2,cx*cy,cx*cz; | ||

| + | cy*cx,cy^2,cy*cz; | ||

| + | cz*cx,cz*cy,cz^2]; | ||

| + | |||

| + | Str:=(X*dis); | ||

| + | stress1[i]:=Modelica.Math.Vectors.length(Str); | ||

| + | end for; | ||

| + | |||

| + | //Safety factor | ||

| + | for i in 1:Trusses loop | ||

| + | if stress1[i]>0 then | ||

| + | safety[i]:=Yield/stress1[i]; | ||

| + | else | ||

| + | safety[i]:=0; | ||

| + | end if; | ||

| + | end for; | ||

| + | |||

| + | end UAS_METNUM; | ||

| + | |} | ||

Latest revision as of 21:24, 14 January 2021

Contents

- 1 Intro - Metode Numerik/11 November 2020

- 2 Aplikasi Modelica - Metode Numerik/18 November 2020

- 3 Fungsi Panggil dalam Modelica - Metode Numerik/18 November 2020

- 4 Finite Element Method for Trusses - Metode Numerik/2 Desember 2020

- 5 Kuis Membuat Class FLowchart - Metode Numerik/18 November 2020

- 6 3D Trusses - Metode Numerik/18 November 2020

- 7 Optimization - Metode Numerik/16 November 2020

- 8 Tugas Besar Metode Numerik (Latihan)- Metode Numerik/23 Desember 2020

- 9 Tugas Besar Metode Numerik - Josiah Enrico S

- 10 Jawaban UAS 2021 - Josiah Enrico S

Intro - Metode Numerik/11 November 2020

Tujuan belajar metode numerik yaitu agar penulis dapat:

1) Memahami konsep dan prinsip dasar metode numerik.

2) Memahami aplikasi metode numerik

3) Menyelesaikan persoalan teknik dengan metoda numerik

4) Mendapat nilai tambah sebagai manusia yang lebih beradab

Aplikasi Modelica - Metode Numerik/18 November 2020

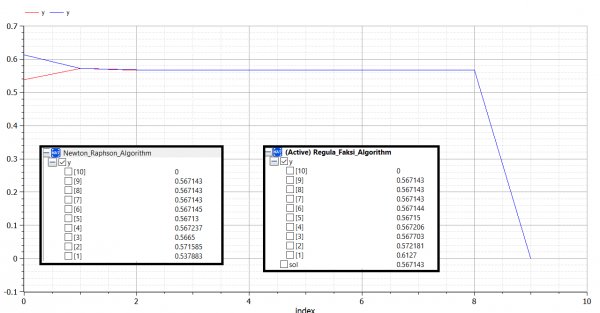

Berikut ini adalah contoh penerapan aplikasi OpenModelica untuk membuat 4 algoritma metode numerik dalam mencari roots of equation (akar persamaan) dari:

f(x) = exp^(-x)-(x)

f'(x) = -exp^(-x)-1

error maksimum = 0.0000001

1) Newton Raphson (Terbuka)

model Newton_Raphson_Algorithm parameter Real g=1; //guess parameter Integer N=20; //max iteration parameter Real er=0.0000001; //error maximum Real a[N]; Real y[N];//function Real ER[N]; //error Real sol; //solution algorithm a[1]:=g; y[1]:=a[1]-(exp(-a[1])-a[1])/(-exp(-a[1])-1); ER[1]:=abs(1-a[1]/y[1]); for i in 2:N loop a[i]:=y[i-1]; y[i]:=a[i]-(exp(-a[i])-a[i])/(-exp(-a[i])-1); ER[i]:=abs(1-y[i-1]/y[i]); if ER[i]<er then sol:=y[i]; break; end if; end for; end Newton_Raphson_Algorithm;

2) Secant (Terbuka)

model Secant_Algorithm parameter Real a=0; //guess parameter Real b=1; //guess parameter Integer N=10; //max iteration parameter Real er=0.0000001; //error maximum Real A[N]; Real B[N]; Real y[N]; Real ER[N]; Real sol; //solution algorithm A[1]:=a; B[1]:=b; y[1]:=B[1]-(exp(-B[1])-B[1])*(A[1]-B[1])/((exp(-A[1])-A[1])-(exp(-B[1])-B[1])); ER[1]:=abs(1-B[1]/y[1]); for i in 2:N loop A[i]:=B[i-1]; B[i]:=y[i-1]; y[i]:=B[i]-(exp(-B[i])-B[i])*(A[i]-B[i])/((exp(-A[i])-A[i])-(exp(-B[i])-B[i])); ER[i]:=abs(1-y[i-1]/y[i]); if ER[i]<er then sol:=y[i]; break; end if; end for; end Secant_Algorithm;

3) Bisection (Tertutup)

model Bisection_Algorithm parameter Real a=0; //guess bawah parameter Real b=1; //guess atas parameter Integer N=50; //max iteration parameter Real er=0.0000001; //error maximum Real fa=(exp(-a)-a); Real fb=(exp(-b)-b); Real A[N]; Real B[N]; Real fy[N]; Real y[N]; Real ER[N]; Real sol; //solution algorithm if fa*fb<0 then A[1]:=a; B[1]:=b; y[1]:=(A[1]+B[1])/2; fy[1]:=exp(-y[1])-y[1]; ER[1]:=1; for i in 2:N loop if fy[i-1]>0 then A[i]:=y[i-1]; B[i]:=B[i-1]; else A[i]:=A[i-1]; B[i]:=y[i-1]; end if; y[i]:=(A[i]+ B[i])/2; fy[i]:=exp(-y[i])-y[i]; ER[i]:=abs(1-y[i-1]/y[i]); if ER[i]<er then sol:=y[i]; break; end if; end for; end if; end Bisection_Algorithm;

4) Regula Falsi (Tertutup)

model Regula_Falsi_Algorithm parameter Real a=0; //guess bawah parameter Real b=1; //guess atas parameter Integer N=20; //max iteration parameter Real er=0.0000001; //error maximum Real A[N]; Real B[N]; Real fa[N]; Real fb[N]; Real fy[N]; Real y[N]; Real ER[N]; Real sol; //solution algorithm A[1]:=a; B[1]:=b; fa[1]:=exp(-A[1])-A[1]; fb[1]:=exp(-B[1])-B[1]; if fa[1]*fb[1]<0 then y[1]:=(A[1]*fb[1]-B[1]*fa[1])/(fb[1]-fa[1]); fy[1]:=exp(-y[1])-y[1]; ER[1]:=1; for i in 2:N loop if fy[i-1]>0 then A[i]:=y[i-1]; B[i]:=B[i-1]; else A[i]:=A[i-1]; B[i]:=y[i-1]; end if; fa[i]:=exp(-A[i])-A[i]; fb[i]:=exp(-B[i])-B[i]; y[i]:=(A[i]*fb[i]-B[i]*fa[i])/(fb[i]-fa[i]); fy[i]:=exp(-y[i])-y[i]; ER[i]:=abs(1-y[i-1]/y[i]); if ER[i]<er then sol:=y[i]; break; end if; end for; end if; end Regula_Falsi_Algorithm;

Berikut link Youtube yang berisi penjelasan tentang algoritma dan penulisan kode OpenModelica keempat metode diatas:

Fungsi Panggil dalam Modelica - Metode Numerik/18 November 2020

Fungsi panggil dalam aplikasi Modelica adalah metode membuat fungsi numerik dalam kelas function yang akan digunakan di dalam permodelan numerik utama (tipe 'class'). metode ini biasanya dipakai untuk menyederhanakan persoalan matematika yang kompleks, seperti persamaan aljabar simultan, sehingga lebih mudah diselesaikan. Dalam artikel ini akan ditampilkan 3 contoh persoalan numerik dengan solusi array atau lebih dari satu anggota:

1) Root of Equation (Newton Raphson dan Regula Falsi)

|

Newton Raphson ... algorithm a[1]:=g; y[1]:=a[1]-(Fungsi(a[1]))/(Der_Fungsi(a[1])); ER[1]:=abs(1-a[1]/y[1]); for i in 2:N loop a[i]:=y[i-1]; y[i]:=a[i]-(Fungsi(a[i]))/(Der_Fungsi(a[1])); ER[i]:=abs(1-y[i-1]/y[i]); if ER[i]<er then sol:=y[i]; break; end if; Regula Falsi ... fa[1]:=Fungsi(A[1]); fb[1]:=Fungsi(B[1]); if fa[1]*fb[1]<0 then y[1]:=(A[1]*fb[1]-B[1]*fa[1])/(fb[1]-fa[1]); fy[1]:=Fungsi(y[1]); ER[1]:=1; ... fa[i]:=Fungsi(A[i]); fb[i]:=Fungsi(B[i]); y[i]:=(A[i]*fb[i]-B[i]*fa[i])/(fb[i]-fa[i]); fy[i]:=Fungsi(y[i]); ER[i]:=abs(1-y[i-1]/y[i]); ... |

fungsi function Fungsi input Real X; output Real Y; algorithm Y:=exp(-X)-X; end Fungsi; fungsi turunan function Der_Fungsi input Real X; output Real Y; algorithm Y:=-exp(-X)-1; end Der_Fungsi; |

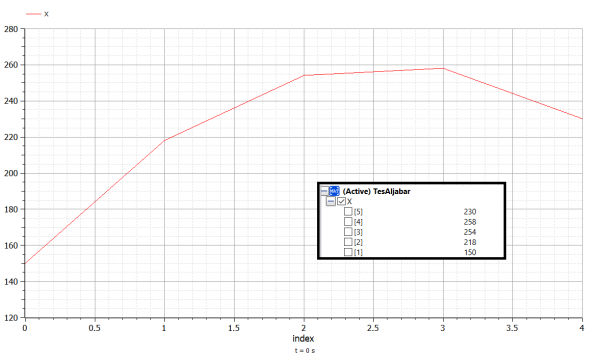

2) Heat Diffusion

Referensi: Versteeg, H. K., Malalasekera, W. (2007). An Introduction to Computational Fluid Dynamics. 2nd Edition. Harlow: Pearson (Example 4.2)

|

Persamaan class TesAljabar

parameter Real A[5,5]=[375,-125,0,0,0;

-125,250,-125,0,0;

0,-125,250,-125,0;

0,0,-125,250,-125;

0,0,0,-125,375];

parameter Real B[5]={29000,4000,4000,4000,54000};

Real X[5];

equation

X=matriks5(A,B);

end TesAljabar;

|

fungsi function matriks5 input Real A[5,5]; input Real B[5]; output Real X[5]; algorithm X:=Modelica.Math.Matrices.solve(A,B); end matriks5; |

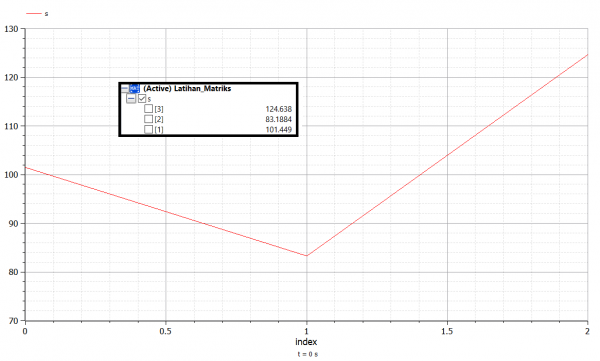

3) Combined Spring Stiffness

Referensi: http://www.sharetechnote.com/html/EngMath_Matrix_FEM_ComplicatedSpring.html

|

Persamaan class Latihan_Matriks

parameter Real c1=1; //spring 1

parameter Real c2=2; //spring 2

parameter Real c3=3; //spring 3

parameter Real c4=4; //spring 4

parameter Real c5=5; //spring 5

parameter Real k1[3,3]=c1*[1,0,0;

0,0,0;

0,0,0];

parameter Real k2[3,3]=c2*[1,-1,0;

-1,1,0;

0,0,0];

parameter Real k3[3,3]=c3*[1,-1,0;

-1,1,0;

0,0,0];

parameter Real k4[3,3]=c4*[1,0,-1;

0,0,1;

-1,0,1];

parameter Real k5[3,3]=c5*[0,0,0;

0,1,-1;

0,-1,1];

parameter Real B[3]={100,200,300};

Real K[3,3];

Real s[3];

algorithm

K:=k1+k2+k3+k4+k5;

s:=matriks3(K,B);

end Latihan_Matriks;

|

fungsi function matriks3 input Real A[3,3]; input Real B[3]; output Real X[3]; algorithm X:=Modelica.Math.Matrices.solve(A,B); end matriks3; |

Berikut link Youtube yang berisi penjelasan tentang algoritma dan penulisan kode OpenModelica latihan diatas:

Berikut juga adalah pemodelan Modelica untuk metode Naive Gauss:

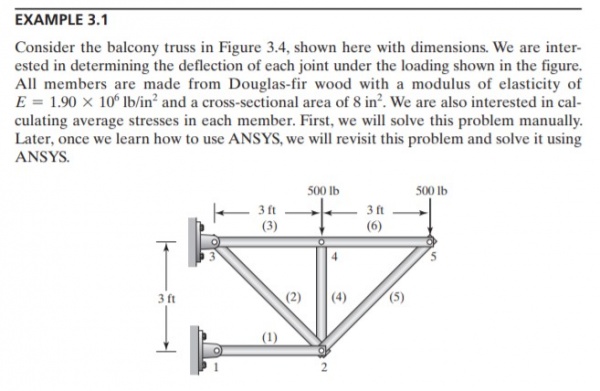

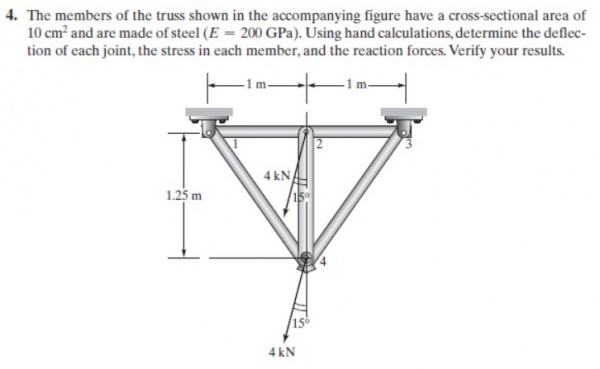

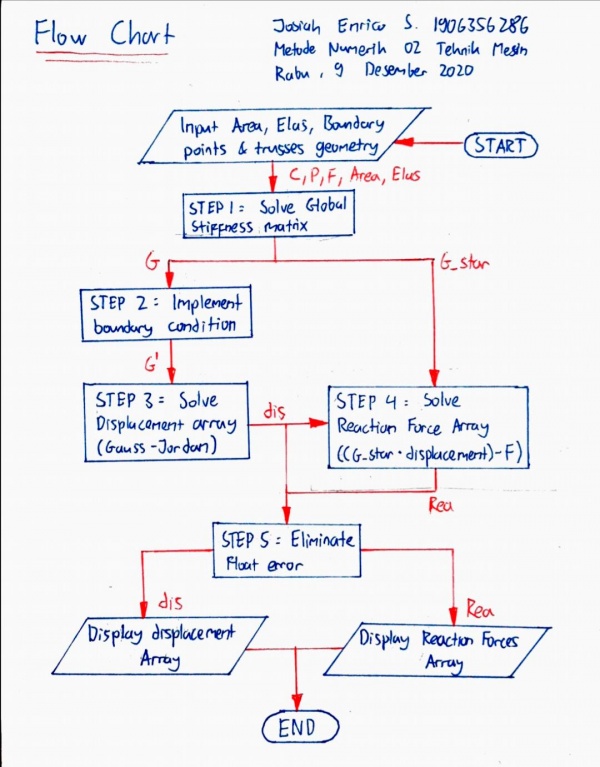

Finite Element Method for Trusses - Metode Numerik/2 Desember 2020

Berikut 2 contoh penggunaan aplikasi Modelica untuk menyelesaikan perhitungan displacement dan reaction force pada trusses:

Trusses Problem 1 (Example 3.1)

|

Persamaan model Trusses

parameter Integer N=10; //Global matrice = 2*points connected

parameter Real A=8;

parameter Real E=1.9e6;

Real G[N,N]; //global

Real Ginitial[N,N]; //global

Real Sol[N]; //global dispplacement

Real X[N]={0,0,0,0,0,0,0,-500,0,-500};

Real R[N]; //global reaction force

Real SolMat[N,1];

Real XMat[N,1];

//boundary coundition

Integer b1=1;

Integer b2=3;

//truss 1

parameter Real X1=0; //degree between truss

Real k1=A*E/36;

Real K1[4,4]; //stiffness matrice

Integer p1a=1;

Integer p1b=2;

Real G1[N,N];

//truss 2

parameter Real X2=135; //degree between truss

Real k2=A*E/50.912;

Real K2[4,4]; //stiffness matrice

Integer p2a=2;

Integer p2b=3;

Real G2[N,N];

//truss 3

parameter Real X3=0; //degree between truss

Real k3=A*E/36;

Real K3[4,4]; //stiffness matrice

Integer p3a=3;

Integer p3b=4;

Real G3[N,N];

//truss 4

parameter Real X4=90; //degree between truss

Real k4=A*E/36;

Real K4[4,4]; //stiffness matrice

Integer p4a=2;

Integer p4b=4;

Real G4[N,N];

//truss 5

parameter Real X5=45; //degree between truss

Real k5=A*E/50.912;

Real K5[4,4]; //stiffness matrice

Integer p5a=2;

Integer p5b=5;

Real G5[N,N];

//truss 6

parameter Real X6=0; //degree between truss

Real k6=A*E/36;

Real K6[4,4]; //stiffness matrice

Integer p6a=4;

Integer p6b=5;

Real G6[N,N];

/*

for each truss, please ensure pXa is lower then pXb (X represents truss element number)

*/

algorithm

//creating global matrice

K1:=Stiffness_Matrices(X1);

G1:=k1*Local_Global(K1,N,p1a,p1b);

K2:=Stiffness_Matrices(X2);

G2:=k2*Local_Global(K2,N,p2a,p2b);

K3:=Stiffness_Matrices(X3);

G3:=k3*Local_Global(K3,N,p3a,p3b);

K4:=Stiffness_Matrices(X4);

G4:=k4*Local_Global(K4,N,p4a,p4b);

K5:=Stiffness_Matrices(X5);

G5:=k5*Local_Global(K5,N,p5a,p5b);

K6:=Stiffness_Matrices(X6);

G6:=k6*Local_Global(K6,N,p6a,p6b);

G:=G1+G2+G3+G4+G5+G6;

Ginitial:=G;

//implementing boundary condition

for i in 1:N loop

G[2*b1-1,i]:=0;

G[2*b1,i]:=0;

G[2*b2-1,i]:=0;

G[2*b2,i]:=0;

end for;

G[2*b1-1,2*b1-1]:=1;

G[2*b1,2*b1]:=1;

G[2*b2-1,2*b2-1]:=1;

G[2*b2,2*b2]:=1;

//solving displacement

Sol:=Gauss_Jordan(N,G,X);

//solving reaction force

SolMat:=matrix(Sol);

XMat:=matrix(X);

R:=Reaction_Trusses(N,Ginitial,SolMat,XMat);

end Trusses;

|

Trusses Problem 2 (Homework)

|

Persamaan class Trusses_HW

parameter Integer N=8; //Global matrice = 2*points connected

parameter Real A=0.001; //Area m2

parameter Real E=200e9; //Pa

Real G[N,N]; //global

Real Ginitial[N,N]; //global

Real Sol[N]; //global dispplacement

Real X[N]={0,0,-1035.2762,-3863.7033,0,0,-1035.2762,-3863.7033};

Real R[N]; //global reaction force

Real SolMat[N,1];

Real XMat[N,1];

//boundary condition

Integer b1=1;

Integer b2=3;

//truss 1

parameter Real X1=0; //degree between truss

Real k1=A*E/1;

Real K1[4,4]; //stiffness matrice

Integer p1a=1;

Integer p1b=2;

Real G1[N,N];

//truss 2

parameter Real X2=0; //degree between truss

Real k2=A*E/1;

Real K2[4,4]; //stiffness matrice

Integer p2a=2;

Integer p2b=3;

Real G2[N,N];

//truss 3

parameter Real X3=90; //degree between truss

Real k3=A*E/1.25;

Real K3[4,4]; //stiffness matrice

Integer p3a=2;

Integer p3b=4;

Real G3[N,N];

//truss 4

parameter Real X4=90+38.6598; //degree between truss

Real k4=A*E/1.6;

Real K4[4,4]; //stiffness matrice

Integer p4a=1;

Integer p4b=4;

Real G4[N,N];

//truss 5

parameter Real X5=90-38.6598; //degree between truss

Real k5=A*E/1.6;

Real K5[4,4]; //stiffness matrice

Integer p5a=3;

Integer p5b=4;

Real G5[N,N];

/*

for each truss, please ensure pXa is lower then pXb (X represents truss element number)

*/

algorithm

//creating global matrice

K1:=Stiffness_Matrices(X1);

G1:=k1*Local_Global(K1,N,p1a,p1b);

K2:=Stiffness_Matrices(X2);

G2:=k2*Local_Global(K2,N,p2a,p2b);

K3:=Stiffness_Matrices(X3);

G3:=k3*Local_Global(K3,N,p3a,p3b);

K4:=Stiffness_Matrices(X4);

G4:=k4*Local_Global(K4,N,p4a,p4b);

K5:=Stiffness_Matrices(X5);

G5:=k5*Local_Global(K5,N,p5a,p5b);

G:=G1+G2+G3+G4+G5;

Ginitial:=G;

//implementing boundary condition

for i in 1:N loop

G[2*b1-1,i]:=0;

G[2*b1,i]:=0;

G[2*b2-1,i]:=0;

G[2*b2,i]:=0;

end for;

G[2*b1-1,2*b1-1]:=1;

G[2*b1,2*b1]:=1;

G[2*b2-1,2*b2-1]:=1;

G[2*b2,2*b2]:=1;

//solving displacement

Sol:=Gauss_Jordan(N,G,X);

//solving reaction force

SolMat:=matrix(Sol);

XMat:=matrix(X);

R:=Reaction_Trusses(N,Ginitial,SolMat,XMat);

end Trusses_HW;

|

Fungsi Panggil

|

Matrice Transformation function Stiffness_Matrices

input Real A;

Real Y;

output Real X[4,4];

Real float_error = 10e-10;

final constant Real pi=2*Modelica.Math.asin(1.0);

algorithm

Y:=A/180*pi;

X:=[(Modelica.Math.cos(Y))^2,Modelica.Math.cos(Y)*Modelica.Math.sin(Y),-(Modelica.Math.cos(Y))^2,-Modelica.Math.cos(Y)*Modelica.Math.sin(Y);

Modelica.Math.cos(Y)*Modelica.Math.sin(Y),(Modelica.Math.sin(Y))^2,-Modelica.Math.cos(Y)*Modelica.Math.sin(Y),-(Modelica.Math.sin(Y))^2;

-(Modelica.Math.cos(Y))^2,-Modelica.Math.cos(Y)*Modelica.Math.sin(Y),(Modelica.Math.cos(Y))^2,Modelica.Math.cos(Y)*Modelica.Math.sin(Y);

-Modelica.Math.cos(Y)*Modelica.Math.sin(Y),-(Modelica.Math.sin(Y))^2,Modelica.Math.cos(Y)*Modelica.Math.sin(Y),(Modelica.Math.sin(Y))^2];

for i in 1:4 loop

for j in 1:4 loop

if abs(X[i,j]) <= float_error then

X[i,j] := 0;

end if;

end for;

end for;

end Stiffness_Matrices;

|

Global Element Matrice function Local_Global

input Real Y[4,4];

input Integer B;

input Integer p1;

input Integer p2;

output Real G[B,B];

algorithm

for i in 1:B loop

for j in 1:B loop

G[i,j]:=0;

end for;

end for;

G[2*p1,2*p1]:=Y[2,2];

G[2*p1-1,2*p1-1]:=Y[1,1];

G[2*p1,2*p1-1]:=Y[2,1];

G[2*p1-1,2*p1]:=Y[1,2];

G[2*p2,2*p2]:=Y[4,4];

G[2*p2-1,2*p2-1]:=Y[3,3];

G[2*p2,2*p2-1]:=Y[4,3];

G[2*p2-1,2*p2]:=Y[3,4];

G[2*p2,2*p1]:=Y[4,2];

G[2*p2-1,2*p1-1]:=Y[3,1];

G[2*p2,2*p1-1]:=Y[4,1];

G[2*p2-1,2*p1]:=Y[3,2];

G[2*p1,2*p2]:=Y[2,4];

G[2*p1-1,2*p2-1]:=Y[1,3];

G[2*p1,2*p2-1]:=Y[2,3];

G[2*p1-1,2*p2]:=Y[1,4];

end Local_Global;

|

Reaction Matrice Equation function Reaction_Trusses input Integer N; input Real A[N,N]; input Real B[N,1]; input Real C[N,1]; Real X[N,1]; output Real Sol[N]; Real float_error = 10e-10; algorithm X:=A*B-C; for i in 1:N loop if abs(X[i,1]) <= float_error then X[i,1] := 0; end if; end for; for i in 1:N loop Sol[i]:=X[i,1]; end for; end Reaction_Trusses; Gauss Jordan function Gauss_Jordan input Integer N; input Real A[N,N]; input Real B[N]; output Real X[N]; Real float_error = 10e-10; algorithm X:=Modelica.Math.Matrices.solve(A,B); for i in 1:N loop if abs(X[i]) <= float_error then X[i] := 0; end if; end for; end Gauss_Jordan; |

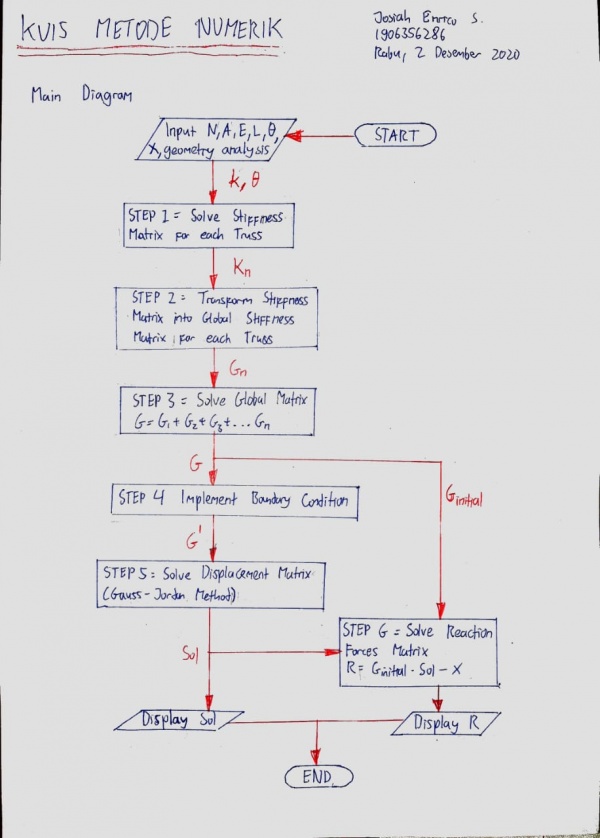

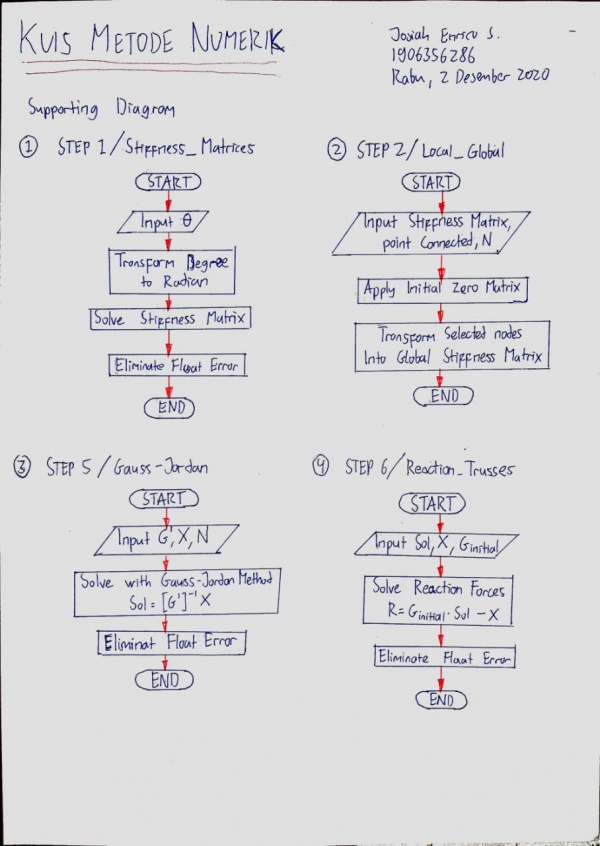

Kuis Membuat Class FLowchart - Metode Numerik/18 November 2020

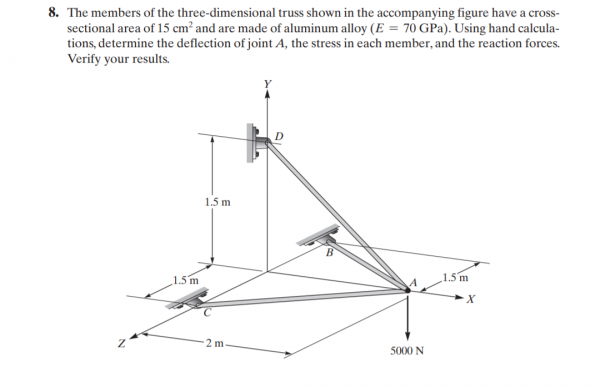

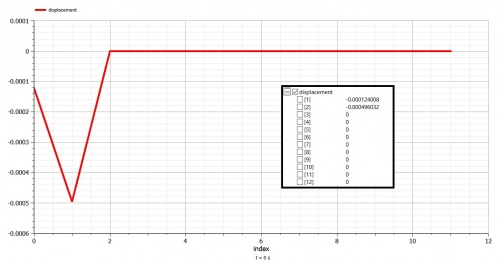

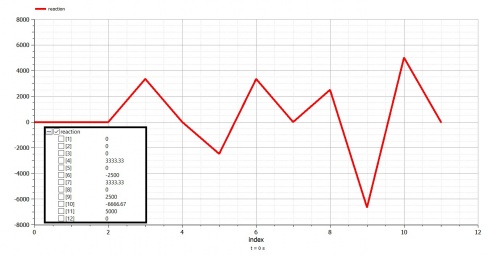

3D Trusses - Metode Numerik/18 November 2020

|

Master class Trusses3D_Tes

//define initial variable

parameter Integer Points=4; //Number of Points

parameter Integer Trusses=3; //Number of Trusses

parameter Real Area=0.0015; //Area

parameter Real Elas=70e9; //Elasticity

//define connection

parameter Integer C[Trusses,2]=[1,2;

1,3;

1,4];

//define coordinates (please put orderly)

parameter Real P[Points,3]=[2,0,0;

0,0,1.5;

0,0,-1.5;

0,1.5,0];

//define external force (please put orderly)

parameter Real F[Points*3]={0,-5000,0,

0,0,0,

0,0,0,

0,0,0};

//define boundary

parameter Integer b[:]={2,3,4};

//solution

Real displacement[N], reaction[N];

protected

parameter Integer N=3*Points;

Integer boundary[3*size(b,1)]=cat(1,(3*b).-2,(3*b).-1,3*b);

Real q1[3], q2[3], g[N,N], G[N,N], G_star[N,N], id[N,N]=identity(N), err=10e-10, cx, cy, cz, L, X[3,3];

algorithm

//Creating Global Matrix

G:=id;

for i in 1:Trusses loop

for j in 1:3 loop

q1[j]:=P[C[i,1],j];

q2[j]:=P[C[i,2],j];

end for;

//Solving Matrix

L:=Modelica.Math.Vectors.length(q2-q1);

cx:=(q2[1]-q1[1])/L;

cy:=(q2[2]-q1[2])/L;

cz:=(q2[3]-q1[3])/L;

X:=(Area*Elas/L)*[cx^2,cx*cy,cx*cz;

cy*cx,cy^2,cy*cz;

cz*cx,cz*cy,cz^2];

//Transforming to global matrix

g:=zeros(N,N);

for m,n in 1:3 loop

g[3*(C[i,1]-1)+m,3*(C[i,1]-1)+n]:=X[m,n];

g[3*(C[i,2]-1)+m,3*(C[i,2]-1)+n]:=X[m,n];

g[3*(C[i,2]-1)+m,3*(C[i,1]-1)+n]:=-X[m,n];

g[3*(C[i,1]-1)+m,3*(C[i,2]-1)+n]:=-X[m,n];

end for;

G_star:=G+g;

G:=G_star;

end for;

//Implementing boundary

for i in boundary loop

for j in 1:N loop

G[i,j]:=id[i,j];

end for;

end for;

//Solving displacement

displacement:=Modelica.Math.Matrices.solve(G,F);

//Solving reaction

reaction:=(G_star*displacement)-F;

//Eliminating float error

for i in 1:N loop

reaction[i]:=if abs(reaction[i])<=err then 0 else reaction[i];

displacement[i]:=if abs(displacement[i])<=err then 0 else displacement[i];

end for;

end Trusses3D_Tes;

|

Berikut adalah hasil simulasi yang dilakukan:

Berikut link Youtube yang berisi penjelasan tentang algoritma dan penulisan kode OpenModelica metode diatas:

Optimization - Metode Numerik/16 November 2020

Function to be solved

function Func_Optimization input Real x; import Modelica.Math; output Real y; algorithm y:=2*sin(x)-x^2/10; end Func_Optimization;

Optimization - Golden Section

model Opt_Gold

parameter Real xlo=0;

parameter Real xhi=4;

parameter Integer N=8; // maximum iteration

parameter Real es=0.0001; // maximum error

Real f1[N], f2[N], x1[N], x2[N], ea[N];

Real xopt, fx;

protected

Real d, xl, xu, xint, R=(5^(1/2)-1)/2;

algorithm

xl := xlo;

xu := xhi;

for i in 1:N loop

d:= R*(xu-xl);

x1[i]:=xl+d;

x2[i]:=xu-d;

f1[i]:=Func_Optimization(x1[i]);

f2[i]:=Func_Optimization(x2[i]);

xint:=xu-xl;

if f1[i]>f2[i] then

xl:=x2[i];

xopt:=x1[i];

fx:=f1[i];

else

xu:=x1[i];

xopt:=x2[i];

fx:=f2[i];

end if;

ea[i]:=(1-R)*abs((xint)/xopt);

if ea[i]<es then

break;

end if;

end for;

end Opt_Gold;

Optimization - Newton

model Opt_Newton parameter Real g=2.5; //initial guess parameter Integer N=8; // maximum iteration parameter Real es=0.0001; // maximum error Real X[N]; Real xopt, fx, ea[N]; algorithm X[1]:=g; ea[1]:=1; for i in 2:N loop X[i]:=X[i-1]-Func_Optimization_Der(X[i-1])/Func_Optimization_Der_Der(X[i-1]); xopt:=X[i]; ea[i]:=abs(1-X[i-1]/X[i]); if ea[i]<es then break; end if; end for; fx:=Func_Optimization(xopt); end Opt_Newton;

Optimization - Parabolic

model Opt_Parabolic

parameter Real g1=0; //initial guess

parameter Real g2=1; //initial guess

parameter Real g3=4; //initial guess

parameter Integer N=5; // maximum iteration

parameter Real es=0.0001; // maximum error

Real x1, x2, x3, xopt, xp[N], ea[N];

//Real xl, xm, xu;

Real fx1, fx2, fx3, fx, A[4], A_star[4];

algorithm

x1:=g1;

x2:=g2;

x3:=g3;

for i in 1:N loop

fx1:=Func_Optimization(x1);

fx2:=Func_Optimization(x2);

fx3:=Func_Optimization(x3);

xp[i]:=(fx1*(x2^2-x3^2)+fx2*(x3^2-x1^2)+fx3*(x1^2-x2^2))/(2*fx1*(x2-x3)+2*fx2*(x3-x1)+2*fx3*(x1-x2));

xopt:=xp[i];

fx:=Func_Optimization(xp[i]);

A:={x1,x2,x3,xp[i]};

A_star:=Modelica.Math.Vectors.sort(A);

if xp[i]>x2 then

x1:=A_star[2];

x2:=A_star[3];

x3:=A_star[4];

else

x1:=A_star[1];

x2:=A_star[2];

x3:=A_star[3];

end if;

end for;

ea[1]:=1;

for i in 2:N loop

ea[i]:=abs(1-xp[i-1]/xp[i]);

if ea[i]<es then

break;

end if;

end for;

end Opt_Parabolic;

Tugas Besar Metode Numerik (Latihan)- Metode Numerik/23 Desember 2020

Tugas Besar Metode Numerik - Josiah Enrico S

Jawaban UAS 2021 - Josiah Enrico S

Revisi dan Narasi

No 1

Langkah-langkah optimasi

- Tentukan tujuan optimasi lalu definisikan semua parameter yang ada.

- Menentukan boundary dan constraint pada struktur

- Menentukan asumsi dalam permodelan struktur

- Melakukan analisa struktur (komputasi)

- Setelah mendapat persamaan utama, variasikan nilai objektif yang akan dioptimasi

- Gunakan metode optimasi yang sesuai

- Setelah mendapatakan nilai optimasi, lakukan pengujian variabel dengan analisa

- Jika hasilnya memuaskan, optimasi selesai. Jika hasilnya belum memuaskan, ulangi dari langkah 6

No 2

| Tujuan Optimasi: |

|

| Asumsi: |

|

| Dalil Fisika: |

|

No 3

| Persamaan aljabar lokal tiap elemen | Persamaan aljabar global tiap elemen |

|

Truss A (1 to 2) [ 0 0 0 0 ] (1x)

k = (A*E/L) [ 0 1 0 1 ] (1y)

[ 0 0 0 0 ] (2x)

[ 0 -1 0 -1 ] (2y)

|

Truss A (1 to 2) [ 0 0 0 0 0 0 0 0 ] (1x)

[ 0 1 0 1 0 0 0 0 ] (1y)

[ 0 0 0 0 0 0 0 0 ] (2x)

k = (A*E/L) [ 0 -1 0 -1 0 0 0 0 ] (2y)

[ 0 0 0 0 0 0 0 0 ] (3x)

[ 0 0 0 0 0 0 0 0 ] (3y)

[ 0 0 0 0 0 0 0 0 ] (4x)

[ 0 0 0 0 0 0 0 0 ] (4y)

|

|

Truss B (2 to 3) [ 0.5 0.5 -0.5 -0.5 ] (2x)

k = (A*E/L) [ 0.5 0.5 -0.5 -0.5 ] (2y)

[-0.5 -0.5 0.5 0.5 ] (3x)

[-0.5 -0.5 0.5 0.5 ] (3y)

|

Truss B (2 to 3) [ 0 0 0 0 0 0 0 0 ] (1x)

[ 0 0 0 0 0 0 0 0 ] (1y)

[ 0 0 0.5 0.5 -0.5 -0.5 0 0 ] (2x)

k = (A*E/L) [ 0 0 0.5 0.5 -0.5 -0.5 0 0 ] (2y)

[ 0 0 -0.5 -0.5 0.5 0.5 0 0 ] (3x)

[ 0 0 -0.5 -0.5 0.5 0.5 0 0 ] (3y)

[ 0 0 0 0 0 0 0 0 ] (4x)

[ 0 0 0 0 0 0 0 0 ] (4y)

|

|

Truss C (2 to 4) [ 0.5 -0.5 -0.5 0.5 ] (2x)

k = (A*E/L) [-0.5 0.5 0.5 -0.5 ] (2y)

[-0.5 0.5 0.5 -0.5 ] (4x)

[ 0.5 -0.5 -0.5 0.5 ] (4y)

|

Truss C (2 to 4) [ 0 0 0 0 0 0 0 0 ] (1x)

[ 0 0 0 0 0 0 0 0 ] (1y)

[ 0 0 0.5 -0.5 0 0 -0.5 0.5 ] (2x)

k = (A*E/L) [ 0 0 -0.5 0.5 0 0 0.5 -0.5 ] (2y)

[ 0 0 0 0 0 0 0 0 ] (3x)

[ 0 0 0 0 0 0 0 0 ] (3y)

[ 0 0 -0.5 0.5 0 0 0.5 -0.5 ] (4x)

[ 0 0 0.5 -0.5 0 0 -0.5 0.5 ] (4y)

|

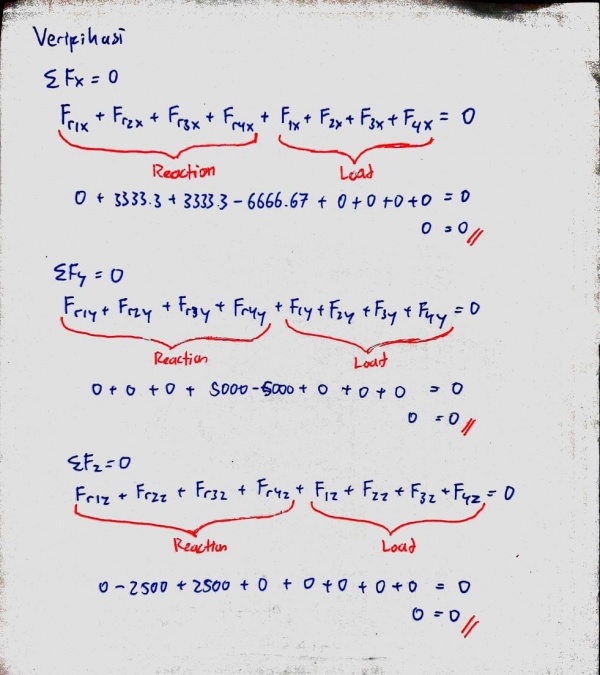

No 4

No 5

Fungsi Objektif

| displacement= | [A*E/L][Uglobal]* deltaL = [F] |

| Reaction Force= | R = [A*E/L][Uglobal]*deltaL - [F] |

| Stress= | Stress = E*(deltaL)/A |

Constraint/Boundary

- Berdasarkan struktur di nomor 3, boundary condition terdapat pada titik 3 dan 4

No 6

Asumsi:

- Area: 0.16 (Persegi 0.4 x 0.4 meter)

- Elastisitas: 193 GPa (SS 304)

- Yield: 215 MPa (SS 304)

- rho air murni: 1000 kg/m3

- Gravitasi: 9,81 m/s2

- Volume air: 200000 gallon / 1136 m3

No 7

|

Kode Modelica model UAS_METNUM

//define initial variable

parameter Integer Points=4; //Number of Points

parameter Integer Trusses=3; //Number of Trusses

parameter Real Yield=215e6; //Yield Strength (Pa)

parameter Real Area=0.16; //Area Block Profile (0.4 * 0.4) (m2)

parameter Real Elas=193e9; //Elasticity SS 304 (Pa)

parameter Real Volume=1135; //m3 from 200000 gallons

parameter Real rho=1000; //kg/m3

parameter Real W=Volume*rho*9.81;

//define connection

parameter Integer C[Trusses,2]=[1,2;

2,3;

2,4];

//define coordinates (please put orderly)

parameter Real P[Points,3]=[0,37,0;

0,8,0;

-8,0,0;

8,0,0];

//define external force (please put orderly)

parameter Real F[Points*3]={0,-W,0,

0,0,0,

0,0,0,

0,0,0};

//define boundary

parameter Integer b[:]={3,4};

//solution

Real displacement[N], reaction[N];

Real check[3];

Real stress1[Trusses];

Real safety[Trusses];

Real dis[3];

Real Str[3];

protected

parameter Integer N=3*Points;

Integer boundary[3*size(b,1)]=cat(1,(3*b).-2,(3*b).-1,3*b);

Real q1[3], q2[3], g[N,N], G[N,N], G_star[N,N], id[N,N]=identity(N), cx, cy, cz, L, X[3,3];

Real err=10e-10, ers=10e-4;

algorithm

//Creating Global Matrix

G:=id;

for i in 1:Trusses loop

for j in 1:3 loop

q1[j]:=P[C[i,1],j];

q2[j]:=P[C[i,2],j];

end for;

//Solving Matrix

L:=Modelica.Math.Vectors.length(q2-q1);

cx:=(q2[1]-q1[1])/L;

cy:=(q2[2]-q1[2])/L;

cz:=(q2[3]-q1[3])/L;

X:=(Area*Elas/L)*[cx^2,cx*cy,cx*cz;

cy*cx,cy^2,cy*cz;

cz*cx,cz*cy,cz^2];

//Transforming to global matrix

g:=zeros(N,N);

for m,n in 1:3 loop

g[3*(C[i,1]-1)+m,3*(C[i,1]-1)+n]:=X[m,n];

g[3*(C[i,2]-1)+m,3*(C[i,2]-1)+n]:=X[m,n];

g[3*(C[i,2]-1)+m,3*(C[i,1]-1)+n]:=-X[m,n];

g[3*(C[i,1]-1)+m,3*(C[i,2]-1)+n]:=-X[m,n];

end for;

G_star:=G+g;

G:=G_star;

end for;

//Implementing boundary

for i in boundary loop

for j in 1:N loop

G[i,j]:=id[i,j];

end for;

end for;

//Solving displacement

displacement:=Modelica.Math.Matrices.solve(G,F);

//Solving reaction

reaction:=(G_star*displacement)-F;

//Eliminating float error

for i in 1:N loop

reaction[i]:=if abs(reaction[i])<=err then 0 else reaction[i];

displacement[i]:=if abs(displacement[i])<=err then 0 else displacement[i];

end for;

//Checking Force

check[1]:=sum({reaction[i] for i in (1:3:(N-2))})+sum({F[i] for i in (1:3:(N-2))});

check[2]:=sum({reaction[i] for i in (2:3:(N-1))})+sum({F[i] for i in (2:3:(N-1))});

check[3]:=sum({reaction[i] for i in (3:3:N)})+sum({F[i] for i in (3:3:N)});

for i in 1:3 loop

check[i] := if abs(check[i])<=ers then 0 else check[i];

end for;

//Calculating stress in each truss

for i in 1:Trusses loop

for j in 1:3 loop

q1[j]:=P[C[i,1],j];

q2[j]:=P[C[i,2],j];

dis[j]:=abs(displacement[3*(C[i,1]-1)+j]-displacement[3*(C[i,2]-1)+j]);

end for;

//Solving Matrix

L:=Modelica.Math.Vectors.length(q2-q1);

cx:=(q2[1]-q1[1])/L;

cy:=(q2[2]-q1[2])/L;

cz:=(q2[3]-q1[3])/L;

X:=(Elas/L)*[cx^2,cx*cy,cx*cz;

cy*cx,cy^2,cy*cz;

cz*cx,cz*cy,cz^2];

Str:=(X*dis);

stress1[i]:=Modelica.Math.Vectors.length(Str);

end for;

//Safety factor

for i in 1:Trusses loop

if stress1[i]>0 then

safety[i]:=Yield/stress1[i];

else

safety[i]:=0;

end if;

end for;

end UAS_METNUM;

|