M. Said Jiddan Walta

Contents

[hide]Introduction

Hello, my name is M. Said Jiddan Walta, commonly referred to as Jiddan. This page will be a platform for me to describe the results of my conscious learning and development during my short time in the Numerical Method class.

NPM: 2106718256

Major: Mechanical Engineering

E-mail: m.said11@ui.ac.id

I entered Mechanical Engineering fueled by a profound interest in ballistics and defense technology, and I hope to learn more about the foundations of mechanics and energy transfer that are the building blocks for understanding my field of interest.

Session Review

23 May 2023 Class

As an introductory class, our lecturer Dr. Ahmad Indra Siswantara introduced himself and his focus of study on the concept of consciousness, and invites us to participate in the discussion on the importance of applying consciousness in our daily lives as well as the recurrence of difficult concepts in the problems that we face that remind us to practice consciousness about the limitations of human understanding. Outside class time, a follow-up discussion was conducted in the class group for practicing consciousness by inviting discussion on the most realistic solution of a typical limit problem. We were invited to explore the notion of infinity and the limitations of computing involving values that are typically referred to as 'undefined'. Lastly, our project for the remainder of the semester was introduced.\

30 May 2023 Class

In todays class of Numerical Method, Pak DAI asked us to discuss the Hydrogen Tank Design and Optimization project within the class with every class member to gain better knowledge on developing our overall results. Throughout the class, the discussion was moderated by Patrick Samperuru as a replacement for the class coordinator, M. Jiddan Walta, who was at the time absent due to exchange matters. In this discussion, we started by making an outline on the project objective function which was to create a functional hydrogen tank design that is optimized following the constraint parameters of pressure at 8 bars, a capacity of 1 liter, and a maximum budget of 500,000 IDR. According to Benarido Amri, the ideal material for a high pressure cylinder has a very high tensile strength, a low density, and does not react with hydrogen or allow hydrogen to diffuse into it. Most pressure cylinders to date have used austenitic stainless steel. Patrick Samperuru then continued the discussion on the material by stating several potential materials that can be used based on the types of the hydrogen tanks, being type I of all metal, type II of metal with carbon fiber wrap, type III composite with metal lining, type IV composite with non-metal lining stating that type I and II is the most probable for the design. Next, M. Azkhariandra Aryaputra stated the importance of several design considerations such as storage tank design, safety measures, leakage mitigation, and material compatibility. Following the discussion of materials, Ariq Dhifan and Fadhlan Dindra added several materials that they want to use.

Next, we conversed the 3 main points needed in our optimization. This include the design variable, objective function, constraint which can be different for every class member. Patrick Samperuru started by explain that his objective function is to accommodate the use of hydrogen tanks in the field that is more complex and dynamic meaning it would need a constraint of a high strength and wear fatigue so that is can used for long term, which is achieved by choosing an all metal tank. For Vegantra Siaga, he wanted a pressure constraint because hydrogen storage systems often have pressure limits to ensure safe operation, where pressure constraints can be defined as upper and lower bounds on the hydrogen storage pressure that prevent the storage system from operating outside the desired pressure range. According to Faris Pasya, space and weight constraints can be used as well depending on the application, there may be limitations on the available space or weight of the pressurized hydrogen system. These constraints can influence the choice of tank size, material selection, and system layout. Next, M. Annawfal Rizky stated that he wants the constraint to be the compatibility with hydrogen, The tank material should be compatible with hydrogen gas to prevent any chemical reactions, embrittlement, or degradation that could affect the tank's performance or safety. Material selection is crucial to ensure compatibility and avoid hydrogen diffusion or leakage. For M. Ikhsan Rahadian, we chose safety due to the high pressure of hydrogen, and its highly flammable, the safety of the tank is very important. choosing the right material such as aluminum alloy 6061 can increase the strength and safety, and also choose the right design.

Numerical Method - Case Study of Pressurized Hydrogen Storage

Substance Study

For the Numerical Method class, we were tasked with a project on the design and optimization of a Pressurized Hydrogen Storage, with the constraint parameters being the gas pressurized at 8 bars and the required storage volume being 1 liters. Hydrogen as a gas is useful for many industrial purposes as well as an energy source for certain vehicles and industrial appliances, and is often stored by the hundreds of liters in large tanks.

Hydrogen in its frequently encountered diatomic form of H2 gas is the lightest gas in the universe and is generally unreactive, but is readily combustible in its gaseous form. As an ultra-light gas, hydrogen occupies a substantial volume under standard conditions of pressure, i.e. atmospheric pressure. In order to store and transport hydrogen efficiently, this volume must be significantly reduced. The general methods for improving hydrogen transport and storage efficiency is through high-pressure storage in the gaseous form, very low temperature storage in the liquid form, or hydride-based storage in the solid form, though the most common being the first two. Having the highest yield of hydrogen in a fixed container volume requires pressurization up to 700 bars or more, which requires large amounts of energy and strong container design. Liquid hydrogen is cryogenic in nature, and therefore needs to be stored in extremely low temperatures to keep it in its liquid state, or at least to keep a majority of it from evaporating. For the case that we are assigned, the required storage amount is small and the pressure is also constrained, therefore the focus is not the efficiency of hydrogen yield being stored but instead the cost and material effectiveness of the container.

For the purpose of this project, it is important to begin designing the product with understanding the substance that it is meant to store, in this case hydrogen pressurized at 8 bars.

In its gaseous form at 8 bars of pressure and local indoor temperature in Indonesia being around 30 degrees Celsius, hydrogen gas has a density of 0.627 kilograms per cubic meter, which results in 1 liter or 0.001 cubic meters of the gas weighing 0.627 grams or less than 0.001 kg. This means that storing the gas at these conditions will only require a container material and design that can withstand wall pressure of 8 bars, while ideally having lower density such that the total weight of the container far exceeds the weight of the gas being stored.

Material Choice

Our goal in this case is to select a suitable material for the storage tank, with our priorities being focused on fulfilling the load requirements presented by the hydrogen in a safe manner, low weight, and cost-effectiveness. Safety is of great importance when designing hydrogen storage. The material used must possess high strength, resistance to fracture, and be capable of withstanding high pressures. Metals like steel and aluminum alloys are commonly employed due to their mechanical properties. However, special attention must be given to hydrogen embrittlement, a phenomenon that can cause material degradation and reduce safety. Thus, selecting materials with high resistance to hydrogen embrittlement, such as specific grades of steel, becomes crucial. Hydrogen has the smallest molecule size, which means it can permeate through certain materials over time. Permeation can lead to hydrogen loss, compromising the efficiency of the storage system and potentially raising safety concerns. Hence, selecting materials with low hydrogen permeability is important. Metals like steel and aluminum have relatively low permeability, especially when coated with appropriate barriers to minimize permeation. Composites, on the other hand, can have higher permeability, although this can be mitigated by employing diffusion barriers or modifying the polymer matrix.

On the topic of optimization of weight, composite materials, such as carbon fiber reinforced polymers (CFRP), offer an advantageous balance between strength and weight. CFRP has been commonly used for hydrogen storage tanks in certain regions, having the walls consist of a lightweight polymer matrix reinforced with carbon fibers, providing exceptional strength-to-weight ratios. These materials enable the construction of lightweight tanks. The cost of materials plays a significant role in the overall economics of hydrogen storage systems. Metals like steel are relatively affordable and widely available, making them cost-effective choices for bulk storage applications. However, advanced alloys with improved resistance to hydrogen embrittlement can be more expensive. In contrast, composite materials like CFRP have higher upfront costs due to their manufacturing processes.

With these factors in mind, the most likely choice is selecting a lighter grade of steel with mechanical properties that can supplement the requirements, with additional modifications and treatments to the material to further lower its hydrogen permeability.

Numerical Method - Design of Pressurized Hydrogen Storage

In the section below, I will proceed to implement knowledge I have learned in Numerical Methods class as well as prior classes in order to determine the most suitable optimized design for the hydrogen storage based on constraints and optimizing objective functions, with the focus being on optimization based on: a) geometrical constraints, b) strength constraints, and c) cost constraints.

Based on our class discussions, I have decided to select AISI 316 austenitic stainless steel as the material for its balance in availability in the public domain, strength and durability, machinability and malleability for manufacture, as well as compatibility with hydrogen permeability reduction treatments. Austenitic stainless steels have also been the one of the main selections for materials used in industrial hydrogen storage manufacture. However, I understand that the material can be difficult to obtain for students, therefore further investigation into more accessible materials are necessary.

Geometrical Constraint

Base Geometry

One of the main components of designing the pressurized hydrogen storage is the measurements and geometry of the storage. Through our discussions in class and individual case studies, students in our class collectively agreed that the ideal shape of the storage is a cylindrical shape akin to those generally utilized by the industry. The parameters of the cylindrical shape however still needs to be found out using the methods that we have learned over the entire course of Numerical Method class.

The goals of the optimization process of this hydrogen storage as mentioned above in the case study section is to create a pressurized hydrogen storage that fulfills the requirements while remaining cost-effective. One of the main contributors to cost of production is the amount of material being used, which in the case of a cylindrical container, equal to the surface area of the product. The lower the total surface area of the product, the lower the total effective material that is required to craft it. For our case, the surface area needs to be minimized while maintaining a constraint of volume being equal to 1 liter or 1000 cubic centimeters. The radius and height of a cylinder that fulfills both qualities can be obtained using a simple optimization function that can be numerically computed using suitable code made in Python or MATLAB. For the purpose of this project, I utilized Python to create a code that manually computes the radius and height of a cylinder of 1000 centimeter cubic volume. There are other libraries such as SciPy that has compiled code for optimization into a singular function, but for the purpose of learning the following code is done manually.

Objective: Minimize surface area of cylindrical structure

Constraint: Internal volume of cylindrical structure must be equal to 1000 cubic centimeters (1 liter)

The first section of the code is to obtain a general range of radius values where the surface area is minimum, shown below:

from math import pi

import pprint

'''

r = radius

circle_area = pi * r**2

circle_circumference = 2 * pi * r

h = height

cylinder_volume = pi * r**2 * h

cylinder_surface = 2 * (pi * r**2) + (2 * pi * r * h)

constraint for cylinder_volume be a constant of 1 liter (cubic centimeter)

cylinder_volume = 1000

h in terms of r

h = 1000/(pi * r**2)

substitute in

cylinder_surface = 2 * (pi * r**2) + (2 * pi * r * 1000/(pi * r**2))

'''

mylist = [] # create a list of (surface area, radius)

for r in range(1, 21): # assume a maximum of 20cm radius

cylinder_surface = 2 * (pi * r**2) + (2 * pi * r * 1000/(pi * r**2))

mylist.append((cylinder_surface, r))

# test

pprint.pprint(mylist)The code above displays iterations from radius of 1 cm to 20 cm and their corresponding surface area values. By inspection, we can see that the minimum surface area occurs in the region between radius of 5 and 6 cm. For precision, we continue the code with a looping function to obtain the precise point where the minimum surface area occurs, and continue with computing the height for verification.

# once we find the range where area is minimum

# we can increment in smaller steps for precision

r = 5

surface_list = []

while True:

cylinder_surface = 2 * (pi * r**2) + (2 * pi * r * 1000/(pi * r**2))

surface_list.append((cylinder_surface, r))

r += 0.01

if r > 6:

break

print('minimum surface area and radius: ', min(surface_list))

min_surface = min(surface_list)[0]

sf = "Minimum surface of a 1000ml tank = {:0.2f} square centimeters"

print(sf.format(min_surface))

radius = min(surface_list)[1]

print("Radius of 1000ml tank = {:0.2f} centimeters".format(radius))

height = 1000/(pi * radius**2)

print("Height of 1000ml tank = {:0.2f} centimeters".format(height))

sf = "Ratio of height to radius of a minimized surface can = {:0.2f}"

print(sf.format(height/radius))

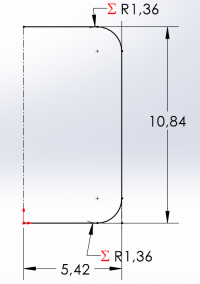

The result obtained by the code is shown on the right, where the suggested geometry for a cylindrical tank for 1 liter volume should maintain a 2:1 height to radius ratio with the radius being 5.42 cm, and the height at 10.84 cm consequently.

End Cap Compensation

Using a purely cylindrical geometry for the storage tank is likely to be dangerous due to the existence of the corners on the ends, which present stress concentration regions or sites of failure. Most pressure vessels take on a curved shape on their ends to reduce stress concentration by using three geometries: hemispherical, ellipsoidal, and torispherical. Highest volume and surface area addition to lowest addition also goes in the same order. Therefore, since our goal is to minimize surface area while maintaining the same volume, it is most efficient to take on a torispherical end cap shape. The torispherical shape can be simplified as the cylindrical shape that has been given partial filleting. This filleting adjustment will reduce the overall volume of the structure, however. Therefore we need to adjust the geometrical parameters to compensate for the reduction from the filleting to create the end cap.

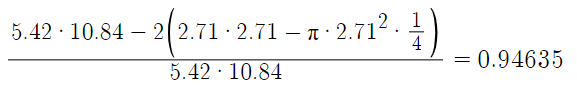

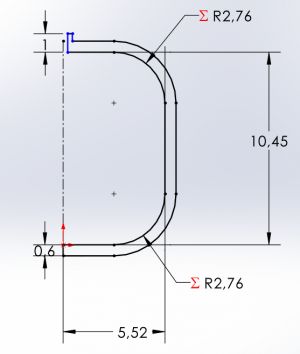

We can set a fillet of radius equal to half the radius of the container to create a smooth curvature for greater stress concentration reduction. An example sketch has been made via a computer-aided design program to visualize the reduction in cross-sectional area from the circumferential face. By law of proportionality, a percentage reduction in the cross sectional area would be equal to the same reduction in volume, therefore we can calculate the percentage reduction and apply inversely to our required volume to obtained the new increased volume constraint.

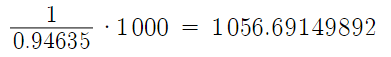

As shown, assuming a fillet radius of half the container radius, we have a new volume constraint of 1056.69 cubic centimeters to account for the percentage reduction in volume following formation of torispherical end caps through filleting. We can repeat the iteration process that was previously used to obtain new radius and height values for the cylinder. Upon iterating the first section of code, we find that the minimum surface area occurs between values of 5 and 6 cm radii again, therefore the upper and lower bounds of the second set of code do not need to be adjusted. The final results as as follows:

minimum surface area and radius: (574.3098652360588, 5.519999999999989)

Minimum surface of a 1056.69ml tank = 574.31 square centimeters

Radius of 1056.69ml tank = 5.52 centimeters

Height of 1056.69ml tank = 10.45 centimeters

Ratio of height to radius of a minimized surface can = 1.89Strength Constraint

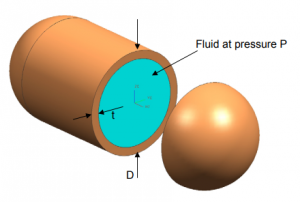

In a pressurized container environment, the most important requirement is that the container material's thickness and strength should be able to withstand the pressure exerted on the walls. Assuming an ideal situation where gaseous movement inside the container is uniform and steady, therefore of equal velocity at every point in space and time, we can assume the internal walls of the container experienced constant static stress equal to the pressure of the gas in the normal direction at every point. In this case, we can disregard the effects of shear stress or bending moments that might be present as theoretically the normal/axial stress presented by the pressure would be the most significant. These kind of assumptions can be grouped into a single assumption where we assume the container to be a thin-walled pressure vessel.

The constraints for this assumption to be true is that the radius must be at least 5 times the wall thickness, which we will verify later. The stresses that exist within a thin-wall cylindrical component are circumferential (hoop) stress and longitudinal stress. Radial stress also exists but can be neglected due to the radius being much greater than the wall thickness. Hoop stress and longitudinal stress can be obtained via the following formulae:

where p is the gage pressure of the fluid and t is the wall thickness.

Since the hoop stress is equal to twice the longitudinal stress, we can set it as the objective function over the latter since quantitatively failure will occur earlier due to the hoop stress instead of the longitudinal stress. Since we have already calculated the container radius previously, have the pressure constraint set at 8 bars of gage pressure from the hydrogen, we can numerically iterate for the thickness of the vessel to obtain a range of values of hoop stresses. From there, we can select thicknesses with corresponding hoop stresses that do not exceed allowable stress of the material, in this case we arbitrarily set at 0.875 of the yield strength of the material. In containment purposes such as these, deformations in the container can already be considered failure or at least compromising for the storage facility, hence the consideration for setting the constraint at the yield strength.

Literary Parameters

The range of wall thickness that is applicable is also not arbitrary outside of remaining less than one-fifth of the vessel radius. ASME BPV Code Section VIII D.1 states that wall thickness should always be at least 1/16 in (1.59 mm), not considering corrosion allowance, material, or dimensions. Literary source "Analysis, Synthesis, and Design of Chemical Processes" gives heuristics for wall thickness for rigidity based on vessel diameter: 4 mm (0.25 in) for 1.07 m (42 in) diameter and less than 8.1mm (0.32 in) for 1.07-1.52 m (42-60 in) diameter, and 11.7 mm (0.38 mm) for more than 1.52 m (60 in) diameter (Turton et al., 2012). Taking a conservative approach of setting the minimum thickness to be in between 1.59mm and 4mm, thereby 2.8mm, we will begin the iteration of the thickness from 2.80mm up to 11.04mm at increments of 0.01mm for precision.

Based on data obtained from Ferrobend, a typical workpiece of AISI 316 stainless steel has the mechanical properties as shown. For the purpose of our testing, we will utilize both a conservative and less conservative method by setting our limit at the yield strength as well as the maximum tensile strength to signify failure.

Iteration Process

We can use a simple code to numerically iterate the possible thickness and hoop stress values:

r = 5.52e-2

p = 800000

t = 2.8e-3

while t < 11e-3:

hoop = (r * p)/(t)

print('for thickness', t, 'hoop stress =', hoop, "Pa")

t += 0.1e-3

if hoop > 205e9:

breakFrom the above code we obtain hoop stress values for each iterated thickness values from 2.8 mm to 11 mm. A further constraint was placed in the final lines where the looping would stop if the total hoop stress exceeded the yield strength of the material (stainless steel AISI 316).

From the results, all possible thickness values from 2.8mm to 11mm on 0.1mm increments remain within the yield strength constraint, therefore are all applicable. Shown below are the results from the code for thickness range 4 mm to 7 mm, with hoop stress values ranging below 10 MPa, which is less than 5% of the yield strength limit.

for thickness 0.004099999999999999 hoop stress = 10770731.707317077 Pa

for thickness 0.004199999999999999 hoop stress = 10514285.714285716 Pa

for thickness 0.004299999999999999 hoop stress = 10269767.441860467 Pa

for thickness 0.004399999999999999 hoop stress = 10036363.636363639 Pa

for thickness 0.0045 hoop stress = 9813333.333333334 Pa

for thickness 0.0046 hoop stress = 9600000.0 Pa

for thickness 0.0047 hoop stress = 9395744.680851063 Pa

for thickness 0.0048000000000000004 hoop stress = 9200000.0 Pa

for thickness 0.004900000000000001 hoop stress = 9012244.897959182 Pa

for thickness 0.005000000000000001 hoop stress = 8831999.999999998 Pa

for thickness 0.005100000000000001 hoop stress = 8658823.529411763 Pa

for thickness 0.0052000000000000015 hoop stress = 8492307.69230769 Pa

for thickness 0.005300000000000002 hoop stress = 8332075.47169811 Pa

for thickness 0.005400000000000002 hoop stress = 8177777.777777774 Pa

for thickness 0.005500000000000002 hoop stress = 8029090.909090905 Pa

for thickness 0.0056000000000000025 hoop stress = 7885714.285714282 Pa

for thickness 0.005700000000000003 hoop stress = 7747368.421052628 Pa

for thickness 0.005800000000000003 hoop stress = 7613793.103448272 Pa

for thickness 0.005900000000000003 hoop stress = 7484745.76271186 Pa

for thickness 0.006000000000000004 hoop stress = 7359999.999999995 Pa

for thickness 0.006100000000000004 hoop stress = 7239344.262295078 Pa

for thickness 0.006200000000000004 hoop stress = 7122580.645161286 Pa

for thickness 0.006300000000000004 hoop stress = 7009523.809523805 Pa

for thickness 0.006400000000000005 hoop stress = 6899999.999999995 Pa

for thickness 0.006500000000000005 hoop stress = 6793846.153846148 Pa

for thickness 0.006600000000000005 hoop stress = 6690909.090909085 Pa

for thickness 0.006700000000000005 hoop stress = 6591044.776119398 Pa

for thickness 0.006800000000000006 hoop stress = 6494117.6470588185 Pa

for thickness 0.006900000000000006 hoop stress = 6399999.999999994 Pa

for thickness 0.007000000000000006 hoop stress = 6308571.428571423 PaCost Constraints

With the geometrical parameters available, we need to compare with the cost constraint that was provided which is that the total cost for materials used should not exceed Rp500.000,-. Therefore, from the material that has been previously considered, we must select the thickness which remain within the cost range. As this is a small-size thin-walled vessel, the most likely method of manufacture is through sheet-metal manufacturing like those used to manufacture storage and beverage cans. Therefore, material purchase would be done in the sheet-metal or plate form.

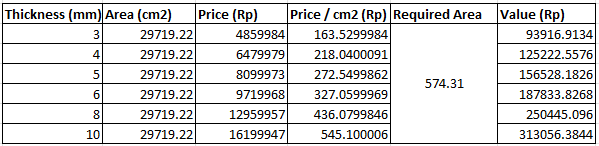

In the table above, the selection of thickness ranges have been minimized to only include those within our region of interest. Since steel plates are rarely distributed at small surface areas such as the one in our application, a cost per area analysis approach is used based on the data obtained from PT Citra Anggun Lestari. Similar to the circumstances encountered in the strength constraint, all possible thickness values result in material costs that are lower than our set cost constraint. Therefore to select the thickness that we will use, we will also consider the need to minimize the weight and maintain a reasonable amount of strength, which suggests the selection of the median 6 mm wall thickness for the container.

CAD Modelling and Simulation

Utilizing the geometrical results that have been obtained after applying constraints, a CAD model can be constructed. An initial sketch pertaining to the determined geometries were made before an offset sketch was constructed with an offset distance equal to the intended thickness. Nearing the upper region, a slight reduction was applied to make room for exit of the gas via a valve mechanism that will be added. The sketch made will only include one half of the cross section.

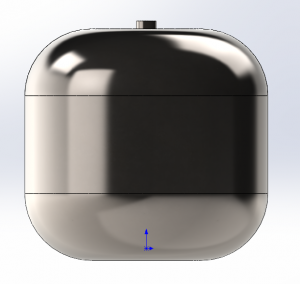

With the half-sketch completed, using the solid revolve function in any CAD software will allow to revolve the closed sketch contour around an axis of rotation, in this case one of the center lines that have been made in the sketch. The result will be a solid model of a compressed cylindrical tank with a psuedo-torispherical end cap with a total volume of 1000.61 cubic centimeters. There is a slight addition to the volume measured in the software likely due to some rounding and truncations done in the iterations for obtaining the measurement, as such is one of the limitations of utilizing numerical approach. However, the discrepancy is negligible and should not affect the design's ability to fulfill its original function.

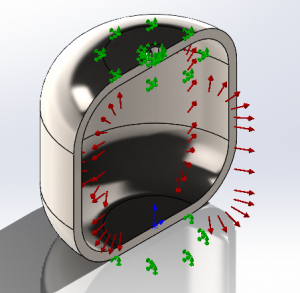

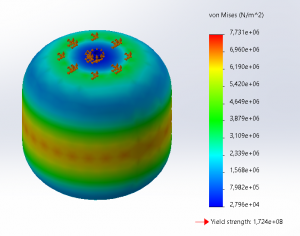

To verify the design's ability to contain the pressurized hydrogen gas at 8 bars of (gage) pressure, a simple static simulation was conducted on the design. The use of a static simulation is justified due to the nature of the assumptions made during the design process, where the container is a thin-walled vessel that experiences primarily normal forces and negligible shear or bending, and that the gas contained inside is uniform and steady in nature with constant properties. A pressure force of 800 kPa, equal to 8 bars of pressure, was applied on all sections of the internal wall through the use of sectional view as seen on the image. A fixed constraint was applied on the upper and lower surface on the outside of the tank as prerequisite for the simulation to run. Automatic meshing is done by the software, however it could be argued that more precise mesh convergence analysis would yield better quality results. Material was set to Stainless Steel AISI 316 with stock properties, with the yield strength being slightly different at 172 MPa instead of the 205 MPa that was used in my case.

Upon running the simulation and setting the deformation scale to 1:1 so as to avoid misleading deformation appearance, a stress plot was obtained, as shown on the corresponding image. In line with the calculations done by the numerical method, the maximum stress experienced by the container was the hoop stress with a value equal to 7.7 MPa, close to the predicted value of 7.4 MPa for a tank thickness of 6 mm. The slight difference is likely to be caused by meshing that could be improved via mesh convergence analysis. However, the most important thing to note is that no region in the container that experienced stress exceeded or even came close to exceeding the limit set by the yield strength of the material, with the maximum stress only being about 5% of the yield strength. Therefore, it can be argued that the design is still overdesigned and reductions in the thickness of the metal is possible to optimize the costs even more.

Conclusion

In conclusion, by applying numerical approach towards setting geometrical, strength, and cost constraints in designing and optimizing a hydrogen storage tank, suitable dimensions can be obtained. Based on the process that was done, the final design was a cylindrical tank with a psuedo-torispherical end cap, with a radius-to-height ratio of 1.89 for the cylindrical body. From the numerical iterations, a large range of thicknesses of the container wall could be used, ranging from the minimum of 2.8 mm to maximum of 11 mm without experiencing yielding or failure. Selecting a material of stainless steel AISI 316 for its properties and confirmed capability for hydrogen storage purposes, a price range for the raw material was obtained. With the intention of optimizing manufacturing costs, it is shown that taking the smallest thickness possible of 3 mm set by the constraints would be most optimal for price and have containment properties that are not as overengineered as the 6 mm selection that was initially used.

Shown above is the final model with adjusted thickness to 3 mm wall thickness and addition of a needle valve for release and addition of gas functions. Moving forward, I find it important to investigate into materials with higher availability and accessibility for students, such as plastics or metals obtained from reused containers (for example used stove gas tanks) in order to manufacture it by ourselves.

My Conscious Effort in Numerical Method Learning - Video Presentation

My video presentation can be accessed here: https://www.youtube.com/watch?v=nMHzQnnjwpA

It was important for me to be mindful and apply conscious effort during the process of this project. To me, what it meant by conscious effort means applying effort while being aware of my abilities, my limitations, and the possible tools that could help my work from both the past and the present. It means being conscious of all the resources that I have available now and have obtained in past courses to select the right course of action, while being aware that there are some methods that are not feasible or those I have limited understanding of therefore requiring consultation with experts or other resources.

From the process and the result of this project, it became clear to me how important and applicative consciousness is for facing our tasks and daily lives. My conscious effort included a step-by-step approach, understanding my abilities and limits, as well as recalling all knowledge that I have collected in the past to tackle a present problem. Through this practice, I hope to face my days maintaining conscious effort in the face of all my problems and remain grateful for all my abilities and shortcomings.