Kelas Metode Numerik 2022

DESIGN AND OPTIMIZATION OF PRESSURIZED HYDROGEN STORAGE

When designing the optimization of pressurized hydrogen storage with a volume of 1 liter, pressure of 8 bar, and a production cost not exceeding Rp500,000.00, there are several considerations to take into account. Here are some important factors to consider:

1. Container Material and Construction

- Choose materials that are safe and resistant to high pressure and corrosion, such as aluminum, stainless steel, or carbon fiber-reinforced composites.

- Ensure that the container construction can safely withstand the desired hydrogen pressure.

2. Safety

- Certification and compliance with applicable safety standards such as ISO 15869 or SAE J2579.

- Consider adequate safety features, such as pressure relief valves, pressure sensors, and fire suppression systems.

3. Space Efficiency

- Design the container to maximize the use of space within the 1-liter volume.

- Utilize optimal packaging techniques to maximize the amount of hydrogen that can be stored within the available space.

4. Storage Efficiency

- Consider the most efficient method of hydrogen storage, such as physical storage as compressed gas or storage in the form of a fuel cell if hydrogen fuel cells are being :considered.

5. Production Cost

- Take into account the cost of materials, production, and testing associated with the storage design.

- Optimize the design to achieve a production cost that does not exceed the budgetary constraints.

6. Reliability

- Ensure that the container design can maintain a stable pressure over the desired period without leaks or potential damage.

7. Regulations

- Ensure that the design complies with applicable regulations and standards in the hydrogen storage industry.

DESIGN CALCULATION

Specification of a Cylindrical Hydrogen Tank

Capacity : 1 liter Pressure : 8 bar Material : ASTM A36 sheet metal Cost : Rp500.000,00

Code to Optimize The Design of Cylindrical Hydrogen Tank

To optimize the design, i write a code in Python to find the optimium thickness, radius, and the height of the tank with cost and volume as a constant variables. Here is the code that i used:

from scipy.optimize import minimize

def objective_function(x):

thickness, radius, height = x[0], x[1], x[2]

# Calculate the weight of the tank (assuming density of ASTM A36 sheet metal)

density_astm_a36 = 7850 # kg/m^3 (density of ASTM A36 sheet metal)

volume = 3.14159 * radius * radius * height / 1000 # Convert to liters

weight = density_astm_a36 * volume

# Calculate the cost of the tank (based on material price per kg)

material_price = 500000 / weight # Rp/kg (maximum allowed cost divided by weight)

cost = weight * material_price

# Define the objective function as a combination of weight and cost

# You can adjust the coefficients based on your preference for weight vs. cost

objective_value = weight + 0.001 * cost

return objective_value

def constraint(x):

thickness, radius, height = x[0], x[1], x[2]

# Volume constraint: tank volume should be 1 liter

volume = 3.14159 * radius * radius * height / 1000 # Convert to liters

# Pressure constraint: tank should handle 8 bar pressure with a safety factor of 2

allowable_stress = 250e6 # Pa (allowable stress for ASTM A36 sheet metal)

inside_radius = radius - thickness # Inner radius of the tank

pressure = 8e5 # Pa (8 bar pressure)

stress = pressure * inside_radius / thickness # Stress in the tank wall

safety_factor = 2.0 # Safety factor

stress_allowable = allowable_stress / safety_factor

return [

volume - 1, # Volume constraint (1 liter)

stress - stress_allowable, # Pressure constraint

thickness - 5, # Minimum thickness constraint (5 mm)

10 - thickness # Maximum thickness constraint (10 mm)

]

# Initial guess for thickness, radius, and height (in mm)

x0 = [10.0, 50.0, 100.0]

# Define bounds for thickness, radius, and height (in mm)

bounds = [

(5, 10), # Bounds for thickness (assumed range from 5 to 10 mm)

(1, 50), # Bounds for radius (assumed range from 1 to 50 mm)

(100, 1000) # Bounds for height (assumed range from 100 to 1000 mm)

]

# Define the optimization problem

problem = {

'type': 'SLSQP',

'fun': objective_function,

'x0': x0,

'bounds': bounds,

'constraints': [{'type': 'ineq', 'fun': lambda x: constraint(x)}]

}

# Solve the optimization problem

result = minimize(problem['fun'], x0=problem['x0'], bounds=problem['bounds'], constraints=problem['constraints'], method=problem['type'])

# Extract the optimal solution

optimal_thickness, optimal_radius, optimal_height = result.x

# Calculate the weight of the tank (assuming density of ASTM A36 sheet metal)

density_astm_a36 = 7850 # kg/m^3 (density of ASTM A36 sheet metal)

volume = 3.14159 * optimal_radius * optimal_radius * optimal_height / 1000 # Convert to liters

weight = density_astm_a36 * volume

# Calculate the cost of the tank (based on material price per kg)

material_price = 500000 / weight # Rp/kg (maximum allowed cost divided by weight)

cost = weight * material_price

# Print the optimal solution with units

print(f"Optimal Thickness: {optimal_thickness:.2f} mm")

print(f"Optimal Radius: {optimal_radius:.2f} mm")

print(f"Optimal Height: {optimal_height:.2f} mm")

print(f"Cost: {cost:.2f} Rp")

The result of the code is:

Optimal Thickness: 5.00 mm Optimal Radius: 24.28 mm Optimal Height: 100.00 mm Cost: 500000.00 Rp

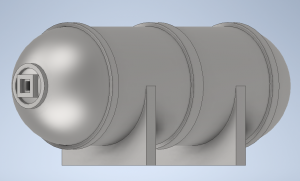

3D MODELLING

After finding out the optimum design using the code above, i try to create the 3D Design using Autodesk Inventor: