Juan Andre (Metode numerik)

Nama: Juan Andre Mendaun Karapa

NPM: 2106728130

Hobi: Tidur

Saya adalah mahasiswa FTUI angkatan 2021 dari jurusan Teknik mesin dan saya adalah salah satu ciptaan terbaik dari Tuhan yang Maha Esa karena pada prinsipnya Tuhan yang Maha Esa itu mendesain manusia dengan sebaik baiknya makhluk.

Saya masuk Teknik Mesin karena terlempar dari jurusan utama saya yaitu kedokteran.

Contents

Tugas hydrogen storage Optimization

Hydrogen storage optimization involves maximizing the efficiency and capacity of hydrogen storage systems.We can solve that with :

1.Understand your storage requirements: Determine the specific needs for hydrogen storage, such as the required capacity, pressure, and temperature range. Consider the intended application and any constraints or limitations.

2.Choose the appropriate storage method: Evaluate different hydrogen storage methods, such as compressed gas, liquid hydrogen, metal hydrides, or chemical hydrides. Each method has its advantages and disadvantages in terms of capacity, energy density, safety, and cost.

3.Optimize storage system design: Consider factors such as storage vessel material, insulation, and pressure containment. Design the storage system to minimize leaks, ensure safety, and maximize capacity. Employ advanced materials and manufacturing techniques to enhance storage efficiency.

4.Optimize operating conditions: Explore the optimal pressure and temperature ranges for hydrogen storage based on the chosen storage method. Higher pressures and lower temperatures generally improve storage capacity, but they may have cost and safety implications. Conduct experiments or simulations to find the best operating conditions.

5.Improve storage materials: Research and develop new materials with higher hydrogen storage capacities and improved kinetics. For example, metal-organic frameworks (MOFs) and carbon-based materials like graphene have shown promise in enhancing hydrogen storage efficiency. Collaborate with researchers and experts in the field to explore cutting-edge materials.

6.Implement storage system monitoring and control: Install sensors and monitoring systems to ensure safe and efficient operation of the hydrogen storage system. Use real-time data to optimize storage conditions and detect any anomalies or leaks promptly.

7.Consider system integration: Account for the integration of hydrogen storage into larger systems, such as fuel cell vehicles or renewable energy storage systems. Optimize the interface between the storage system and the end-use application to maximize overall efficiency.

8.Conduct thorough safety assessments: Hydrogen storage optimization must prioritize safety. Perform rigorous safety assessments, including risk analysis, to identify potential hazards and implement appropriate safety measures. Adhere to industry standards and regulations to ensure safe storage and handling practices.

9.Continuously improve through research and development: Stay updated with advancements in hydrogen storage technologies and materials. Collaborate with researchers, universities, and industry experts to leverage their knowledge and expertise. Invest in research and development to continuously optimize and innovate hydrogen storage systems.

FINAL REPORT progress Case Study Optimization of Hydrogen Storage

Requirements: Designing hydrogen storage at 8 bar with a capacity of 1 liter and budget of Rp 500.000

first of all, we need a material

so I choose stainless steel Grade 201, because :

Corrosion Resistance: Stainless steel exhibits excellent corrosion resistance, which is crucial when storing hydrogen. Hydrogen gas can cause embrittlement and degradation in some materials, but stainless steel resists hydrogen-induced cracking and degradation, ensuring the integrity and safety of the storage system.

Strength and Durability: Stainless steel has high strength and durability, making it suitable for high-pressure applications. It can withstand the forces exerted by the stored hydrogen without deforming or failing, ensuring the structural integrity of the storage vessel.

Wide Availability: Stainless steel is widely available and commonly used in various industries. This availability contributes to a competitive market, making stainless steel a cost-effective option for hydrogen storage compared to some specialized or less commonly used materials.

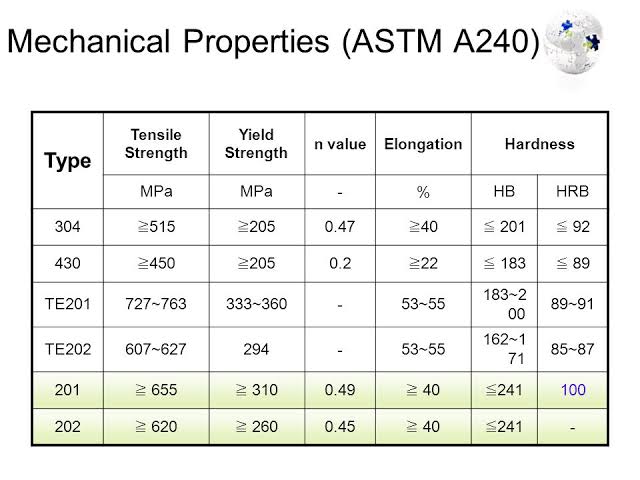

below are the properties

After that I design Geometry Optimization with the code below ;

import math

pi=3.14

check=[]

for R in range (1,100):

height = 1000/(pi*R**2)

area_surface=((2*pi*R) * height) + ((pi*R**2)*2)

check.append((area_surface,height))

smallest_R=min(check)

print(smallest_R)

the output is the smallest area surface : ( area surface, height) in cm

(557.0, 12.738853503184714)

with calculation on the basic area of the surface formula using a variable that we already know we got: r=7.3 cm

in summary, we got

area surface : 557.0 cm

height : 12.73, and

radius (r) :7.3 cm

Next we calculate the max pressure and its thickness with code ;

R = 7.3e-2

P = 800000

t = 4e-2

check=[]

while t < 100:

hoop = (P * R)/(t)

t += 1

check.append((hoop,t))

if hoop > 310e9:

break

value=max(check)

print(value)

the output is : (pressure,thickness)

(1459999.9999999998, 1.04)

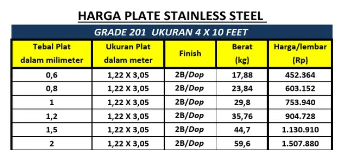

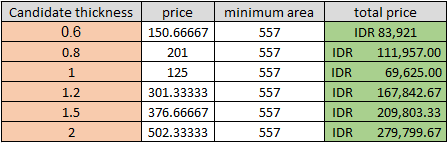

So after that, we compare the material,select,and calculate with real-life material price

The following is a list of prices and their calculations.

as shown in the table the price budget of Rp 500.000 is more than enough to design hydrogen storage at 8 bar with a capacity of 1 liter,to be more specific the stainless steel with thickness of 2mm because we have to consider some safety factor.

My Conscious Efforts on Numerical Method Learning & Its Application in Hydrogen Storage Design Optimization

Presentasi Akhir

Juan Andre Mendaun Karapa

2106728130

Metode Numerik-02