Ihza Lathansa (Metnum)

Nama: Ihza Lathansa

NPM: 2106728143

Jurusan: Teknik Mesin

Tugas hydrogen storage Optimization

Hydrogen Storage Optimazation adalah proses meningkatkan metode dan teknologi yang digunakan untuk menyimpan hidrogen dengan efisien dan efektif. Hidrogen adalah pembawa energi yang serbaguna dan memiliki potensi untuk memainkan peran yang signifikan dalam sistem energi bersih dan berkelanjutan. Namun, salah satu tantangan dalam memanfaatkan hidrogen adalah kerapatan rendah dan energi per unit volume, yang membutuhkan teknik penyimpanan khusus.

To optimize hydrogen storage, you can follow these general steps:

1. Define the Objective: Clearly articulate the specific objective you want to achieve through the optimization process. For example, it could be to maximize storage capacity, minimize cost, optimize safety, or strike a balance between multiple factors.

2. Identify Variables and Constraints: Determine the key variables that affect the storage system's performance, such as storage volume, pressure, temperature, and cost. Also, consider any constraints that need to be satisfied, such as safety regulations, infrastructure limitations, or operational requirements.

3. Formulate a Mathematical Model: Develop a mathematical model that represents the relationship between the variables, constraints, and the objective function. The model should accurately capture the behavior of the hydrogen storage system and allow for efficient optimization.

4. Choose an Optimization Method: Select an appropriate optimization method based on the characteristics of the problem. Consider factors like the size and complexity of the search space, the presence of nonlinearities or discrete decisions, and the available computational resources. Genetic algorithms, simulated annealing, particle swarm optimization, and mathematical programming techniques like linear programming or nonlinear programming can be considered.

5. Implement the Optimization Algorithm: Translate the mathematical model and the chosen optimization method into a computer program. This program should take the model inputs, constraints, and objective function and use the optimization algorithm to find the optimal or near-optimal solution.

6. Perform Sensitivity Analysis: Analyze the sensitivity of the optimized solution to changes in key parameters. This analysis helps to understand how variations in variables or constraints affect the overall performance of the hydrogen storage system.

7. Validate and Refine: Validate the optimized solution by comparing it against real-world data or validated simulation models. If necessary, refine the model or optimization approach based on the insights gained during the validation process.

8. Iterate and Improve: Optimization is an iterative process, and it may be necessary to refine the model or adjust the objective and constraints based on feedback or new information. Continuously evaluate and improve the optimization results to achieve better performance.

9. Consider Practical Considerations: While optimizing the storage system, take into account practical considerations such as safety, regulatory requirements, infrastructure limitations, and environmental impacts. Ensure that the optimized solution is feasible and aligned with real-world constraints.

FINAL REPORT Optimization of Hydrogen Storage

1.Requirements : Designing hydrogen storage at 8 bar with a capacity of 1 liter and budget of Rp 500.000

2.Material Constrain

first of all, we need a material

so I choose stainless steel Grade 201, because :

Corrosion Resistance: Stainless steel exhibits excellent corrosion resistance, which is crucial when storing hydrogen. Hydrogen gas can cause embrittlement and degradation in some materials, but stainless steel resists hydrogen-induced cracking and degradation, ensuring the integrity and safety of the storage system.

Strength and Durability: Stainless steel has high strength and durability, making it suitable for high-pressure applications. It can withstand the forces exerted by the stored hydrogen without deforming or failing, ensuring the structural integrity of the storage vessel.

Wide Availability: Stainless steel is widely available and commonly used in various industries. This availability contributes to a competitive market, making stainless steel a cost-effective option for hydrogen storage compared to some specialized or less commonly used materials.

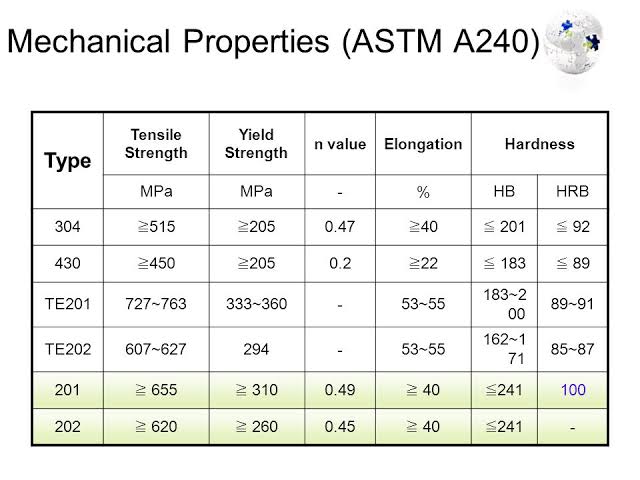

below are the properties