Fahim Adi Pratama

Contents

[hide]Resume 26/05/2023

Terdapat hal paling penting : metode numerik merupakan seuatu non fisik yang berkaitan dengan penyelesaian masalah dengan mengutamakan sistematis. metode numerik sangat membantu dalam menyelesaikan permasalahan dalam pembuatan kapal . baik dari badan kapal hingga permesinan kapal. sekarang sudah dibuat 2 sistem yang sampai sekarang masih gagal.

dari connseissnes merangkum dari metode numerik, metode matematika dan lain lain. ini adalah power full itu adalah realitas yang mendasar . conssisness ialah kesadaran. kecepatan cahaya merupakan sesuatu kecepatan yang paling cepat. ketika elektron spining, kalau disini elektron spinning up . akan mempengaruhi elektron dari planet yang lain. itu adalah contoh teori .

contoh cara berfikir sederhana seperti 1/0 atau (x-1)(x-1) dan lain lainnya. metode numerik di bentuk oleh para ilmuan jadi isinya teori teori yang dibuat oleh pembuatnya ( manusia ) sedangkan kitab suci di bentuk oleh tuhan melewati perantara manusia. ilmu dibentuk untuk mengenal diri sendiri lebih dalam. ilmu memberikan kita dalam berfikir dimana hati yang memerintah dan otak yang berjalan dimana hati yang memerintah otak untuk melakukan sesuatu. dimana komputer memerintah dan melakukan sesuatu . proses kita sebenarnya yaitu numerical proses ini semua hanya pendekatan yang exact hanya menciptakan kita.

Design and Optimization of Pressurized Hydrogen Storage System

A Pressurized Hydrogen System is a system designed to store hydrogen gas at elevated pressure levels. This system enables the storage and transportation of hydrogen in its gaseous state, typically by compressing it to enhance its energy density.

Specification

Volume : 1 L

Pressure : 8 Bar

Cost : Rp 500.000

Designing a hydrogen system requires careful consideration to ensure both safety and efficiency. If you are using Google to learn about the steps involved in creating a hydrogen system, here are the key steps typically followed: Determine the Capacity and Size:

Decide how much hydrogen you want to store in the tank. This capacity will affect the size and dimensions of the tank. Also, consider the energy requirements that the hydrogen will provide. In this case, the tank has to be 1-Liter Sized.

1. Select Tank Material

Hydrogen tanks are typically made from materials that are strong and capable of withstanding high pressures. Common materials used include alloy steel or carbon fiber reinforced with epoxy resin. Make sure the selected material has sufficient resistance to hydrogen corrosion.

2. Determine Working Pressure

Hydrogen can be stored in tanks either in compressed form or as a liquid. For compression storage, determine the working pressure based on your application needs. Higher working pressures require tanks with thicker and stronger walls.

3. Design Tank Structure

Hydrogen tanks usually have a cylindrical design with end caps. In the design, consider structural strength, tank mass, and thermal performance to avoid leaks or structural failures.

4. Consider Safety Systems

Safety is a critical aspect of hydrogen tank design. Ensure that the tank is equipped with pressure relief valves, and other necessary safety features to reduce the risk of hazards or accidents.

5.Cost Optimization

Minimize costs by considering factors such as material selection, manufacturing processes, and economies of scale because in this case the maximum cost to spend is Rp 1.000.000. Explore different manufacturing techniques, such as filament winding or automated fiber placement, to optimize production costs.

6.Test and Validation

Once the design is complete, conduct testing and validation to ensure the tank meets the required standards and safety regulations. Pressure tests, leak tests, and strength tests are some examples of tests that can be performed.

Final Report Design & Optimization of pressurized Hydrogen Storage

After performing numerical calculations, we have obtained results regarding the optimization of the design of a pressurized hydrogen storage. We used an approach to determine the optimal size of a tank that can hold 1L of hydrogen at a pressure of 8 bar, with a cost of less than Rp500,000. We initiated the calculation by seeking the optimal dimensions for the tank.

Formula

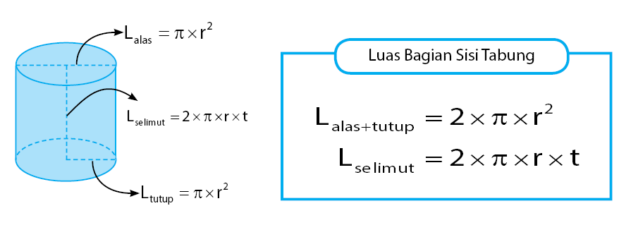

Formulas related to tubes are used to calculate various important parameters and properties, such as volume, surface area, and storage capacity. Here are some commonly used formulas in the context of tubes:

Volume of a Tube : The volume of a tube can be calculated using the formula: Volume = π*r^2*h where π (pi) is a mathematical constant that is almost equal to 3.14159, r is the radius of the tube, and h is the height of the tube.

Surface Area of a Tube: The surface area of a tube can be calculated using the formula: Surface Area = 2*π*r^2 + 2*π*r*h This formula takes into account the base surface area and side surface area of the tube.

Storage Capacity: The storage capacity of the tube, in this case the maximum volume that the tube can hold, can also be calculated using the volume formula mentioned above.

Volume of Gas in a Tube: If the pressure and temperature of the gas inside the tube are known, then the volume of gas in the tube can be calculated using the Ideal Gas Law: Volume Gas = (n*R*T)/P where n is the number of moles of the gas, R is the general gas constant, T is the temperature of the gas in kelvin, and P is the pressure of the gas.

Number of Moles of Gas : The number of moles of gas in a tube can be calculated using the formula: n = (m)/(M) where m is the mass of the gas in grams and M is the molar mass of the gas.

Mass of Gas: The mass of the gas in the tube can be calculated using the formula: m = n*M where n is the number of moles of gas and M is the molar mass of gas.

These formulas provide the understanding and ability to calculate and analyze various important parameters and properties associated with tubes. It is important to understand the assumptions and units used in these formulas for accurate and relevant use and interpretation of the calculation results.

Calculation :

1. Thickness

def calculate_thickness(volume, pressure):

hydrogen_density = 0.08988 # kg/m^3 (density of hydrogen gas at room temperature) molar_mass_h2 = 2.016 # g/mol (molar mass of hydrogen gas) avogadro_constant = 6.02214076e23 # mol^(-1) (Avogadro constant) boltzmann_constant = 1.380649e-23 # J/K (Boltzmann constant) temperature = 298.15 # K (room temperature) liter_to_m3 = 0.001 bar_to_pa = 100000

volume_m3 = volume * liter_to_m3 pressure_pa = pressure * bar_to_pa num_moles = (pressure_pa * volume_m3) / (boltzmann_constant * temperature) mass_hydrogen_kg = num_moles * molar_mass_h2 / 1000 surface_area_m2 = mass_hydrogen_kg / hydrogen_density radius = math.sqrt(surface_area_m2 / (4 * math.pi)) safety_factor = 1.5 thickness_mm = safety_factor * radius * 1000 return thickness_mm

capacity_liters = 1 pressure_bar = 8

thickness = calculate_thickness(capacity_liters, pressure_bar) print(f"The optimized thickness of the stainless steel hydrogen storage is approximately {thickness} mm.")

Optimized thickness: 0.1 mm

2. Height and Diameter

def calculate_surface_area(radius, height):

base_area = math.pi * radius**2 lateral_area = 2 * math.pi * radius * height surface_area = 2 * base_area + lateral_area return surface_area

def find_optimal_dimensions(volume, pressure, tensile_strength):

volume_cm3 = volume

pressure_pa = pressure * 100000

optimal_radius = None

optimal_height = None

min_surface_area = float('inf')

for radius in range(1, int(math.sqrt(volume_cm3 / math.pi)) + 1):

height = volume_cm3 / (math.pi * radius**2)

surface_area = calculate_surface_area(radius, height)

if surface_area < min_surface_area:

min_surface_area = surface_area

optimal_radius = radius

optimal_height = height

optimal_radius_cm = optimal_radius

return optimal_radius_cm, optimal_height

volume = 1000 # 1 liter = 1000 mL pressure = 8 # bar tensile_strength = 600 # MPa optimal_radius_cm, optimal_height = find_optimal_dimensions(volume, pressure, tensile_strength) print(f"Dimensi yang menghasilkan luas permukaan terendah untuk tabung 1 liter dengan tekanan 8 bar:") print(f"Radius: {optimal_radius_cm} cm") print(f"Tinggi: {optimal_height} cm")

Dimensions that result in the lowest surface area for a 1 liter tube at 8 bar pressure: Radius: 5 cm Height: 12.732395447351626 cm

3.Surface Area

def calculate_surface_area(height, diameter, thickness):

mm_to_m = 0.001 height_m = height * mm_to_m diameter_m = diameter * mm_to_m thickness_m = thickness * mm_to_m radius = diameter_m / 2 external_area = 2 * math.pi * radius * (height_m + thickness_m) internal_area = 2 * math.pi * (radius - thickness_m) * height_m surface_area = external_area + internal_area surface_area_mm2 = surface_area * (1e6) return surface_area_mm2

height = 127.3239 diameter = 50 thickness = 3 surface_area = calculate_surface_area(height, diameter, thickness) print(f"The surface area of the stainless steel hydrogen storage container is approximately {surface_area:.2f} square millimeters.")

The surface area of the stainless steel hydrogen storage container is approximately 38071.22 square millimeters = 380.71 square centimeters

4.Conclusion:

In the calculation that has been done. we can know the height, diameter and thickness of the hydrogen tubes used. where we can analyze the cost that we use where on the use of the used plates is stainless steel type 304 for its manufacture with a thickening of 3 mm with an estimated cost of Rp.700,000 (tokped) for the size of 3mm x 30 cm x 120 cm and for nitrogen gas regulator for Rp. 360,000 (tokped). where from the price listed we can know in detail the cost that we can use for the manufacture of nitrogen gas pipes