Alifian Firdaus Adji Arrazaq

Contents

[hide]Introduction

Hi! I'm Alifian Firdaus Adji Arrazaq (2206100193), a passionate mechanical engineering student at the University of Indonesia. I have a strong interest in the intersection of education and technology. I believe that knowledge is a double-edged sword; it empowers us to achieve great things, but it also has the potential to blind us to other possibilities. That's why I'm always open to new experiences and ideas, constantly seeking to broaden my horizons.

Discussion : Consciousness and Its Importance

Consciousness is a complex and multifaceted concept that refers to an individual's subjective awareness of their thoughts, feelings, sensations, and experiences. It involves the ability to perceive, understand, and have self-awareness of oneself and the surrounding world. In the context of Islam, consciousness, or "taqwa" in Arabic, holds significant relevance. Taqwa can be understood as God-consciousness or mindfulness of Allah's presence in every aspect of life. It is a fundamental concept in Islamic teachings, emphasizing the awareness of one's actions and intentions in relation to Allah's commands and prohibitions.

In Islam, consciousness plays a central role in one's spiritual and moral development. It encourages believers to be mindful of their thoughts, words, and deeds, and to strive for righteousness and piety. The Quran repeatedly emphasizes the importance of taqwa, stating that those who possess it are more mindful of their obligations to Allah and are more likely to avoid sinful behavior. By cultivating consciousness in their daily lives, Muslims aim to align their actions with the teachings of Islam. It involves being aware of the consequences of one's choices and seeking to live a life that pleases Allah and benefits oneself and others. Consciousness helps individuals avoid wrongdoing, promotes ethical behavior, and fosters a deeper connection with their faith.

Furthermore, consciousness in Islam extends beyond individual behavior and encompasses social and environmental awareness. Muslims are encouraged to be conscious of the well-being of others, to promote justice and compassion, and to be responsible stewards of the Earth. This holistic approach to consciousness highlights the interconnectedness of individuals, society, and the environment. Ultimately, consciousness in Islam serves as a guiding principle that directs believers towards a righteous and fulfilling life. It encourages self-reflection, accountability, and a constant striving for spiritual growth and moral excellence. By being conscious of their thoughts, actions, and responsibilities, Muslims aim to live in accordance with the teachings of Islam and fulfill their purpose as servants of Allah.

Project : Building A Hydrogen Tank

Why Hydrogen Tank?

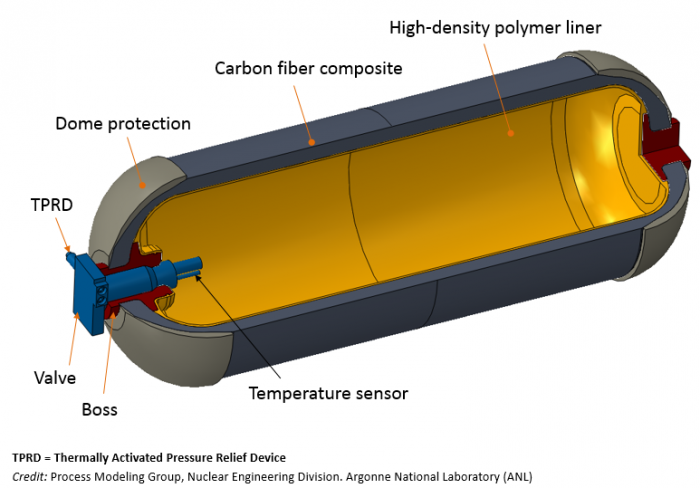

Hydrogen tanks are storage devices specifically designed to hold hydrogen gas under high pressure. They play a crucial role in various applications, such as hydrogen fuel cell vehicles, stationary hydrogen storage systems, and industrial processes.

Here's how hydrogen tanks typically function:

1. Pressure containment: Hydrogen tanks are built to withstand high pressure because hydrogen gas needs to be stored at elevated pressures to achieve sufficient energy density. The tanks are constructed using materials that have high strength and can safely contain the pressurized hydrogen gas.

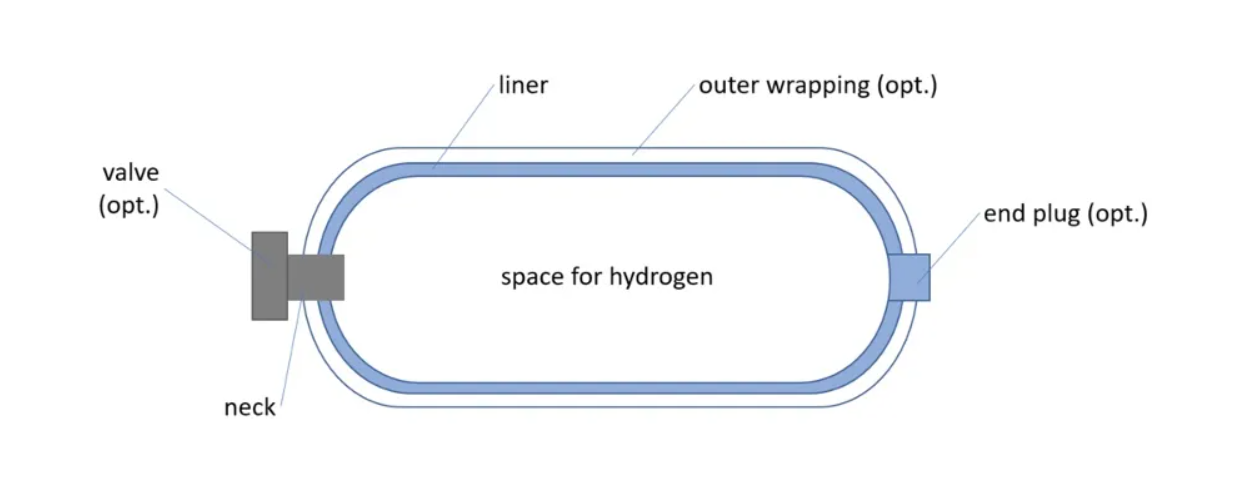

2. Tank design: Hydrogen tanks come in different shapes and sizes, but they generally have a cylindrical or spherical shape. They are often made of lightweight materials like carbon fiber reinforced polymer (CFRP) or metal alloys, such as aluminum or steel. These materials provide strength while keeping the weight of the tank relatively low.

3. Pressure regulation: Hydrogen tanks incorporate pressure regulation systems to control the pressure inside the tank. This includes pressure relief valves that release excess hydrogen gas if the pressure inside the tank exceeds the safe operating limits. The pressure regulation system helps maintain a consistent pressure within the tank.

4. Filling and dispensing: Hydrogen tanks can be filled with hydrogen gas through specialized filling stations equipped with high-pressure dispensing systems. The hydrogen gas is compressed and injected into the tank until it reaches the desired pressure level. Similarly, during dispensing, the stored hydrogen gas can be extracted and used for various applications like powering fuel cells.

5. Safety features: Hydrogen tanks incorporate several safety features to minimize the risk of accidents. These may include pressure sensors to monitor the internal pressure, temperature sensors to prevent overheating, and rupture disks as additional safety measures. The tanks are designed to withstand impacts, vibrations, and other external forces that may occur during transportation or operation.

It's important to note that hydrogen is highly flammable, so ensuring the safe design, manufacturing, and handling of hydrogen tanks is critical to prevent any potential hazards. Stringent safety standards and regulations govern the production and use of hydrogen tanks to ensure their reliability and minimize the associated risks.

Building a safe and efficient hydrogen tank requires careful consideration of various factors, including materials, design, and safety measures. While I can provide some general guidance, it's important to note that designing and constructing a hydrogen tank requires expertise and adherence to applicable regulations and standards. Consulting with professionals in the field is strongly recommended. Here are some key points to consider:

Material Selection: Hydrogen tanks can be made from various materials, such as high-strength steel, aluminum, or composite materials. Each material has its own advantages and considerations in terms of weight, strength, and compatibility with hydrogen. Consult with experts to determine the most suitable material for your specific application.

Tank Design: The tank should be designed to withstand the desired pressure and volume requirements. Factors to consider include wall thickness, shape, and reinforcement methods. Seek professional assistance to ensure the design meets safety standards and regulatory requirements.

Safety Measures: Hydrogen is highly flammable and requires special safety precautions. Include safety features such as pressure relief devices, burst discs, and temperature sensors to mitigate potential risks. It is crucial to follow safety guidelines and standards for hydrogen storage.

Sealing and Leakage Prevention: Proper sealing is critical to prevent leaks. Ensure all connections and joints are securely sealed, and consider using suitable sealing materials specifically designed for hydrogen applications.

Testing and Certification: Rigorous testing is necessary to validate the integrity and safety of the hydrogen tank. Hydrostatic and pressure cycling tests should be conducted to ensure the tank can withstand the desired pressure and volume. Compliance with relevant regulations and obtaining necessary certifications is vital.

Installation and Usage: Proper installation and handling of the hydrogen tank are crucial for safety. Follow manufacturer's instructions and best practices for installation, operation, and maintenance. Consider integrating additional safety features, such as pressure gauges and hydrogen sensors, for monitoring and control.

Compliance with Regulations: Hydrogen storage systems are subject to specific regulations and standards, depending on the jurisdiction and application. Ensure compliance with applicable codes, regulations, and industry standards, such as those established by the American Society of Mechanical Engineers (ASME) or International Organization for Standardization (ISO).

CALCULATION To calculate the specifications of a hydrogen tank with a maximum pressure of 8 bar and a volume of 1 liter, we need to consider the required dimensions and the properties of the material used. Here's a rough calculation based on general assumptions:

Determine the Required Dimensions: To calculate the dimensions of the tank, we need to assume a specific shape. Let's consider a cylindrical tank for simplicity. The formula for the volume of a cylinder is: Volume = π * r^2 * h, where π is a mathematical constant (approximately 3.14159), r is the radius of the cylinder, and h is the height. Since the volume is given as 1 liter, we convert it to cubic meters: Volume = 1 liter = 0.001 cubic meters.

Now, we can rearrange the formula to solve for the radius: r = sqrt(Volume / (π * h))

Let's assume a reasonable height for the cylinder, such as 0.5 meters: r = sqrt(0.001 / (3.14159 * 0.5)) r ≈ 0.1124 meters (or 112.4 millimeters).

Determine the Material: Select a suitable material for the tank construction. High-strength steel is commonly used for hydrogen storage. It has different grades, each with its own mechanical properties.

Verify Pressure and Safety: Ensure that the selected material and tank dimensions can withstand the desired pressure of 8 bar using professional analysis, testing, and adherence to safety standards are critical to confirming the tank's safety and performance.

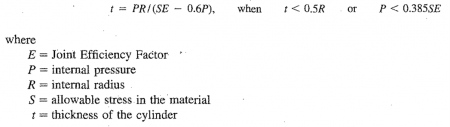

Thickness Calculation based on ASME Section VIII Pressure Vessel standardization.

1. Material allowable stress value :

Material : ASTM A36 sheet metal

Yield Strength (Sy) : 36 Ksi

Allowable stress value = 2/3 x Sy = 24 Ksi

2. Wall and head minimum thickness :

Thickness formula for circumferential stress direction :

3. Thickness formula for longitudinal stress direction :

E = 0,60 (Single-welded butt joint without use of backing strip)

P = 8 bar = 116 Psi

R = 50 mm = 1,97 inch

S = 24000 Psi

Corrosion allowance = 1 mm = 0,039 inch

t = 116x(1,97+0,039) / (24000x0,6)-(0,6x116) = 0,0162 + corrosion allowance = 0,5526 inch

t = 1,4 mm (Circumferential) ; t = 1,2 mm (Longitudinal)

So, the minimum thickness of the sheet metal is 1,4 mm

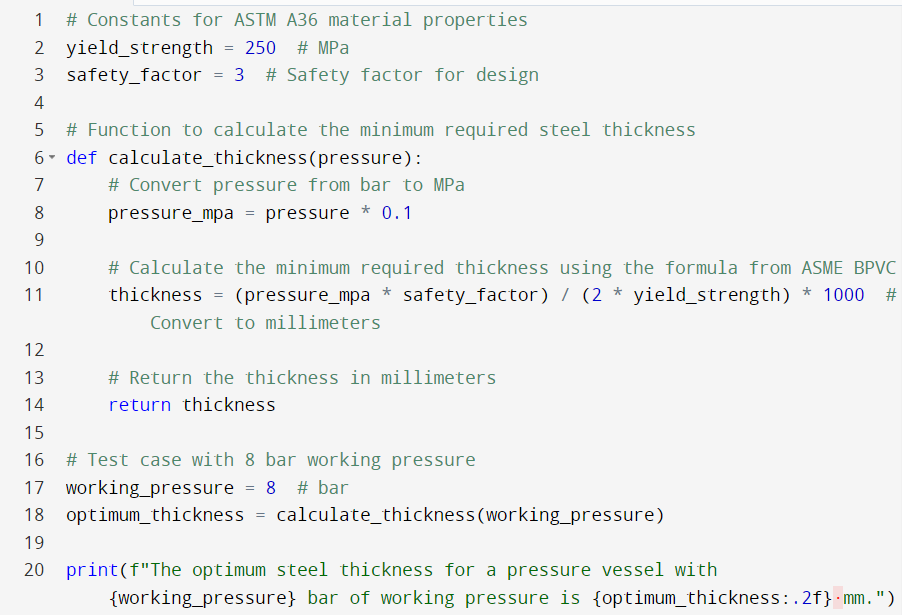

NUMERICAL CALCULATION USING PYTHON

The code used to calculate and display the optimum steel thickness for a pressure vessel with the specified working pressure is :

This Python code will calculates the minimum required steel thickness for a pressure vessel based on given material properties and a safety factor.

Let's break down the code step by step:

1. Constant:

- `yield_strength` represents the yield strength of the ASTM A36 steel material in megapascals (MPa). It is set to 250 MPa. - `safety_factor` is the safety factor used in the design calculations. It is set to 3, indicating a safety margin of 3 times the expected load.

2. Function Definition:

- The `calculate_thickness` function takes the `pressure` as input, which represents the working pressure of the vessel in bar. - Inside the function, the `pressure` is converted from bar to megapascals (MPa) by multiplying it with 0.1. - The minimum required thickness is calculated using the formula from the ASME Boiler and Pressure Vessel Code (BPVC), which is a standard used for designing pressure vessels. - The calculated thickness is converted from meters to millimeters by multiplying it with 1000. - Finally, the function returns the calculated thickness.

3. Test Case:

- A test case is provided to demonstrate the usage of the `calculate_thickness` function. - The `working_pressure` variable is set to 8 bar, representing the working pressure of the pressure vessel. - The `calculate_thickness` function is called with `working_pressure` as the argument, and the result is assigned to the `optimum_thickness` variable.

4. Output:

- The program uses a formatted string (`f-string`) to display the result. - It prints a message that includes the working pressure and the calculated optimum steel thickness for the pressure vessel. - The `:.2f` inside the formatted string ensures that the `optimum_thickness` value is displayed with 2 decimal places.

By running the program, it will calculate and display the optimum steel thickness for a pressure vessel with the specified working pressure.

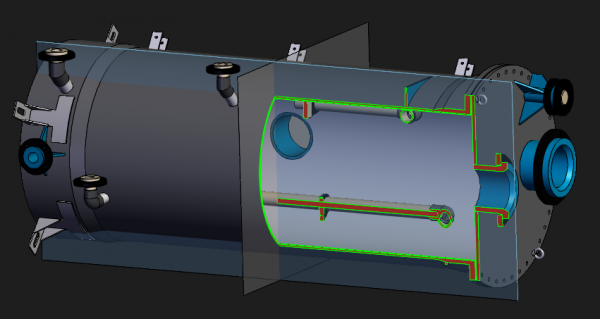

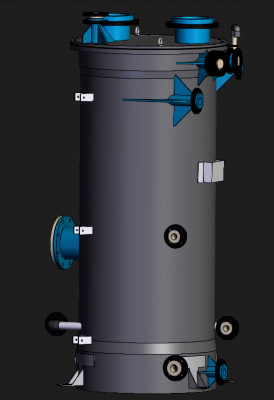

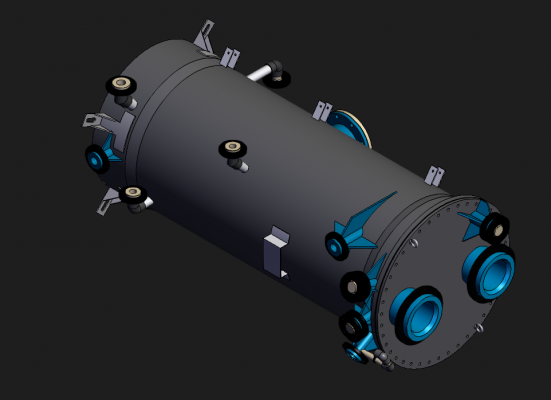

FINAL DESIGN

COST ESTIMATING

Material Cost:

Plat carbon / mild Steel 80 x 160 x 1.5 mm (1 each) = 55.000

Cap End diameter 80 mm (2 each) = 120.000

Pressure Gauge 1-15 Bar (1 each) = 155.000

Total Material Cost = 330.000

Production Cost :

Rolling Plate 80 x 160 x 1.5 mm = 25.000

Welding Plate = 20.000

Coating = 20.000

Total Production Cost = 65.000

Total Cost Estimation : Rp.395.000