Akhtar Hendrisyahputra

Contents

[hide]Introduction

Halo semuanya! perkenalkan nama saya Akhtar Hendrisyahputra, saya mahasiswa jurusan teknik mesin angkatan 2021 dengan NPM 2106655173 dan peserta kelas Metode Numerik 03 yang diajar oleh pak DAI, pak Engkos dan pak Agung salam kenal semuanya!

Conscious

Consciousness refers to our subjective awareness of ourselves and the world around us. It is the state of being awake, alert, and able to perceive, experience, and respond to our environment. Consciousness encompasses our thoughts, sensations, emotions, and perceptions. Consciousness is a complex phenomenon that has been the subject of philosophical, psychological, and scientific inquiry. It is often considered a fundamental aspect of human experience, distinguishing us from non-conscious entities.There are different theories and perspectives on the nature of consciousness. Some theories propose that consciousness arises from the activity of the brain and the interactions of neural networks. According to these theories, specific patterns of neuronal activity give rise to subjective experiences and mental states.

Optimization Design Of Hydrogen Strorage With 8 Bar Preassure

In this essay, I will explain some of the possibilities needed to make an optimal design of a 1 liter hydrogen strorage with a pressure of 8 bar and a maximum cost of 500 IDR. Considering safety aspects, material selection and efficient design.

What is Hydrogen? Hydrogen is the lightest and most abundant element in the universe. It is represented by the symbol "H" on the periodic table and has an atomic number of 1. In its simplest form, hydrogen consists of a single proton and a single electron. Hydrogen is a colorless, odorless, and tasteless gas at standard temperature and pressure. It is highly flammable and can react explosively with oxygen under certain conditions. Hydrogen is the primary component of water (H2O), which consists of two hydrogen atoms bonded to one oxygen atom.

How we Optimize Design of Hydrogen Strorage? Designing a hydrogen storage cylinder requires careful consideration of several factors to ensure safety, efficiency, and reliability. Here are some key considerations when designing a 1-liter capacity hydrogen storage cylinder with a pressure of 8 bar:

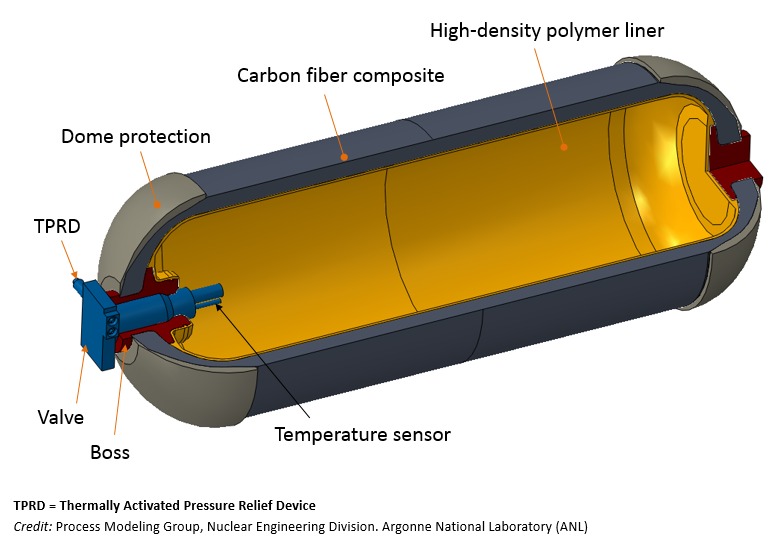

Material Selection: Choose materials that can withstand high-pressure hydrogen environments and prevent hydrogen embrittlement. Common materials for hydrogen storage cylinders include high-strength steels, aluminum alloys, or composite materials.

Cylinder Design and Dimensions: Determine the appropriate size, shape, and wall thickness of the cylinder to accommodate 1 liter of hydrogen and withstand the desired pressure of 8 bar. Consider factors such as weight, portability, and space constraints.

Safety Features: Incorporate safety features to prevent overpressure situations, such as pressure relief valves or rupture disks. These mechanisms are crucial to prevent excessive pressure buildup and ensure the integrity of the cylinder.

Leak Prevention: Employ robust sealing mechanisms and ensure the cylinder has no leaks to prevent hydrogen loss and maintain the required pressure. Proper sealing techniques, such as O-rings or gaskets, should be considered.

Cylinder Testing and Certification: Conduct thorough testing to ensure the cylinder meets safety standards and regulations. This includes hydrostatic testing to assess the structural integrity and leak tests to verify the cylinder's gas-tightness. Compliance with relevant standards, such as ISO 11119 for hydrogen storage, is essential.

Transport and Handling Considerations: Consider requirements for transportation and handling of the hydrogen storage cylinder. Ensure the design complies with regulations for storage, transport, and use of hydrogen gas cylinders.

Compatibility with Hydrogen Infrastructure: Consider the compatibility of the cylinder design with hydrogen refueling infrastructure or other hydrogen utilization systems. Connections, valves, and fittings should be designed to facilitate safe and efficient filling and emptying processes.

Environmental Considerations: Ensure the cylinder design minimizes environmental impact, considering factors such as materials used, recyclability, and end-of-life disposal.

It is important to note that designing a hydrogen storage cylinder involves complex engineering considerations and safety regulations. It is advisable to consult experts in the field of hydrogen storage and follow relevant industry standards and guidelines to ensure a safe and effective design.

Coding Python

Dalam upaya mengurangi biaya produksi perlu dilakukan penghematan material yang dilakukan dengan mendesain tangki penyimpanan hidrogen dengan bentuk yang efisien dan tidak boros, namun juga tetap memperhatikan faktor keamanan produk. berikut ukuran minimal dari sebuah tangki hidrogen 1 liter bertekanan 8 bar dengan material stainless steel 304.

1. Ketebalan

import math

def calculate_thickness(pressure, capacity):

# Konstanta material stainless steel 304 tensile_strength = 586 # MPa safety_factor = 2.5

# Konversi tekanan menjadi Pa pressure_pa = pressure * 1e5

# Konversi kapasitas menjadi m^3 capacity_m3 = capacity / 1000

# Menghitung ketebalan minimum thickness = (pressure_pa * capacity_m3 * safety_factor) / (2 * math.pi * tensile_strength)

return thickness

- Input tekanan dan kapasitas

pressure_bar = 8 capacity_liters = 1

- Menghitung ketebalan minimum

thickness_mm = calculate_thickness(pressure_bar, capacity_liters)

- Menampilkan hasil

print(f"Ketebalan minimum tangki: {thickness_mm:.2f} mm")

Didapatkan Hasil untuk ketebalan minimum dari sebuah tangki hidrogen 1 liter bertekanan 8 bar dengan material stainless steel yaitu sebesar 0.54 mm

2. Tinggi dan lebar

import math

def calculate_thickness(pressure, capacity):

# Konstanta material stainless steel 304 tensile_strength = 586 # MPa safety_factor = 2.5

# Konversi tekanan menjadi Pa pressure_pa = pressure * 1e5

# Konversi kapasitas menjadi m^3 capacity_m3 = capacity / 1000

# Menghitung ketebalan minimum thickness = (pressure_pa * capacity_m3 * safety_factor) / (2 * math.pi * tensile_strength)

return thickness

def calculate_optimal_dimensions(thickness):

# Menghitung tinggi optimal height = thickness * 2

# Menghitung diameter optimal diameter = math.sqrt((4 * thickness) / math.pi)

return height, diameter

- Input tekanan dan kapasitas

pressure_bar = 8 capacity_liters = 1

- Menghitung ketebalan minimum

thickness_mm = calculate_thickness(pressure_bar, capacity_liters)

- Menghitung tinggi dan diameter optimal

height_mm, diameter_mm = calculate_optimal_dimensions(thickness_mm)

- Menampilkan hasil

print(f"Ketebalan minimum tangki: {thickness_mm:.2f} mm") print(f"Tinggi optimal tangki: {height_mm:.2f} m") print(f"Diameter optimal tangki: {diameter_mm:.2f} m")

Didapatkan Hasil untuk tinggi dan radius Optimal dari sebuah tangki hidrogen 1 liter bertekanan 8 bar dengan material stainless steel yaitu tinggi 10.09cm dan radius 8.30cm

3. Luas Permukaan

import math

def calculate_surface_area(height, diameter):

# Menghitung luas permukaan base_area = math.pi * ((diameter/2) ** 2) lateral_area = math.pi * diameter * height surface_area = 2 * base_area + lateral_area

return surface_area

- Input tinggi dan diameter

height_mm = 100 # Contoh tinggi dalam mm diameter_mm = 83 # Contoh diameter dalam mm

- Menghitung luas permukaan

surface_area_mm2 = calculate_surface_area(height_mm, diameter_mm)

- Menampilkan hasil

print(f"Luas permukaan tangki: {surface_area_mm2:.2f} mm^2")

Didapatkan Hasil untuk luas permukaan dari sebuah tangki hidrogen 1 liter bertekanan 8 bar dengan material stainless steel yaitu sebesar 368.9643 cm^2

biaya produksi

untuk harga dari plat stainless steel 304 dengan tebal 0.5mm per cm2 adalah sekitar 550 rp. maka harga untuk plat dengan luas permukaan 368.964 cm2 tersebut adalah 202.400.00. untuk regulator berkisar di 120.000.00, dan ongkos pengerjaan diasumsikan di angka 150.000.00(tergantung bengkel). jadi total biaya produksi 1 unit tabung hidrogen tersebut adalah 472.000.00