Pressurized Hydrogen Storage Optimization

Contents

Pressurized Hydrogen Storage Optimization

Tugas : Merancang dan mengoptimalkan tangki penyimpanan hidrogen bertekanan 1 liter (8 bar)

Dalam merancang konsep tangki hidrogen dengan kapasitas 1 liter, tekanan 8 bar, dan biaya produksi maksimal Rp. 500.000, berikut adalah beberapa langkah dan pertimbangan yang perlu diperhatikan:

Pemilihan Bahan Tangki: Pertimbangkan penggunaan bahan yang kuat dan ringan, seperti aluminium atau serat karbon, untuk meminimalkan biaya produksi dan memenuhi persyaratan kekuatan. Pastikan bahan tersebut mampu menahan tekanan 8 bar dengan aman.

Desain dan Ukuran Tangki: Merancang tangki dengan ukuran dan bentuk yang tepat untuk memuat kapasitas 1 liter hidrogen dan menahan tekanan 8 bar. Pertimbangkan untuk mengoptimalkan ukuran tangki agar dapat mengurangi penggunaan bahan dan mengendalikan biaya produksi.

Konstruksi dan Pengelasan: Pastikan tangki dirancang dengan sambungan yang kuat dan aman. Gunakan metode pengelasan seperti TIG (Tungsten Inert Gas) atau MIG (Metal Inert Gas) yang sesuai untuk menggabungkan bagian-bagian tangki. Selalu patuhi standar keamanan dalam proses pengelasan.

Sistem Penguncian dan Penyegelan: Pastikan tangki dilengkapi dengan sistem penguncian yang efektif untuk mencegah kebocoran hidrogen. Lakukan pemeriksaan dan pengujian kebocoran secara menyeluruh untuk memastikan tangki dapat mempertahankan tekanan yang diinginkan selama penggunaan.

Perlindungan dan Keamanan: Sertakan sistem perlindungan dan katup pelepas tekanan untuk mengurangi risiko kegagalan dan kelebihan tekanan pada tangki. Perhatikan faktor keamanan yang sangat penting dalam perancangan tangki hidrogen.

Biaya Produksi: Selama merancang tangki, perhatikan biaya produksi secara keseluruhan agar tetap berada dalam batas maksimal Rp. 500.000. Pilih bahan dan metode konstruksi yang efisien untuk mencapai tujuan ini. Hitunglah biaya bahan, biaya tenaga kerja, dan biaya produksi lainnya dengan cermat.

Selain itu, penting untuk memperhatikan manajemen risiko dalam merancang tangki hidrogen. Beberapa pertimbangan yang dapat diikuti antara lain:

Identifikasi Risiko: Lakukan identifikasi risiko yang terkait dengan tangki hidrogen, seperti kebocoran hidrogen, kegagalan struktural, kelebihan tekanan, atau reaksi kimia yang tidak diinginkan. Perhatikan juga faktor-faktor lingkungan dan keamanan yang relevan.

Analisis Risiko: Lakukan analisis risiko secara sistematis untuk menilai probabilitas dan dampak setiap risiko yang diidentifikasi. Prioritaskan risiko berdasarkan tingkat keparahan dan kemungkinan terjadinya.

Mitigasi Risiko: Berdasarkan hasil analisis risiko, buat rencana mitigasi yang efektif untuk mengurangi risiko yang diidentifikasi. Misalnya, implementasikan sistem deteksi kebocoran hidrogen yang sensitif, pilih material dengan kekuatan yang sesuai, dan sertakan perangkat pelepas tekanan yang terpercaya.

Material Tangki: Pilih material yang cocok untuk tangki hidrogen dengan mempertimbangkan faktor risiko. Pastikan material tersebut tahan terhadap korosi dan embrittlement akibat hidrogen. Lakukan pengujian material secara menyeluruh untuk memastikan kesesuaiannya.

Desain Struktural: Rancang struktur tangki dengan mempertimbangkan kekuatan, keamanan, dan risiko terkait. Gunakan metode analisis struktural seperti finite element analysis (FEA) untuk memastikan kekuatan dan integritas struktural yang memadai.

Pengelasan dan Sambungan: Pastikan pengelasan dan sambungan pada tangki dilakukan dengan hati-hati dan sesuai dengan standar keamanan. Lakukan pengujian non-destruktif untuk memastikan kualitas pengelasan dan sambungan.

Pengujian Kebocoran dan Tekanan: Lakukan pengujian tekanan dan kebocoran secara rutin untuk memastikan integritas tangki. Terapkan protokol pengujian yang ketat dan dokumentasikan hasil pengujian secara cermat.

Sistem Pelepas Tekanan Darurat: Pasang sistem pelepas tekanan darurat, seperti katup pelepas tekanan, yang akan berfungsi saat tekanan melebihi batas aman. Pastikan sistem tersebut dirancang dengan benar dan diuji secara teratur.

Pelatihan Operator dan Prosedur Keselamatan: Lakukan pelatihan operator yang komprehensif tentang penanganan, pengoperasian, dan pemeliharaan tangki hidrogen. Tetapkan prosedur keselamatan yang jelas dan pastikan operator memahaminya dengan baik.

Pemantauan dan Pemeliharaan Rutin: Lakukan pemantauan dan pemeliharaan rutin pada tangki hidrogen untuk mengidentifikasi masalah potensial sebelum terjadi kegagalan. Lakukan pemeriksaan dan pengujian secara berkala.

Perlu dicatat bahwa perancangan yang tepat dari tangki hidrogen membutuhkan pemahaman mendalam tentang teknologi dan keamanan tangki tekanan. Selalu berpegang pada standar dan regulasi yang berlaku, dan dapatkan bantuan dari ahli terkait jika diperlukan.

Geometrical Constraint

from math import pi

import pprint

'''

r = radius

circle_area = pi * r**2

circle_circumference = 2 * pi * r

h = height

cylinder_volume = pi * r**2 * h

cylinder_surface = 2 * (pi * r**2) + (2 * pi * r * h)

constraint for cylinder_volume be a constant of 1 liter (cubic centimeter)

cylinder_volume = 1000

h in terms of r

h = 1000/(pi * r**2)

substitute in

cylinder_surface = 2 * (pi * r**2) + (2 * pi * r * 1000/(pi * r**2))

'''

mylist = [] # create a list of (surface area, radius)

for r in range(1, 21): # assume a maximum of 20cm radius

cylinder_surface = 2 * (pi * r**2) + (2 * pi * r * 1000/(pi * r**2))

mylist.append((cylinder_surface, r))

# test

pprint.pprint(mylist)

r = 5

surface_list = []

while True:

cylinder_surface = 2 * (pi * r**2) + (2 * pi * r * 1000/(pi * r**2))

surface_list.append((cylinder_surface, r))

r += 0.01

if r > 6:

break

print('minimum surface area and radius: ', min(surface_list))

min_surface = min(surface_list)[0]

sf = "Minimum surface of a 1000ml tank = {:0.2f} square centimeters"

print(sf.format(min_surface))

radius = min(surface_list)[1]

print("Radius of 1000ml tank = {:0.2f} centimeters".format(radius))

height = 1000/(pi * radius**2)

print("Height of 1000ml tank = {:0.2f} centimeters".format(height))

sf = "Ratio of height to radius of a minimized surface can = {:0.2f}"

print(sf.format(height/radius))

Material Strength Constraint

The constraints for this assumption to be true is that the radius must be at least 5 times the wall thickness, which we will verify later. The stresses that exist within a thin-wall cylindrical component are circumferential (hoop) stress and longitudinal stress. Radial stress also exists but can be neglected due to the radius being much greater than the wall thickness. Hoop stress and longitudinal stress can be obtained via the following formulae:

where p is the gage pressure of the fluid and t is the wall thickness.

Since the hoop stress is equal to twice the longitudinal stress, we can set it as the objective function over the latter since quantitatively failure will occur earlier due to the hoop stress instead of the longitudinal stress. Since we have already calculated the container radius previously, have the pressure constraint set at 8 bars of gage pressure from the hydrogen, we can numerically iterate for the thickness of the vessel to obtain a range of values of hoop stresses. From there, we can select thicknesses with corresponding hoop stresses that do not exceed allowable stress of the material, in this case we arbitrarily set at 0.875 of the yield strength of the material. In containment purposes such as these, deformations in the container can already be considered failure or at least compromising for the storage facility, hence the consideration for setting the constraint at the yield strength.

Literary Parameters

The range of wall thickness that is applicable is also not arbitrary outside of remaining less than one-fifth of the vessel radius. ASME BPV Code Section VIII D.1 states that wall thickness should always be at least 1/16 in (1.59 mm), not considering corrosion allowance, material, or dimensions. Literary source "Analysis, Synthesis, and Design of Chemical Processes" gives heuristics for wall thickness for rigidity based on vessel diameter: 4 mm (0.25 in) for 1.07 m (42 in) diameter and less than 8.1mm (0.32 in) for 1.07-1.52 m (42-60 in) diameter, and 11.7 mm (0.38 mm) for more than 1.52 m (60 in) diameter (Turton et al., 2012). Taking a conservative approach of setting the minimum thickness to be in between 1.59mm and 4mm, thereby 2.8mm, we will begin the iteration of the thickness from 2.80mm up to 11.04mm at increments of 0.01mm for precision.

Based on data obtained from Ferrobend, a typical workpiece of AISI 316 stainless steel has the mechanical properties as shown. For the purpose of our testing, we will utilize both a conservative and less conservative method by setting our limit at the yield strength as well as the maximum tensile strength to signify failure.

Iteration Process

We can use a simple code to numerically iterate the possible thickness and hoop stress values:

r = 5.52e-2

p = 800000

t = 2.8e-3

while t < 11e-3:

hoop = (r * p)/(t)

print('for thickness', t, 'hoop stress =', hoop, "Pa")

t += 0.1e-3

if hoop > 205e9:

breakFrom the above code we obtain hoop stress values for each iterated thickness values from 2.8 mm to 11 mm. A further constraint was placed in the final lines where the looping would stop if the total hoop stress exceeded the yield strength of the material (stainless steel AISI 316).

From the results, all possible thickness values from 2.8mm to 11mm on 0.1mm increments remain within the yield strength constraint, therefore are all applicable. Shown below are the results from the code for thickness range 4 mm to 7 mm, with hoop stress values ranging below 10 MPa, which is less than 5% of the yield strength limit.

for thickness 0.004099999999999999 hoop stress = 10770731.707317077 Pa

for thickness 0.004199999999999999 hoop stress = 10514285.714285716 Pa

for thickness 0.004299999999999999 hoop stress = 10269767.441860467 Pa

for thickness 0.004399999999999999 hoop stress = 10036363.636363639 Pa

for thickness 0.0045 hoop stress = 9813333.333333334 Pa

for thickness 0.0046 hoop stress = 9600000.0 Pa

for thickness 0.0047 hoop stress = 9395744.680851063 Pa

for thickness 0.0048000000000000004 hoop stress = 9200000.0 Pa

for thickness 0.004900000000000001 hoop stress = 9012244.897959182 Pa

for thickness 0.005000000000000001 hoop stress = 8831999.999999998 Pa

for thickness 0.005100000000000001 hoop stress = 8658823.529411763 Pa

for thickness 0.0052000000000000015 hoop stress = 8492307.69230769 Pa

for thickness 0.005300000000000002 hoop stress = 8332075.47169811 Pa

for thickness 0.005400000000000002 hoop stress = 8177777.777777774 Pa

for thickness 0.005500000000000002 hoop stress = 8029090.909090905 Pa

for thickness 0.0056000000000000025 hoop stress = 7885714.285714282 Pa

for thickness 0.005700000000000003 hoop stress = 7747368.421052628 Pa

for thickness 0.005800000000000003 hoop stress = 7613793.103448272 Pa

for thickness 0.005900000000000003 hoop stress = 7484745.76271186 Pa

for thickness 0.006000000000000004 hoop stress = 7359999.999999995 Pa

for thickness 0.006100000000000004 hoop stress = 7239344.262295078 Pa

for thickness 0.006200000000000004 hoop stress = 7122580.645161286 Pa

for thickness 0.006300000000000004 hoop stress = 7009523.809523805 Pa

for thickness 0.006400000000000005 hoop stress = 6899999.999999995 Pa

for thickness 0.006500000000000005 hoop stress = 6793846.153846148 Pa

for thickness 0.006600000000000005 hoop stress = 6690909.090909085 Pa

for thickness 0.006700000000000005 hoop stress = 6591044.776119398 Pa

for thickness 0.006800000000000006 hoop stress = 6494117.6470588185 Pa

for thickness 0.006900000000000006 hoop stress = 6399999.999999994 Pa

for thickness 0.007000000000000006 hoop stress = 6308571.428571423 Pa

Cost Constraints

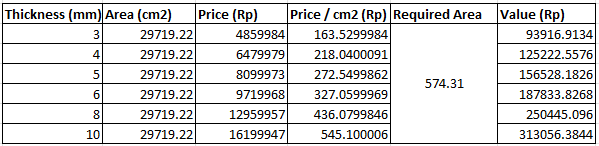

With the geometrical parameters available, we need to compare with the cost constraint that was provided which is that the total cost for materials used should not exceed Rp500.000,-. Therefore, from the material that has been previously considered, we must select the thickness which remain within the cost range. As this is a small-size thin-walled vessel, the most likely method of manufacture is through sheet-metal manufacturing like those used to manufacture storage and beverage cans. Therefore, material purchase would be done in the sheet-metal or plate form.

In the table above, the selection of thickness ranges have been minimized to only include those within our region of interest. Since steel plates are rarely distributed at small surface areas such as the one in our application, a cost per area analysis approach is used based on the data obtained from PT Citra Anggun Lestari. Similar to the circumstances encountered in the strength constraint, all possible thickness values result in material costs that are lower than our set cost constraint. Therefore to select the thickness that we will use, we will also consider the need to minimize the weight and maintain a reasonable amount of strength, which suggests the selection of the median 6 mm wall thickness for the container.