Analisis aliran didalam Cyclone Separator dengan Simulasi CFD menggunakan CFDSOF

Analisis aliran didalam Cyclone Separator dengan Simulasi CFD menggunakan CFDSOF Abstrak

Contents

1. Pengantar

Abi Rizky

Cyclone separators or simply, cyclones, are separation devices which use the principles of inertia to remove particulate matter from flue gases. These are used in many air pollution control systems due to their ability to remove large particulate matters (PMs). And as such, protects finer filtration systems from having to filter larger, more abrasive particles, since finer filters tend to be more sensitive and are generally more expensive.

These devices work much like a centrifuge, but unlike a centrifuge, the flow of dirty air is continuous. The dirty gas is fed into the main chamber, which led the flow to form a vortex due to the geometry of the device. As the flow gets closer to the lower parts, the vorticity increases; however due to inertia, PMs cannot keep up with the vortex within the separator. This led to them being left behind and drop down through the outlet underneath the device. The flue gas then flows upwards, creating a new vortex as it reaches the gas outlet at the top due to buoyant forces.

Agus Nuryadi

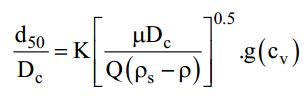

The first systematic design based on the residence time theory for all groups of cyclones and hydrocyclones were proposed by Massarani (1997). In this principle, if the time it stays inside the cyclone is equal to or longer than the time required to hit the wall, a particle of a given size will be captured. The cut's size corresponds to the particle size that, if entered precisely at the center of the inlet pipe, enters the wall during the residence period (t) (Svarovsky, 1984). Massarani equation-related diameter of cut size (d50); parameter (K) Depending on the shape of the cyclone; the physical properties of the system; and the volumetric feed flow rate (Q), as revealed in the equation below.

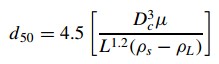

Where g(cv) introduces the effect of concentration on the cut size diameter, g (cv) is approximately equal to one for studies with a heavily diluted suspension. Furthermore, The nomographs by Zanker can be used to make a preliminary estimate of the size of cyclone needed. The specialist manufacturers of hydrocyclone equipment should be consulted to determine the best arrangements and design for a particular application. Zanker’s method is outlined below and illustrated in the Example below and based on an empirical equation by Bradley (1960):

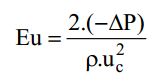

Where, d50 is the particle diameter for which the cyclone is 50 per cent efficient, Dc is diameter of the cyclone chamber, u is liquid viscosity, L is feed flow rate, pl = density of the liquid, and ps = density of the solid. The Euler number is the other significant parameter in the cyclone analysis (Eu). The pressure drop in the cyclone ( ∆ P) with the kinetic energy per unit volume of feeding refers to this dimensionless amount. Also, The greater the number of Euler values, the greater the equipment's cost of energy. By equation, the Euler number is defined.

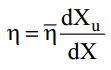

where uc is the average velocity of the fluid in the cylindrical section of the cyclone. Parameter K and the Euler number (Eu) for the Lapple cyclone, as well as the range of gas velocity in the feed section (u), according to Massarani. The ratio between the mass of particles accumulated in the underflow and the mass of particles fed into the cyclone determined the overall efficiency of the separation (η).

Individual separation efficiency (η) is a parameter related to the equipment's separation efficiency for just one particle size. This variable is determined based on knowledge of the overall separation efficiency (η (head)) and the particles' grade distribution in the underflow and feeding, as shown in the following equation. An individual efficiency of separation of 50%, the cut size diameter.

The Eulerian-Lagrangian method and the multiphase particle in cell (MPPIC) method have been used in this study. The model of the MPPIC is a Model Collision in CFDSOF. First of all, PIC models are derived from a Liouville equation describing the time evolution of a particle distribution function.

2. Objektif

1. Performing CFD analysis on Cyclone Separator using various parameters obtained from literatures

2. Analyzing the result obtained from the CFD analysis, such as bulk diameter of the discrete phase, velocity fields, and pressure gradients.

3. Understanding the impacts of various boundary conditions on various aspects of the simulations, such as convergencies, how boundary conditions impact results, and how the flow itself behaves during simulation.

4. Applying knowledge regarding CFD analysis, such as how to choose timesteps for transient flows, making sure that the meshes are applied correctly, and applying boundary and flow conditions.

5. Verifying the results through the means of grid independence study, which ensures the calculations are correct regardless of the meshing, and the difference between results are within the margin of error.

6. Validating the results by comparing the results with literatures and real applications.