Tri Aji Setyawan

Biodata

Tri Aji Setyawan 1906301324

Saya merupakan mahasiswa teknik mesin UI angkatan 2019. saya menyukai teknik mesin karena tertarik pada bidang manufaktur dan karena teknik mesin sendiri memiliki prospek kerja yang luas. hal yang saya pelajari sebelum uts ini adalah mengenai turunan numerik, deret mclaurin , interpolasi, regresi, pengertian dari metode numerik, pseucode.

MINGGU KE 1

- Tujuan mempelajari metode numerik

- 1. matching dengan tujuan belajar: memahami konsep dan prinsip dasar di dalam metnum. contoh persamaan aljabar, algorithma, pencocokan kurva, persamaan diferensial parsial.

- 2. dapat menerapkan pemahaman terhadap konsep di dalam permodelan numerik ( pengaplikasian metode numerik )

- 3. mampu menerapkan metnum di dalam persoalan keteknikan.

- 4. untuk mencapai poin 1,2,3, yaitu dengan cara moral value (adab). untuk menambah nilai tambah / adabsehingga kita menjadi orang yang lebih beradab

TUGAS 1

Pada pertemuan sebelumnya , saya mendapatkan tugas untuk membuat video terkait penggunaan aplikasi open modelica

MINGGU KE 2

perbedaan openmodelica dengan python , open modelicca lebih ke bahasa permodelan sedangkan python hanya bahasa cpoding. kelebihan dari open modelicca yaitu :

- menggunakan bahasa permodelan yang cocok untuk seorang engineer

- proses perhitungan lebih cepat

- pengguna aplikasi openmodelica cukup banyak penggunanya, dan termasuk open teknologi (free).

pada minggu kedua, saya mempelajari mengenai cara memanggil fungsi dalam suatu kelas tertentu

Tugas 2

mengaplikasikan penggunaan fitur function dan class pada open modelica. Membuat sebuah fungsi berupa persamaan aljabar simultan dengan variabel array kemudian membuat class untuk memanggil fungsi tersebut. Persamaan aljabar simultan adalah sebuah persoalan matematika yang kompleks sehingga penyelesaian perlu dengan menggunakan tools, agar dapat dibuat lebih sederhana.

pada tugas kali ini saya mencoba menyelesaikan suatu soal sistem persamaan linier menggunakan metode gauss

MINGGU KE 3

Pada pertemuan ketiga, Pak Dai menjelaskan mengenai tiga aplikasi metode numerik yang sering digunakan dalam menyelesaikan permasalahan teknik

- 1. Computation Fluid Dynamics (CFD)

- 2. Finite Element Analysis

- 3. Metode Stokastik.

Pak Dai kemudian menugaskan untuk membuat fungsi mengenai gauss jordan. kemudian dijelaskan oleh cristo dengan fungsi sebagai berikut :

// Gauss-Jordan Algorithm // Transforms input matrix A into reduced row echelon form matrix B // Christopher S.E. November 2020 input Real [:,:] A; // An augmented matrix of m*n output Real [:,:] B; // Output matrix in reduced row echelon form // Local variables

protected Integer h = 1; // Initialize pivot row Integer k = 1; // Initialize pivot column Integer m = size(A,1); // Number of rows in matrix Integer n = size(A,2); // Number of columns in matrix Integer c = 0; // Index counter Integer max_row; // Row index of max number in pivot column

Real [:] pivot_column; // Vector containing pivot column data Real [:] pivot_row; // Vector containing backwards pivot row data Real [:,:] temp_array; // Stores matrix data when switching rows Real r; // Ratio value used for row operations

// Limit to handle floating point errors Real float_error = 10e-10;

algorithm

// Transfer input matrix A into variable B B := A;

while h <= m and k <= n loop

// Dealing with floating point errors

for i in 1:m loop

for j in 1:n loop

if abs(B[i,j]) <= float_error then

B[i,j] := 0;

end if;

end for;

end for;

// Finding the pivot

pivot_column := {B[i,h] for i in h:m};

// Get position index of lowest row with greatest pivot number

c:= h-1;

for element in pivot_column loop

c := c+1;

if abs(element) == max(abs(pivot_column)) then

max_row := c;

end if;

end for;

// No pivot in this column, move on to next column

if B[max_row, k] == 0 then

k := k+1;

else

// Swap Rows h <-> max_row

temp_array := B;

temp_array[h] := B[max_row];

temp_array[max_row] := B[h];

B:= temp_array;

// Divide pivot row by pivot number

B[h] := B[h]/B[h,k];

// For all rows below the pivot

for i in (h+1):m loop

// Store the ratio of the row to the pivot

r := B[i,k] / B[h,k];

// Set lower part of pivot column to zero

B[i,k] := 0;

// Operations on the remaining row elements

for j in (k+1):n loop

B[i,j] := B[i,j] - B[h,j] * r;

end for;

end for;

// Move on to next pivot row and column

h := h+1;

k := k+1;

end if;

end while;

// The matrix is now in row echelon form

// Set values of (h,k) to (m,n) h := m; k := n;

while h >= 1 and k >=1 loop

// Dealing with floating point errors

for i in 1:m loop

for j in 1:n loop

if abs(B[i,j]) <= float_error then

B[i,j] := 0;

end if;

end for;

end for;

// Finding the pivot

pivot_row := {B[h,i] for i in 1:k};

// Get position index k of pivot

c := 0;

for element in pivot_row loop

c := c+1;

if element <> 0 then

break;

end if;

end for;

k := c;

// No pivot in this row, move on to next row

if B[h, k] == 0 then

h := h-1;

else

// Perform row operations

for i in 1:(h-1) loop

r := B[i,k];

B[i] := B[i] - B[h] * r;

end for;

// Move on to next pivot row and column

h := h-1;

k := k-1;

end if;

end while;

// The matrix is now in reduced row echelon form

end GaussJordan;

PR 3

menyelesaikan 2 soal dengan open modelica yang berhubungan dengan engineering

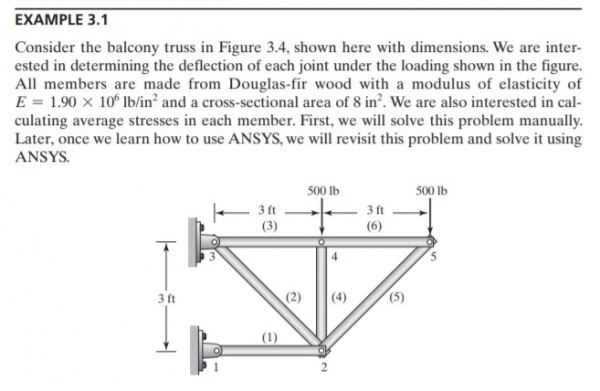

problem 1 ( pada example 3.1)

*model Trusses

parameter Integer N=10; //Global matrice = 2*points connected

parameter Real A=8;

parameter Real E=1.9e6;

Real G[N,N]; //global

Real Ginitial[N,N]; //global

Real Sol[N]; //global dispplacement

Real X[N]={0,0,0,0,0,0,0,-500,0,-500};

Real R[N]; //global reaction force

Real SolMat[N,1];

Real XMat[N,1];

//boundary coundition

Integer b1=1;

Integer b2=3;

//truss 1

parameter Real X1=0; //degree between truss

Real k1=A*E/36;

Real K1[4,4]; //stiffness matrice

Integer p1a=1;

Integer p1b=2;

Real G1[N,N];

//truss 2

parameter Real X2=135; //degree between truss

Real k2=A*E/50.912;

Real K2[4,4]; //stiffness matrice

Integer p2a=2;

Integer p2b=3;

Real G2[N,N];

//truss 3

parameter Real X3=0; //degree between truss

Real k3=A*E/36;

Real K3[4,4]; //stiffness matrice

Integer p3a=3;

Integer p3b=4;

Real G3[N,N];

//truss 4

parameter Real X4=90; //degree between truss

Real k4=A*E/36;

Real K4[4,4]; //stiffness matrice

Integer p4a=2;

Integer p4b=4;

Real G4[N,N];

//truss 5

parameter Real X5=45; //degree between truss

Real k5=A*E/50.912;

Real K5[4,4]; //stiffness matrice

Integer p5a=2;

Integer p5b=5;

Real G5[N,N];

//truss 6

parameter Real X6=0; //degree between truss

Real k6=A*E/36;

Real K6[4,4]; //stiffness matrice

Integer p6a=4;

Integer p6b=5;

Real G6[N,N];

/*

for each truss, please ensure pXa is lower then pXb (X represents truss element number)

*/

algorithm

//creating global matrice

K1:=Stiffness_Matrices(X1);

G1:=k1*Local_Global(K1,N,p1a,p1b);

K2:=Stiffness_Matrices(X2);

G2:=k2*Local_Global(K2,N,p2a,p2b);

K3:=Stiffness_Matrices(X3);

G3:=k3*Local_Global(K3,N,p3a,p3b);

K4:=Stiffness_Matrices(X4);

G4:=k4*Local_Global(K4,N,p4a,p4b);

K5:=Stiffness_Matrices(X5);

G5:=k5*Local_Global(K5,N,p5a,p5b);

K6:=Stiffness_Matrices(X6);

G6:=k6*Local_Global(K6,N,p6a,p6b);

G:=G1+G2+G3+G4+G5+G6;

Ginitial:=G;

//implementing boundary condition

for i in 1:N loop

G[2*b1-1,i]:=0;

G[2*b1,i]:=0;

G[2*b2-1,i]:=0;

G[2*b2,i]:=0;

end for;

G[2*b1-1,2*b1-1]:=1;

G[2*b1,2*b1]:=1;

G[2*b2-1,2*b2-1]:=1;

G[2*b2,2*b2]:=1;

//solving displacement

Sol:=Gauss_Jordan(N,G,X);

//solving reaction force

SolMat:=matrix(Sol);

XMat:=matrix(X);

R:=Reaction_Trusses(N,Ginitial,SolMat,XMat);

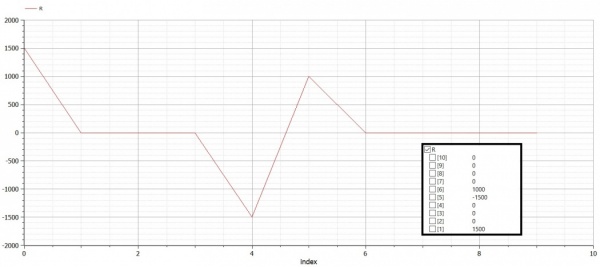

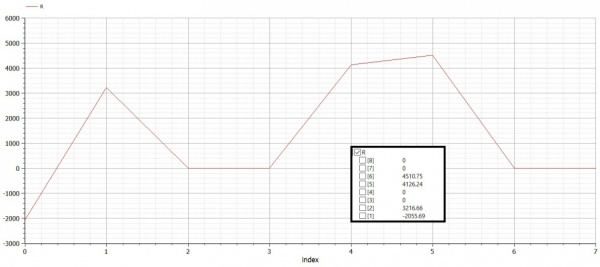

end Trusses;Grafik Reaction forces

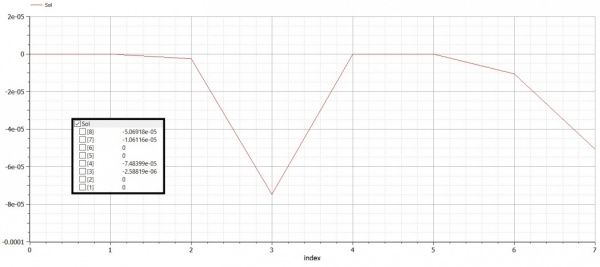

Grafik Diplacement

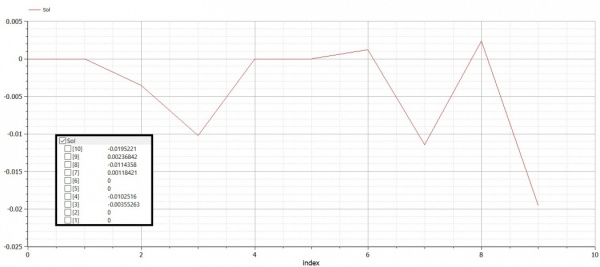

problem 2 ( PR NO 4 )

*class MetodeTrusses

parameter Integer N=8; //Global matrice = 2*points connected

parameter Real A=0.001; //Area m2

parameter Real E=200e9; //Pa

Real G[N,N]; //global

Real Ginitial[N,N]; //global

Real Sol[N]; //global dispplacement

Real X[N]={0,0,-1035.2762,-3863.7033,0,0,-1035.2762,-3863.7033};

Real R[N]; //global reaction force

Real SolMat[N,1];

Real XMat[N,1];

//boundary condition

Integer b1=1;

Integer b2=3;

//truss 1

parameter Real X1=0; //degree between truss

Real k1=A*E/1;

Real K1[4,4]; //stiffness matrice

Integer p1a=1;

Integer p1b=2;

Real G1[N,N];

//truss 2

parameter Real X2=0; //degree between truss

Real k2=A*E/1;

Real K2[4,4]; //stiffness matrice

Integer p2a=2;

Integer p2b=3;

Real G2[N,N];

//truss 3

parameter Real X3=90; //degree between truss

Real k3=A*E/1.25;

Real K3[4,4]; //stiffness matrice

Integer p3a=2;

Integer p3b=4;

Real G3[N,N];

//truss 4

parameter Real X4=90+38.6598; //degree between truss

Real k4=A*E/1.6;

Real K4[4,4]; //stiffness matrice

Integer p4a=1;

Integer p4b=4;

Real G4[N,N];

//truss 5

parameter Real X5=90-38.6598; //degree between truss

Real k5=A*E/1.6;

Real K5[4,4]; //stiffness matrice

Integer p5a=3;

Integer p5b=4;

Real G5[N,N];

/*

for each truss, please ensure pXa is lower then pXb (X represents truss element number)

*/

algorithm

//creating global matrice

K1:=Stiffness_Matrices(X1);

G1:=k1*Local_Global(K1,N,p1a,p1b);

K2:=Stiffness_Matrices(X2);

G2:=k2*Local_Global(K2,N,p2a,p2b);

K3:=Stiffness_Matrices(X3);

G3:=k3*Local_Global(K3,N,p3a,p3b);

K4:=Stiffness_Matrices(X4);

G4:=k4*Local_Global(K4,N,p4a,p4b);

K5:=Stiffness_Matrices(X5);

G5:=k5*Local_Global(K5,N,p5a,p5b);

G:=G1+G2+G3+G4+G5;

Ginitial:=G;

//implementing boundary condition

for i in 1:N loop

G[2*b1-1,i]:=0;

G[2*b1,i]:=0;

G[2*b2-1,i]:=0;

G[2*b2,i]:=0;

end for;

G[2*b1-1,2*b1-1]:=1;

G[2*b1,2*b1]:=1;

G[2*b2-1,2*b2-1]:=1;

G[2*b2,2*b2]:=1;

//solving displacement

Sol:=Gauss_Jordan(N,G,X);

//solving reaction force

SolMat:=matrix(Sol);

XMat:=matrix(X);

R:=Reaction_Trusses(N,Ginitial,SolMat,XMat);

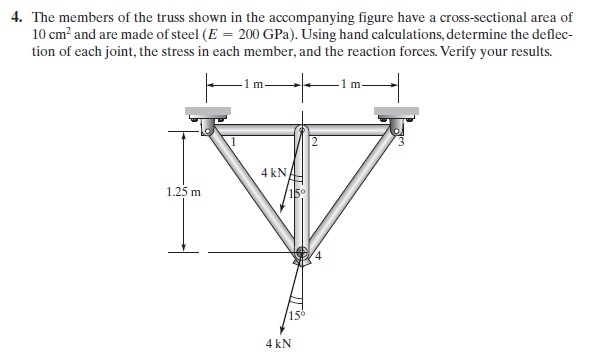

end MetodeTrusses;Grafik Reaction Process

Grafik Diplacement

Transformasi Matriks

function Stiffness_Matrices

input Real A;

Real Y;

output Real X[4,4];

Real float_error = 10e-10;

final constant Real pi=2*Modelica.Math.asin(1.0);

algorithm

Y:=A/180*pi;

X:=[(Modelica.Math.cos(Y))^2,Modelica.Math.cos(Y)*Modelica.Math.sin(Y),-(Modelica.Math.cos(Y))^2,-Modelica.Math.cos(Y)*Modelica.Math.sin(Y);

Modelica.Math.cos(Y)*Modelica.Math.sin(Y),(Modelica.Math.sin(Y))^2,-Modelica.Math.cos(Y)*Modelica.Math.sin(Y),-(Modelica.Math.sin(Y))^2;

-(Modelica.Math.cos(Y))^2,-Modelica.Math.cos(Y)*Modelica.Math.sin(Y),(Modelica.Math.cos(Y))^2,Modelica.Math.cos(Y)*Modelica.Math.sin(Y);

-Modelica.Math.cos(Y)*Modelica.Math.sin(Y),-(Modelica.Math.sin(Y))^2,Modelica.Math.cos(Y)*Modelica.Math.sin(Y),(Modelica.Math.sin(Y))^2];

for i in 1:4 loop

for j in 1:4 loop

if abs(X[i,j]) <= float_error then

X[i,j] := 0;

end if;

end for;

end for;

end Stiffness_Matrices;Global Element Matrice

function Local_Global

input Real Y[4,4];

input Integer B;

input Integer p1;

input Integer p2;

output Real G[B,B];

algorithm

for i in 1:B loop

for j in 1:B loop

G[i,j]:=0;

end for;

end for;

G[2*p1,2*p1]:=Y[2,2];

G[2*p1-1,2*p1-1]:=Y[1,1];

G[2*p1,2*p1-1]:=Y[2,1];

G[2*p1-1,2*p1]:=Y[1,2];

G[2*p2,2*p2]:=Y[4,4];

G[2*p2-1,2*p2-1]:=Y[3,3];

G[2*p2,2*p2-1]:=Y[4,3];

G[2*p2-1,2*p2]:=Y[3,4];

G[2*p2,2*p1]:=Y[4,2];

G[2*p2-1,2*p1-1]:=Y[3,1];

G[2*p2,2*p1-1]:=Y[4,1];

G[2*p2-1,2*p1]:=Y[3,2];

G[2*p1,2*p2]:=Y[2,4];

G[2*p1-1,2*p2-1]:=Y[1,3];

G[2*p1,2*p2-1]:=Y[2,3];

G[2*p1-1,2*p2]:=Y[1,4];

end Local_Global;

Reaction Matrice Equation

function Reaction_Trusses

input Integer N;

input Real A[N,N];

input Real B[N,1];

input Real C[N,1];

Real X[N,1];

output Real Sol[N];

Real float_error = 10e-10;

algorithm

X:=A*B-C;

for i in 1:N loop

if abs(X[i,1]) <= float_error then

X[i,1] := 0;

end if;

end for;

for i in 1:N loop

Sol[i]:=X[i,1];

end for;

end Reaction_Trusses;Gauss Jordan

function Gauss_Jordan

input Integer N;

input Real A[N,N];

input Real B[N];

output Real X[N];

Real float_error = 10e-10;

algorithm

X:=Modelica.Math.Matrices.solve(A,B);

for i in 1:N loop

if abs(X[i]) <= float_error then

X[i] := 0;

end if;

end for;

end Gauss_Jordan;MINGGU KE 4

Kuis pada hari rabu tanggal 2 desember 2020

membuat diagram class dan flowchart dari fungsi yang telah dibuat josiah