Difference between revisions of "Muhamad Azkhariandra Aryaputra"

(→Axial Steam Turbine) |

(→Axial Steam Turbine) |

||

| Line 172: | Line 172: | ||

*Area of 0.5 m x 0.1 m | *Area of 0.5 m x 0.1 m | ||

*V1= 0.01 m/s and V2= 0.013 m/s | *V1= 0.01 m/s and V2= 0.013 m/s | ||

| + | |||

| + | |||

*Simulation | *Simulation | ||

[[File:Screenshot 2023-11-20 015119.png|300px]] | [[File:Screenshot 2023-11-20 015119.png|300px]] | ||

Revision as of 01:46, 20 November 2023

Contents

Introduction

Name: Muhamad Azkhariandra Aryaputra

NPM: 2106657765

Major: Mechanical Engineering KKI

DoB: 1 January 2003

E-mail: azkha.aryaputra@gmail.com

Hello everyone !

My name is Muhamad Azkhariandra Aryaputra, you can call me Azkha. Right now I'm a Mechanical Engineering student at University of Indonesia and taking Numerical Method class with Pak DAI as the lecturer.

Hydrogen Storage Optimization

Hydrogen storage optimization entails enhancing hydrogen storage technologies' efficiency, capacity, safety, and cost-effectiveness. Because hydrogen has a low energy density, efficient storage is essential for its broad use as an energy carrier. Improving the efficiency, safety, and cost-effectiveness of storing and consuming hydrogen under high-pressure circumstances is referred to as optimizing pressurized hydrogen. Pressurized hydrogen storage is a typical approach for increasing energy density and making hydrogen feasible as an energy carrier.

The objective for this project is to minimize the cost of the material but with good quality and safe material to ensure the optimization of hydrogen storage tank. To achieve this objective there are several constraint that must be considered. The key aspects of the optimization of hydrogen storage are :

Storage Tank Design: Optimizing pressurized hydrogen storage entails creating storage tanks that can bear high pressures safely. The materials used in the tank must be sturdy, lightweight, and resistant to hydrogen embrittlement. To attain the appropriate strength-to-weight ratio, advanced composite materials such as carbon fiber composites are frequently used.

Cost: The cost optimization of hydrogen storage involves finding the most cost-effective solutions for storing hydrogen gas.

Safety Measures: In pressurized hydrogen storage, safety is a vital factor. Implementing safety precautions to prevent leaks, ruptures, or explosions is part of the optimization process. This incorporates pressure release systems, burst discs, and stringent testing and inspection methods to assure the storage tanks' integrity.

Mitigation of Hydrogen Leakage: Minimizing hydrogen leakage is critical for ensuring the safety and efficiency of pressurised hydrogen systems. To reduce leaks, optimization efforts include the use of modern sealing technologies such as metal-to-metal seals or elastomeric seals. Regular maintenance, inspection, and leak detection procedures are also necessary to detect and rectify any potential leaks as soon as possible.

Material Compatibility: Optimizing pressurized hydrogen storage necessitates examining the hydrogen compatibility of storage tank materials. Hydrogen can induce embrittlement or penetration in some materials, resulting in decreased strength or hydrogen loss. To increase the longevity and performance of pressurized hydrogen storage systems, researchers are designing materials that are resistant to hydrogen embrittlement and penetration.

Compressed Hydrogen

The earliest and most essential element in the universe is hydrogen. It has the smallest atomic weight of any element and is made up of a positively charged nucleus proton and a negatively charged electron. Hydrogen is a colorless and odorless gas under typical or ordinary conditions. The most established hydrogen storage technique is compressed hydrogen storage, which includes the physical storage of compressed hydrogen gas in high-pressure tanks. Near-term technology for onboard car hydrogen storage currently consists of 35 and 70 MPa nominal working-pressure compressed gas containers. Compressed hydrogen is often kept in cylinders or high pressure tanks constructed of pressure-resistant materials. The pressure at which hydrogen is compressed varies, although it is often held at pressures ranging from 5,000 to 10,000 pounds per square inch (psi) or more. These high pressures enable more hydrogen to be stored in a given volume. Compressed hydrogen is employed in many different applications, such as fuel cell automobiles, industrial operations, and energy storage systems. It is an essential type of hydrogen storage, particularly for mobile applications, because it allows for relatively small and lightweight storage systems.

Material

The material that is used for this project is Aluminum 6061. Aluminum 6061 is a precipitation-hardened aluminum alloy comprising the principal alloying components magnesium and silicon. It has high mechanical qualities, is weldable, and is widely extruded (second only to 6063 in popularity). It is one of the most prevalent general-purpose aluminum alloys. The aluminum alloy 6061 is a significant raw material for aluminum liner carbon fiber full-wrapped composite gas cylinders, the hydrogen compatibility of which impacts the safety and dependability of gas cylinders to a large extent. Aluminum 6061 is chosen because the relative cost of this material is not too expensive but very suitable for the pressurized hydrogen tank material.

Design

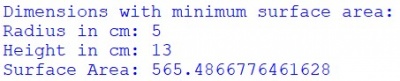

The optimization of the design is for making the hydrogen tank for the minimal cost, so the calculation for the diameter and the height of the tank is presented below

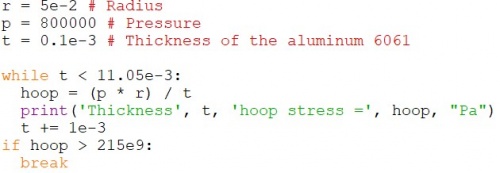

The thickness of the tank

From the result above the estimation of the thickness of the tank is around 6 mm. The cost for the 6 mm Aluminum 6061 is Rp130.000 (240 cm^2). The total area of the tank that have been calculated is 565 cm^2. Therefore for the total cost is 565/240 x Rp130.000 = Rp306.000

Conclusion

We know from the explanation above the constraints for this hydrogen tank optimization project is the cost and the design. The design that is used for this project is cylindrical shape tank with the diameter 10 cm and the height of 13 cm. These diameter and height is calculated because we want to minimize the cost but with the wanted volume. From that design the material that used for this project is Aluminum 6061 and therefore we got the cost for the project is Rp306.000.

ECS 1 Class

ECS 1 First Meeting

Einstein quotes about education : What is left after you’re forgotten all you have learned. Mr Dai said what if you all forgot about calculus. What is the purpose of calculus? I think calculus is not just about solving differentials, derivatives or others. Calculus is used for us to solve everyday problems because it makes us think critically. Energy conversion system is a very wide subject so students must not focus on just the equation, but why we used that equation to solve the energy conversion system problem.

Energy has a key word which is efficiency. We must count every energy that is useful for us because all that energy must be calculated to know how efficient that energy is. In my opinion energy is the source of life because humans need energy to live in this world. There are several laws of energy and one of them is that energy can be converted to another form of energy.

There are three principles of logic, the first one is law of identity, the second one id law of no contradiction, and the third one is aw of the middle excluded.

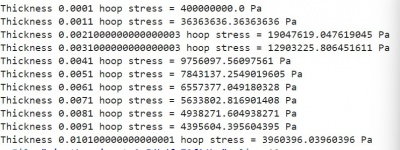

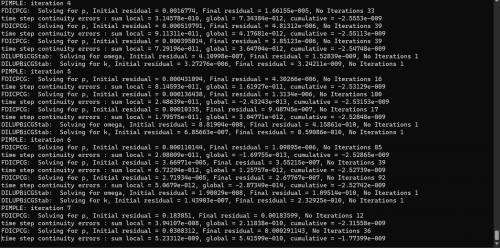

CFD Simulation

CFC simulation of Vertical Axis Wind Turbine with initial condition of:

- Start Time = 0

- End Time = 0.5

- Inlet Velocity = (12 0 0)

By using command prompt

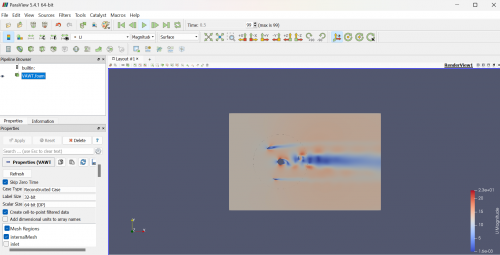

and visualize it with Paraview

This is the simulation of VAWT blade speed with paraview at the time of 0.5 s

ECS Second Week

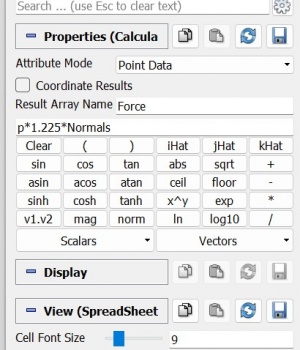

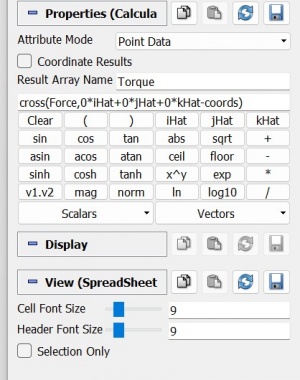

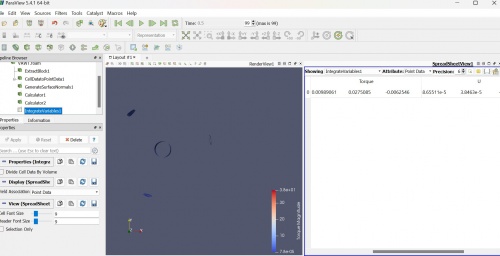

In this week we learnt about the calculation of the torsion of the VAWT by using Paraview

Using the calculator feature to calculate the torque

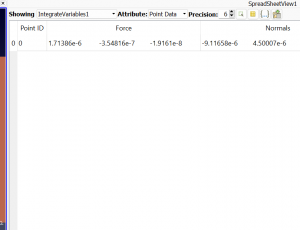

And we can got the result

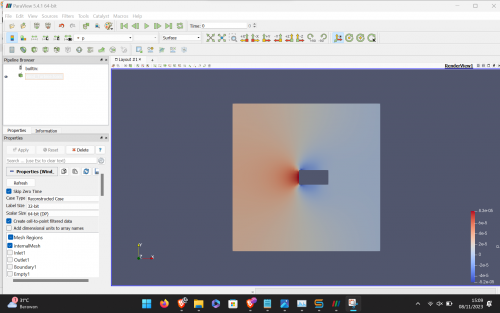

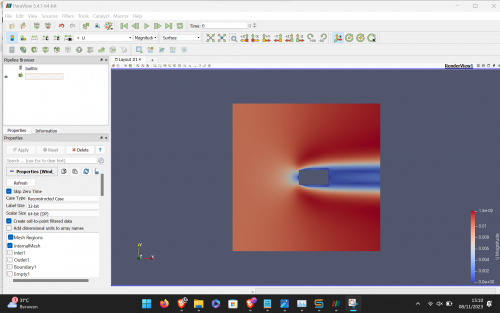

We also calculated the pressure of single blade in a simulation with the dimension of 1 x 3 x 1 meter with base mesh of 10 x 10 x 0.1 meter with velocity of 0.01 m/s

The figure shows a high-pressure area at the front of a blade, which can contribute to the turbine's rotation. Theoretically, a larger blade surface area results in higher pressure, but it also increases weight due to the additional material required.

We also can calculate the velocity

Axial Steam Turbine

Overview

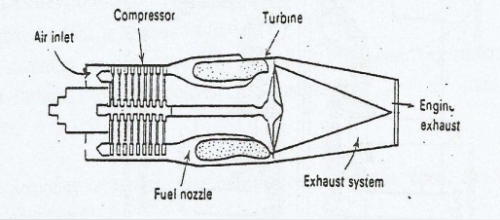

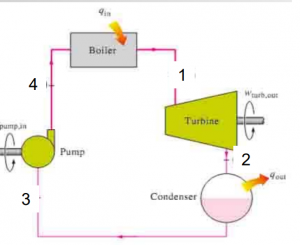

The purpose of steam turbines is to transform the thermal energy contained in steam into mechanical energy. Thermal power plants employ them to generate energy. The electric generator is powered by the steam that is directed via the turbine and onto several revolving blades. These power stations run on nuclear, coal, natural gas, or other fossil fuels.

A steam turbine is a heat engine that achieves a closed state to the optimal reversible expansion process by employing numerous stages to get most of its development in thermodynamic efficiency.

Advantages of steam turbine are simple, reliable, cheap maintenance costs , and steam cleaner from pollution so it can be used for various purposes.

Generally it divided into 2 main types Impulse and Reaction. If static pressure drops occur mainly occur in stationary nozzles with only little or no static pressure drops that occur at the flow through the rotor, the turbine is known as an impulse turbine. In contrast to the reaction turbine, a small percentage of the pressure will fall on the static nozzle and most or the major decrease in pressure will occur in the rotor.

Principle

When a gas or vapor travels through a vapor nozzle and is ejected from it at high speeds into the rotor, some of its thermal energy is transformed into kinetic energy when the static pressure decreases. The flow between the blades changes momentum, which causes torque to be produced and the shaft to revolve (as in water turbines).

Steam Turbine Magic Square:

Calculation

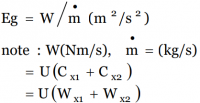

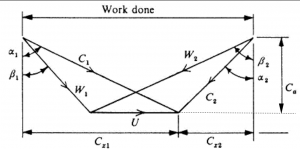

The direction of the flow angle is calculated against the direction of the axial flow. Note: in other literature it is often used flow direction according to the relative flow of the blade.

The Euler Equation for the Axial Steam Turbine : E = U(Cx1-Cx2)/g

With the velocity triangle :

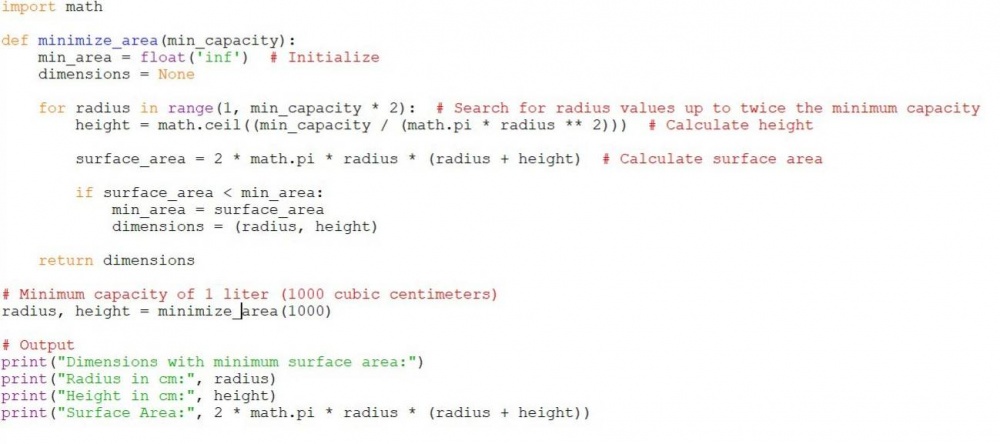

Manual Calculation and Simulation Calculation

- With assumptions of steady state, laminar, and incompressible flow

- Area of 0.5 m x 0.1 m

- V1= 0.01 m/s and V2= 0.013 m/s

- Simulation