Difference between revisions of "Evi Elisa Ambarita"

(→UTS) |

(→UTS) |

||

| Line 194: | Line 194: | ||

3. Draft paper project komputasi teknik | 3. Draft paper project komputasi teknik | ||

| + | |||

| + | Design Development of Strength Testing using CFD on Mini Container Construction with Knock-Down System for Multipurpose Vessel | ||

| + | |||

| + | |||

| + | '''Background''' | ||

| + | |||

| + | Indonesia has thousands of ports including small ports. A lot of small ports cannot be categorized as a cargo port since there is no standard facilities to be a cargo port, such as crane and container car. Whereas the citizens dwelling there still need food storage even just a little. Therefore, in order to support their needs, this study proposed a mini container design with dimension and mass of 12 times smaller than the regular container so that it can be carried only by a pick-up car and forklift. Moreover, this mini container was especially designed with known-down system to minimize the space and decrease the center or gravity while toting it in empty condition. | ||

| + | |||

| + | The design has been presented on author's bachelor thesis in 2016. Autodesk inventor software was utilized to simulate and test the construction of mini container for stress analysis. It was concluded that the container is safe to be used in small cargo port since the safety factor was above 1, the deflection was under 3 mm, and the von mises stress of mini container was less than the material yield stress of carbon steel. | ||

| + | |||

| + | Due to time constraints, the strength testing can only be done using inventor software for stress analysis. Even though, there are still many aspects that need to be investigated further, such as temperature, pressure, corrosion, etc. As known, factors as wind flow, water density, food types, can affect the material utilized for the mini container. Therefore, the current study submits a validation of material strength and feasibility tests of mini container construction using CFD method, so that it can be made as an international standard and commercialized. | ||

| + | |||

| + | |||

| + | '''Objectives''' | ||

| + | |||

| + | 1. Further examine the strength material of mini container construction | ||

| + | |||

| + | 2. Validate the simulation results of stress analysis on mini container construction using CFD method | ||

| + | |||

| + | 3. Define the best material for mini container | ||

| + | |||

| + | '''Problem Formulation''' | ||

| + | |||

| + | 1. What other aspects influence the material strength of mini container construction can be shown in CFD method? | ||

| + | |||

| + | 2. What kind of material is suitable for this mini container? | ||

| + | |||

| + | 3. What kind of storage is suitable for this mini container? | ||

| + | |||

| + | |||

| + | '''Methodology''' | ||

| + | |||

| + | This study will utilize numerical method. Since the design has been performed on previous study, so this study will straight away use ansys software to simulate and test the material applying CFD method. The trial and error will be done to receive the best results of material by adjusting the carbon content of the material and a number of load the mini container can carried. | ||

| + | |||

| + | |||

| + | '''Hypothesis''' | ||

| + | |||

| + | The validation will support the statement of previous study which is to utilize carbon steel AISI 1060 with 0.6% of carbon. | ||

Revision as of 22:19, 25 March 2020

Contents

BIODATA

Nama : Evi Elisa Ambarita

NPM : 1906324044

Jurusan : Konversi energi, Teknik mesin, Universitas Indonesia

Email : evi.elisa91@ui.ac.id

Pengenalan Diri

Baseline of my knowledge and skill related to computing

I am a master student of mechanical engineering in Universitas Indonesia. I got my undergraduate degree from Marine Engineering of Universitas Indonesia in Januari 2016. For my bachelor thesis, i designed a mini container with 1 per 12 of the 12 feet container size using autodesk inventor software which applies finite element approach for stress analysis.

After got my bachelor degree, I worked for a year in a Shipyard company in Jakarta. I was in engineering department working on new ship building design for pipe system using autodesk autocad 2D and 3D software. From May 2018 until August 2020, I moved to Nagasaki, Japan to work with engineering consultant company. In 2 years, I finished 3 projects about ship building, bridge construction, and main foundation of tidal turbine. The company utilized a software known as LS-DYNA whose concept is Incompressible Computational Fluid Dynamics (ICFD) . With that software, i tested the construction strength of tidal turbine foundation. Moreover, I was registered as a research student in Nagasaki University. I learned about Ansys software with Linux program to design and simulate the tidal turbine.

After worked for 3 years in total, I decided to continue my study in Universitas Indonesia. I have a big desire to construct the real tidal turbine in Indonesian's ocean, since Indonesia has great potential of ocean current to generate the electricity around 75 GW. Now for my papers and master thesis, I have been working on design development on diffuser angle of horizontal axis tidal turbine for efficiency optimization by controlling water flow passively. This utilizes CFD solver of Ansys software.

In the conclusion, I have been working on engineering designing software since 2015 until now. Hopefully I'll be able to apply all these knowledge about engineering computation on the technology development for Indonesia.

Pendahuluan Komputasi Teknik

I. Pengertian

Komputasi teknik adalah suatu kegiatan menambah, kurang, kali, bagi angka-angka yang disebut numerik dari eksak dengan menggunakan komputer. Inti berfikir dalam pemograman adalah input-proses-output. Dimana algoritma manusia dalam dipindahkan dalam bentuk algoritma computer, yang disebut dengan bahasa pemograman.

II. Tujuan Pembelajaran

1. Mampu memahami konsep-konsep dan prinsip-prinsip didalam pelajaran komputasi teknik, seperti konsep iterasi, konsep error (floating point error), dsb.

2. Mampu menerapkan pemahaman tersebut dalam menyelesaikan masalah didalam masyarakat

3. Memiliki pengenalan diri yang lebih tentang muhasabah, skill, value, dsb.

Sinopsis Skripsi

Judul: Perancangan Mini Kontainer dengan Sistem Bongkar Pasang untuk Angkutan Kapal Serbaguna

Ringkasan:

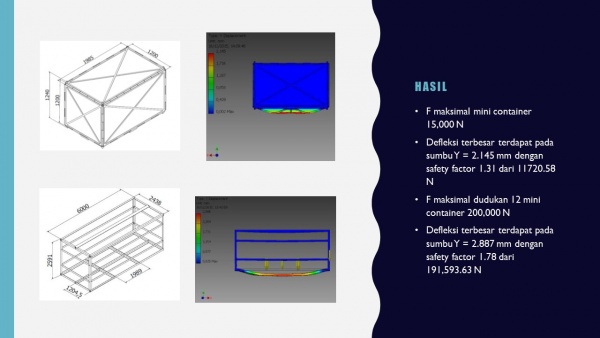

Indonesia masih memiliki banyak pelabuhan kecil dengan fasilitas yang tidak memadai layaknya pelabuhan besar. Fasilitas tersebut diantaranya crane yang mampu mengangkut kontainer 20 ft dan mobil truk kontainer. Dengan keadaan tersebut, maka pelabuhan-pelabuhan tersebut tidak dapat digunakan untuk transportasi barang dari pulau satu ke pulau lainnya. Oleh karena itu, diperlukan suatu benda dengan dimensi dan massa yang lebih kecil dibandingkan kontainer biasa. Pada skripsi ini, untuk tujuan pelayaran rakyat, penulis mendesain mini kontainer dengan dimensi dan massa 12 kali lebih kecil dibandingkan kontainer biasa, sesuai spesifikasi bak mobil pick up mitsubishi colt L300. Disamping itu, mini kontainer ini dirancang khusus dengan sistem bongkar pasang untuk mengurangi ruang dan titik gravitasi pada saat membawa mini kontainer dalam keadaan kosong. Penelitian ini dilakukan dengan metode numerik yakni mendesain dan mensimulasi kekuatan dari mini kontainer tersebut menggunakan pendekatan finite element yang terdapat pada software autodesk inventor. Berdasarkan simulasi stress analysis menggunakan software tersebut, maka mini container ini dikategorikan kuat dan mampu menjadi standar nasional untuk diaplikasikan di pelabuhan-pelabuhan kecil.

Korelasi terkait sinopsis skripsi dengan komputasi teknik

Desain mini kontainer pada skripsi ini dirancang menggunakan software autodesk inventor dengan pendekatan finite element pada stress analysis.

Presentasi Sinopsis Skripsi

Quiz

Model Komputasi Teknik

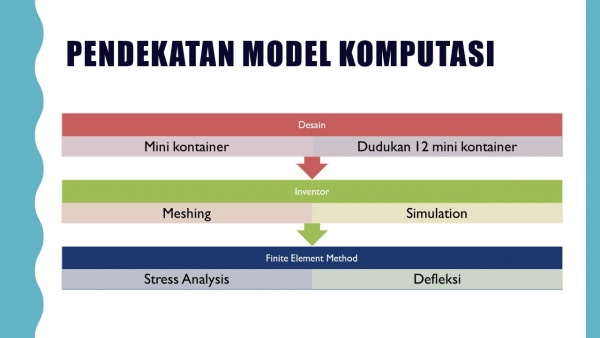

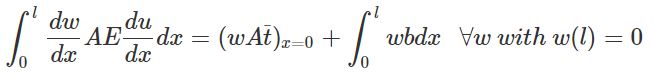

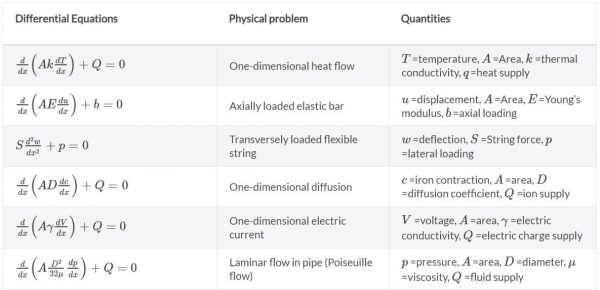

Pengerjaan skripsi saya menggunakan perangkat lunak inventor yang didasarkan pada Finite Element Method (FEM) untuk stress analysis. FEM adalah model perhitungan numerik yang menemukan perkiraan solusi untuk masalah persamaan differensial parsial dan integrasi lainnya yang dihasilkan dari hasil diskritisasi benda kontinum. Apa yang dilakukan FEM adalah membagi sebuah masalah besar menjadi bagian-bagian yang lebih kecil dan sederhana. Dalam Autodesk Inventor Stress Analysis, itu membutuhkan struktur yang complex dan mengubahnya menjadi bagian-bagian lebih kecil (meshing process) dan kemudian menyelesaikan persamaan dengan sistem persamaan yang memiliki input yang berbeda-beda, seperti constraints, materials, and loads.

In stress analysis, the weak form is called the principle of virtual work.

dimana,

w = deflection

u = displacement

A = area

E = young’s modulus

b = axial loading

Untuk persamaan lainnya terkait Finite Element Analysis dapat dilihat pada tabel dibawah ini,

source: https: //www. simscale.com/docs/content/simwiki/fea/whatisfea.html

Extended Abstract

Nama: Evi Elisa Ambarita Judul: Mini Container Design with Knock-Down System for Multipurpose Vessel Transportation.

In fact, Indonesia still has a lot of small ports whose facilities are not as compatible as big ports’ such as a container truck and crane with small power which is not able to lift a 20 ft container. Accordingly, those harbours cannot be categorized as a cargo port. Therefore, this study proposed a mini container design with dimension and mass of 12 times smaller than the regular container so that it can be carried only by a pick-up car and forklift. Moreover, this mini container was especially designed with known-down system to minimize the space and decrease the centre or gravity while toting it in empty condition. The inventor software was utilized to design and simulate mini container, also to test its material strength well known as stress analysis. The software applies finite element method (FEM) to subdivide a large system into smaller and simpler parts. To be able to run simulations, a mesh, consisting of up to millions of small elements that together form the shape of the structure needs to be created. Calculations are made for every single element. Combining the individual results gives the result of the structure. Afterwards, the simulation was conducted by inputting the stress distribution of force value and the fixed constraint. The result of this numerical method was represented the von mises stress, 1st and 3rd principal stress to obtain the occurred displacement when there was bending on the object. Based on the simulation and calculation, this mini container was concluded to meet the ISO standard about size and material of container to carry cargo for multipurpose vessel transportation.

Optimasi Kebutuhan Energi Manusia

Sebagai unit dari energi, kalori mengacu pada energi yang diperoleh dari makanan dan minuman yang kita konsumsi setiap hari. Kalori sangat penting bagi tubuh manusia. Tanpa kalori, sel-sel dalam tubuh akan mati, dan organ-organ vital seperti jantung dan paru-paru tidak akan mampu melaksanakan fungsi dasarnya.

Di Indonesia, berdasarkan rekomendasi Angka Kecukupan Gizi (AKG) dari Kementerian Kesehatan RI, rata-rata kebutuhan untuk pria usia 30 – 49 tahun adalah 2625 kkal per hari. Sedangkan perempuan usia 30 – 49 tahun adalah 2150 kkal per hari, demikian seperti dikutip dari laman depkes.go,id.

Menghitung Kalori

Terdapat dua jenis kalori, yaitu kalori kecil yang ditulis dalam satuan “kal” dan kalori besar atau “kilokalori” (kkal), dengan perhitungan 1 kkal sama dengan 1.000 kal. Cara menghitung kalori yang kita butuhkan menurut P2PTM Kemenkes RI sangat sederhana, karena hanya berdasarkan jenis kelamin dan tinggi badan. Sebelum menghitung, kita harus mengetahui terlebih dahulu tinggi badan (TB) dalam sentimenter dan Berat Badan Ideal (BBI) dengan rumus sebagai berikut:

BBI = (TB-100) – (10% x (TB – 100))

Selanjutnya, kita dapat hitung Kebutuhan Kalori Basal (KKB) atau Basal Metabolic Rate (BMR). KKB merupakan kebutuhan kalori yang dibutuhkan oleh tubuh untuk metabolisme basal, yakni metabolisme yang wajib dilakukan mahluk hidup walaupun tidak membutuhkan energi. Ini berarti metabolisme tubuh akan tetap berjalan meskipun dalam keadaan tidur atau tidak melakukan apa-apa. Berikut adalah rumus menghitung angka KKB:

KKB Laki-laki = 30 kkal x BBI

KKB Perempuan = 25 kkal x BBI

Menghitung Kebutuhan Kalori Total (KKT)

Kebutuhan kalori total adalah jumlah kebutuhan kalori tubuh ditambah dengan jumlah kalori saat melakukan aktivitas fisik. Kita mengenal tiga jenis aktivitas, yaitu

1. Aktivitas ringan seperti membaca (10%), menyetir mobil (10%), kerja kantoran (10%), mengajar (20%), berjalan (20%).

2. Aktivitas sedang: kerja rumah tangga (20%), jalan cepat (30%), bersepeda (30%).

3. Aktivitas berat: aerobik (40%), mendaki (40%), dan jogging (40%)

Rumus KKT = KKB + Aktivitas Fisik - Faktor Koreksi

Faktor koreksi adalah sebagai berikut:

Usia 40 - 59 tahun, nilai koreksinya minus 5%

Usia 60 - 69 tahun, nilai koreksinya minus 10%

Usia >70 tahun, nilai koreksinya minus 20%

Resource: https:// www.anlene.com/id/ms/berapa-banyak-kalori-yang-anda-butuhkan-setiap-hari.html

9 Maret 2020

Berikut tahapan dalam menganalisa suatu masalah:

1. Initial thinking (analisis) untuk mengidentifikasi masalah (objektif) yang akan diselesaikan, dapat berupa masalah terstruktur yakni terkait SOP, dan unstructured issue terkait modifikasi.

2. Mengembangkan rumusan (permodelan matematis) yang mengandung asumsi (tergantung pengetahuan, ilmu, dan pengalaman kita), dimana asumsi sama dengan batasan masalah.

3. Pengumpulan data yang dibutuhkan untuk menyelesaikan permodelan matematis diatas.

4. Simulasi = menjalankan atau mengeksekusi model (constraint) yang kita buat dengan suatu variabel bebas

5. Verifikasi = resolve the equation right, menguji apakah model yang dilakukan tidak ada kesalahan numerik, contohnya kesalahan ngitung, pada proses meshing

6. Validasi = resolve the right equation, menguji kebenaran / keaktualan dari hasil simulasi tadi

7. Result dan discussion

8. Recommendation

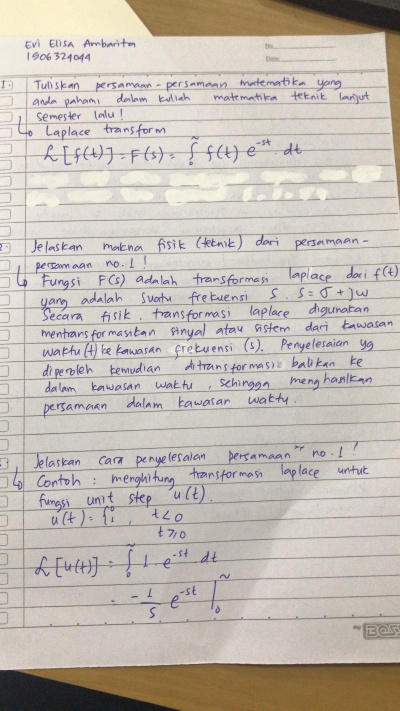

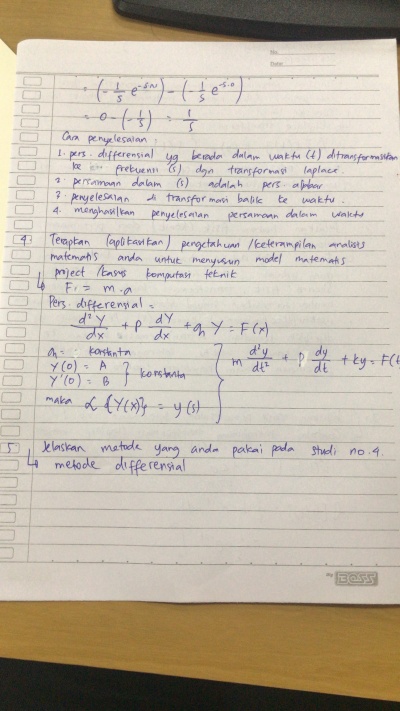

UTS

1. Video presentasi hasil belajar terkait pengetahuan (konsep/teori) dan keterampilan (menggunakan komputasi teknik)

2. Laporan hasil tugas optimasi kebutuhan energi manusia.

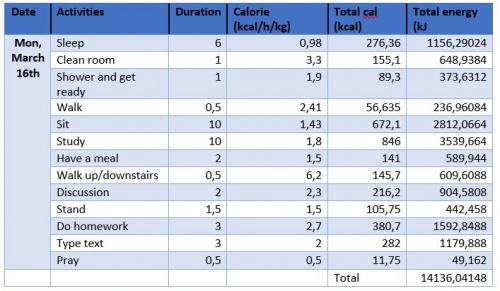

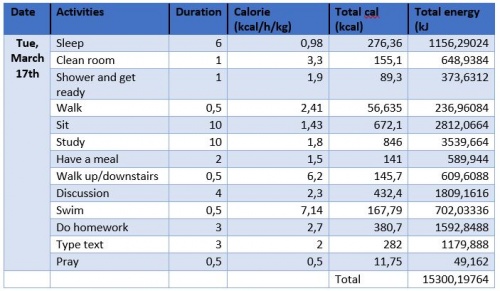

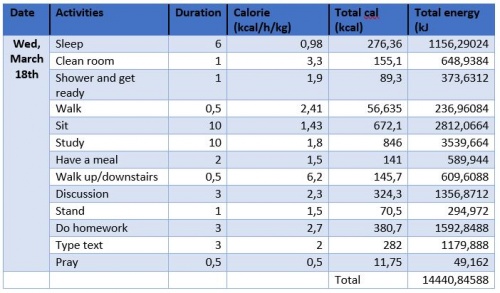

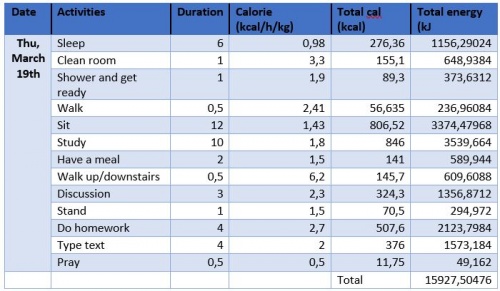

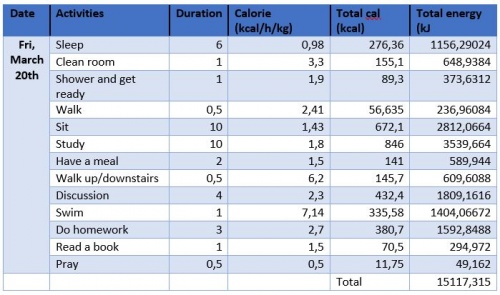

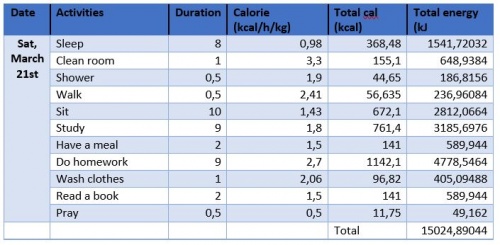

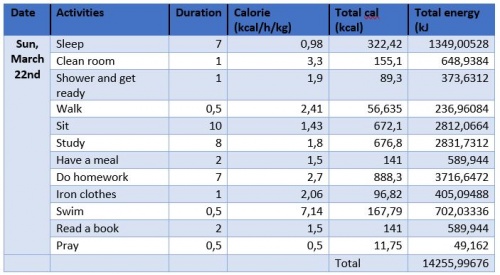

Berdasarkan hasil diskusi kelas pada ( http://air.eng.ui.ac.id/index.php?title=Optimasi_Sistem_Energi_pada_Manusia ) ini, berikut optimasi kebutuhan energi saya pribadi selama seminggu (March 16th - 22nd),

Kebutuhan kalori yang saya butuhkan dalam 1 minggu:

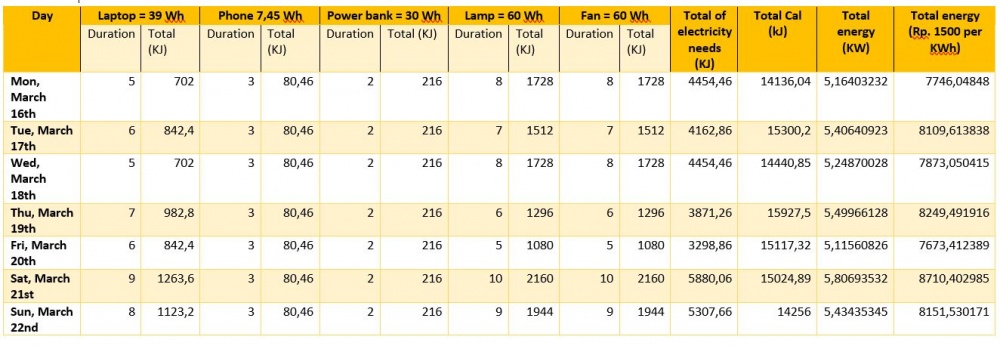

Kebutuhan listrik yang saya butuhkan dalam 1 minggu:

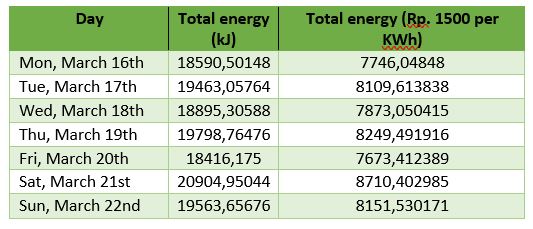

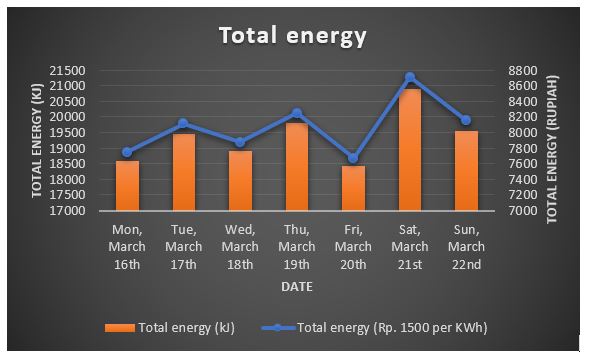

Sehingga diperoleh total energi dan total biaya yang saya butuhkan dalam seminggu:

Dan menghasilkan grafik sebagai berikut:

3. Draft paper project komputasi teknik

Design Development of Strength Testing using CFD on Mini Container Construction with Knock-Down System for Multipurpose Vessel

Background

Indonesia has thousands of ports including small ports. A lot of small ports cannot be categorized as a cargo port since there is no standard facilities to be a cargo port, such as crane and container car. Whereas the citizens dwelling there still need food storage even just a little. Therefore, in order to support their needs, this study proposed a mini container design with dimension and mass of 12 times smaller than the regular container so that it can be carried only by a pick-up car and forklift. Moreover, this mini container was especially designed with known-down system to minimize the space and decrease the center or gravity while toting it in empty condition.

The design has been presented on author's bachelor thesis in 2016. Autodesk inventor software was utilized to simulate and test the construction of mini container for stress analysis. It was concluded that the container is safe to be used in small cargo port since the safety factor was above 1, the deflection was under 3 mm, and the von mises stress of mini container was less than the material yield stress of carbon steel.

Due to time constraints, the strength testing can only be done using inventor software for stress analysis. Even though, there are still many aspects that need to be investigated further, such as temperature, pressure, corrosion, etc. As known, factors as wind flow, water density, food types, can affect the material utilized for the mini container. Therefore, the current study submits a validation of material strength and feasibility tests of mini container construction using CFD method, so that it can be made as an international standard and commercialized.

Objectives

1. Further examine the strength material of mini container construction

2. Validate the simulation results of stress analysis on mini container construction using CFD method

3. Define the best material for mini container

Problem Formulation

1. What other aspects influence the material strength of mini container construction can be shown in CFD method?

2. What kind of material is suitable for this mini container?

3. What kind of storage is suitable for this mini container?

Methodology

This study will utilize numerical method. Since the design has been performed on previous study, so this study will straight away use ansys software to simulate and test the material applying CFD method. The trial and error will be done to receive the best results of material by adjusting the carbon content of the material and a number of load the mini container can carried.

Hypothesis

The validation will support the statement of previous study which is to utilize carbon steel AISI 1060 with 0.6% of carbon.