Difference between revisions of "Tanveer khan"

Tanveer.khan (talk | contribs) |

Tanveer.khan (talk | contribs) |

||

| Line 10: | Line 10: | ||

<youtube width="500" height="400">ChowopXiO3M </youtube> | <youtube width="500" height="400">ChowopXiO3M </youtube> | ||

| + | |||

| + | |||

| + | Task#02 (Pipe stress analysis using Ansys 2021R2): | ||

| + | [[File:Displacment.jpg]] | ||

| + | |||

| + | I used the following specifications for the stress analysis of the pipe using the Ansys 2021R2; | ||

| + | |||

| + | 1) Material: Structural steel. | ||

| + | 2) Length: 200mm. | ||

| + | 3) Outer Diameter: 50mm. | ||

| + | 4) Inner Diameter: 45mm. | ||

| + | 5) Thickness: 2.5mm. | ||

| + | |||

| + | Boundary conditions: | ||

| + | 1) Fixed right end | ||

| + | 2) Applied load to the left end (Load= 50N) | ||

| + | |||

| + | Result: | ||

| + | As we can see from the picture, the maximum deformation is 1.3372e-004 mm at the applied load end and the minimum deformation is 0mm at the fixed end. This follows the concept of each element elongation which can sum up to give us the whole displacement. The colors of the pipe represent various ranges of displacements at the specific regions, here the red color region represents a large displacement region while blue represents the small displacement region. Moreover, the color bar on the left side shows color codes with various values that we can see on the pipe, ranging from 0mm to 1.3372e-004 mm. | ||

Revision as of 10:34, 10 September 2024

Hello! Welcome to my Wiki page.

I am Tanveer khan from Pakistan, studying at the Faculty of Engineering Universitas Indonesia(FTUI). My major is Mechanical engineering and my specialty is manufacturing and automation systems.

I've enrolled in a Finite Element and Multiphysics course to gain a deeper understanding of the fundamental principles and applications of FEM, as well as to explore various types of simulations.

Task#01 (DAI5 Framework)

Hello, I am Tanveer Khan presenting the DAI5 Framework, an innovative approach developed by Dr. Ahmed Indra (DAI). This method, DAI5, focuses on intentions, initial thinking, idealizations, and instruction sets for effective problem-solving. I discuss the unique aspects of DAI5 and how it differs from traditional approaches, emphasizing the importance of clarity and specificity in instructions. Viewers are encouraged to understand the significance of setting clear objectives and simplifying complex problems.

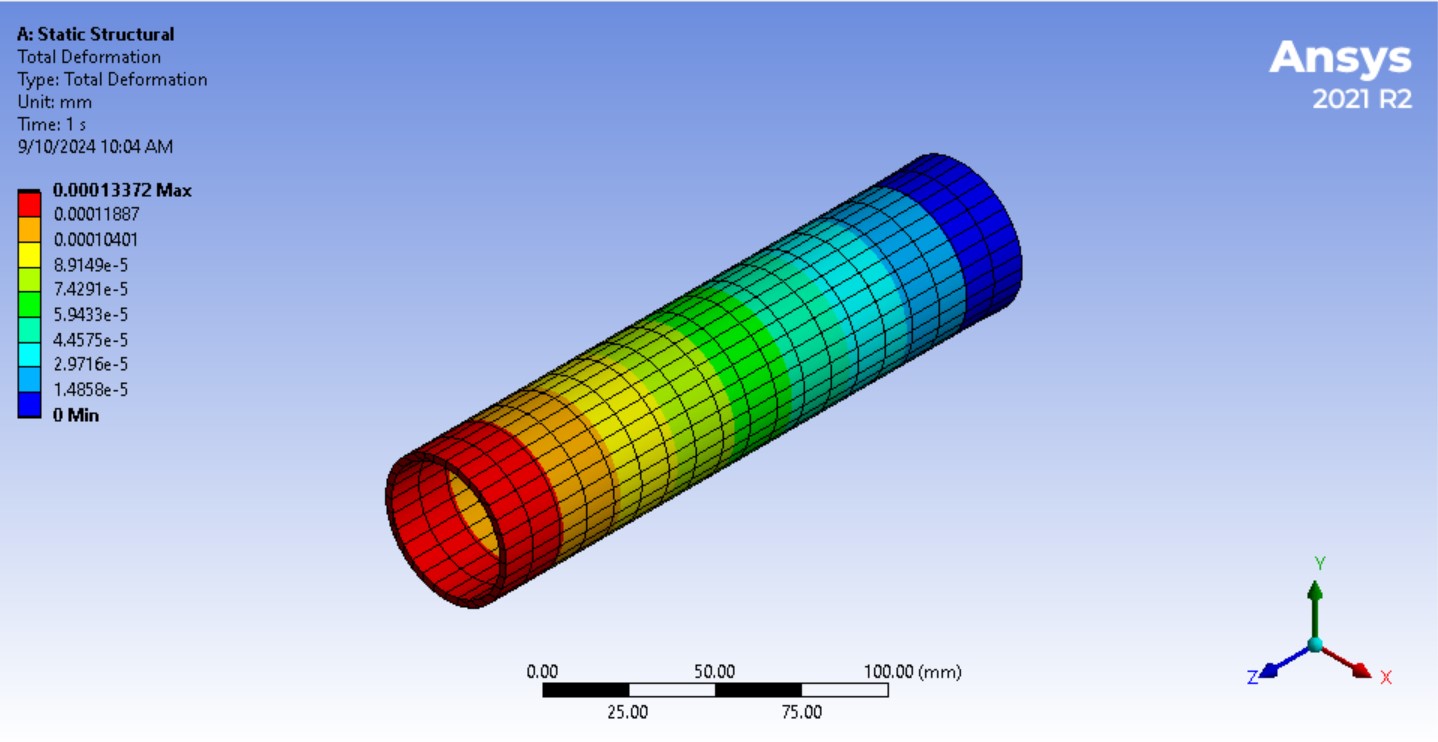

Task#02 (Pipe stress analysis using Ansys 2021R2):

I used the following specifications for the stress analysis of the pipe using the Ansys 2021R2;

1) Material: Structural steel. 2) Length: 200mm. 3) Outer Diameter: 50mm. 4) Inner Diameter: 45mm. 5) Thickness: 2.5mm.

Boundary conditions: 1) Fixed right end 2) Applied load to the left end (Load= 50N)

Result: As we can see from the picture, the maximum deformation is 1.3372e-004 mm at the applied load end and the minimum deformation is 0mm at the fixed end. This follows the concept of each element elongation which can sum up to give us the whole displacement. The colors of the pipe represent various ranges of displacements at the specific regions, here the red color region represents a large displacement region while blue represents the small displacement region. Moreover, the color bar on the left side shows color codes with various values that we can see on the pipe, ranging from 0mm to 1.3372e-004 mm.