Difference between revisions of "Zefanya Valeryan H.H. (Metode Numerik)"

(→Designing & Calculation of Hydrogen Storage Optimization) |

(→Designing & Calculation of Hydrogen Storage Optimization) |

||

| Line 39: | Line 39: | ||

Penulis | Penulis | ||

| − | == | + | =Pressurized Hydrogen Storage Optimization= |

| + | ==Pressurized Hydrogen Storage== | ||

| + | : | ||

| + | : Pressurized hydrogen storage involves compressing hydrogen gas and storing it in specially designed tanks or cylinders. These tanks are built to withstand high pressures, typically ranging from a few hundred to several thousand pounds per square inch (psi). Pressurized storage offers advantages such as simplicity, portability, and fast refueling times. However, it also presents challenges related to weight, safety, and limited storage capacity. Tank materials must be robust, and strict testing is necessary to prevent leaks or ruptures. Alternative storage methods like cryogenic storage and hydrogen carriers are being explored to address these limitations and optimize hydrogen storage and utilization. | ||

| − | |||

| − | + | ==Factors Involved in Designing and Optimizing a Pressurized Hydrogen Storage== | |

| − | + | : [[File: Hydrogen_Storage_Example_Farras Hafizh.jpg|450px|thumb|middle| Simple example of a pressurized hydrogen tank (source: doosanmobility.com)]] | |

| − | + | : | |

| − | + | : Designing and optimizing a pressurized hydrogen storage involves several factors and processes to ensure its safety, efficiency, and performance. Here are some key considerations in the design and optimization process: | |

| − | + | : | |

| − | + | : '''Storage Capacity''' | |

| − | + | : The required storage capacity of hydrogen must be determined based on the anticipated demand and usage. Factors such as the desired duration of storage, refill frequency, and system requirements play a role in determining the storage capacity. | |

| − | + | :'''Material Selection''' | |

| − | + | : The choice of materials for the storage tank is crucial. Factors such as material strength, corrosion resistance, hydrogen compatibility, weight, and cost need to be considered. The selected material should meet safety standards, regulatory requirements, and be suitable for the specific application. | |

| − | + | :'''Pressure Requirements''' | |

| − | + | : Determining the optimal operating pressure is critical to balance storage capacity, tank weight, and safety. Higher pressures allow for more hydrogen storage within a given volume, but it increases material requirements and safety considerations. The pressure requirements should align with the intended use and regulatory standards. | |

| − | + | :'''Safety Considerations''' | |

| − | + | : Safety is paramount in hydrogen storage design. Factors such as material integrity, leak prevention, pressure relief mechanisms, and appropriate safety measures need to be incorporated. Standards and guidelines from regulatory bodies, such as the International Organization for Standardization (ISO) and national safety codes, should be followed. | |

| − | + | :'''Structural Design''' | |

| − | + | : The structural design of the storage tank must ensure its mechanical integrity and resistance to external loads, vibrations, and impacts. Finite element analysis (FEA) and other engineering calculations are performed to determine the optimal tank shape, thickness, reinforcement, and support structures. | |

| − | + | :'''Thermal Management''' | |

| − | + | : Hydrogen storage systems may require thermal management to control temperature variations. Insulation, cooling, or heating mechanisms are employed to maintain the desired hydrogen temperature range and prevent thermal stresses. | |

| − | + | :'''Cost Optimization''' | |

| − | + | : Optimization techniques, such as mathematical modeling and numerical methods, can be applied to minimize costs while meeting performance and safety requirements. This includes optimizing material usage, tank size, manufacturing processes, and other relevant parameters. | |

| − | + | :'''Regulatory Compliance''' | |

| − | + | : Compliance with relevant regulations, standards, and codes is essential in the design and operation of pressurized hydrogen storage. It ensures safety, environmental protection, and compatibility with industry norms. | |

| − | + | :'''Hydrogen Purity''' | |

| − | + | : The required purity level of hydrogen for the specific application should be considered. Impurities in the hydrogen stream can impact the integrity and performance of the storage system. Depending on the application, purification processes may be needed to remove impurities. | |

| − | + | :'''Fill and Discharge Rates''' | |

| − | ''' | + | : The desired fill and discharge rates of hydrogen affect the design and optimization of the storage system. Factors such as the available infrastructure, operational requirements, and efficiency considerations influence the sizing of valves, piping, and other components. |

| − | + | :'''System Integration''' | |

| − | + | : Pressurized hydrogen storage systems are often integrated with other components and subsystems, such as hydrogen production units, fuel cells, or transportation systems. Seamless integration and compatibility with these systems are important to ensure overall system performance. | |

| − | + | :'''Environmental Considerations''' | |

| − | + | : Environmental factors, including temperature variations, exposure to corrosive substances, and seismic activity, should be taken into account during the design process. Adequate protection and design measures, such as coatings, seismic restraints, and environmental monitoring, may be required. | |

| − | + | :'''Manufacturing and Fabrication Methods''' | |

| − | + | : The manufacturing and fabrication techniques employed impact the quality, cost, and scalability of the storage system. Selection of appropriate manufacturing methods, such as welding, forming, or composite layup, needs to be aligned with the chosen materials and desired characteristics. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Revision as of 23:47, 5 June 2023

Contents

BIODATA

Nama :

Zefanya Valeryan Harbangan Hutabarat

NPM :

2106630611

TTL :

Depok, 31 Januari 2003

Program Studi :

Teknik Mesin

KATA PENGANTAR

Puji syukur saya panjatkan ke hadirat Tuhan Yang Maha Esa. Atas rahmat dan berkat-Nya, penulis dapat menjalani perkuliahannya di jurusan teknik mesin di Universitas Indonesia.

Tidak lupa penulis mengucapkan rasa terima kasih kepada Bapak Dr. Ir. Ahmad Indra Siswantara selaku dosen untuk mata kuliah metode numerik yang telah membantu penulis dalam mengerjakan laman ini. Penulis juga mengucapkan terima kasih kepada teman-teman serta asisten dosen yang telah memberikan masukan serta pengetahuan dalam pembuatan laman ini.

Laman ini berisikan catatan serta tugas saya selama menjalani mata kuliah mekanika fluida dasar. Bagi para mahasiswa yang mencari sumber pengetahuan tentang mekanika fluida dasar, maka laman ini dapat menjadi salah satu sarana pembelajaran.

Penulis menyadari adanya kekurangan pada laman ini. Oleh karena itu, saran dan kritik senantiasa diharapkan demi perbaikan laman ini. Penulis juga berharap agar laman ini dapat memberikan pengetahuan tentang mekanika fluida dasar kepada orang banyak.

Depok, 25 Mei 2023

Penulis

Pressurized Hydrogen Storage Optimization

Pressurized Hydrogen Storage

- Pressurized hydrogen storage involves compressing hydrogen gas and storing it in specially designed tanks or cylinders. These tanks are built to withstand high pressures, typically ranging from a few hundred to several thousand pounds per square inch (psi). Pressurized storage offers advantages such as simplicity, portability, and fast refueling times. However, it also presents challenges related to weight, safety, and limited storage capacity. Tank materials must be robust, and strict testing is necessary to prevent leaks or ruptures. Alternative storage methods like cryogenic storage and hydrogen carriers are being explored to address these limitations and optimize hydrogen storage and utilization.

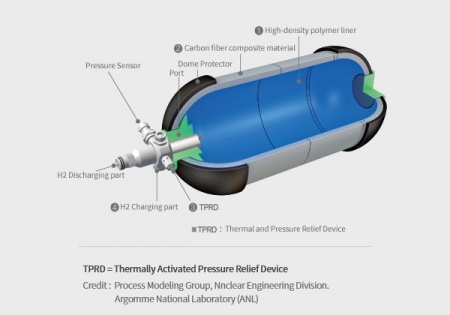

Factors Involved in Designing and Optimizing a Pressurized Hydrogen Storage

- Designing and optimizing a pressurized hydrogen storage involves several factors and processes to ensure its safety, efficiency, and performance. Here are some key considerations in the design and optimization process:

- Storage Capacity

- The required storage capacity of hydrogen must be determined based on the anticipated demand and usage. Factors such as the desired duration of storage, refill frequency, and system requirements play a role in determining the storage capacity.

- Material Selection

- The choice of materials for the storage tank is crucial. Factors such as material strength, corrosion resistance, hydrogen compatibility, weight, and cost need to be considered. The selected material should meet safety standards, regulatory requirements, and be suitable for the specific application.

- Pressure Requirements

- Determining the optimal operating pressure is critical to balance storage capacity, tank weight, and safety. Higher pressures allow for more hydrogen storage within a given volume, but it increases material requirements and safety considerations. The pressure requirements should align with the intended use and regulatory standards.

- Safety Considerations

- Safety is paramount in hydrogen storage design. Factors such as material integrity, leak prevention, pressure relief mechanisms, and appropriate safety measures need to be incorporated. Standards and guidelines from regulatory bodies, such as the International Organization for Standardization (ISO) and national safety codes, should be followed.

- Structural Design

- The structural design of the storage tank must ensure its mechanical integrity and resistance to external loads, vibrations, and impacts. Finite element analysis (FEA) and other engineering calculations are performed to determine the optimal tank shape, thickness, reinforcement, and support structures.

- Thermal Management

- Hydrogen storage systems may require thermal management to control temperature variations. Insulation, cooling, or heating mechanisms are employed to maintain the desired hydrogen temperature range and prevent thermal stresses.

- Cost Optimization

- Optimization techniques, such as mathematical modeling and numerical methods, can be applied to minimize costs while meeting performance and safety requirements. This includes optimizing material usage, tank size, manufacturing processes, and other relevant parameters.

- Regulatory Compliance

- Compliance with relevant regulations, standards, and codes is essential in the design and operation of pressurized hydrogen storage. It ensures safety, environmental protection, and compatibility with industry norms.

- Hydrogen Purity

- The required purity level of hydrogen for the specific application should be considered. Impurities in the hydrogen stream can impact the integrity and performance of the storage system. Depending on the application, purification processes may be needed to remove impurities.

- Fill and Discharge Rates

- The desired fill and discharge rates of hydrogen affect the design and optimization of the storage system. Factors such as the available infrastructure, operational requirements, and efficiency considerations influence the sizing of valves, piping, and other components.

- System Integration

- Pressurized hydrogen storage systems are often integrated with other components and subsystems, such as hydrogen production units, fuel cells, or transportation systems. Seamless integration and compatibility with these systems are important to ensure overall system performance.

- Environmental Considerations

- Environmental factors, including temperature variations, exposure to corrosive substances, and seismic activity, should be taken into account during the design process. Adequate protection and design measures, such as coatings, seismic restraints, and environmental monitoring, may be required.

- Manufacturing and Fabrication Methods

- The manufacturing and fabrication techniques employed impact the quality, cost, and scalability of the storage system. Selection of appropriate manufacturing methods, such as welding, forming, or composite layup, needs to be aligned with the chosen materials and desired characteristics.