Paper-1: Dynamic modeling of an industrial R2R FCC unit

Dynamic modelling of an industrial R2R FCC unit

https://doi.org/10.1016/j.ces.2006.11.003

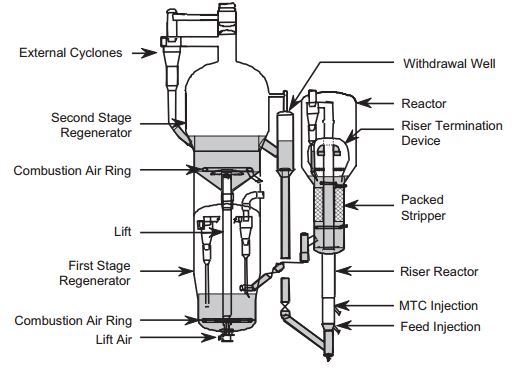

In this paper, a dynamic model for a R2R type FCC unit is presented. The model includes the riser, the stripper/disengager, the regeneration system and the catalyst transport lines. Mass, energy and pressure balances are performed for each of these sections. Simulation results for steady state are presented and compared qualitatively to those obtained from previous FCC models. The dynamic behaviour of the system is explored through two perturbations in open loop, one on the fresh feed flow rate and one on the air flow rate to the first regenerator. The results illustrate the consistency of the model and are in agreement with what has been observed in studies available in the open literature.

Resume

two regenerator proccesing.

The main assumptions are instantaneous and complete feed vaporisation, pseudo-steady state for the riser, which is modelled as an adiabatic plug flow reactor with a six-lump kinetic model, a CSTR dynamic model for the stripping/disengagement vessel and a CSTR dynamic model to describe each regenerator. The lift between the regenerators is also modelled asa plug flow reactor in pseudo-steady state. The catalyst circulation rate through each standpipe is determined by the pressure drop across a slide valve and is given by a valve equation.