Multiphase Gas-Liquid Flow Behavior CFD Simulation in a T-junction Microchannel with Variation in Aspect Ratio and Cross-Sectional Shape with Constant Hydrodynamic Diameter

Authored by

Bintang Farhan Muhammad, Department of Mechanical Engineering, University of Indonesia

Contents

Synopsis

Microchannel has been widely used for the purpose of mixing of a multiphase flow. Several factors has been known in which determines the performance of mixing in microchannel, including the flow regime and operational parameters. Past research found that fluid velocity and slug length has an effect to the mass transport coefficient inside the flow regime. The flow regime itself is also affected by the geometry of the microchannel. However, according to a review written by Sattari-Nafabajadi et al. (2018), researches on the effect of microchannel size are not sufficient to decide whether it is worthy enough to decrease the cross-sectional area to increase mixing performance in compromise of the pressure drop. Other than that, the aspect ratio, which regarded as the effective parameter on the manufacturing expenses, was not investigated in depth in the past research. Therefore, it is necessary to find the influence of aspect ratio and other geometrical parameters to the flow regime and characteristics. This research aims to simulate using CFD the affect of aspect ratio to axial dispersion and pressure drop in a T-junction microchannel with several cross-sectional shapes. The cross sectional shapes to be included in this research is the square, circle, and trapezoidal shape. Hopefully, findings in this research will help to give suggestion on the effective geometrical parameters for microchannels and give insights for further experimental research.

Abstract

N/A

Introduction

Multiphase flow provides an enhancement in performance parameters compared to single phase flow. Single phase flow has long diffusion time and Taylor dispersion and this problem can be reduced by adding a second immiscible fluid into the flow regime. This enhancement in mixing is measured by the reduction in the residence time distribution (RTD) due to the segmented flow that enhances mixing across phase boundaries and reduces dispersion. However, larger multiphase flow device usually cannot handle the flow parameters with high precision control. Thus, a new approach is required to deal with the pointed out limitation.

Micro-channels is one type of micro-structured device that flows two phase of fluids into a micro scale channel. Micro-structured device have a higher precision in the control of dispersion using high precision ability to control the generation of bubbles/droplets in the desired size. Heat and mass transfer coefficients are two to three orders of magnitude higher than the conventional counterparts. In micro-channels, many previous research has shown different flow behavior due to significant difference with an order-of-magnitude in the hydraulic diameter.

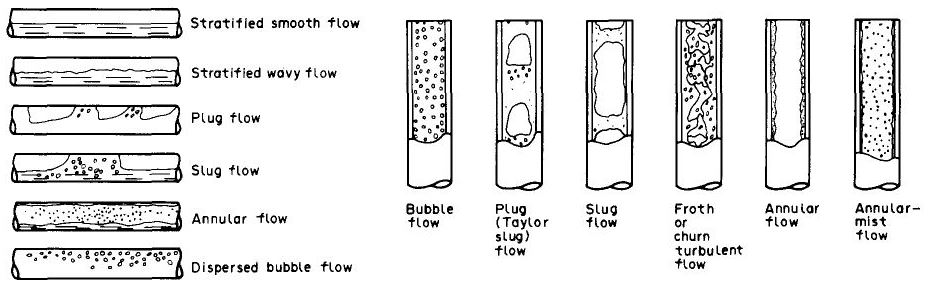

Although the flow should be laminar and well predicted due to low Reynolds number, the interfacial forces add complexity in micro-channel flow regime. Based on the review done by Gunther & Jensen (2006), flow patterns take several different forms, including channel spanning, slugs, suspended droplets, and wall wetting films, which depends on interaction among gravitational, interfacial, inertia, and viscous forces. Flow patterns in micro-channels is shown in figure 1 for horizontal and vertical micro-channels. This forces varies with operational condition and the geometry of the micro-channel itself. Kawahara et al. (2002) did an experimental research on gas-liquid micro-channel and found that there is a gradual shift in flow patterns with increasing gas and liquid flow rates. Based on the review of Sattari-Nafabajadi et al. (2018), will produce different mass transfer coefficient with different inlet angles, with variation in 60, 90,120,and 150 degrees, and the highest mass transfer coefficient was found to be at 90 degrees, which is a T-junction microchannel.

Although micro-fluidic flow research has been widely done, several topics has not yet been covered. Sattari-Nafabajadi et al. (2018) reviewed that researches on the effect of microchannel size are not sufficient to decide whether it is worthy enough to decrease the cross-sectional area to increase mixing performance in compromise of the pressure drop. Other than that, the aspect ratio, which regarded as the effective parameter on the manufacturing expenses, was not investigated in depth in the past research. Detailed assessment of influence of the channel cross section on dispersion also has not yet been established (Gunther & Jensen, 2006). Therefore, it is necessary to find the influence of aspect ratio and other geometrical parameters to the flow regime and characteristics.

This work aims to simulate using computational fluid dynamics to analyze the effect of geometrical parameters to its flow pattern and characteristics. In more detail, the research objectives are as follows:

1) To analyze the variation of cross-sectional shape with constant hydrodynamic diameter micro-channel to flow patterns, pressure drop, axial dispersion, and RTD;

2) To analyze the variation of aspect ratio in circular cross-section micro-channel to the flow pattern, pressure drop, axial dispersion, and RTD;

3) To analyze the possible future experimental research based on the numerical simulation results;

The following chapters after this introduction will be structured as follows: 1) methodology, explains the flow mechanics and parameters, software and hardware utilized in this research, computational method, and fluid model verification; 2) Results and discussion; and 3) Conclusion.

Methodology

Flow mechanism and Parameters

Software & Hardware Description

Model Assumption and Verification

Flow Parameters and Boundary Condition

Results and Discussion

Conclusion

Acknowledgement

This research was conducted to complete the computational fluid dynamics class, in Mechanical Engineering Department, Universitas Indonesia, as the final project. The author thank Dr. Ahmad Indra as our advisor, and also Bang Edo, Bang Bani, Ales, Abi, Elvin, Mas Agus, and all other students for the valuable discussion in creating this research paper.