Multiphase Gas-Liquid Flow Behavior CFD Simulation in a T-junction Microchannel with Variation in Aspect Ratio and Cross-Sectional Shape with Constant Hydrodynamic Diameter

Authored by

Bintang Farhan Muhammad, Department of Mechanical Engineering, University of Indonesia

Contents

Synopsis

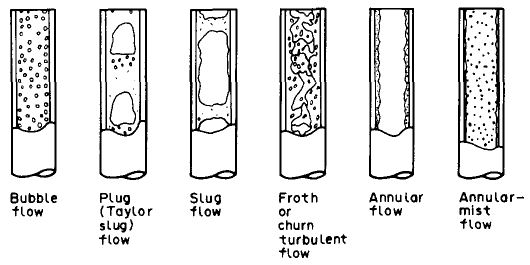

Microchannel has been widely used for the purpose of mixing of a multiphase flow. Several factors has been known in which determines the performance of mixing in microchannel, including the flow regime and operational parameters. Past research found that fluid velocity and slug length has an effect to the mass transport coefficient inside the flow regime. The flow regime itself is also affected by the geometry of the microchannel. However, according to a review written by Sattari-Nafabajadi et al. (2018), researches on the effect of microchannel size are not sufficient to decide whether it is worthy enough to decrease the cross-sectional area to increase mixing performance in compromise of the pressure drop. Other than that, the aspect ratio, which regarded as the effective parameter on the manufacturing expenses, was not investigated in depth in the past research. Therefore, it is necessary to find the influence of aspect ratio and other geometrical parameters to the flow regime and characteristics. This research aims to simulate using CFD the affect of aspect ratio to axial dispersion and pressure drop in a T-junction microchannel with several cross-sectional shapes. The cross sectional shapes to be included in this research is the square, circle, and trapezoidal shape. Hopefully, findings in this research will help to give suggestion on the effective geometrical parameters for microchannels and give insights for further experimental research.

Abstract

N/A

Introduction

equation=<math> \rho\frac{D\mathbf{u}}{Dt} = - \nabla p + \nabla \cdot \boldsymbol \tau + \rho\,\mathbf{g} </math>

Research Objectives and Scope

Methodology

Software & Hardware Description

Model Assumption and Verification

Flow Parameters and Boundary Condition

Results and Discussion

Conclusion

Acknowledgement

This research was conducted to complete the computational fluid dynamics class, in Mechanical Engineering Department, Universitas Indonesia, as the final project. The author thank Dr. Ahmad Indra as our advisor, and also Bang Edo, Bang Bani, Ales, Abi, Elvin, Mas Agus, and all other students for the valuable discussion in creating this research paper.