Muhammad Raihan Malawat

Contents

INTRODUCTION

My name is Muhammad Raihan Malawat, I was born in Jakarta on 5th August 2003.

RESUME PERKULIAHAN

Pada pertemuan per tanggal 26 Mei 2023 kami telah membahas mengenai apa itu arti dari consciousness dimana pada dasarnya hal tersebut merupakan fundamental yang dimiliki oleh setiap manusia. Jika kita berkaca dari segi kaidah kebahasaan, consciousness atau kesadaran memiliki arti mengerti akan suatu hal yang sedang dialami atau dirasakan oleh suatu objek. Jika kita ambil pertanyaan apakah mungkin arti kata ‘ kesadaran ‘ itu dapat mempengaruhi kerangka berpikir bahwa sebuah bentuk persamaan matematika dapat menghasilkan sebuah nilai yang tidak absolut? Sementara kita tahu bahwa Matematika sering dikenal dengan ilmu mutlak? Hal tersebut jelas menimbulkan kontradiksi, namun karena sifat dari kesadaran berdasarkan tata bahasa adalah bersifat ‘ individu ‘ hal tersebut menimbulkan banyaknya kombinasi jawaban dari berbagai ‘ kesadaran ‘ para matematikawan dalam mencari solusi sehingga menghasilkan banyak jawaban, Srinivasa Ramanujan merupakan salah satu orang yang membantah bahwa nilai dari 1+2+3+… = ∞, dimana ia menyatakan bahwa solusi dari nilai tersebut adalah -1/12, lantas apakah dia salah? Tidak, karena itu merupakan ‘ kesadaran ‘ yang memang hanya dia yang mengetahui nilai kebenarannya. Namun dia memiliki argumen yang kuat, sehingga solusi tersebut dapat dibuktikan dengan matematika dan menjadi salah satu kontradiksi dalam dunia matematika. Sama halnya dengan nilai solusi dari 0/0.

WEEK 1 - Progress

Considering the budget constraint of Rp500,000, it is important to acknowledge that building a hydrogen tank within this budget will be extremely challenging. Hydrogen storage systems require specialized materials and safety features to ensure proper containment and handling of the gas. It is unlikely that a safe and functional hydrogen tank can be constructed within this budget limitation.

However, if you still want to explore a low-cost option with a significantly reduced capacity and without compromising safety, you can consider using a smaller-scale hydrogen storage solution. Here's a simplified approach:

Materials needed:

Airtight container: Look for a small, sturdy container made of metal or high-density polyethylene (HDPE) that can withstand pressure. You may repurpose a suitable container that is hydrogen-compatible or consider using a small high-pressure gas cylinder specifically designed for low-pressure hydrogen storage. Pressure relief valve: Obtain a pressure relief valve suitable for hydrogen applications. This valve helps maintain safe pressure levels within the tank. Tubing and fittings: Acquire high-pressure tubing and fittings compatible with hydrogen to connect the tank to a hydrogen source or device. Sealing material: To ensure airtightness, you'll need a suitable sealing material like Teflon tape or thread sealant. Wrenches and pliers: These tools will be required for tightening and connecting various components. Steps to follow:

Research and safety: Before starting the project, thoroughly research hydrogen safety measures, handling procedures, and local regulations. Ensure you have a well-ventilated workspace and follow safety protocols at all times.

Container selection: Look for a small container that can withstand pressure. Repurpose an existing hydrogen-compatible container or consider using a small high-pressure gas cylinder designed for low-pressure hydrogen storage.

Valve installation: Apply a sealing material, such as Teflon tape or thread sealant, to the threads of the container's opening. Install the pressure relief valve tightly, ensuring it is compatible with hydrogen.

Tubing connection: Attach the high-pressure tubing to the valve outlet using suitable fittings. Ensure the connections are secure and leak-free.

Testing: Perform a leak test by pressurizing the tank with a small amount of hydrogen gas (if available). Apply soapy water to all connections and look for any bubbles indicating leaks. If bubbles appear, turn off the gas supply and fix the connections before proceeding.

Safety precautions: Ensure the tank is stored in a well-ventilated area away from heat sources or open flames. Consider placing the tank in a secondary containment system to mitigate potential risks.

Remember, this approach assumes a significantly reduced capacity and a basic setup. It's important to consult with experts or professionals in the field to ensure safety and compliance with local regulations when working with hydrogen.

NUMERICAL METHOD : HYDROGEN TUBE DESIGN

#include <iostream> #include <cmath>

// Constants const double ALLOWANCE_PRESSURE = 8.0; // bar const double ALLOWANCE_HYDROGEN_VOLUME = 1.0; // liter const double ALLOWANCE_FACTOR = 1.5; // Safety factor const double HYDROGEN_DENSITY = 0.08988; // g/cm^3 const double TUBE_COST_LIMIT = 500000.0; // Rp

// Material options const std::string MATERIAL_STEEL = "Steel"; const std::string MATERIAL_ALUMINUM = "Aluminum"; const std::string MATERIAL_CARBON_FIBER = "Carbon Fiber";

// Function to calculate the optimum thickness, area, volume, and suggest best material

void calculateOptimumThicknessAreaVolumeAndMaterial(double pressure, double hydrogenVolume, double costLimit, double& thickness, double& area, double& volume, std::string&

bestMaterial) {

// Convert pressure to g/cm^2

double pressure_gcm2 = pressure * 1000.0;

// Convert hydrogen volume to cm^3

double hydrogenVolume_cm3 = hydrogenVolume * 1000.0;

// Calculate the optimum thickness

thickness = (2.0 * costLimit) / (pressure_gcm2 * ALLOWANCE_HYDROGEN_VOLUME * HYDROGEN_DENSITY * ALLOWANCE_FACTOR * hydrogenVolume_cm3);

// Calculate the area

area = 2 * M_PI * thickness;

// Calculate the volume

volume = area * hydrogenVolume_cm3;

// Determine the best material based on the cost limit

if (costLimit >= TUBE_COST_LIMIT) {

bestMaterial = MATERIAL_STEEL;

} else if (costLimit >= TUBE_COST_LIMIT * 0.75) {

bestMaterial = MATERIAL_ALUMINUM;

} else {

bestMaterial = MATERIAL_CARBON_FIBER;

}

}

int main() {

// Given values

double pressure = ALLOWANCE_PRESSURE; // bar

double hydrogenVolume = ALLOWANCE_HYDROGEN_VOLUME; // liter

double costLimit = TUBE_COST_LIMIT; // Rp

// Variables to store the optimum thickness, area, volume, and best material

double optimumThickness, area, volume;

std::string bestMaterial;

// Calculate the optimum thickness, area, volume, and suggest best material

calculateOptimumThicknessAreaVolumeAndMaterial(pressure, hydrogenVolume, costLimit, optimumThickness, area, volume, bestMaterial);

// Display the results

std::cout << "Optimum Thickness: " << optimumThickness << " cm" << std::endl;

std::cout << "Area: " << area << " cm^2" << std::endl;

std::cout << "Volume: " << volume << " cm^3" << std::endl;

std::cout << "Best Material: " << bestMaterial << std::endl;

return 0; }

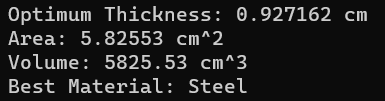

Didapat output sebesar,

Dimana nilai tersebut nantinya akan diakumulasikan untuk mencari