Muhammad Keanu Azel

Contents

Consciousness

if the function x=1 is used in the initial equation, then the result is undefined

and if the function is simplified first, we get the equation x+1 = 2

Since these answers conflict, mathematicians have concluded that the division of 0 by 0 cannot be assigned a definite value. It leads to an ambiguous situation where different reasonable answers can be derived, and hence, it is considered undefined or indeterminate.

in my opinion the concept of infinty thaught us about solving mathematical cases isnt always about the answer, but about the process. likelife, there are many ways to find answers or be successful, and there's nothing wrong which way you're taking, like all of us in our own way to develop to be better and successful

Hydrogen Fuel

Hydrogen can be stored in three ways: As a compressed gas in high-pressure tanks. As a liquid in dewars or tanks (stored at -253°C). As a solid by either absorbing or reacting with metals or chemical compounds or storing in an alternative chemical form

Hydrogen shows promise as an energy storage solution, and researchers are developing materials that can help store hydrogen for long durations at low cost and high energy efficiency. large pores within the crystals can store hydrogen gas. Hydrides chosen for storage applications provide low reactivity (high safety) and high hydrogen storage densities. Leading candidates are lithium hydride, sodium borohydride, lithium aluminium hydride and ammonia borane.

This is how NASA store Hydrogen

Because liquid oxygen and liquid hydrogen are both cryogenic, gases that can be liquefied only at extremely low temperatures, they pose enormous technical challenges. Liquid hydrogen must be stored at minus 423°F and handled with extreme care. To keep it from evaporating or boiling off, rockets fuelled with liquid hydrogen must be carefully insulated from all sources of heat, such as rocket engine exhaust and air friction during flight through the atmosphere. Once the vehicle reaches space, it must be protected from the radiant heat of the Sun. When liquid hydrogen absorbs heat, it expands rapidly; thus, venting is necessary to prevent the tank from exploding. Metals exposed to the extreme cold of liquid hydrogen become brittle. Moreover, liquid hydrogen can leak through minute pores in welded seams. Solving all these problems required an enormous amount of technical expertise in rocket and aircraft fuels cultivated over a decade by researchers at the National Advisory Committee for Aeronautics (NACA) Lewis Flight Propulsion Laboratory in Cleveland. Today, liquid hydrogen is the signature fuel of the American space program and is used by other countries in the business of launching satellites. In addition to the Atlas, Boeing's Delta III and Delta IV now have liquid-oxygen/liquid-hydrogen upper stages.

Design and Optimization of 1-Litre Pressurized Hydrogen Storage with 8 Bar Pressure Capability

•Determine the storage container: Select a suitable material for the storage container that can withstand high pressure and is compatible with hydrogen. Carbon fiber-reinforced composite materials, such as carbon fiber wrapped with epoxy resin, are commonly used for high-pressure hydrogen storage due to their lightweight and high strength.

•Determine the container shape and volume: Design the container shape to fit the available space and ensure structural integrity. Consider cylindrical or spherical shapes, which are efficient for pressure vessels. Aim for a volume of 1 liter to meet your requirements.

•Incorporate safety features: Safety is paramount when dealing with pressurized hydrogen. Include safety valves and rupture disks to prevent overpressure situations. Install pressure relief devices that will vent hydrogen safely in case of emergencies.

•Consider insulation: To minimize energy losses and maintain the temperature of stored hydrogen, incorporate appropriate insulation materials such as multi-layered insulation (MLI). This helps to reduce heat transfer and maintain the hydrogen at optimal storage conditions.

•Integrate pressure regulation: Include a pressure regulation system to maintain the desired pressure within the storage system. This system should consist of pressure sensors, pressure regulators, and control mechanisms to ensure safe and reliable operation.

•Optimize the system design: Utilize computer-aided engineering (CAE) tools to simulate the behavior of the storage system under various conditions. This allows you to optimize the design by adjusting factors like material thickness, container shape, and safety features to ensure efficient operation.

•Conduct performance testing: Build a prototype of the storage system and perform thorough testing to validate its performance. Test the system's pressure-holding capability, endurance under cyclic loading, and evaluate its overall efficiency.

•Consider refueling and integration: Ensure that the storage system can be easily refueled and integrated into the larger hydrogen infrastructure. Consider the connection points, filling procedures, and compatibility with refueling stations or other hydrogen supply sources.

•Compliance with regulations and standards: Ensure that the design complies with relevant safety regulations and standards, such as ISO 15869 or national regulations specific to hydrogen storage systems.

•Continuously monitor and improve: Once deployed, continuously monitor the storage system's performance and collect data to identify any areas for improvement. Use this information to refine the design and optimize future iterations.

Remember, designing and optimizing hydrogen storage systems requires expertise in engineering and a thorough understanding of hydrogen safety practices. Consultation with experts in the field is highly recommended to ensure the design meets all safety requirements and industry standards

Basic Design of Hydrogen Tank

A hydrogen tank, also known as a hydrogen storage vessel, is designed to store hydrogen gas safely and efficiently. The basic design of a hydrogen tank depends on the intended application and the type of hydrogen storage technology used. There are several common designs for hydrogen tanks:

Type I Tank: Type I tanks are made of steel and typically used for low-pressure storage of hydrogen gas. They are usually cylindrical in shape and have a single steel shell. Type I tanks are relatively heavy and have limited storage capacity.

Type II Tank: Type II tanks are similar to Type I tanks but have an additional layer, known as a hoop wrap, made of carbon fiber or glass fiber. The hoop wrap provides reinforcement to the tank and allows for increased storage capacity without significantly increasing the weight. Type II tanks are used for medium-pressure storage.

Type III Tank: Type III tanks consist of a steel liner wrapped with carbon fiber or glass fiber composite materials. The liner provides a gas-tight barrier, while the composite wrap adds strength to the tank structure. Type III tanks offer a good balance between weight, storage capacity, and pressure rating.

Type IV Tank: Type IV tanks are the most advanced and lightweight hydrogen storage solution. They feature a polymer liner that acts as a gas barrier, followed by a carbon fiber composite wrap. The composite wrap provides structural integrity to the tank. Type IV tanks can withstand high pressures and offer the highest storage capacity compared to other types.

In addition to the basic design, hydrogen tanks typically include several components to ensure safe operation and facilitate the storage and dispensing of hydrogen gas. These components may include:

Pressure relief devices: To prevent over-pressurization, tanks are equipped with pressure relief valves or burst discs that release excess pressure. Valve systems: Tanks have inlet and outlet valves for filling and emptying hydrogen gas. Safety features: Tanks incorporate safety mechanisms such as rupture disks, thermal sensors, and pressure gauges to monitor and maintain safe operating conditions. Insulation: For cryogenic hydrogen storage, tanks may have an insulating layer to minimize heat transfer and maintain low temperatures. Mounting brackets: Tanks are designed with brackets or fittings to secure them in the desired location, such as in a vehicle or stationary storage system. It's important to note that the design of a hydrogen tank may vary based on factors such as intended application, storage pressure, and regulatory requirements. Advanced technologies and materials are continuously being developed to improve the efficiency, safety, and capacity of hydrogen storage systems.

Pressurized hydrogen storage optimization

Optimizing pressurized hydrogen storage involves maximizing the storage capacity, ensuring safety, and improving efficiency. Here are some key considerations for optimizing pressurized hydrogen storage:

Pressure rating: Selecting the appropriate pressure rating is crucial for optimizing storage capacity. Higher pressure allows for greater storage density but increases the weight and cost of the tank. The pressure rating should be chosen to balance storage capacity with other factors such as safety and material requirements.

Tank materials: Choosing lightweight and high-strength materials is important to optimize storage capacity while minimizing weight. Composite materials, such as carbon fiber or glass fiber reinforced polymers, offer a good balance between strength and weight. Advanced materials and manufacturing techniques can lead to improved storage efficiency.

Tank design: Optimized tank designs can maximize storage capacity within space and weight constraints. Design considerations include the shape of the tank (e.g., cylindrical or spherical) and the utilization of space within the storage system. Advanced design techniques, such as topology optimization and additive manufacturing, can help improve the efficiency of the tank structure.

Safety features: Ensuring safety is paramount in hydrogen storage. Tanks should incorporate safety features such as pressure relief devices, burst discs, and rupture disks to prevent over-pressurization. Proper venting systems and safety mechanisms should be in place to mitigate the risks associated with hydrogen storage.

Thermal management: Hydrogen storage systems may require thermal management to maintain the desired temperature range. Insulation and cooling systems can minimize heat transfer and prevent hydrogen from reaching critical temperatures. This is particularly important for cryogenic storage where maintaining low temperatures is essential.

System integration: Optimizing pressurized hydrogen storage involves considering the entire system, including the tank, valves, piping, and safety components. Effective integration and compatibility between these elements are essential for optimal performance and safety.

Regulatory compliance: Compliance with relevant regulations and standards is crucial for ensuring safe and legal operation of pressurized hydrogen storage systems. Understanding and adhering to regulatory requirements can help optimize the design and operation of the storage system.

It's worth noting that ongoing research and development in hydrogen storage technologies are focused on improving storage efficiency, increasing storage capacity, and reducing costs. Innovations such as metal hydrides, chemical storage, and cryo-compressed storage may offer further optimization opportunities in the future.

Optimizing pressurized hydrogen storage involves maximizing the storage capacity, ensuring safety, and improving efficiency. Here are some key considerations for optimizing pressurized hydrogen storage:

Pressure rating: Selecting the appropriate pressure rating is crucial for optimizing storage capacity. Higher pressure allows for greater storage density but increases the weight and cost of the tank. The pressure rating should be chosen to balance storage capacity with other factors such as safety and material requirements. Tank materials: Choosing lightweight and high-strength materials is important to optimize storage capacity while minimizing weight. Composite materials, such as carbon fiber or glass fiber reinforced polymers, offer a good balance between strength and weight. Advanced materials and manufacturing techniques can lead to improved storage efficiency. Tank design: Optimized tank designs can maximize storage capacity within space and weight constraints. Design considerations include the shape of the tank (e.g., cylindrical or spherical) and the utilization of space within the storage system. Advanced design techniques, such as topology optimization and additive manufacturing, can help improve the efficiency of the tank structure. Safety features: Ensuring safety is paramount in hydrogen storage. Tanks should incorporate safety features such as pressure relief devices, burst discs, and rupture disks to prevent over-pressurization. Proper venting systems and safety mechanisms should be in place to mitigate the risks associated with hydrogen storage. Thermal management: Hydrogen storage systems may require thermal management to maintain the desired temperature range. Insulation and cooling systems can minimize heat transfer and prevent hydrogen from reaching critical temperatures. This is particularly important for cryogenic storage where maintaining low temperatures is essential. System integration: Optimizing pressurized hydrogen storage involves considering the entire system, including the tank, valves, piping, and safety components. Effective integration and compatibility between these elements are essential for optimal performance and safety. Regulatory compliance: Compliance with relevant regulations and standards is crucial for ensuring safe and legal operation of pressurized hydrogen storage systems. Understanding and adhering to regulatory requirements can help optimize the design and operation of the storage system. It's worth noting that ongoing research and development in hydrogen storage technologies are focused on improving storage efficiency, increasing storage capacity, and reducing costs. Innovations such as metal hydrides, chemical storage, and cryo-compressed storage may offer further optimization opportunities in the future.

Pressurized Hydrogen Storage Optimization

import math from scipy.optimize import minimize

def calculate_tank_properties(diameter, height):

# Menghitung volume tangki volume_m3 = (math.pi * (diameter**2) * height) / 4

# Menghitung luas permukaan tangki radius = diameter / 2 surface_area = 2 * math.pi * radius * (radius + height)

# Konversi diameter, tinggi, dan luas permukaan ke dalam satuan cm diameter_cm = diameter * 100 height_cm = height * 100 surface_area_cm2 = surface_area * 10000

return diameter_cm, height_cm, surface_area_cm2

def cost_function(x):

diameter = x[0] height = x[1]

# Menghitung luas permukaan tangki _, _, surface_area_cm2 = calculate_tank_properties(diameter, height)

# Menghitung biaya berdasarkan luas permukaan # Anggap harga material adalah Rp 100 per cm^2 cost = surface_area_cm2 * 100

return cost

# Mendefinisikan batasan ukuran tangki

diameter_bounds = (0.1, 100) # batasan diameter antara 0.1 cm dan 100 cm height_bounds = (0.1, 100) # batasan tinggi antara 0.1 cm dan 100 cm

# Mendefinisikan nilai awal diameter dan tinggi

x0 = [1, 1] # nilai awal diameter 1 cm, tinggi 1 cm

# Melakukan optimisasi dengan menggunakan metode minimize dari library scipy

result = minimize(cost_function, x0, bounds=(diameter_bounds, height_bounds))

# Mengambil nilai diameter dan tinggi yang dioptimasi

diameter_opt = result.x[0] height_opt = result.x[1]

# Menghitung luas permukaan tangki yang dioptimasi

diameter_cm, height_cm, surface_area_cm2 = calculate_tank_properties(diameter_opt, height_opt)

print("Diameter tangki oksigen (cm):", diameter_cm) print("Tinggi tangki oksigen (cm):", height_cm) print("Luas permukaan tangki oksigen (cm^2):", surface_area_cm2)

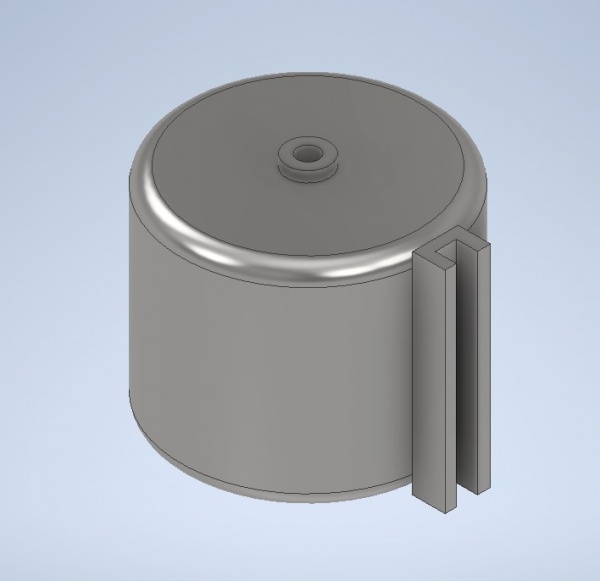

Untuk pembuatan tabung hidrogen dengan budget Rp 500.000,00 dan dapat menampung sebanyak 1 liter hidrogen serta memiliki pressure 8 bar. Tabung yang akan dibuat tergolong kecil dan juga low pressure, sehingga menggunakan bahan dasar mild steel welded sudah cukup dengan ketebalan 6 mm. Namun jika masih dirasa kurang aman ketebalan dinding tabung bisa dinaikkan sampai 10 mm tergantung dengan sisa budget yang dimiliki. Lalu untuk dimensi finalnya adalah diameter tabung menyesuaikan dengan standar yaitu 80 mm dan untuk tinggi tabungnya sendiri 80.19 mm.