Klaugusta Adimillenva

Biodata diri

Nama: Klaugusta Adimillenva

NPM: 1806227976

Tempat/Tanggal Lahir: Tangerang/12 Agustus 2000

Saya adalah Mahasiswa Fakultas Teknik Universitas Indonesia. Progam Internasional Teknik Mesin angkatan 2018. Disaat ini saya sedang menempuh semester 6 dari perkuliahan, atau bagian genap dari tahun ketiga perkuliahan. Alasan saya mengambil Program Teknik mesin sebagai Prodi saya adalah ketertarikan saya dalam berbagai bidang seperti konversi energi, manufaktur, dan penerbangan. Harapan saya dengan menempuhi Prodi ini adalah untuk bekerja dibidang - bidang tersebut setelah lulus dari Universitas Indonesia. Alasan lain dari menempuhi Prodi ini untuk saya adalah dengan berusaha saat nanti sudah lulus untuk membantu masyarakat Indonesia mencapai Sila ke - 5, yaitu "Keadilan Sosial Bagi Seluruh Rakyat Indonesia". Disini maksud saya untuk mencapai keadilan sosial adalah untuk semua rakyat Indonesia untuk mendapat titik mulai yang sama dan fair. Dan seluruh rakyat Indonesia layak mendapatkan kesejahteraan seperti edukasi, kesehatan, dan kestabilan ekonominya mereka sendiri (sandang dan pangan). Saya ingin menciptakan sesuatu ciptaan yang bisa menyamakan lapangan bermain untuk semua orang mencapai kehidupan yang sejahtera.

To explain energy to elementary school children, I would say that energy is the ability to do work or to make something move or change in some way. It is different from power, which represents the rate at which energy is used. However, it can be described in many different categories: form of energy (heat, light, motion, electrical, chemical, nuclear, and gravity); potential or kinetic energy; renewable or non-renewable.

Pertemuan 23-02-2021

Di hari ini saya Alhamdulillah sehat dan bahagia!

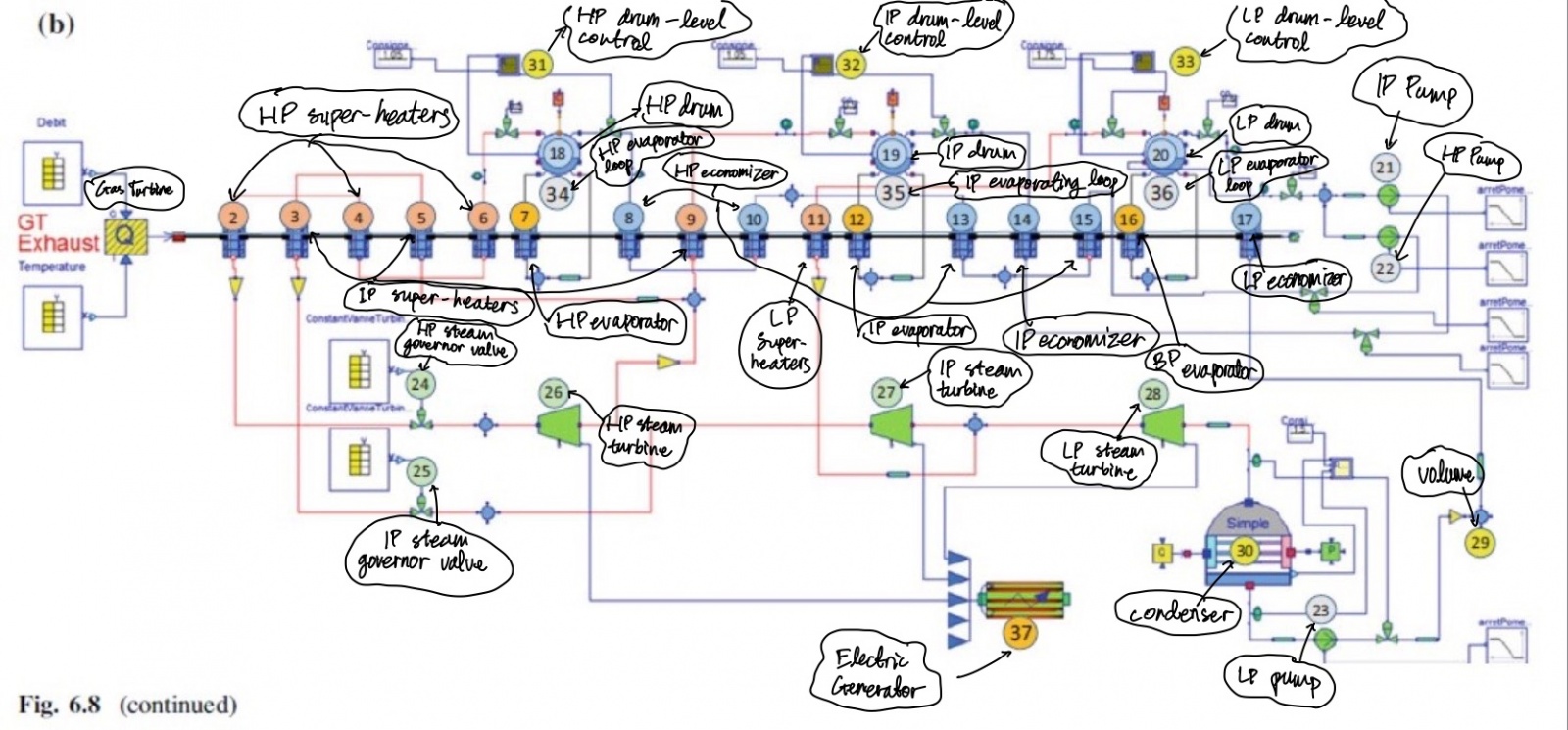

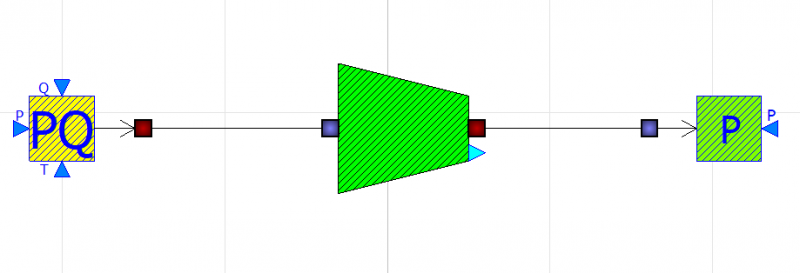

Pada hari ini kita sebagai kelas diberi tugas untuk membuat skema seperti:

Sunday, 28 February 2021

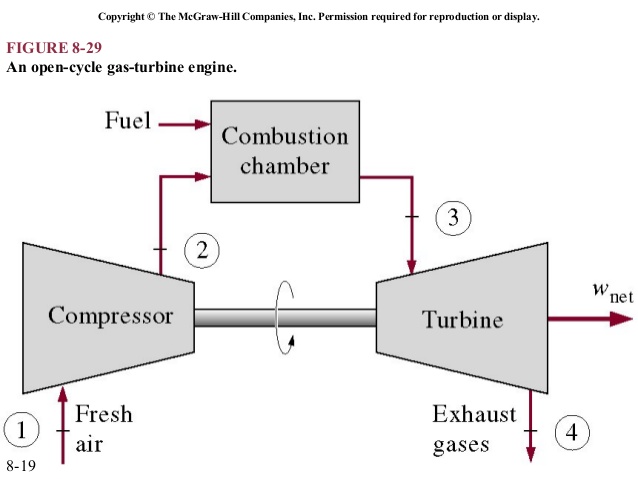

Assignment 2: Modelling of an open - cycle gas turbine

Gas turbines usually operate on an open - cycle, where fresh air at ambient condition is drawn into the compressor, where its temperature and pressure is constant pressure. The high temperature gas then enter turbine, where it expands to atmospheric pressure while subsequently converting its enthalpy into power.

The process called the Brayton Cycle, can be summarized into 4 internally reversible process:

1-2 Isentropic compression (in a compressor)

2-3 Constant-pressure heat addition

3-4 Isentropic expansion (in a turbine)

4-1 Constant-pressure heat rejection

Ideal Brayton cycle:

isentropic process – ambient air is drawn into the compressor, where it is pressurized. isobaric process – the compressed air then runs through a combustion chamber, where fuel is burned, heating that air—a constant-pressure process, since the chamber is open to flow in and out. isentropic process – the heated, pressurized air then gives up its energy, expanding through a turbine (or series of turbines). Some of the work extracted by the turbine is used to drive the compressor. isobaric process – heat rejection (in the atmosphere).

With openmodellica, we can make a simple system which can simulate the power output of a single stage open - cycle gas turbine. We could use the pre - existing models in the openmodellica libraries to create the system.

Tuesday, 09 March 2021

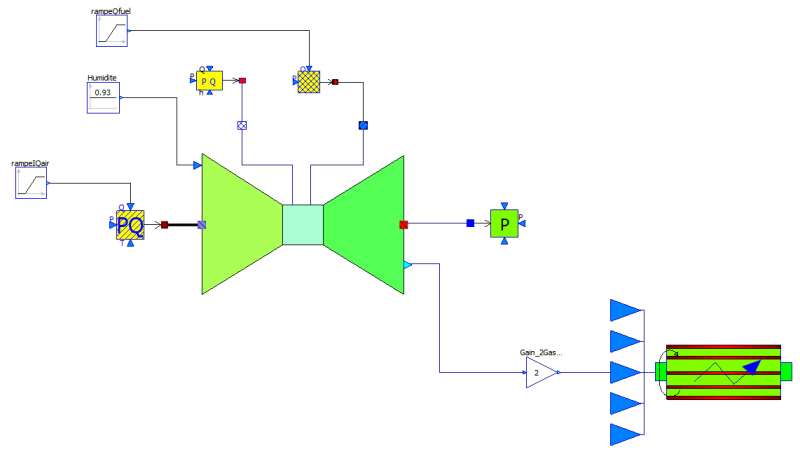

Today we learn a simple combustion design simulation. In the class we were taught to experiment ourselves with the tools provided by OMEdit by playing around with the parameters. The result was a model that looked like:

Unfortunately due to technical problems, my version of OMEdit failed to simulate the model due to it was perceived as a translation error. With that in mind I decided to reinstall a different version of OMEdit and retry the same model on it again.

The day ended with a conclusion that we should at least try to edit our own parameters as we please to see how the system acts and how the results will change.

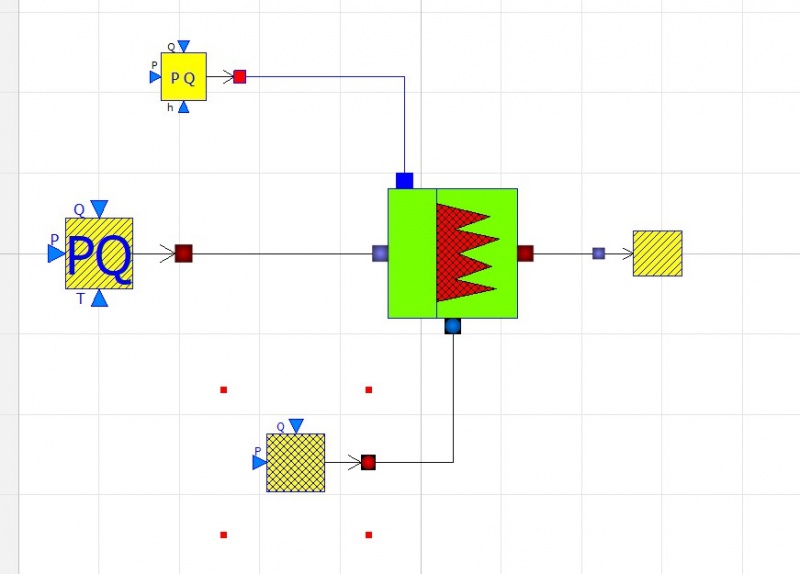

Wednesday, 10 March 2021

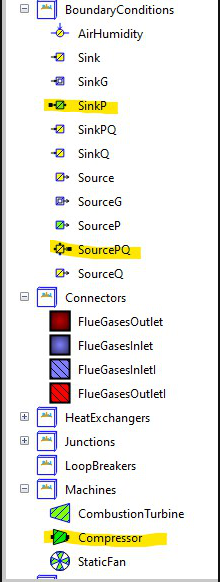

Today we learn about making a simple compressor simulation with OMEdit. On the previous meeting my version of OMEdit was not sufficient to simulate my previous model, so I went ahead and reinstall a different version of OMEdit that is qualified to take in simulations. With that I could finally begin making the model of the compressor on my newer version of OMEdit. The result was a model that looked like:

For this model I used these three components and these parameters to make the model:

With all of these done we could finally simulate the results and look at the graph itself. The results were: