Difference between revisions of "Daffa Muhammad Thaariq"

(→INTRODUCTION) |

(→Hydrogen Vehicle) |

||

| (29 intermediate revisions by the same user not shown) | |||

| Line 6: | Line 6: | ||

'''2206100211''' | '''2206100211''' | ||

| − | Hello everyone i'm Daffa, and i'm | + | Hello everyone i'm Daffa, and i'm Mechanical Engineering student from University of Indonesia, |

| + | my motto is | ||

''"Kerja! Kerja! Kerja!"'' | ''"Kerja! Kerja! Kerja!"'' | ||

| + | |||

| + | == Hydrogen Vehicle == | ||

| + | |||

| + | A hydrogen vehicle is a vehicle that uses hydrogen fuel for motive power. Hydrogen vehicles include hydrogen-fueled space rockets, as well as ships and aircraft. Power is generated by converting the chemical energy of hydrogen to mechanical energy, either by reacting hydrogen with oxygen in a fuel cell to power electric motors or, less commonly, by burning hydrogen in an internal combustion engine. | ||

| + | |||

| + | '''How It's Works Hydogen Vehicle With Fuel Cell''' | ||

| + | |||

| + | [[File:DMT cara kerja H2.jpg|500px]] | ||

| + | |||

| + | |||

| + | |||

| + | '''How To Design Hydrogen Gas Tank''' | ||

| + | |||

| + | [[File:DMT tank h2.jpg|500px]] | ||

| + | |||

| + | |||

| + | the detailed steps in designing a gas cylinder based on volume and pressure scientifically: | ||

| + | |||

| + | 1. Determine requirements and specifications: Determine the necessary requirements for the gas cylinder, including the desired volume, working pressure, the type of gas to be stored, and relevant safety factors. Ensure that you refer to applicable standards and regulations in the industry or relevant application. | ||

| + | |||

| + | 2. Identify gas properties: Understand the properties of the gas to be stored in the cylinder, such as gas density, compressibility, and thermal factors. This information is important to understand how the gas will behave within the cylinder. | ||

| + | |||

| + | 3. Select suitable cylinder material: Based on the properties of the gas, choose an appropriate cylinder material. Commonly used materials include carbon steel, stainless steel, aluminum, or composite materials. Ensure that the chosen material has sufficient strength to handle the pressure and relevant chemical properties of the gas. | ||

| + | |||

| + | 4. Calculate cylinder strength: Utilize the principles of material strength and finite element analysis to calculate the strength of the cylinder. This involves calculating the thickness of the cylinder wall, diameter, working stress, and safety factors. Ensure that the cylinder can withstand the desired pressure without experiencing structural failure. | ||

| + | |||

| + | 5. Design cylinder geometry: Determine the appropriate cylinder geometry, including diameter, length, and shape, based on your requirements. Employ geometric calculations to ensure that the cylinder has sufficient volume to accommodate the desired gas volume. | ||

| + | |||

| + | 6. Calculate leakage and pressure loss: Perform calculations to estimate the rate of gas leakage and pressure loss within the cylinder. This may involve factors such as joint types, seals, or valves used. Ensure that the leakage and pressure loss remain within acceptable limits. | ||

| + | |||

| + | 7. Design safety systems: Consider appropriate safety systems for the gas cylinder, such as safety valves, pressure relief valves, and pressure indicators. Ensure that the safety systems are designed to handle emergency situations and maintain user safety. | ||

| + | |||

| + | 8. Design verification: Conduct detailed analysis, simulations, and testing according to applicable standards to verify the gas cylinder design. This includes strength testing, pressure testing, and leakage testing. Ensure that the design meets the specified safety, reliability, and performance requirements. | ||

| + | |||

| + | 9. Production and inspection: Produce the gas cylinder according to the verified design specifications. During production, perform quality inspections and testing to ensure that the cylinder meets the specified standards. | ||

| + | |||

| + | These steps involve a scientific approach to designing a gas cylinder based on volume and pressure, considering material properties, structural integrity, safety requirements, and industry standards. | ||

| + | |||

| + | |||

| + | '''Sample Case''' | ||

| + | Design a hydrogen gas tank with a storage capacity of 1 liter and a pressure of 8 bar | ||

| + | 1. Because the pressure is not too big, the material used is Carbone Kevlar | ||

| + | |||

| + | [[File:Properti_kevlar_DMT.png|400px]] | ||

| + | |||

| + | 2. if the specified diameter is 8 cm then the length of the tube can be determined by | ||

| + | |||

| + | [[File:Kode_Tabung_DMT.png|420px]] | ||

| + | |||

| + | 3. The dimensions of hydrogen gas tank | ||

| + | |||

| + | d = 8 cm | ||

| + | |||

| + | t = 14,56 cm | ||

| + | |||

| + | 4. Calculate the material of Hydrogen Gas Tank | ||

| + | |||

| + | [[File:Selibut_Tabumg_DMT.png|420px]] | ||

| + | |||

| + | L = 566.95 cm^2 | ||

| + | |||

| + | 5. Determine the price of a Hydrogen Gas Tank | ||

| + | |||

| + | we can use a simple calculation, it is known that the price of carbon fiber is IDR 470 000 /m^2 square and from previous calculations we need 0.567 m^2, so the price of raw materials we spend for one gas cylinder is IDR 266 466 | ||

| + | |||

| + | Video Persentasi[https://www.youtube.com/watch?v=IpaOCyihago] | ||

Latest revision as of 23:19, 11 June 2023

INTRODUCTION

Daffa Muhammad Thaariq

2206100211

Hello everyone i'm Daffa, and i'm Mechanical Engineering student from University of Indonesia, my motto is

"Kerja! Kerja! Kerja!"

Hydrogen Vehicle

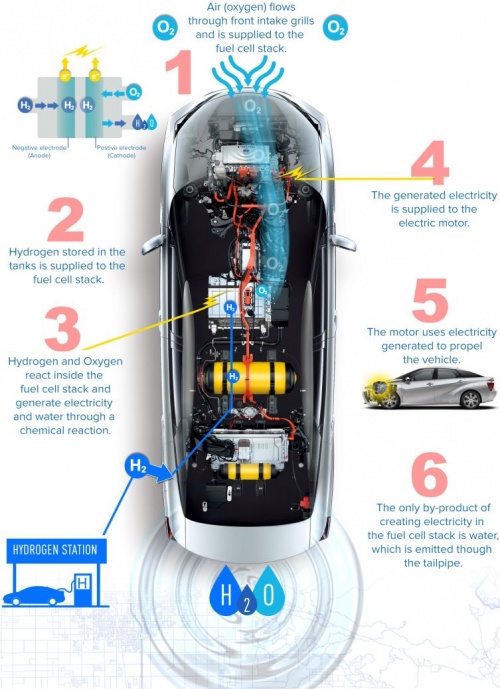

A hydrogen vehicle is a vehicle that uses hydrogen fuel for motive power. Hydrogen vehicles include hydrogen-fueled space rockets, as well as ships and aircraft. Power is generated by converting the chemical energy of hydrogen to mechanical energy, either by reacting hydrogen with oxygen in a fuel cell to power electric motors or, less commonly, by burning hydrogen in an internal combustion engine.

How It's Works Hydogen Vehicle With Fuel Cell

How To Design Hydrogen Gas Tank

the detailed steps in designing a gas cylinder based on volume and pressure scientifically:

1. Determine requirements and specifications: Determine the necessary requirements for the gas cylinder, including the desired volume, working pressure, the type of gas to be stored, and relevant safety factors. Ensure that you refer to applicable standards and regulations in the industry or relevant application.

2. Identify gas properties: Understand the properties of the gas to be stored in the cylinder, such as gas density, compressibility, and thermal factors. This information is important to understand how the gas will behave within the cylinder.

3. Select suitable cylinder material: Based on the properties of the gas, choose an appropriate cylinder material. Commonly used materials include carbon steel, stainless steel, aluminum, or composite materials. Ensure that the chosen material has sufficient strength to handle the pressure and relevant chemical properties of the gas.

4. Calculate cylinder strength: Utilize the principles of material strength and finite element analysis to calculate the strength of the cylinder. This involves calculating the thickness of the cylinder wall, diameter, working stress, and safety factors. Ensure that the cylinder can withstand the desired pressure without experiencing structural failure.

5. Design cylinder geometry: Determine the appropriate cylinder geometry, including diameter, length, and shape, based on your requirements. Employ geometric calculations to ensure that the cylinder has sufficient volume to accommodate the desired gas volume.

6. Calculate leakage and pressure loss: Perform calculations to estimate the rate of gas leakage and pressure loss within the cylinder. This may involve factors such as joint types, seals, or valves used. Ensure that the leakage and pressure loss remain within acceptable limits.

7. Design safety systems: Consider appropriate safety systems for the gas cylinder, such as safety valves, pressure relief valves, and pressure indicators. Ensure that the safety systems are designed to handle emergency situations and maintain user safety.

8. Design verification: Conduct detailed analysis, simulations, and testing according to applicable standards to verify the gas cylinder design. This includes strength testing, pressure testing, and leakage testing. Ensure that the design meets the specified safety, reliability, and performance requirements.

9. Production and inspection: Produce the gas cylinder according to the verified design specifications. During production, perform quality inspections and testing to ensure that the cylinder meets the specified standards.

These steps involve a scientific approach to designing a gas cylinder based on volume and pressure, considering material properties, structural integrity, safety requirements, and industry standards.

Sample Case

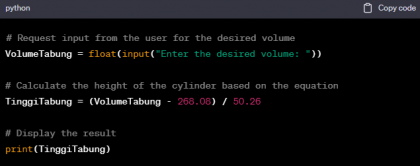

Design a hydrogen gas tank with a storage capacity of 1 liter and a pressure of 8 bar

1. Because the pressure is not too big, the material used is Carbone Kevlar

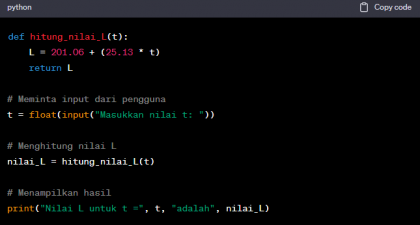

2. if the specified diameter is 8 cm then the length of the tube can be determined by

3. The dimensions of hydrogen gas tank

d = 8 cm

t = 14,56 cm

4. Calculate the material of Hydrogen Gas Tank

L = 566.95 cm^2

5. Determine the price of a Hydrogen Gas Tank

we can use a simple calculation, it is known that the price of carbon fiber is IDR 470 000 /m^2 square and from previous calculations we need 0.567 m^2, so the price of raw materials we spend for one gas cylinder is IDR 266 466

Video Persentasi[1]