Difference between revisions of "Arlington Parlindungan Parjuangan"

(→Basic Design of Hydrogen Tank) |

(→Basic Design of Hydrogen Tank) |

||

| Line 39: | Line 39: | ||

'''Tank Safety Percautions''', a simple hydrogen storage simple shoudl at least consist of a check valve to prevent backflow of hydrogen gas, a temperature activated preasure relied device (TPRD) that opens when it senses high tempreature in order to release hydrogen gas in a controled manner, an automatic shutoff valve installed in the hydrogen lines in order to cut the hydrogen supply if an emergency occur, and a preasure valve in order to know the current capacity of the tank. | '''Tank Safety Percautions''', a simple hydrogen storage simple shoudl at least consist of a check valve to prevent backflow of hydrogen gas, a temperature activated preasure relied device (TPRD) that opens when it senses high tempreature in order to release hydrogen gas in a controled manner, an automatic shutoff valve installed in the hydrogen lines in order to cut the hydrogen supply if an emergency occur, and a preasure valve in order to know the current capacity of the tank. | ||

| + | |||

| + | [[File:Screenshot_2023-06-03_194650.png]] | ||

| + | |||

'''Safety Factor''', for safety reasons the tank specification must be able to withstand at least 2.5 times the specified preasure in order to be safe. So if we specify the tank to hold 8 bars of preasure, the tank must be able to withstand at least 20 bars of preasure to be safely used commercialy. | '''Safety Factor''', for safety reasons the tank specification must be able to withstand at least 2.5 times the specified preasure in order to be safe. So if we specify the tank to hold 8 bars of preasure, the tank must be able to withstand at least 20 bars of preasure to be safely used commercialy. | ||

Revision as of 19:39, 3 June 2023

Meet the Team

Halo semual, perkenalkan nama saya Arlington (21067329730) dari Departemen Teknik Mesin

Design and Optimization of a Hydrogen Storage for 1 liter (8 bar)

Many autmotive companies have been researching their own hydrogen PEM (Proton Exchange Membrane) fuel cells since the 90s, our purpose in developing this type a vehicles for the long range possabilities compared to oil and gas, seeing that the internal combustion engine (ICE) is reaching its maximum potential, and we estimate that battery EVs eventually will have a massive effect to climate change due to the construction of the lithium ion batteries, hydrogen fuel cell might be the next alternative to our zero emmisions future.

Hydrogen Fuel Cell Technology

Basicly hydrogen power takes advantage from the following chemical reaction, 2𝐻2 + 𝑂2 → 2𝐻2𝑂 + Q

But unfortunately that reaction can not ocure because of the high activation energy at room temprature. But, if we use a catalyst with a stoichiometric mix of H2 and O2 (like Pt metal), we can lower the activation energy needed, and this is our basis for hydrogen fuel.

The reacgtion before is made to happen in two spatially separated half reaction,

2𝐻2(𝑔) → 4𝐻+ + 4 𝑒− (occurring at the anode) 𝑂2(𝑔) + 4 𝑒− → 2𝑂2− (occurring at the cathode)

First, the H+ and O2- are created at separate electrodes, but subsequently H+ diffuses from the anode to the cathode through an H+- conducting membrane. The last part of the reaction occurs spontaneously at the cathode, with 4𝐻+ + 2𝑂2− → 2𝐻2O

We can approximate the thermal afficiency of ICE is around 35%, the thermal efficiency of this chemical proses currently is about 50%. Proton Exchange Membrane (PEM) are capable of high power density, efficiency, performs sufficient in cold environments makes it pontentially great for the future of climate change in the automotive market.

Application for Motorbikes Currently many big automotive companies have their own concept for hydrogen motorbikes, suzuki is prototyping the burgman, using a 8 kW motor and range up to 320 km. And in the sport bike sector there is the BMW HP Kunst prototype, using a cryogenic hydrogen storage system with a 100 kW fuel system.

Basic Design of Hydrogen Tank

Our objective is to design a hydrogen tank that is capable of storing around 1 liter of hydrogen at 8 bars of preasure, with a budget of Rp 500.00,-. In order to achive the necessary spesifications there are a few things we need to take in to considerations, such as

Material, ideally we can use carbon fiber composites for the base material of the storang tank, but due to the limited budget that we have we can use a simple material that is used generally and easy to work and form with like aluminum or mild steel, this way the material and manufacturing cost of the tank is relatively low.

Flow Mechanism, flow mechanism meaning the output and input (refueling) of the tank. Due to the relatively low preasure that we are dealing with, normal compressor couplers are sufficient enough for this application.

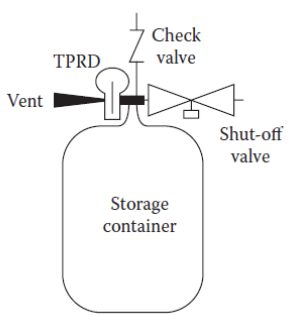

Tank Safety Percautions, a simple hydrogen storage simple shoudl at least consist of a check valve to prevent backflow of hydrogen gas, a temperature activated preasure relied device (TPRD) that opens when it senses high tempreature in order to release hydrogen gas in a controled manner, an automatic shutoff valve installed in the hydrogen lines in order to cut the hydrogen supply if an emergency occur, and a preasure valve in order to know the current capacity of the tank.

Safety Factor, for safety reasons the tank specification must be able to withstand at least 2.5 times the specified preasure in order to be safe. So if we specify the tank to hold 8 bars of preasure, the tank must be able to withstand at least 20 bars of preasure to be safely used commercialy.