Difference between revisions of "Aldebaran Fernanda Octavian"

(→Compressed Hydrogen Storage Tank Design) |

(→Compressed Hydrogen Storage Tank Design) |

||

| Line 81: | Line 81: | ||

'''Head Design :''' | '''Head Design :''' | ||

| + | |||

| + | [[File:Head_Design.png|500x500px]] | ||

Revision as of 01:56, 29 May 2023

Introduction

Hello! my name is Alde, I'm in mechanical engineering major continuing my study from diploma 3 to bachelor's degree throughout University of Indonesia parallel program.

Life motto? Everybody has their own start and finish line, start creating yours.

Full name : Aldebaran Fernanda Octavian

NPM : 2206100180

Compressed Hydrogen Storage Tank Design

Customer requirement list :

1. Storage tank volume is approximately 1 liter.

2. Hydrogen is compressed to 8 bar of gauge pressure.

3. Normal operating condition (room temperature and humidity).

4. Output and input port for hydrogen filling and exerting.

5. Add pressure regulator for output port.

6. Maximum budget is 500.000 rupiah.

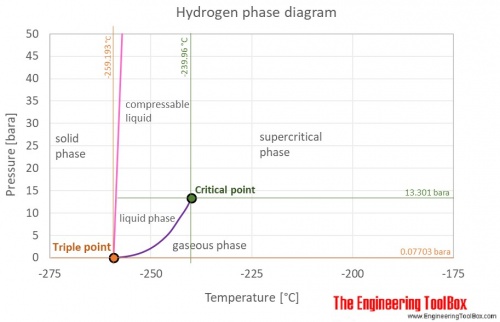

Determining hydrogen phase :

According to hydrogen phase diagram above, hydrogen at 8 bar of gauge pressure and 25 degree Celsius, is in gaseous phase.

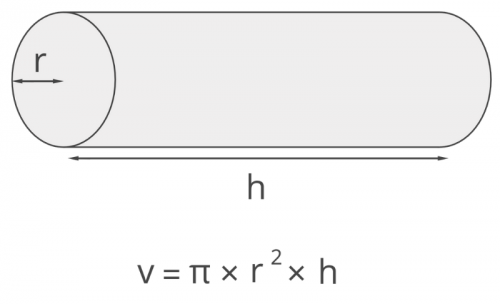

Determining tank size :

First step is to determine the tank inner diameter : 100 mm

According to the equation above, the inner height of the tank is h = 1.000.000 / 3,14 x 50 x 50 = 127,32 mm

Tank design calculation :

All of the design calculation are based on ASME Section VIII Pressure Vessel standardization.

1. Material allowable stress value :

Material : ASTM A36 sheet metal ; Yield Strength (Sy) : 36 Ksi

Allowable stress value = 2/3 x Sy = 24 Ksi

2. Wall and head minimum thickness :

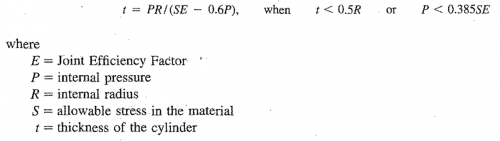

Thickness formula for circumferential stress direction :

Thickness formula for longitudinal stress direction :

E = 0,60 (Single-welded butt joint without use of backing strip)

P = 8 bar = 116 Psi

R = 50 mm = 1,97 inch

S = 24000 Psi

Corrosion allowance = 1 mm = 0,039 inch

t = 116x(1,97+0,039) / (24000x0,6)-(0,6x116) = 0,0162 + corrosion allowance = 0,5526 inch

t = 1,4 mm (Circumferential) ; t = 1,2 mm (Longitudinal)

So, the minimum thickness of the sheet metal is 1,4 mm

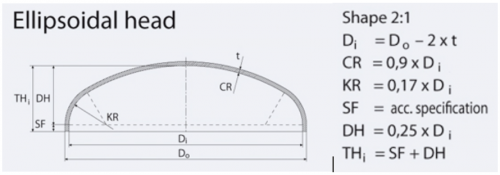

Head Design :