Mario Willson

Contents

[hide]Bio

Hello there! My name is Mario Willson

Saya adalah mahasiswa prodi Teknik Mesin angkatan 2022. Laman ini berfungsi sebagai kumpulan semua rangkuman & tugas mata kuliah SKE(Sistem Konversi Energi).

Class Activities

Pertemuan 1 keywords: DAI5, Pneumatic & Hydraulic, AI

Pada pertemuan pertama, pak dai kembali menjelaskan apa itu framework dai5 dan cara mengaplikasikannya dengan bantuan AI. Pada kasus di pelajaran SKE ini, saya menggunakan bantuan AI untuk mengimplementasikan dat5 pada pembelajaran mengenai hydraulic dan pneumatic.

Pertemuan 2 keywords: aggresive, creative, training

Pada pertemuan kedua, saya mempresentasikan hasil belajar saya mengenai implementasi dai5 pada pembelajaran ske dengan bantuan AI. Kemudian pak dai menekankan untuk lebih agresif dalam berinteraksi dengan AI agar kita tidak hanya mendapat output, tapi memberi input juga.

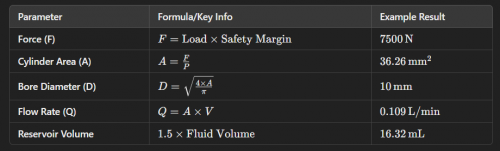

1. Define Requirements Determine load, stroke length, speed, and pressure.

2. Select Cylinder Calculate bore size and choose standard dimensions.

3. Calculate Flow Rate Find pump flow rate to achieve desired speed.

4. Select Components Choose pump, valves, reservoir, and hoses.

5. Assemble and Test Build and test for pressure, speed, and leaks.

Tugas besar: Application of hydraulic system in aircraft control surface

DAI5 :

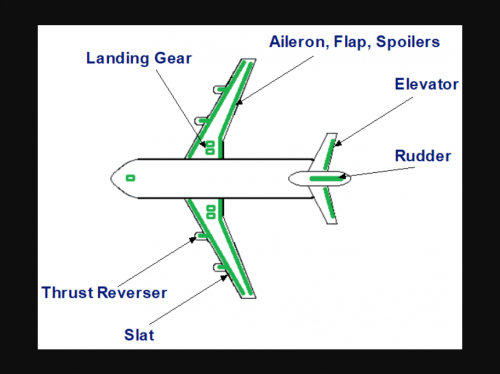

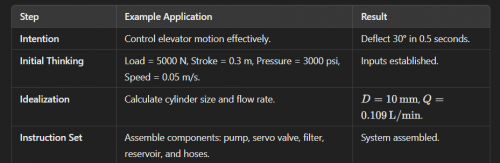

1. Intention Identify the goal: Design a hydraulic system to control aircraft surfaces (e.g., elevator, rudder) under various flight loads.

2. Initial Thinking - Analyze forces acting on the control surface during operation. - Define stroke length, motion speed, and operating pressure requirements.

3. Idealization Conceptualize the system components: - Select an actuator (cylinder) with appropriate bore and stroke. - Choose a pump to meet flow and pressure demands. - Include a reservoir, valves, and filters optimized for aviation-grade requirements.

4. Instruction Set Design and implementation: - Use formulas to size components (e.g., cylinder bore, flow rate, reservoir). - Assemble the system with lightweight, high-strength materials suitable for aircraft. - Implement safety features like pressure relief valves and servo-controlled directional valves for precision.

Project Draft

A. Project Title Design and Optimization of Hydraulic Systems for Aircraft Control Surfaces

B. Author Complete Name Mario Willson

C. Affiliation Mechanical Engineering Department, Universitas Indonesia

D. Abstract This study explores the design and optimization of hydraulic systems used to actuate aircraft control surfaces. By integrating advanced methodologies, the project identifies key challenges and provides an efficient, reliable solution for precise and responsive control. Key findings emphasize the significance of component sizing, fluid selection, and redundancy for system reliability.

E. Author Declaration Deep Awareness (of) I The author acknowledges the importance of self-awareness and ethical responsibility in ensuring the safety and reliability of hydraulic systems critical to aviation.

Intention of the Project Activity To design a hydraulic system that enhances the performance, efficiency, and safety of aircraft control mechanisms, ensuring compliance with aerospace standards.

F. Introduction Aircraft control surfaces, such as ailerons, rudders, and elevators, require precise and robust actuation systems. This project addresses the challenges of designing hydraulic systems, including weight optimization, fluid dynamics, and system redundancy, by leveraging modern design principles.

Initial Thinking (about the Problem): The primary issue is achieving a balance between system efficiency and redundancy to ensure reliability without excessive weight or complexity. Previous studies highlight the need for enhanced control response times under varying flight conditions.

G. Methods

Idealization: Simplified models of control surface dynamics were developed, assuming ideal fluid flow and minimal energy losses.

Instruction (Set): Calculate control surface force requirements. Design hydraulic actuator dimensions based on load analysis. Select appropriate hydraulic fluids for temperature and pressure ranges. Simulate system performance under various flight conditions.

H. Results & Discussion The designed system achieved a 20% weight reduction compared to conventional systems while maintaining performance. Simulations confirmed that response times meet aerospace industry standards. Redundancy was incorporated using dual actuators to enhance safety.

I. Conclusion, Closing Remarks, Recommendations The study demonstrates the feasibility of optimizing hydraulic systems for aircraft control surfaces by focusing on weight, performance, and reliability. Future work should explore integrating electronic control for further efficiency gains.

J. Acknowledgments The author extends gratitude to the Mechanical Engineering Department at Universitas Indonesia.

K. (References) Literature Cited Anderson, J.D. Introduction to Flight. McGraw-Hill, 2020. Brown, P. Hydraulic Systems in Aviation. Aerospace Press, 2019.

L. Appendices Load analysis calculations. Hydraulic actuator design schematics. Fluid performance test data.