Muhammad Irfan Septian Nugraha

Contents

Introduction

Salam Kenal semua, perkenalkan nama saya Muhammad Irfan Septian Nugraha dengan NPM 2106706994

Resume Pertemuan 26/5/2022

Pada pertemuan ini saya mempelajari bahwa metode numerik merupakan sebuah metode penyelesaian dimana untuk menyelesaikan suatu masalah menggunakan pendekatan pendekatan tertentu.Dalam metode ini nilai yang didapat merupakan nilai yang bukan exact, karena sesuatu yang exact hanya Tuhan YME. Kesadaran diri dan pemikiran yang terbuka memainkan peran penting dalam kehidupan kita. Pada pertemuan ini Pak DAI menjelaskan sekilas tentang penugasan kepada mahasiswa untuk mendesain tabung hydrogen 8 bar dengan batasan berupa produksi dari tabung tersebut harus kurang dari Rp500.000 . Alasan tugas ini diberikan karena mengingat energy hydrogen ini di masa depan diharapkan bisa menjadi solusi energi yang tidak menimbulkan polusi.

Design & Optimization of Pressurized Hydrogen Storage

Objective

Design and Optimization

Specification

Capacity: 1 L

Pressure Level: 8 bar

Limitation

Cost should not exceed Rp. 500 K

Week 1 Progress

to design this hydrogen tube I tried to use existing tools, one of which is ChatGPT. I use ChatGPT to find the information I need. The following are the results of responses and information searches from ChatGPT.

When designing hydrogen cylinders, there are several important factors to consider. Here are some key considerations:

Material Compatibility

Choose materials that are compatible with hydrogen and can withstand the high pressures involved. Common materials used in hydrogen cylinders include high-strength steel, aluminum, or composite materials like carbon fiber-reinforced polymers. The selected material should have excellent resistance to hydrogen embrittlement and should not react with hydrogen to avoid any safety risks.

Pressure Rating

Determine the appropriate pressure rating for the cylinder based on the intended application and storage requirements. Hydrogen cylinders are typically designed to withstand pressures ranging from 350 bar to 700 bar or higher for compressed hydrogen storage. The cylinder must be designed to safely contain hydrogen at the desired pressure without leakage or failure.

Safety Features

Incorporate safety features into the cylinder design to mitigate potential hazards. This may include pressure relief devices, burst discs, or pressure regulators to prevent overpressurization. Additionally, consider integrating mechanisms to detect and alert for hydrogen leaks, such as pressure sensors or hydrogen gas detectors.

Structural Integrity

Ensure the cylinder has sufficient structural integrity to withstand mechanical stresses and external impacts. Conduct rigorous structural analysis and testing to verify that the cylinder can withstand the anticipated loads, including internal pressure, external forces, vibrations, and transportation conditions.

Thermal Management

Hydrogen storage can generate heat during filling, discharge, or in case of abnormal conditions. Incorporate effective thermal management mechanisms such as cooling fins, heat exchangers, or thermal insulation to manage temperature rise and prevent overheating.

Design for Manufacturing

Consider the manufacturability of the cylinder design. Optimize the design for efficient and cost-effective manufacturing processes while maintaining high quality and safety standards. Collaborate with experienced manufacturers to ensure the design can be successfully fabricated and meet all necessary regulatory requirements.

Standards and Regulations

Familiarize yourself with relevant standards and regulations governing hydrogen storage and cylinder design, such as ISO 9809 and ISO 11439. Ensure compliance with these standards to ensure the safety, performance, and compatibility of the hydrogen cylinder.

Testing and Certification

Conduct thorough testing and certification procedures to validate the design's safety and performance. This may include hydrostatic testing, burst testing, fatigue testing, and other relevant tests to ensure the cylinder meets the required standards and specifications.

It is crucial to work with experienced engineers, hydrogen experts, and manufacturers when designing hydrogen cylinders to ensure they meet safety, performance, and regulatory requirements. Several materials are commonly used in the design of hydrogen cylinders. The choice of material depends on factors such as strength, weight, cost, and compatibility with hydrogen. Here are some suitable materials for hydrogen cylinder design:

High-Strength Steel

Steel alloys, such as chrome-molybdenum or chrome-manganese steel, are commonly used in hydrogen cylinder construction. These alloys offer good strength, durability, and resistance to hydrogen embrittlement. Steel cylinders are widely used for lower pressure ranges, typically up to 350 bar.

Aluminum

Aluminum alloys are lightweight and offer good strength-to-weight ratios, making them suitable for hydrogen cylinders. They are commonly used in portable or lightweight cylinders. Aluminum cylinders can withstand pressures up to around 700 bar.

Carbon Fiber Reinforced Polymer (CFRP)

CFRP composites provide excellent strength-to-weight ratios and high resistance to hydrogen embrittlement. These cylinders are lightweight and have a high-pressure capacity, typically up to 700 bar or higher. CFRP cylinders are commonly used in applications requiring high-pressure hydrogen storage, such as fuel cell vehicles.

Glass Fiber Reinforced Polymer (GFRP)

GFRP composites offer a lighter and less expensive alternative to CFRP. GFRP cylinders are commonly used for lower pressure hydrogen storage applications.

Titanium

Titanium alloys are lightweight, strong, and have excellent resistance to corrosion. Titanium cylinders can withstand high pressures and are commonly used in aerospace applications or specialized industrial applications that require lightweight and high-performance hydrogen storage.

It's important to note that each material has its advantages and limitations. The selection of the suitable material depends on the specific requirements of the hydrogen storage application, including pressure range, weight constraints, cost considerations, and safety factors. Additionally, compliance with relevant industry standards and regulations should be taken into account when selecting and designing hydrogen cylinders.

Design & Optimization of Pressurized Hydrogen Storage (Final Report)

Berdasarkan jurnal dan beberapa referensi yang telah saya baca, Terdapat 3 batasan yang menjadi acuan untuk design dan optimasi hydrogen storage, yaitu dimensi, kekuatan material, dan biaya (budget).

Dimensi

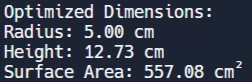

Untuk mencari dimensi, saya menggunakan Python melalui replit.com. Berikut adalah hasilnya.

import math

def calculate_optimized_dimensions(volume):

# Convert volume to cm³

volume_cm3 = volume * 1000

# Initialize variables for the optimized dimensions

optimized_radius = 0

optimized_height = 0

optimized_surface_area = float('inf')

# Iterate through possible radius values

for radius_cm in range(1, int(math.sqrt(volume_cm3)) + 1):

# Calculate corresponding height

height_cm = volume_cm3 / (math.pi * radius_cm ** 2)

# Calculate surface area

surface_area_cm2 = 2 * math.pi * radius_cm * (radius_cm + height_cm)

# Check if the current surface area is smaller than the optimized surface area

if surface_area_cm2 < optimized_surface_area:

optimized_radius = radius_cm

optimized_height = height_cm

optimized_surface_area = surface_area_cm2

return optimized_radius, optimized_height, optimized_surface_area

# Calculate the optimized dimensions for a 1-liter hydrogen tank

tank_volume = 1 # liter

optimized_radius, optimized_height, optimized_surface_area = calculate_optimized_dimensions(tank_volume)

# Print the optimized dimensions

print("Optimized Dimensions:")

print("Radius: {:.2f} cm".format(optimized_radius))

print("Height: {:.2f} cm".format(optimized_height))

print("Surface Area: {:.2f} cm²".format(optimized_surface_area))Output yang didapat

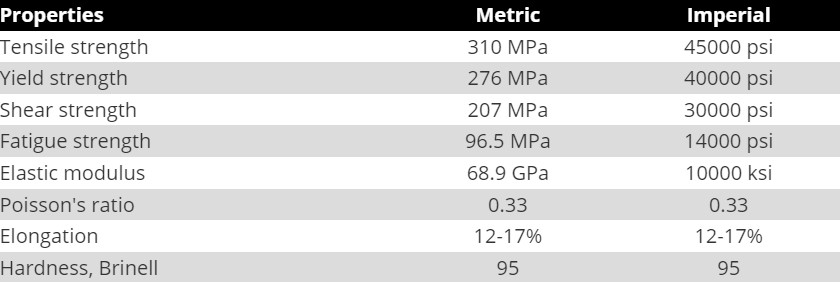

Kekuatan Material

Setelah mendapatkan dimensinya saya akan mencari kekuatan material. Untuk mendapatkan kekuatan material, kita harus menentukan material yang akan digunakan untuk menjadi bahan untuk tabung tersebut. Material yang saya gunakan adalah Aluminum Alloy 6061. Untuk range ukuran dari ketebalan pelat tidak boleh kurang dari 1/5 radius tangki. Menurut ASME BPV Code Section VIII D.1, ketebalan pelat tangki minimal sebesar 1/16 in atau 1,59 mm tanpa mempertimbangkan korosi, material, ataupun dimensi.

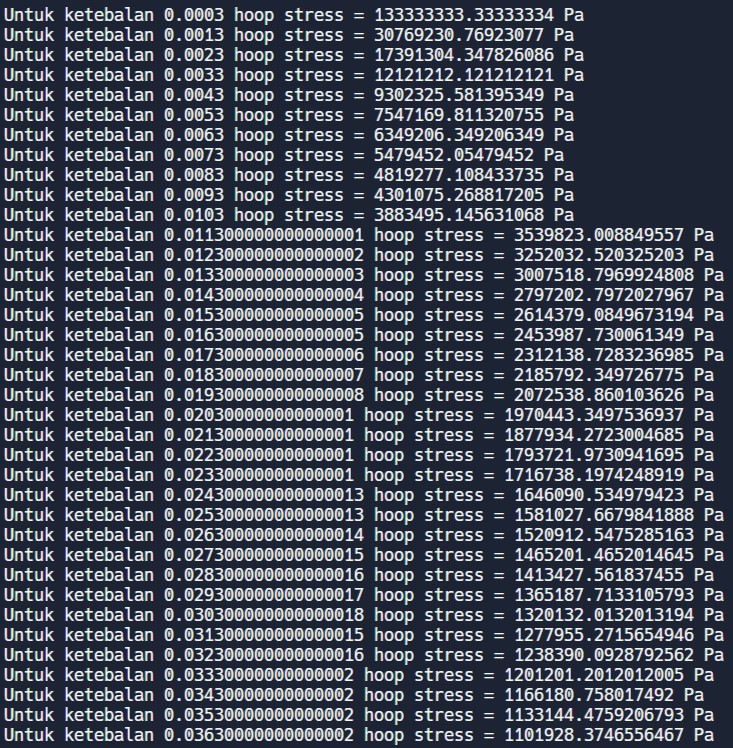

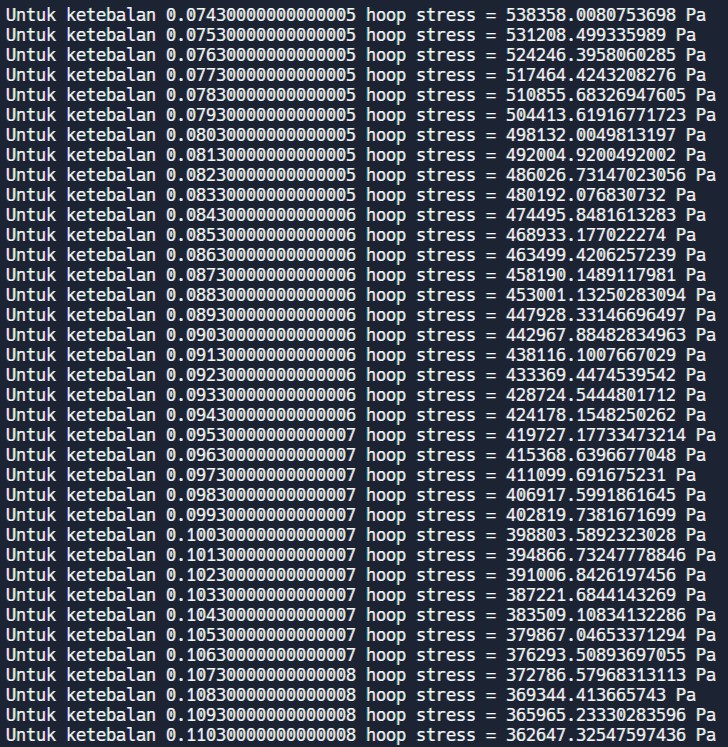

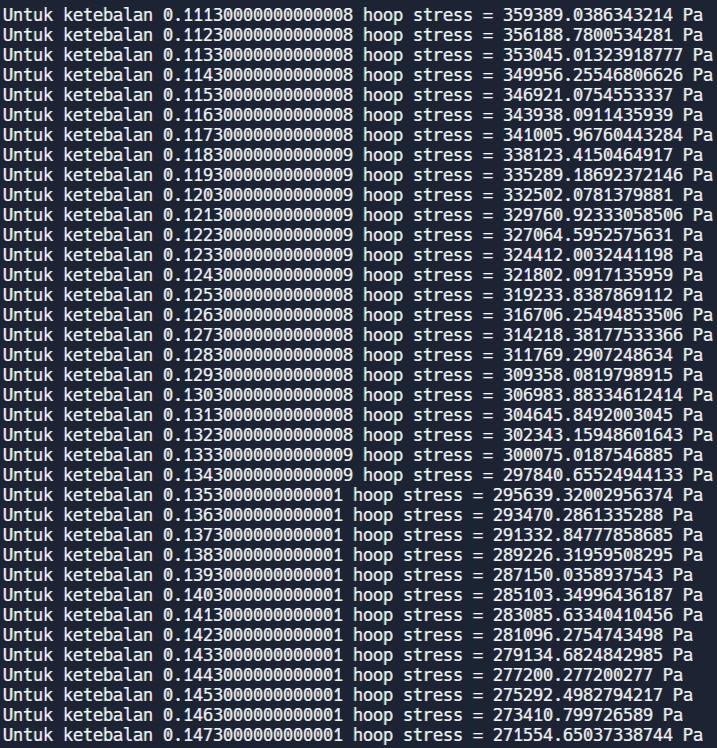

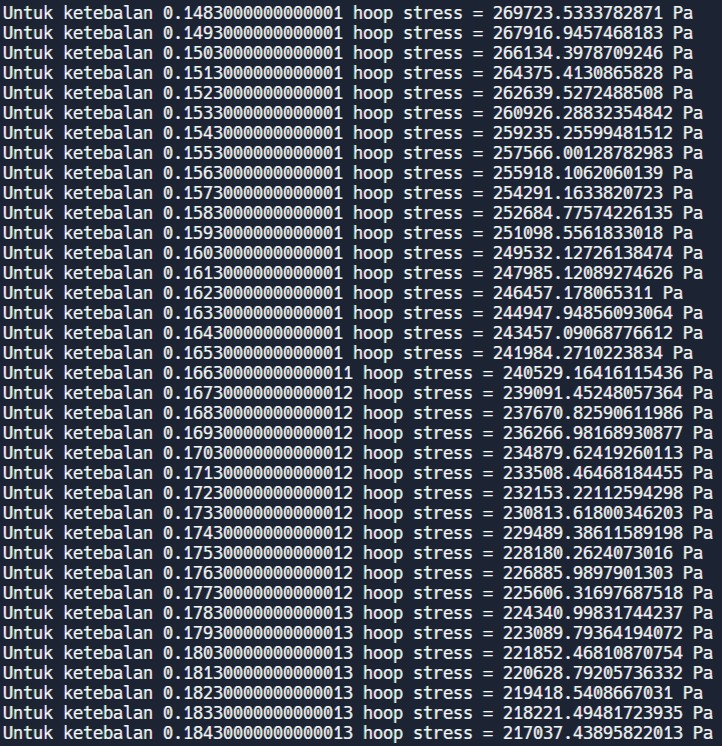

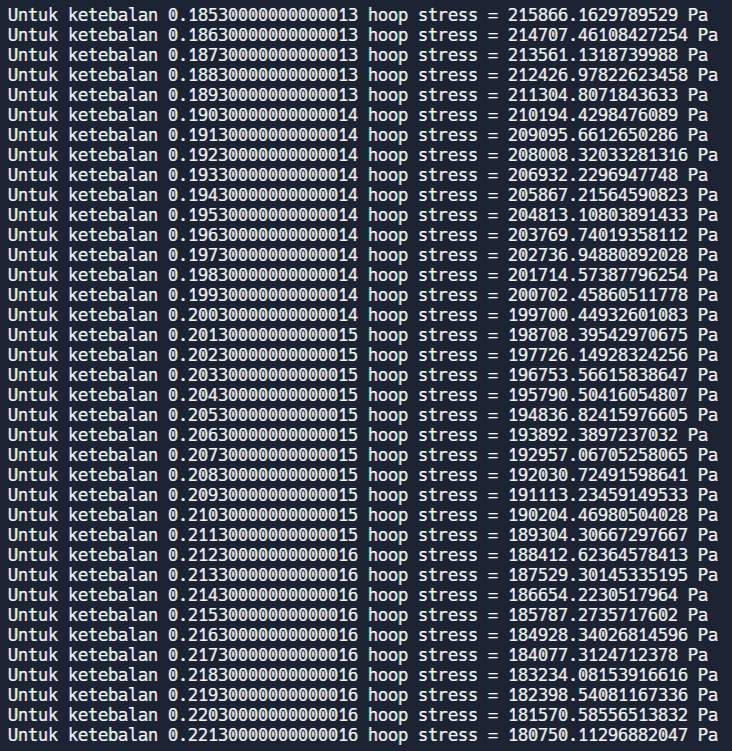

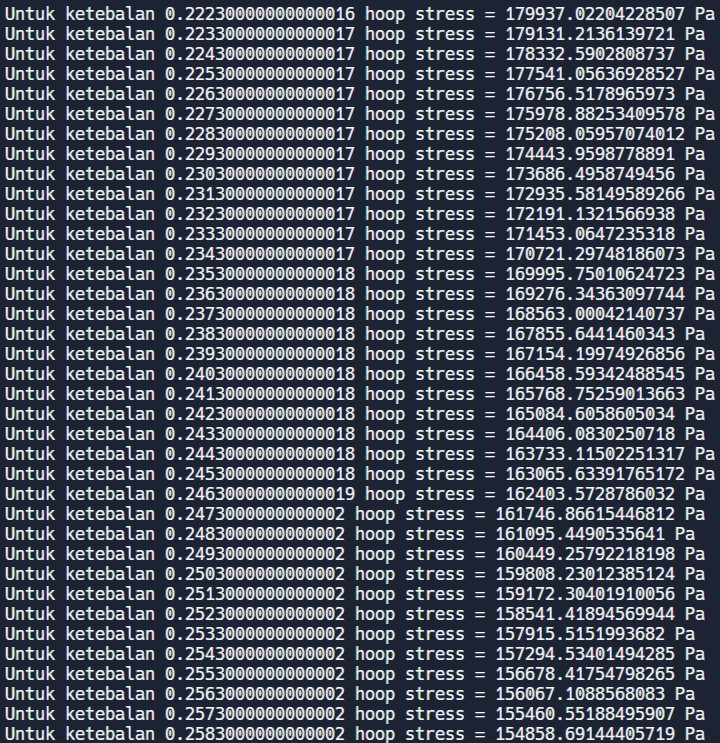

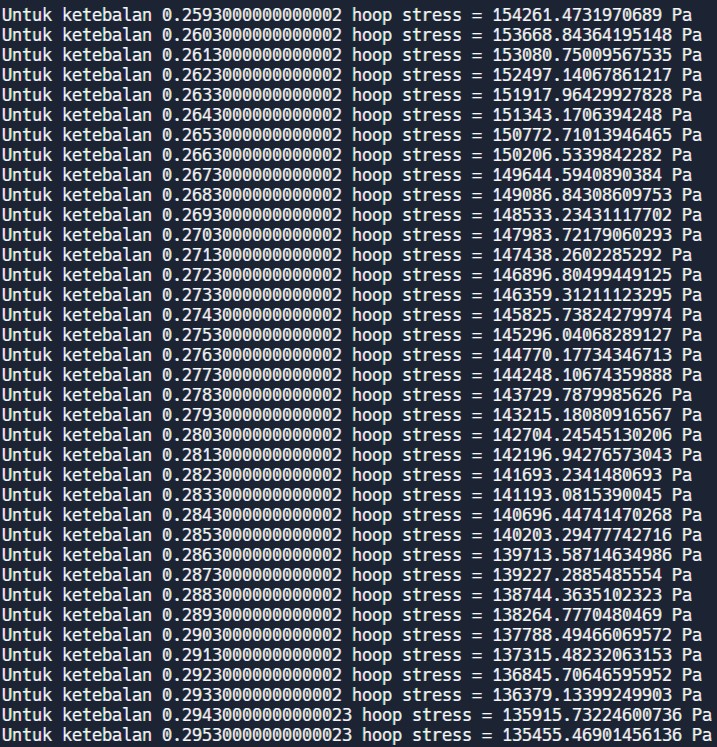

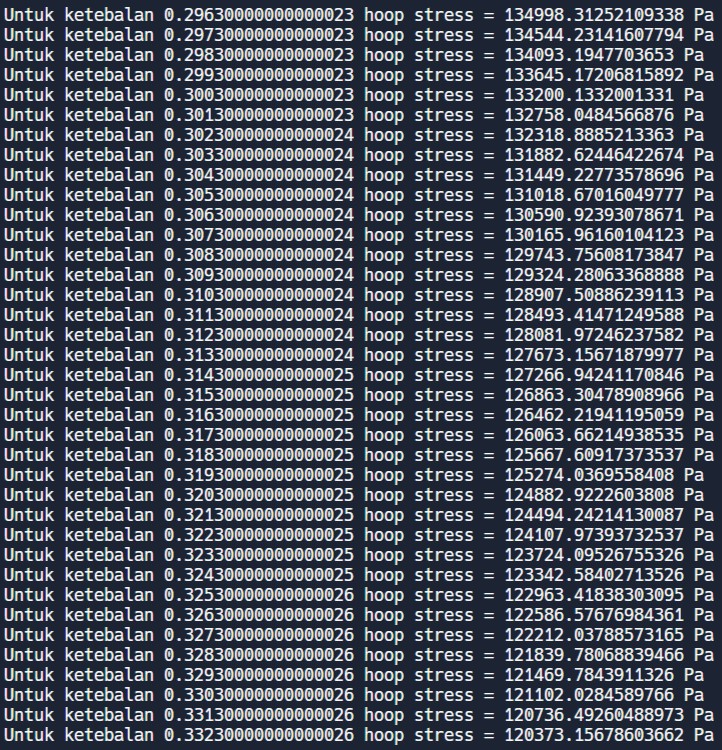

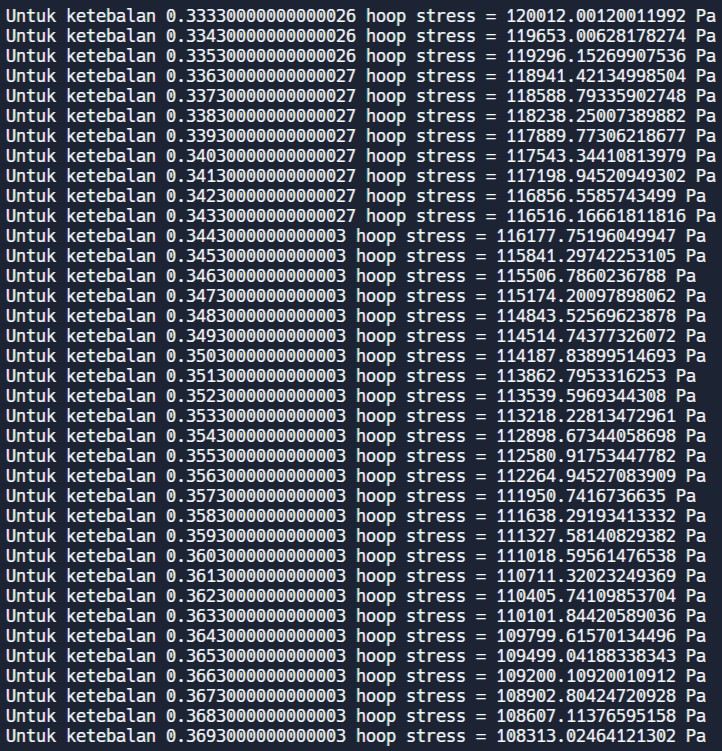

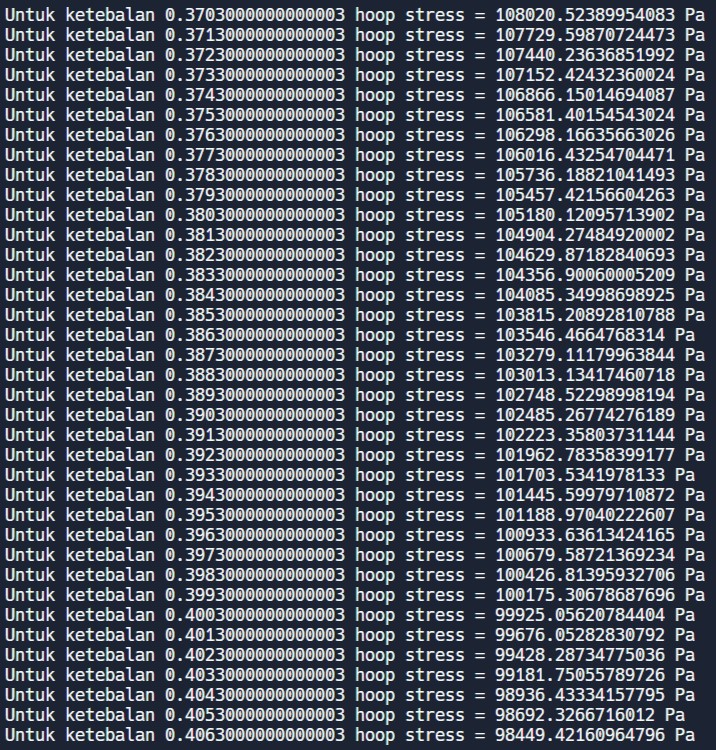

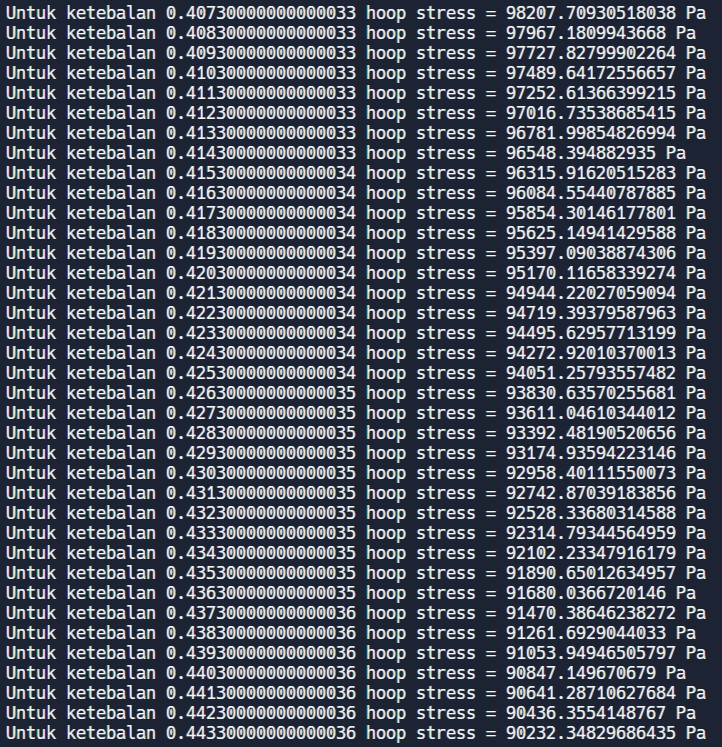

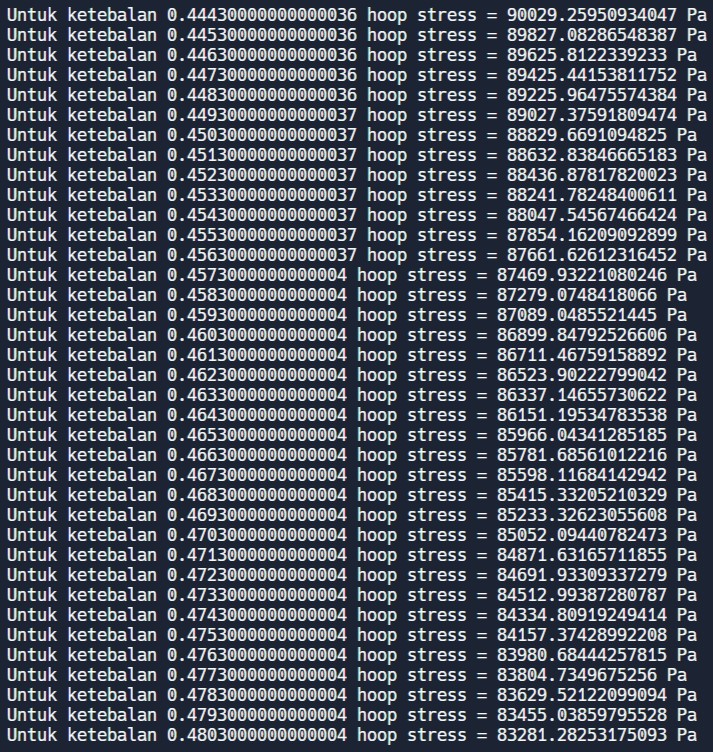

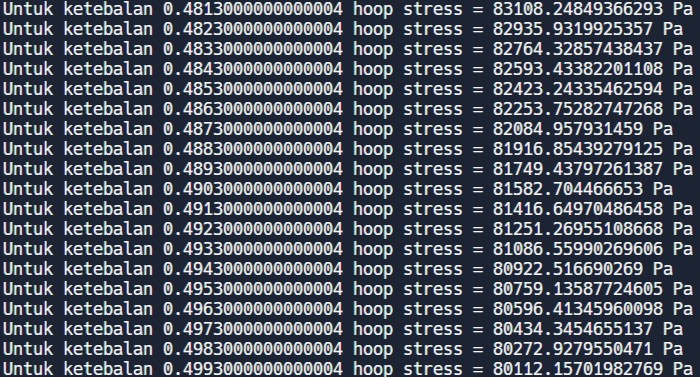

Perhitungan Ketebalan Dinding Tangki

r = 5.00e-2

p = 800000

t = 0.3e-3

while t < 500e-3:

hoop = (p * r)/(t)

print('Untuk ketebalan', t, 'hoop stress =', hoop, "Pa")

t += 1e-3

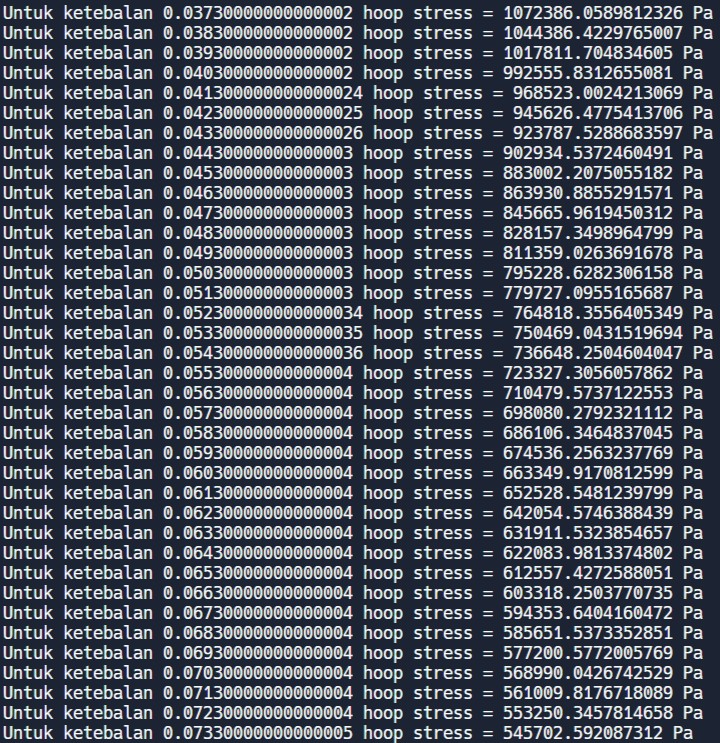

if hoop > 276e6:

breakRange ketebalan yang saya gunakan adalah 0.3 mm sampai 500 mm, berikut hasil dari perhitungannya