Wahid Amir Chairudin

Contents

[hide]Introduction

Perkenalkan nama saya Wahid Amir Chairudin, biasa dipanggil Wahid

Saya lahir di Kota Surakarta pada tanggal 10 April 2002

Saat ini selama saya menjalankan perkuliahan, saya bertempat tinggal di rumah indekos di daerah Kukusan, Beji, Depok.

Saya adalah mahasiswa Program Studi Teknik Perkapalan - Fakultas Teknik Universitas Indonesia, dengan NPM 2106708570

Resume Perkuliahan 1 - 26 Mei 2023

[Tempat Perkuliahan : Gedung S.305 || Waktu Perkuliahan : 16.00 - 17.40]

Pada pertemuan pertama ini kita membahas beberapa hal terkait dengan introduction dan konsep dasar pembelajaran di kelas Metode Numerik.

Di awal kelas Pak Ahmad Indra Siswantara (DAI) memberikan penjelasan tentang ketertarikan mahasiswa terhadap mata kuliah metode numerik. Pak Dai menekankan bahwa sebagai mahasiswa kita harus memaksimalkan potensi diri kita selagi usia kita masih muda dan berusaha semaksimal mungkin untuk memahami apa yang sedang kita pelajari dan kita ikuti selama menajalani kelas perkuliahan.

Di masa kini, ada teknologi yang dinamakan Chat GPT yang dapat kita gunakan secara maksimal untuk mendapatkan dan mencari data - data konkrit dari sebuah materi yang kita bingungkan.

Pak DAI juga menjelaskan terkait dengan metode ujian yang nantinya akan diterapkan di kelas yang beliau ampu. Metode ujian yang digunakan adalah "Blank Paper Question Sheet" dimana mahasiswa diberikan kesempatan untuk menulis dan membuat materi serta pertanyaan yang akan dibuat masing - masing oleh mahasiswa mengenai segala macam ilmu yang sudah didapatkan selama mengikuti kelas perkuliahan. Pak DAI mengharapkan mahasiswa mengerti tentang materi yang sudah disampaikan selama mengikuti perkuliahan dan dituangkan kedalam kertas yang diberikan.

Pak DAI pada pertemuan pertama juga menunjuk beberapa mahasiswa untuk menjelaskan apa yang mereka dapat selama mengikuti kelas perkuliahan Metode Numerik.

Kemudian, Pak DAI juga me-remind tentang materi apa yang dikirimkan di Grup WA dan juga menjelaskan sekilas tentang penugasan kepada mahasiswa untuk membuat dan mengoptimasi tabung hydrogen yang diberikan batasan berupa produksi dari tabung tersebut harus kurang dari Rp500.000 . Alasan tugas ini diberikan karena mengingat energy hydrogen ini di masa depan diharapkan bisa menjadi solusi energi yang tidak menimbulkan polusi dan juga tidak menjadi sampah akibat pertukaran energi.

Pada akhir sesi perkuliahan Pak DAI memberikan case study dan juga analogi pendekatan yang menginspirasi mahasiswa untuk lebih giat dalam menuntut ilmu dan juga mendekatkan diri kepada Tuhan YME, agar di dalam perjalanan perkuliahan kita senantiasa mengingat bahwa segalanya tidak ada yang sempurna dan pasti kecuali Yang Maha Esa.

Design & Optimization of Pressurized Hydrogen Storage

Objective : Design and Optimization Of Pressurized Hydrogen Storage

Spesification :

Capacity : 1 Litres

Pressure Level : 8 bar

Limitation : Cost should not exceed Rp.500.000

Week 1 Progress

In week 1 I did some research on Hydrogen Storage and some of the limitations that have been set for this assignment. I Consciously think that to collect some data related to what needs are needed to understand the basics of designing and optimizing Hydrogen Storage. There are lots of considerations that must be collected and must be researched if we want to optimize a product that already exists. Collecting data in a short time will certainly be a challenge. This is where I have a solution for using AI technology that is being widely discussed in the world, namely the GPT Chat. GPT Chat provides many outlines of considerations that we can use in designing and optimizing a tool or product.

ChatGPT Response

ChatGPT provides several considerations and steps that we can take and examine in optimizing Hydrogen Storage. Among them are: Tank Selection, Tank Material, Tank Safety, Cost Optimization, and several other additions

System Requirements

The initial system requirements that must be considered before designing and optimizing Hydrogen Storage include the selection of tanks and their materials, pressure regulators, valves and fittings as well as safety features that are applied to the Hydrogen Storage.

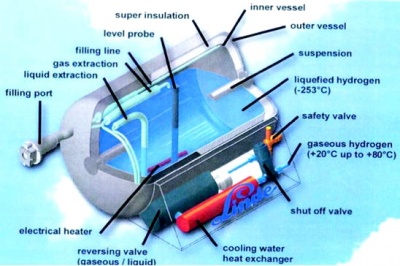

Storage Method

In this case the storage method that we can use within the limits specified above is Cryogenic Tanks where this storage method involves storing hydrogen in liquid form at very low temperatures. Cryogenic tanks, often insulated vessels, are used to store and maintain hydrogen in its liquid state.

Material Selection

Choose a gas cylinder made of steel, as it is generally more affordable than other materials like aluminum alloy. Steel cylinders are widely used for compressed gas storage and offer good strength and durability.

System Design

In developing and optimizing the detailed Hydrogen storage for storage systems, we consider factors such as vessel shape, internal volume, structural integrity, valve placement and fitting, thermal management, and pressure relief mechanisms. The design software that can help us to do the design is computer-assisted (CAD) which can also be combined with other mechanical analysis software such as Ansys or other CFD analysis.

Safety Measures

Ensure that the selected tank has proper safety features, such as pressure relief mechanisms and valves, to prevent over-pressurization. It should comply with safety standards like ISO 11119 for gas cylinders, ISO 16111 or ASME Boiler and Pressure Vessel Code.

Optimization Techniques

To optimize your hydrogen storage design for cost-effectiveness and compactness, you can follow these steps:

- Determine Storage Requirements,

- Evaluate Different Storage Methods,

- Assess Material Choices,

- Optimize Cylinder Size,

- Utilize Standardized Components,

- Explore Economical Manufacturing Processes,

- Consider System Integration,

- Conduct Cost-Benefit Analysis,

- Safety and Compliance,

- Continuous Improvement.

Manufacturing Process

Investigate cost-effective manufacturing processes, such as mass production techniques, to reduce production costs. Optimizing manufacturing processes can lead to cost savings and increased efficiency

Performance Testing

To optimize hydrogen storage for cost-effectiveness and compactness through performance testing, you can follow these steps:

- Define Performance Metrics,

- Establish Test Procedures,

- Conduct Comparative Testing,

- Analyze Test Results,

- Iterative Design Optimization,

Based on the test results and analysis, iterate the design optimization process. Modify or refine the design elements to improve cost-effectiveness and compactness while maintaining desired performance levels. Consider factors like material selection, geometry, insulation, and pressure control mechanisms.

Regulatory Compliance

Regulatory compliance is essential when designing and optimizing hydrogen storage systems to ensure safety, environmental protection, and adherence to applicable laws and regulations. Here are some key considerations for regulatory compliance in designing and optimizing hydrogen storage :

- Familiarize Yourself with Regulations,

- Safety Standards and Codes,

- Pressure Vessel Regulations,

- Hazardous Materials Transportation Regulations,

- Environmental Regulations,

- Permits and Approvals,

- Third-Party Certification,

- Documentation and Record-Keeping,

- Ongoing Compliance Monitoring,

- Consultation with Experts.

Lifecycle Considerations

When designing and optimizing hydrogen storage systems, it's crucial to consider lifecycle considerations to ensure the long-term performance, sustainability, and cost-effectiveness of the system. Here are key lifecycle considerations to keep in mind:

- System Durability and Reliability,

- Maintenance and Inspection,

- Efficiency and Performance Optimization,

- Safety Management,

- Environmental Impact,

- End-of-Life Considerations,

- Cost Analysis,

- Technological Advancements,

- Regulatory Compliance.

Continuous Improvement

Continuously seek opportunities for improvement through feedback, monitoring, and technological advancements. Stay updated with the latest developments in hydrogen storage technologies to identify cost-effective and compact solutions.

Consideration of Hydrogen Storage Design and Optimization Tasks

Before working on the design task of optimizing hydrogen storage tanks, I need to know some of the considerations used to design the hydrogen storage. Among them:

Properties of Hydrogen:

Things to know when considering is the nature of the hydrogen itself. There are several important properties to consider in optimizing the storage system, which include:

1. Light Gas: Hydrogen is the element with the smallest atomic mass in the periodic table so it has a very low density. At standard temperature and pressure, hydrogen exists as a gas.

2. Reactivity: Hydrogen is a very reactive element, it can react with many other elements, such as oxygen, halogens, and alkali metals and form various compounds.

3. Formation of Water: Hydrogen reacts with oxygen exothermically to form water (H2O).

4. Properties of Acids and Alkalis: Hydrogen can act as an acid or an alkali in chemical reactions. When hydrogen liberates H+ ions, it acts as an acid and when it is the other way around, it becomes an alkali.

5. Soluble in Water: Hydrogen is a gas which dissolves in water. When hydrogen dissolves in water, it forms a solution called hydrogen water which has acidic or alkaline properties depending on the number of H+ or OH- ions.

Storage Materials:

For the record, hydrogen is a material that is still being researched today so that there are many possible changes made by humans in handling this hydrogen. In carrying out hydrogen storage, there are several materials that can be used:

1. Metal Tanks: Metal tanks such as steel or aluminum tanks are the most commonly used method of hydrogen storage. Hydrogen can be stored in high pressure containers that are strong and can withstand the pressure generated by hydrogen gas.

2. Absorbent Materials: Some materials can be used as hydrogen absorbers, which can bind and store hydrogen in their molecular structure. Examples include metal alloys such as magnesium-nickel (Mg-Ni) alloys, magnesium-ric (Mg-Ti) alloys, or magnesium-nickel-aluminum (Mg-Ni-Al) alloys.

3. Adsorbent Material: Adsorbent materials such as activated carbon or zeolite have the ability to hydrogen bond on their surface.

4. Chemicals: Several chemical compounds such as ammonia borane (NH3BH3) or metal-organic hydrates such as lithium alanate (LiAlH4) and sodium borohydride (NaBH4) can be used as hydrogen storage.

5. Nanostructural Materials: Materials with nanometer structures such as carbon nanotubes or graphene have potential as hydrogen storage methods. The large surface area and unique properties of this nanostructural material can increase the hydrogen adsorption capacity.