Aqiel Saiful Fatah

Impulse and Reaction Turbines

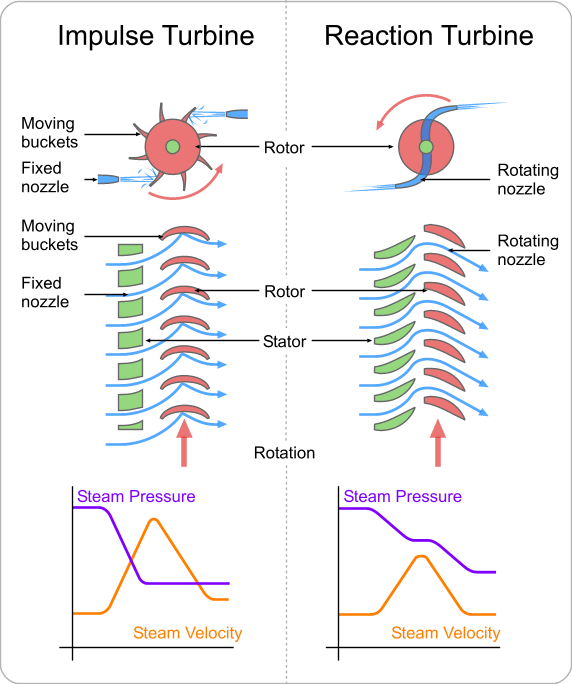

Steam turbines are the most used mover in power plants, refineries, and processing plants. Based on the operating principle the steam turbine can be classified as these two types;

1. Impulse turbine 2. Reaction turbine

Impulse Turbines

Impulse steam turbines consists of stationary steam nozzles and a rotor with rotating buckets. What happens when the steam passes through these nozzles is hit the buckets at a high velocity causing the rotor to rotate at a high speed. In the nozzle, pressure, and enthalpy of the steam decreases whilst velocity, and volume of the steam increases.

Pressure energy is converted into kinetic energy through these nozzles. There are two types of nozzles;

1. Convergent nozzles, which are used for smaller pressure drops and develops eddy-currents 2. Convergent-divergent nozzles, which prevent eddy current and cause larger pressure drops

Impulse Principle: High pressure steam enters a stationary nozzle of a steam turbine and exits in the form of a high-speed jet. This will then hit the shaped turbine blade and the flow direction will change. The change in direction will produce an impulse force, which will cause the blade to move and the rotor to rotate.

In impulse turbines, pressure drops and velocity increases when steam passes through the nozzles. When steam passes through the blades, velocity drops but pressure is constant. This is the distinguishing feature of an impulse turbine; pressure at the inlet of the blades is equal to the outlet.

Reaction Turbines

Quite different to impulse turbines, reaction turbines have steam expand through its moving blades thus resulting in a reaction force that moves the rotor.

A reaction turbine has rows of fixed blades and moving blades that alternate in its position. Steam expands in the fixed blades first to increase its velocity as it drops in pressure. Then steam enters the moving blade rows where its direction is changed and results in an impulse force which moves the blade. Whilst moving the blade, steam expands further and drops its pressure even more giving a reaction force to the blades. Steam pressure drops in both fixed and moving blades, where the absolute velocity increases in fixed blade rows and decreases in moving blade rows. The distinguishing feature of reaction turbines is that pressure is different between the inlet of the moving blades and the outlet of the moving blades. Also, there is a n unbalanced thrust will be developed onto the rotor, which needs special adjustments.