Muhammad Fikri Zulkarnaen

Introduction Perkenalkan Nama saya Muhammad Fikri Zulkarnaen dari Teknik Perkapalan angkatan 2021, Saya lahir di Jakarta pada 29 Mei 2003, Saya bersekolah di TK Besuki, SMPN 115 Jakarta, SMAN 3 Jakarta

Contents

- 1 RECAP KERJA PRAKTIK PERTAMINA EP CEPU

- 2 Resume Pertemuan 26/05/2023

- 3 Optimization & Design of Pressurized Hydrogen Storage

- 4 Design Calculation

- 5 Code For The Design

- 6 Result Of the Code

- 7 3D Model For Hydrogen Storage Design & Optimization

- 8 Conclusion

- 9 Video Presentation of My Conscious Efforts in Numerical Method Learning and Its Application in Hydrogen Storage Design

RECAP KERJA PRAKTIK PERTAMINA EP CEPU

Assalamualaikum bapak dai, perkenalkan nama saya muhammad fikri zulkarnaen (fikri), pada kolom wikipage ini izinkan saya memngumpulkan recap yang telah saya buat saat saya melaksanakan kegiatan kerja praktik di PT Pertamina EP Cepu

Recap dibuat dalam weekly journey yaitu recap minggu 1 - minggu 8

RECAP MINGGU 1 pada minggu pertama kami melaksanakan KP di Pertamina Ep cepu patrajasa office, kami hadir pukul 7 pagi WIB, setelah itu kami menuju ke lantai 5 untuk berkoordinasi dengan receptionist terkait KP ini, kemudian kami diarahkan ke lantai 11 untuk bertemu dengan Human Resource pertamina EP Cepu, kemudian kami diantarkan oleh pihak HC menuju lantai 5 wing 3(lokasi kantor Supply chain Managament Zona 12), lalu kami dikenalkan dengan mentor, mentor saya yaitu atas nama Bapak Ferdy Zakhrifady, kemudian kami melaksanakan safety induction yang dipaparkan oleh divisi HSSE, selanjutnya kami diarahkan untuk mengikuti induction yang diadakan oleh SCM Zona 12 yang dipimpin oleh Asisten manager Procurement, Asisten manager general service dan mentor2 kami. pada minggu pertama kami diberi materi berupa PTK 007 dan Juklak pengadaan barang dan jasa, yaitu berisi segala pedoman mengenai peraturan dan kebijakan terkait pengadaan di linkgup pertamina upstream(eksplorasi dan produksi).

RECAP MINGGU 2 Pada minggu kedua kami diajak untuk mengikuti Pre bid, dimana pada Prebid ini merupakan salah satu rangkaian dari proses pengadaan yang ada pada Proses pemilihan vendor. selain itu kami diberi PPT yang berkaitan dengan Supply Chain Management Zona 12, yang berisi materi2-materi serta alur semua proses di zona 12 ini. kemudian kami memperlajari lebih lanjut terkait PTK 007 dan Juklak pengadaan barang dan jasa. selain itu kami juga mempelajari banyak penamaan dan istilah baru seperti TKDN, HPS/OE, Vendor lokal, Vendor Nasional,KKKS dan lain sebagainya. minggu kedua difokuskan untuk melakukan pemahaman yang mendalam terkait dengan divisi yang kami tempatkan.

RECAP MINGGU 3 Minggu ketiga kami diajak kembali untuk mengikuti kegiatan Prebid, pada minggu ini kami sudah mulai paham mengenai alur yang ada pada SCM Zona 12 ini, lalu kami melakukan banyak obrolan dengan mentor maupun pekerja yang berada di SCM Zona 12 ini, selanjutnya kami bertemu dengan manager SCM yaitu bapak gunanto, pada obrolan tersebut kami menjelaskan bahwa kami akan mengarahkan untuk mencari topik yang berkaitan dengan Green supply chain/green procurement, beliau tertarik dengan topik ini dan menyarankan untuk memperlajari lebih lanjut terkait green SCM/Procurement dan cara mengimplementasikan terutama di dunia eksplorasi dan produksi, yang dimana memiliki rules dan safety yang sangat ketat.selain itu kami juga mempelajari aplikasi/webiste yang digunakan dalam tahapan proses pengadaan yaitu CIVD (centralize intelligent vendor database) dan PADI( pasar digital), pada minggu ketiga ini kami mempelajari banyak hal seperti yang saya paparkan diatas.

RECAP MINGGU 4

Resume Pertemuan 26/05/2023

RESUME PERTEMUAN PERTAMA

pada peetemuan pertama dengan pak ahmad indra siswantara(DAI) kamu diberi penjelasan tentang ketertarikan terhadap mata kuliah metode numerik. dan pak dai menekankan bahwa kita harus berusaha semaksimal mungkin daripada kita menyontek dan tidak tau arah materi tersebut. penggunaan chatGPT harus dipakai secara maksimal, karena dapat digunakan untuk mencari data konkret. pada ujian dengan pak DAI, blank question sheet dimanaa mahasiswa diharapkan mengerti materi yang diujikan, pak DAI bercerita tentang pengalaman nya mengajar mekanika fluida. lalu pak DAI menunjuk beberapa orang untuk menjelaskan kemabali penjelasan metode numerik dan materi yang telah disampaikan di grup WA. lalu kami diberi tugas untuk mendesain sebuah penerapan metode numerik untuk sebuah alat penyimpanan hidrogen berbentuk tabung

buat desain optimum, volum tabung 1 liter, dengan tekanan 8? desain dengan batasan harga gaboleh lebih dari 500 ribu, untuk mencampur dengan bahan bakar di motor agar lebih irit , pilih material sendiri, lebar dan tinggi sendiri

Hal yang paling penting oleh pak DAI adalah realitas, dimana jika kita tidak merasakan dampaknya, pasti kita akan lupa. lalu pak DAI menjelaskan tentang chatGPT dimana kita harus bisa membuat pertanyaan sebaik mungkin ke sistem tersebut

lalu dilanjutkan dengan pembahasan mengenai dasar pemikiran dan kepercayaan yang kita anut, menjelaskan tentang qbit atu quantum bit, lalu kita diberikn pertanyaan mengenai pembagian dan pengurangan dan diminta menjelaskan mengapa memilih jawaban tersebut, atas dasar apa dan kenapa?

Optimization & Design of Pressurized Hydrogen Storage

according to the given task specifications, I get the following data

Objective : Design and Optimization Of Pressurized Hydrogen Storage

Spesification :

Capacity : 1 Litres

Pressure Level : 8 bar

Cost should not exceed Rp.500.000

WEEK 1 PROGRESS

the first thing i did was to search from several web and data provider for info about the model assigned, i found several examples of shapes and models that are almost similar to the task given, next think i do is use chatGPT as a tool to provide several data of the task given, and here's the data :

as we know, in the given task, we need to make a design and optimization of pressurrized Hydrogen storage system with a capacity of 1 litres, a pressure level of 8 bar, and a maximum material price of $33 (Rp.500.000 Rupiah)

we will need to make some specific design choices. Please note that this design is based on assumptions and approximations, and a real-world implementation would require further engineering and safety considerations

Material Selection

Aluminum Alloy: Aluminum provides a good balance of strength, weight, and cost for pressurized hydrogen storage systems. The selected alloy should have sufficient tensile strength and corrosion resistance.

Cylinder Design

Cylinder Shape: Select a cylindrical shape as it provides structural integrity and efficient use of space.

Cylinder Dimensions: Determine the dimensions based on the desired 1-liter capacity. Let's assume a cylinder with a height of 300 mm and a diameter of 100 mm.

Cylinder Thickness

We need to calculate the reuired wall thickness to ensure the cylinder can withstand the internal pressure of 8 bar. so we can use the formula to calculate the wall thickness, t = (P*D)/(2*S) P is for pressure, D for Diameter and S is Safety Factor

Cylinder End Caps

Design flat end caps that can securely seal the cylinder and withstand the internal pressure. The end caps should be made of the same aluminum alloy as the cylinder body. The thickness of the end caps can be the same as the cylinder wall thickness.

Valve System

we can choose a suitable valve system that allows for easy filling and controlled release of hydrogen. Select a valve that can handle the pressure and is compatible with hydrogen. Consider a cost-effective valve option within the given budget.

Manufacturing Process

Choose a manufacturing process, such as extrusion or deep drawing, that can shape and form the cylinder and end caps from the selected aluminum alloy. Consider the cost-effectiveness and feasibility of the chosen manufacturing process within the given budget.

Cost Considerations

As I have mentioned at the beginning of the paragraph, the maximum price of this design is 33 us dollars, so we need to optimize the design and dimensions to minimize material usage while meeting the pressure and capacity requirements. Consider manufacturing techniques that can help reduce production costs, such as bulk purchasing of materials or economies of scale in production.

The data that I collected in the first week is the most general data from this case, further details will be finalized soon and for the 3D model of the Hydrogen Storage System, it will be done as soon as possible

Design Calculation

Capacity of the Hydrogen Storage : 1 litres

Pressure : 8 Bar

Cost : Rp. 500.000 (33 US dollar)

Material : A36 Sheet Metal

Code For The Design

to make a design code I use the pychram application, first I search to find the optimal thickness, height and volume of the tube with a predetermined budget

and here's the code :

Def objective_function(x): thickness, radius, height = x[0], x[1], x[2]

# Calculate the weight of the tank (assuming density of ASTM A36 sheet steel) density_astm_a36 = 7850 # kg/m^3 (density of ASTM A36 sheet steel) quantity = 3.14159 * radius * radius * top / 1000 # Convert to liters weight = density_astm_a36 * volume

# Calculate the price of the tank (based on fabric price according to kg) material_price = 500000 / weight # Rp/kg (most allowed price divided through weight) cost = weight * material_price

# outline the objective function as a aggregate of weight and price # you could modify the coefficients based for your desire for weight vs. Value objective_value = weight + zero.001 * fee

go back objective_value

Def constraint(x): thickness, radius, height = x[0], x[1], x[2]

# volume constraint: tank extent need to be 1 liter extent = 3.14159 * radius * radius * peak / 1000 # Convert to liters

# pressure constraint: tank ought to manage 8 bar strain with a safety element of two allowable_stress = 250e6 # Pa (allowable pressure for ASTM A36 sheet steel) inside_radius = radius - thickness # internal radius of the tank strain = 8e5 # Pa (eight bar stress) stress = stress * inside_radius / thickness # stress inside the tank wall safety_factor = 2.0 # protection thing stress_allowable = allowable_stress / safety_factor

go back [ volume - 1, # Volume constraint (1 liter)

stress - stress_allowable, # Pressure constraint

thickness - 5, # Minimum thickness constraint (5 mm)

10 - thickness # Maximum thickness constraint (10 mm)]

# initial bet for thickness, radius, and height (in mm) X0 = [10.0, 50.0, 100.0]

# outline bounds for thickness, radius, and height (in mm) Bounds = [(5, 10), # Bounds for thickness (assumed range from 5 to 10 mm) (1, 50), # Bounds for radius (assumed range from 1 to 50 mm) (100, 1000) # Bounds for height (assumed range from 100 to 1000 mm) ]

# outline the optimization trouble Trouble = 'type': 'SLSQP', 'fun': objective_function, 'x0': x0, 'bounds': bounds, 'constraints': ['type': 'ineq', 'fun': lambda x: constraint(x)]

# resolve the optimization trouble End result = minimize(hassle['fun'], x0=trouble['x0'], bounds=trouble['bounds'], constraints=hassle['constraints'], technique=problem['type'])

# Extract the most reliable answer Optimal_thickness, optimal_radius, optimal_height = end result.X

# Calculate the burden of the tank (assuming density of ASTM A36 sheet metallic) Density_astm_a36 = 7850 # kg/m^three (density of ASTM A36 sheet metallic) Volume = three.14159 * optimal_radius * optimal_radius * optimal_height / one thousand # Convert to liters Weight = density_astm_a36 * volume

# Calculate the price of the tank (based on fabric rate per kg) Material_price = 500000 / weight # Rp/kg (most allowed cost divided by weight) Price = weight * material_price

# Print the optimum answer with units Print(f"best Thickness: optimal_thickness:.2f mm") Print(f"premiere Radius: optimal_radius:.2f mm") Print(f"most beneficial height: optimal_height:.2f mm") Print(f"cost: value:.2f Rp")

Result Of the Code

Optimal Height : 100 mm

Optimal Radius : 25 mm

Optimal Thickness : 5 mm

Price : Rp. 450.000 (budget emphasis)

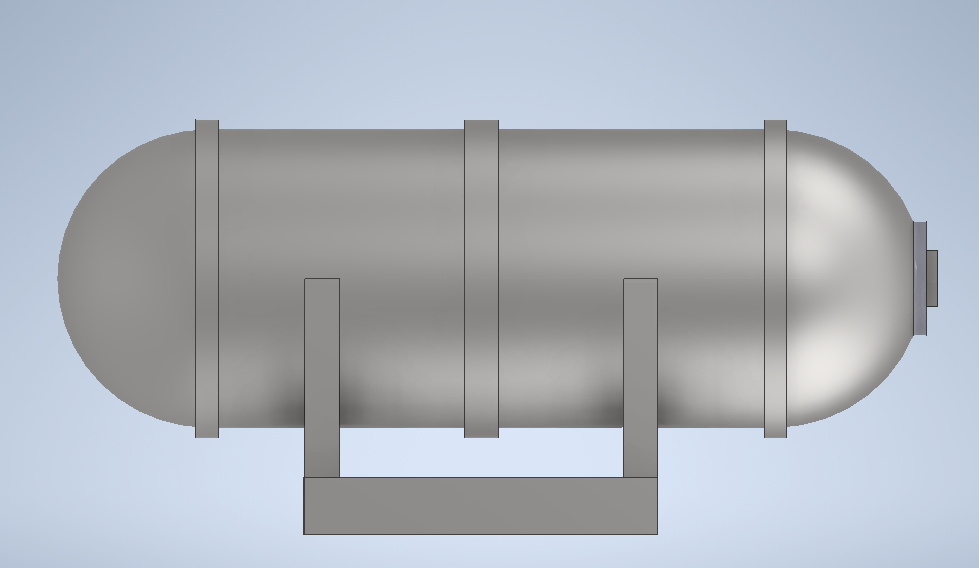

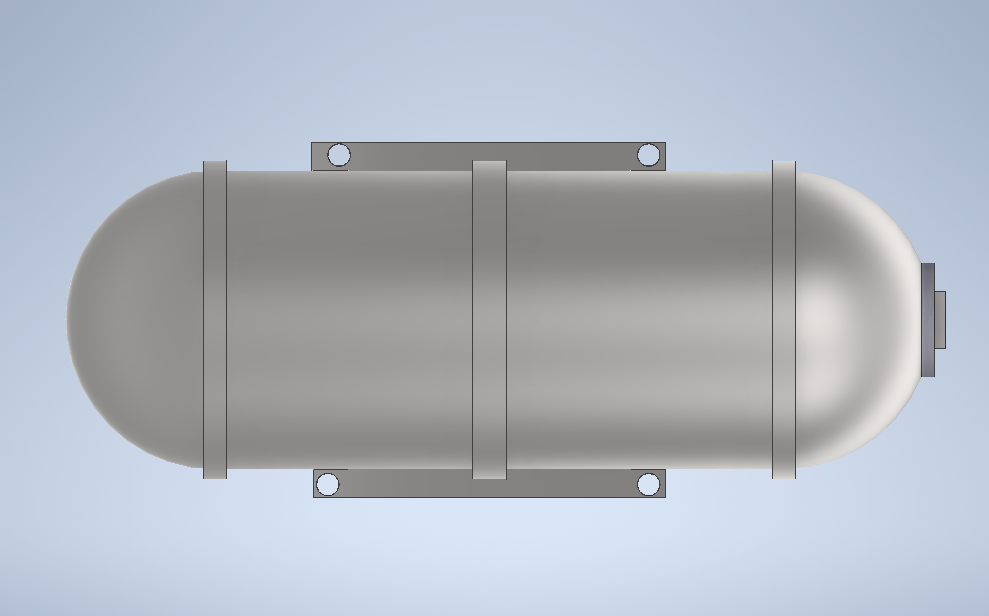

3D Model For Hydrogen Storage Design & Optimization

Conclusion

So, in this task, I can conclude that it is possible to make a hydrogen storage with a capacity of 1 litres with a pressure of 8 bar and a price of less than Rp. 500.000 rupiah

Using A36 Steel Metal material,and in this assignment I got the dimensions of hydrogen storage in the form of 100 mm heights, 5 mm thickness.

To reduce expenses because the price per meter of this material ranges from Rp. 200,000 - Rp. 300,000, and in this assignment I got the dimensions of hydrogen storage in the form of 100 mm high, 5 mm thickness, the rest of the money are used to cut the metal steel and assembly the product (Hydrogen Storage), and we can make up to 3-4 Hydrogen Storage