Ariq Dhifan

Contents

Introduction

Name: Ariq Dhifan

NPM: 2106657323

Major: Mechanical Engineering KKI

DoB: 22 June 2003

E-mail: ariqdhifan7@gmail.com

Assalamualaikum Hello Everyone! My name is Ariq Dhifan, an undergradute student majoring in Mechanical Engineering at Universitas Indonesia. Currently I am taking Numerical Method class with Pak DAI as my lecturer.

Case Study of Pressurized Hydrogen Storage

The effectiveness, security, and utility of the storage system are all improved as part of the process of optimizing pressurized hydrogen storage. Here are several essential factors for pressurized hydrogen storage optimization:

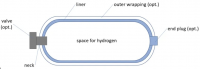

Tank Design and Materials: The storage tanks' design and materials are crucial to optimization. The tanks may be made out of strong, lightweight materials like high-strength metals or innovative composites while yet preserving structural integrity. Tank shapes that have been optimized can increase storage capacity while still fitting into the available area.

Safety precautions: When dealing with compressed hydrogen, safety is of the highest importance. Leaks may be avoided and the integrity of the storage tanks can be guaranteed by putting strong safety measures into place, such as strict manufacturing standards, quality control processes, and routine inspections. Effective pressure release and venting

Storage Pressure: The energy density and usability of the storage system are influenced by the pressure level at which hydrogen is kept in storage. A greater storage pressure makes it possible to store more hydrogen in a given container, but it also creates issues with tank weight, cost, and safety. Finding the ideal balance between storage pressure, energy density, and pragmatic concerns for the particular application is the goal of optimization.

Systems for Filling and Dispensing: Systems for filling and dispensing are essential for pressurized hydrogen storage. Systems that are optimized should reduce fill time, guarantee precise pressure control during filling, and enable safe and regulated hydrogen dispensing.

Thermal management: Controlling the storage tanks' temperature is crucial for achieving peak performance. Thermal insulation can minimize energy losses and keep the pressure within the appropriate range by reducing heat transfer to the hydrogen that has been stored. As needed, active cooling or heating systems can be used to control the temperature.

System Integration: When optimizing pressurized hydrogen storage, the transportation and end-use systems as well as the storage tanks must all be taken into account. To guarantee effective and flawless operation, integration with fuel cell systems or other hydrogen consumption technologies may be enhanced.

Cost Factors: When doing optimization, it is important to take into account all associated costs, such as those related to materials, production methods, and infrastructure needs. Pressurized hydrogen storage must be widely used, and this depends on finding affordable options that nevertheless retain performance and safety.

Substance That Contained

Hydrogen is a colorless, odorless gas. It is easily ignited. Once ignited it burns with a pale blue, almost invisible flame. The vapors are lighter than air. It is flammable over a wide range of vapor/air concentrations. Hydrogen is not toxic but is a simple asphyxiate by the displacement of oxygen in the air. Under prolonged exposure to fire or intense heat the containers may rupture violently and rocket. Hydrogen is used to make other chemicals and in oxyhydrogen welding and cutting.

Compressed hydrogen (CGH2, CH2 or CGH2) is hydrogen at its gaseous state but kept under pressure, typically at 350 bar (5,000 psi) and 700 bar (10,000 psi). This substance thus simplifies the issue of storing hydrogen, as this element in its gaseous state presents an excessively low density, which meant tank sizes needed to be enormous posing not only logistical but also safety issues. On the other hand, cryo compressed hydrogen is kept at cryogenic (-150º) temperatures, and presents a higher hydrogen density, thus pushing the storage possibilities further. While storing hydrogen has always represented a challenge, the discovery of efficient methods for it is boosting the so-called “hydrogen economy”. In fact, a number of options are being investigated today in search for the right one. At this point, the physical storage of compressed hydrogen in tanks stands out as the technology facilitating onboard automotive storage. Pressure values here remain between 350 and 700 bar (5,000 and 10,000 psi). The main difference would be developing a storage solution that is able not only to generate cryogenic temperatures, but also can be pressurized at nominal pressure levels of between 250-350 atm.

Pressure Tank Material

The density of 304 steel is around 8 g/cm3, or 0.289 lb/in3. Type 304 steel also comes into three main varieties: 304, 304L, and 304H alloys, which chemically differ based on carbon content. 304L has the lowest carbon percentage (0.03%), 304H has the highest (0.04-0.1%), and balanced 304 splits the difference (0.08%). In general, 304L is reserved for large welding components that do not require post-welding annealing, as the low carbon percentages increase ductility. Conversely, 304H is most used in elevated temperatures where the increased carbon content helps preserve its strength while hot.

Type 304 steel is austenitic, which is simply a type of molecular structure made from the iron-chromium-nickel alloy blend. It makes 304 steel essentially non-magnetic, and gives it a lower weakness to corrosion between grains thanks to austenitic steels being generally low carbon. 304 steel welds well using most welding methods, both with and without fillers, and it easily draws, forms, and spins into shape. AISI 304 will be my choice for the tank material due to its cost that relatively cheap and it is also a high-strength material. AISI 304 satisfy our variables in cost realm.

Coding

Initializing Surface Area for hydrogen tank

import numpy as np

from scipy.optimize import minimize

def objective(x):

# x[0] represents radius, x[1] represents height

radius = x[0]

height = x[1]

# Calculate the surface area of thte cylinder

surface_area = 2 * np.pi * radius * (radius + height)

return surface_area

def constraint(x):

# x[0] represents radius, x[1] represents height

radius = x[0]

height = x[1]

# Calculate the internal volume of the cylinder

volume = np.pi * radius**2 * height

# Difference between the volume and the desired value

return volume - 1000

# Initial value of radius and height

x0 = [5.0, 10.0]

# Variable constraints (radius and height)

bounds = [(0, None), (0, None)]

constraint_dict = {'type': 'eq', 'fun': constraint}

result = minimize(objective, x0, method='SLSQP', bounds=bounds, constraints=constraint_dict)

# Optimization results

print("Optimization results:")

print("Radius: {:.2f} cm".format(result.x[0]))

print("Height: {:.2f} cm".format(result.x[1]))

print("Surface Area: {:.2f} cm^2".format(result.fun))OUTPUT

Optimization results:

Radius: 5.52 cm

Height: 10.43 cm

Surface Area: 553.79 cm^2Finding The Thickness of The Pressure Tank (8 bar)

r = 5.52e-2 # Tank Radius

p = 800000 # 8 Bar Pressure

t = 2.7e-3 # Minimum Thickness

while t < 11.05e-3:

hoop = (p * r) / t

print('Thickness', t, 'hoop stress =', hoop, "Pa")

t += 1e-3

if hoop > 215e9: #Yield Strength of AISI 304

breakOUTPUT

Thickness 0.0027 hoop stress = 16355555.555555554 Pa

Thickness 0.0037 hoop stress = 11935135.135135135 Pa

Thickness 0.0047 hoop stress = 9395744.680851063 Pa

Thickness 0.0057 hoop stress = 7747368.421052631 Pa

Thickness 0.0067 hoop stress = 6591044.776119403 Pa

Thickness 0.0077 hoop stress = 5735064.935064935 Pa

Thickness 0.0087 hoop stress = 5075862.068965518 Pa

Thickness 0.0097 hoop stress = 4552577.319587628 Pa

Thickness 0.010700000000000001 hoop stress = 4127102.8037383175 Pa

Cost Constraints

Due to our objective variable that limit our budget at Rp.500.000, We have done research on some distributor website that sell 2-10 mm thick Stainless steel 304 plates. With the thickness 5 mm thick, the material cost at Rp.133.000 with total dimension 5 mm x 20 cm x 20 cm. So, looking from this reference for 553,79 cm^2 surface area it costs around Rp.184.135 for 1 unit. The rest of cost we use to pay welding and labour fee. Overall, it satisfy our variable.

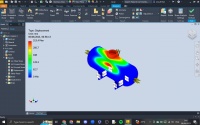

Design and Conclusions

From this design that we make using the good material option, analysis said that might be a little bit error of design when we give the tank design pressure at 8 bar there is some area that still red that cause crack or any other risks. Due to its durability, availability, and affordability, using AISI 304 stainless steel as a compressed hydrogen tank material is an excellent choice. However, during tank design and operation, elements like hydrogen embrittlement, a decreased strength-to-weight ratio, and a constrained operational temperature range should be carefully taken into this project.

Energy Conversion System 1 Class

1st Class Summary

Pak DAI told us about one of Einstein’s quotes that everyone is a genius.But it works when we also try hard and always believe in ourself that we can finish all of our task with a perfect finish. In my opinion about energy in the previous lecture, energy is a source potential that can't be produced or destroyed that helps us in our daily life with various forms. We can change or transform this energy to another form such as electricity to kinetic energy. Energy conversion, also termed as energy transformation, is the process of changing one form of energy into another. Energy conversion occurs everywhere and every minute of the day. There are numerous forms of energy like thermal energy, electrical energy, nuclear energy, electromagnetic energy, mechanical energy, chemical energy, sound energy, etc. On the other hand, the term Energy Transformation is used when energy changes forms from one form to another. Whether the energy is transferred or transformed, the total amount of energy doesn’t change, and this is known as the law of conservation of Energy.