Talk:Putri Adelia Suryani

.

Contents

Introduction

Perkenalkan nama saya Putri Adelia Suryani. Saya lahir di Depok pada 8 September 2003. Saya berdomisili di Depok.

Design & Optimization of Pressurized Hydrogen Storage

Tugas kali ini adalah untuk mendesain dan mengoptimalisasi tabung penyimpanan hidrogen dengan kriteria:

Volume/kapasitas : 1 liter Tekanan : 8 bar Biaya : Tidak lebih dari Rp 500.000

Karena keterbatasan pengetahuan saya, saya menggunakan bantuan ChatGP untuk mencari tau bagaimana prosedur dalam mendesain dan mengoptimalisasi tabung penyimpanan hidrogen. Dan berikut merupakan jawaban yang diberikan:

Designing and optimizing a cost-effective compact pressurized hydrogen storage system involves considering various elements and following specific procedures. Here's an explanation of the key elements and steps involved:

1. System Requirements: Start by defining the specific requirements of your hydrogen storage system. This includes determining the desired capacity (e.g., 1 liter), pressure level (e.g., 8 bar), cost limitations, and any other relevant factors specific to your application.

2. Material Selection: Selecting the appropriate materials is crucial for achieving a cost-effective design. Consider materials such as steel or aluminum alloys for the storage vessel. These materials offer good strength, durability, and cost efficiency.

3. Design Optimization: The optimization process involves balancing various factors to achieve an efficient and cost-effective design. Consider the following aspects:

a. Vessel Design: Optimize the geometry, wall thickness, and dimensions of the storage vessel to ensure it can withstand the desired pressure and safely store hydrogen. This involves conducting structural analysis and considering safety factors.

b. Safety Considerations: Ensure that the storage system incorporates safety features such as pressure relief devices, burst discs, and appropriate sealing mechanisms. This is essential to prevent over-pressurization and mitigate any potential hazards.

c. Heat Management: Efficiently manage heat transfer within the system to minimize energy losses and maintain hydrogen storage conditions. Consider insulation materials or designs to reduce heat transfer and improve system performance.

d. Leak Prevention: Implement effective sealing mechanisms and conduct rigorous testing to minimize the risk of hydrogen leakage. This ensures the system maintains its integrity and maximizes the storage efficiency.

4. Cost Optimization: To achieve a cost-effective design, consider the following strategies:

a. Material Cost: Select materials that offer a good balance between cost and performance. Compare prices from different suppliers to obtain the most cost-effective options.

b. Manufacturing Techniques: Optimize manufacturing processes to minimize costs while ensuring quality and safety. Consider techniques like forming, welding, and machining that provide efficient production and reduce material waste.

c. Scale and Production Volume: Consider the potential benefits of scaling up production to achieve economies of scale. Higher production volumes can help reduce unit costs.

d. Lifecycle Cost Analysis: Evaluate the overall lifecycle cost of the storage system, considering factors such as maintenance, inspection, and replacement. This analysis can help identify areas for cost reduction.

5. Testing and Validation: Thoroughly test the designed storage system to validate its performance and ensure it meets the desired requirements. Conduct tests to evaluate pressure resistance, leakage prevention, and overall system reliability.

6. Regulatory Compliance: Ensure compliance with applicable regulations and standards related to hydrogen storage. This includes safety codes and guidelines set by regulatory bodies to ensure the system meets safety and performance requirements.

It's important to note that the specific procedures and considerations may vary depending on the application, intended use, and available resources. Working with experts in hydrogen storage system design and leveraging their expertise can greatly assist in the optimization process.

Material Selection

The choice of the best and most cost-effective material for a hydrogen tube depends on various factors such as safety requirements, operating conditions, budget constraints, and specific application needs. However, some commonly used materials for hydrogen tube applications include:

1. Stainless Steel: Stainless steel, such as 304 or 316L, is a popular choice for hydrogen tubes due to its excellent corrosion resistance, high strength, and relatively low cost compared to other materials. It offers a good balance of performance, durability, and affordability.

2. Aluminum: Aluminum is lightweight, has good corrosion resistance, and is relatively low in cost. It is commonly used in certain applications where weight reduction is a critical factor, such as automotive hydrogen fuel tanks. However, aluminum may require special surface treatments to improve its compatibility with hydrogen.

3. Composite Materials: Composite materials, such as carbon fiber reinforced polymers (CFRP), can offer high strength-to-weight ratios and excellent corrosion resistance. However, they are generally more expensive than metallic materials and may require additional manufacturing processes.

4. Titanium: Titanium is lightweight, has excellent corrosion resistance, and offers high strength. It is commonly used in aerospace and high-performance applications. However, titanium is more expensive compared to stainless steel and other materials, which may limit its cost-effectiveness.

The selection of the best material will depend on the specific requirements of the hydrogen tube application, including factors such as desired weight, operating pressure, regulatory compliance, and budget limitations. It is recommended to consult with experts or engineering professionals who can evaluate the specific needs of the application and provide tailored recommendations based on those requirements.

After careful consideration, we decided to go with Stainless Steel 316L because Stainless steel 316L offers several advantages as a material for hydrogen tube applications:

1. Corrosion Resistance: Stainless steel 316L has excellent corrosion resistance, making it highly suitable for hydrogen storage applications. It resists corrosion from hydrogen gas, moisture, and other aggressive substances, ensuring the integrity and durability of the tube over time.

2. High Strength: Stainless steel 316L has good mechanical properties, including high tensile strength and yield strength. This allows it to withstand high-pressure conditions encountered in hydrogen storage systems, ensuring the tube can safely contain the hydrogen gas at the desired pressure levels.

3. High-Temperature Resistance: Stainless steel 316L exhibits good resistance to high temperatures, making it suitable for applications where the hydrogen gas may be stored or transported at elevated temperatures. It can maintain its structural integrity and mechanical properties under these conditions.

4. Compatibility with Hydrogen: Stainless steel 316L is compatible with hydrogen gas, meaning it does not react or degrade when exposed to hydrogen. This is important for ensuring the purity and stability of the stored hydrogen gas and preventing any adverse reactions between the gas and the tube material.

5. Widely Available: Stainless steel 316L is a commonly used material and is readily available in various forms, such as pipes, tubes, and sheets. This availability makes it easier to source and manufacture hydrogen storage tubes using this material.

6. Cost-Effectiveness: Compared to other materials like titanium or carbon fiber composites, stainless steel 316L is generally more cost-effective. It provides a good balance between performance, durability, and cost, making it an attractive choice for hydrogen storage applications where cost considerations are important.

Overall, stainless steel 316L offers a combination of corrosion resistance, high strength, temperature resistance, compatibility with hydrogen, and cost-effectiveness, making it a favorable material for hydrogen tube applications.

Dimensional Calculations

To determine the optimal height, we use Python coding as below:

import math

def calculate_optimal_height(volume, pressure, yield_strength, safety_factor):

# Convert pressure from bar to Pascal pressure_pa = pressure * 1e5

# Calculate the radius based on the volume radius = math.sqrt(volume / (math.pi))

# Calculate the allowable stress based on the yield strength and safety factor allowable_stress = yield_strength / safety_factor

# Calculate the optimal height height = (2 * pressure_pa * radius) / allowable_stress

return height

- Data input

volume = 1000 # Volume in cm^3 (1 liter) pressure = 8 # Pressure in bar yield_strength = 215e6 # Yield strength of stainless steel in Pa safety_factor = 2 # Safety factor for design

- Calculate optimal height

optimal_height = calculate_optimal_height(volume, pressure, yield_strength, safety_factor)

- Output

print(f"Optimal height of the stainless steel hydrogen tube: {optimal_height} m")

Which, determines the optimal height: 26 cm and radius: 5 cm

Dimensional Calculations #2

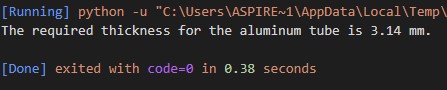

To determine the optimal thickness, we use the coding below:

import math

def calculate_thickness(radius, height, pressure, material_yield_strength):

inner_radius = radius outer_radius = radius + thickness hoop_stress = pressure * inner_radius / thickness required_thickness = hoop_stress * outer_radius / material_yield_strength return required_thickness

- Constants for Aluminum 6061

yield_strength = 215 * 10**6 # in Pascals (Pa)

- Tube dimensions

radius = 0.05 # in meters (m) height = 0.26 # in meters (m) pressure = 8 * 10**5 # in Pascals (Pa)

- Convert dimensions to centimeters (cm)

radius_cm = radius * 100 height_cm = height * 100

- Calculate required thickness

thickness = 0.1 # initial guess for thickness in cm tolerance = 0.001 # tolerance for convergence in cm

while True:

required_thickness = calculate_thickness(radius_cm, height_cm, pressure, yield_strength)

if abs(thickness - required_thickness) < tolerance:

break

thickness = required_thickness

- Convert thickness back to millimeters (mm)

thickness_mm = thickness * 10

- Output the result

print(f"The required thickness for the aluminum tube is {thickness_mm:.2f} mm.")