Muhamad Maulana Fahmi

Intro

Hello my name is Muhamad Maulana Fahmi

NPM : 2206100275

Design and Optimization of 1 Liter Pressured Hydrogen (8bar) Storage

Following are some fundamental principles for creating a pressurized tank that can hold 1 liter of hydrogen at 8 bar:

1. Determine the necessary pressure rating: The required pressure for effective storage and usage of the hydrogen will depend on the specific use and the pressure rating of the tank. The required pressure rating in this situation is 8 bar.

2. Choose the right materials: The tank's materials must be compatible with hydrogen and strong enough to handle the specified pressure. Aluminum, composite materials, and high-strength steel are frequently used for hydrogen storage tanks.

3. Calculate the tank's size based on the volume of hydrogen needed and the tank's pressure tolerance. The tank at least should be around 100 mm in diameter and about 300 mm in length/height for a 1 liter tank operating at 8 bar pressure.

4. Designing the tank's structure will ensure that it can handle the necessary pressure rating while reducing stress concentrations. Additionally, the tank should be built with leak protection and security in mind. A cylindrical shape with hemispherical ends is a typical design for a 1 liter tank operating at 8 bar pressure.

5. Installing safety equipment To ensure safe operation and prevent over-pressurization, the tank should be fitted with safety features such pressure relief valves, rupture disks, and temperature sensors.

Cost

Our budget is Rp.500.000, we try to reduce the cost at lower as possible but with the maximum output

The common material for hydrogen tank is SS304/316L. For saving the cost we're going to use SS304 as material for this hydrogen tank.

let's assume this the price of the material

cheap gas regulator for around Rp.100.000

workload cost (welding, cutting, bending, etc.) Rp. 90.000

the total cost is Rp.500.000

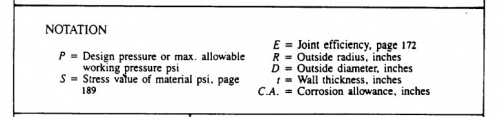

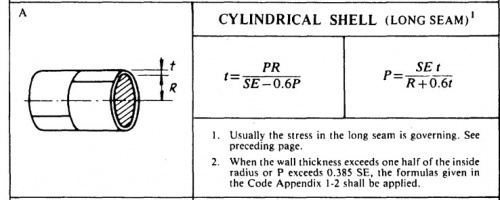

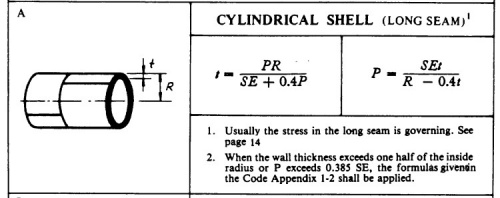

Simple Calculation

Tank inner diameter: 100mm

Tank Height : 1.000.000 / 3,14 x 50 x 50 = 127,32 mm

SS304 yield strengh 29 ksi. Allowable stress = 19 ksi

E = 0.70

P = 8 bar = 116 psi

S = 19000 Psi

R = 50mm = 1,97 inch

Corrosion Allowance = 1.5mm = 0,06 inch

> t inside dimension = 116 x (1,97 + 0,06) / (19000 x 0,6)-(0,7 x 116) = 0,0208 inch + corrosion allowance = 0,0808 inch (2,0mm)

> t outside dimension = 116 x (1,97 + 0,06) / (19000 x 0,4)-(0,7 x 116) = 0,0313 + corrosion allowance = 0,0913 inch (2,3mm)-

the minimum thickness of the material is 2,3mm

Alternative

If we need the hydrogen tank in hurry, need to save more budget and or for experimental study, i suggest using empty portable fire extinguisher tank.

the price are cheaper than manufacturing own tank

there are pros and cons when using portable fire extinguisher

the 1 kg tank could store around 11 litres of hydrogen

the tank operating at 10-20 bar

the size is around 90mm(diameter) x 330mm(height)

the tank price are ranging around from Rp. 120.000 to Rp. 300.000