Gradinal Aditya Widjojo

Design & Optimization of 1 Litre Pressurized Hidrogen Storage

Hydrogen is the lightest and most abundant element in the universe. It is represented by the chemical symbol H and has an atomic number of 1. In its pure form, hydrogen exists as a colorless, odorless, and highly flammable gas.

When it comes to utilizing hydrogen as a source of vehicle fuel, it typically involves using fuel cells. Fuel cells are devices that convert the chemical energy of hydrogen and oxygen into electrical energy, with water being the primary byproduct. One way to utilize hydrogen as a source of vehicle fuel is, Hydrogen Storage. Hydrogen gas needs to be stored in a suitable manner, often in high-pressure tanks or in a chemically bound form, such as in metal hydrides.

Designing an optimal hydrogen storage system involves considering factors such as storage capacity, safety, weight, volume, cost, and efficiency. There are several methods for hydrogen storage, and the choice depends on the specific application and requirements. Here are a few common approaches:

1. Compressed Gas Storage: Hydrogen gas can be stored in high-pressure tanks. The tanks must be designed to withstand the pressure and ensure safety. Composite materials, such as carbon fiber-reinforced polymer, are often used for their strength and lightweight properties.

2. Liquid Hydrogen Storage: Hydrogen can be cooled and liquefied at extremely low temperatures (-253°C or -423°F). Liquid hydrogen offers higher energy density compared to compressed gas, but it requires specialized cryogenic storage systems to maintain low temperatures.

3. Metal Hydride Storage: Hydrogen can be stored by chemically binding it to certain metal alloys or compounds, known as metal hydrides. The metal hydrides absorb and release hydrogen based on temperature and pressure conditions.

4. Chemical Hydride Storage: Hydrogen can be stored in solid-state chemical compounds known as chemical hydrides. These compounds have a high hydrogen content and release hydrogen through a chemical reaction triggered by temperature or pressure changes.

It's important to note that the choice of hydrogen storage method depends on various factors, including the specific application, storage requirements, and safety considerations.

In this study, we will be using option number one, which is to use Compressed Gas Storage.

The advantages of utilizing hydrogen as a vehicle fuel include:

1. Zero Emissions: Hydrogen fuel cell vehicles produce zero greenhouse gas emissions when driven, as the only byproduct is water vapor.

2. Energy Efficiency: Fuel cell vehicles can be more energy-efficient compared to internal combustion engines, as the electrochemical conversion process is more efficient than burning fossil fuels.

However, there are also some challenges to overcome:

1. Hydrogen Production: The most common method of hydrogen production is through natural gas reforming, which is not a carbon-neutral process. Developing renewable and sustainable methods for hydrogen production is crucial.

2. Infrastructure: Establishing an extensive hydrogen refueling infrastructure is necessary to support widespread adoption of hydrogen fuel cell vehicles. Currently, hydrogen refueling stations are less common compared to conventional gasoline stations.

3. Storage and Distribution: Hydrogen has low energy density, so it needs to be stored and distributed at high pressures or in liquid form, which requires specialized equipment and infrastructure.

Efforts are underway to address these challenges and improve the viability and availability of hydrogen as a vehicle fuel.

Manufacturing Requirement:

1. Storage tank volume is approximately 1 liter.

2. Hydrogen is compressed to 8 bar of gauge pressure.

3. Normal operating condition (room temperature and humidity).

4. Output and input port for hydrogen filling and exerting.

5. Add pressure regulator for output port.

6. Maximum budget is 500.000 rupiah.

Compressed Hydrogen Storage Tank Design and Calculations

Tank Size Inner Diameter: 80mm Inner height of tank: H = 1.000.000/3.14x40x40 = 200mm

Desing Calculation 1. Material Selection: Stainless steel 316L (Yield Strenght = 30 Ksi, Allowable Stress Value = 20 Ksi )

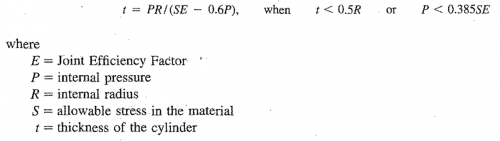

2. Thickness formula for circumferential stress direction:

Thickness formula for longitudinal stress direction:

E = 0.70 (For welded shells without radiography examination) P = 8 bar = 116 psi R = 40mm = 1,6 inch S = 20000 Psi Corrosion Allowance = 1.5mm = 0,06 inch t circumferential = 116 x (1,6 + 0,06) / (20000 x 0,7) - (0,7 x 116) = 0,0138 inch. (With corrosion allowance = 0,0738 inch = 1,9mm) t longitudinal = 116 x (1,6 + 0,06) / (2 x 20000 x 0,7) + (0,4 x 116) = 0.0068 inch. (With corrosion allowance = 0,0668 inch = 1,7mm) Hence, minimum thickness for the material is = 1,9mm

Advantages of SS 316L for Compressed Hydrogen Storage Tank:

1.Pressure Resistance: Stainless steel 316L has excellent strength properties, including high tensile strength and good resistance to deformation under pressure. It is capable of withstanding the 8 bar pressure in your hydrogen pressure vessel.

2.Corrosion Resistance: Stainless steel 316L provides excellent corrosion resistance, even in the presence of hydrogen. This is crucial for maintaining the integrity of the pressure vessel and preventing leakage or failures due to corrosion.

3.Hydrogen Compatibility: Stainless steel 316L has been used successfully in hydrogen service applications and demonstrates good resistance to hydrogen embrittlement. However, it's essential to ensure that the vessel is designed and fabricated using appropriate welding techniques to mitigate the risk of hydrogen-induced cracking.

4.Wide Availability: Stainless steel 316L is a commonly available material and is widely used in various industries for its excellent mechanical and corrosion-resistant properties.