Mekanika Fluida - Josiah Enrico S (1906356286)

Contents

Title: Modelica-based Simulation of Viscous Flow Through Pipes Using Finite Element Formulation

Abstract

As the piping system has always become an integral part of any fluid-related mechanical system, controlling and measuring the flow properties, such as pressure, flow rate and Reynolds number inside the pipe is a necessary field to master in order to engineer the efficient arrangement. These properties are critical and can be analytically computed by considering fluid factors like density or viscosity and the pipe dimension. Unfortunately, this current method is not scalable since it is examined too onerous and time-consuming to address complex systems. On the other hand, many numerical method programming has been developed to help engineers overcome those problems. This white paper will recreate one simple problem of a multiple pipes system utilizing Modelica programming language and compare it with the current analytical technique to verify the results. This simulation is expected to be a base in developing a scalable program for multiple pipe systems in further work.

Background and Problem Introduction

Objectives

The objectives of this study are as follows:

- Develop a Modelica-based simulation to compute the pressure, flow rate, and Reynolds numbers in the selected points.

- Validate the results with the corresponding resources.

- Verify the results with the parameters and boundaries.

Methodology

- The Analytical Calculation

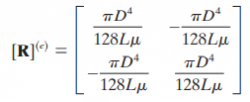

- Based on the formula analysis above, we can first determine the local elemental flow resistance in each of 6 points. The matrix can be written as

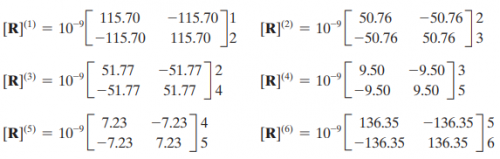

- And the local matrix of the 6 points or nodes are

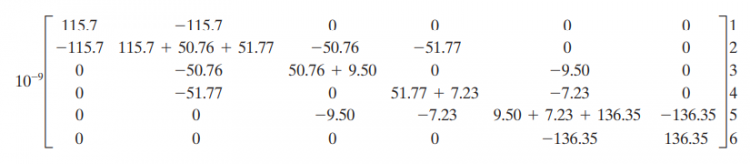

- Then, we can sum up all the local elemental matrices into the global resistance matrix. So, we obtain

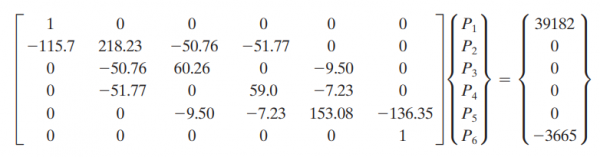

- Applying the boundary condition and making matrix equation, we have

- Solving the simultaneous algebra system using Gauss Jordan, we have the pressure as follows

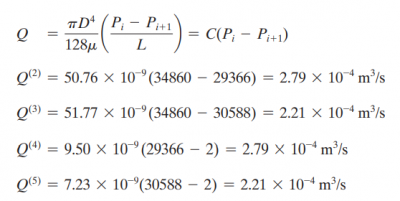

- And the flowrate distribution in each pipe are

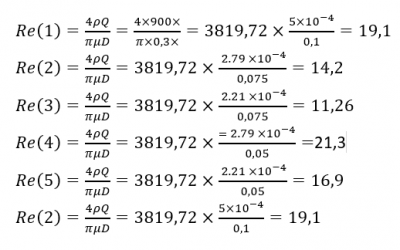

- In addition, we could also calculate the Reynolds number as follows

- The Simulation Program

- This program is separated into two sections, the first one is the definition phase where the operator needs to input all the properties and the pipe geometry at once. There are 2 fluid properties considered which are dynamic viscosity (N∙s/m2)to calculate the head loss and the density (kg/m3) to calculate the Reynolds number. To set the limit point and boundary condition, the measured pressure (Pa) at the inlet and outlet are also defined at point 1 and 6. Afterward, the parameter of piping like its diameter and installed distance are collected using 2 column matrix. The additional data of Q inlet or point 1 is used to verify the result at the end of the simulation.

- The second section is the algorithm section where those data are processed into the requested solution. This step will include the steps mentioned in the analytical calculation above starting from making the local 4x4 matrix of elemental flow resistance, combining them to one global 6x6 matrix, applying boundary conditions, and finally computing the pressure at 6 points also flow rate and Reynolds number at 6 connected pipes.

model Tugas_Besar_Mekflu

// ==================================== DEFINITION PHASE ====================================

parameter Real miu = 0.3 "dynamic viscosity";

parameter Real rho = 900 "density";

parameter Real Qinlet = 5e-4 "flow rate inlet";

parameter Real Pinlet = 39182 "pressure inlet";

parameter Real Poutlet = -3665 "pressure inlet";

parameter Integer boundary[:] = {1, 6} "Boundary Point";

parameter Integer nPipe = 6 "number of piping";

parameter Integer nPoint = 6 "number of point connected";

final constant Real pi=2*Modelica.Math.asin(1.0);

//Inputing pipe connection, length (L) and diameter (D)

parameter Real data[nPipe,2] = [ 70.71, 0.1 ;

50.99, 0.075 ;

50 , 0.075 ;

53.85, 0.05 ;

70.71, 0.05 ;

60 , 0.1 ];

parameter Integer no[nPoint,2] = [ 1, 2;

2, 3;

2, 4;

3, 5;

4, 5;

5, 6];

//Solution

Real Pressure[nPoint], Flowrate[nPipe], Reynolds[nPipe];

protected

Real g[nPoint,nPoint], G[nPoint,nPoint], id[nPoint,nPoint]=identity(nPoint), P[nPoint], Res;

// ==================================== SOLUTION PHASE ====================================

algorithm

//Iterating to create global matrice

for i in 1:nPipe loop

Res:= pi*data[i,2]^4/(128*data[i,1]*miu);

g:=zeros(nPoint,nPoint);

g[no[i,1],no[i,1]]:= Res;

g[no[i,1],no[i,2]]:= -Res;

g[no[i,2],no[i,1]]:= -Res;

g[no[i,2],no[i,2]]:= Res;

G:= G+g;

end for;

//Implementing boundary

for i in boundary loop

for j in 1:nPoint loop

G[i,j]:= id[i,j];

end for;

end for;

//Solving pressure in each point connected

P[boundary[1]]:= Pinlet;

P[boundary[2]]:= Poutlet;

Pressure:= Modelica.Math.Matrices.solve(G,P);

//Solving flowrate in each pipe

for i in 1:nPipe loop

Flowrate[i]:= pi*data[i,2]^4/(128*data[i,1]*miu)*(Pressure[no[i,1]]-Pressure[no[i,2]]);

end for;

//Solving Reynolds Number in each pipe flow

for i in 1:nPipe loop

Reynolds[i]:= 4*rho*Flowrate[i]/(pi*miu*data[i,2]);

end for;

end Tugas_Besar_Mekflu;

|

Result and Analysis

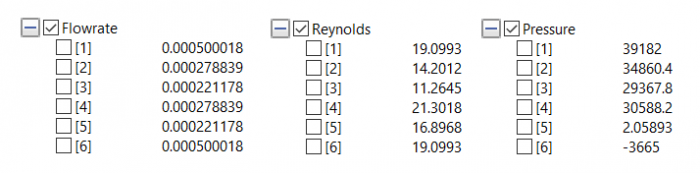

The simulation results are:

- Validation

The validation of the simulation results can be proved when we compare them with the analytical results derived from a matrix formulation. This analytical method was discussed by Moavani (2008) and the comparison between them shows almost one hundred percent of acceptance. The deviation of those numbers is relatively small and only resulted from rounding. Thus, if the analytical results are correct, we could validate the simulation is accurate.

- Verification

The verification of the simulation can be observed between the measured flowrate at the first node or the inlet before the calculation and the flowrate results. At first, the flow rate defined as 5 x 10^-4 m3/s. But at the end of the simulation, we get 0.000500018. These number is quite similar therefore it verify the simulation results.

Conclusions

In conclusion, the simulation program is feasible and gives satisfactory results

In conclusion, CFD simulation of elutriation using CFDSof modeling gives satisfactory results and can describe the elutriation process that occurs in the plastic industry. Even though it only tests a customized piece of apparatus rather than the entire elutriator geometry design, the simulation can capture the flow behavior of fluid inside the chamber when the density and particle diameter is varied. Since the simulation results show acceptance of the terminal velocity analysis compared to the existing literature, it is hoped that the methodology used in this study can be adopted for further research in the future