Difference between revisions of "Benaya S. H. Munte"

Benaya.sahap (talk | contribs) |

Benaya.sahap (talk | contribs) |

||

| Line 1: | Line 1: | ||

== '''Planning for a design and optimization of a 1 liter pressurized hydrogen storage/tank''' == | == '''Planning for a design and optimization of a 1 liter pressurized hydrogen storage/tank''' == | ||

| − | [[File:H2_Hydrogen.jpg | | + | [[File:H2_Hydrogen.jpg |300px|]] |

As the lightest, most common and most abundant element in the universe, is one of the most essential building blocks of the universe. It comprises about 75% of its elemental mass and 90% of its observable atoms. | As the lightest, most common and most abundant element in the universe, is one of the most essential building blocks of the universe. It comprises about 75% of its elemental mass and 90% of its observable atoms. | ||

Revision as of 23:00, 11 June 2023

Contents

Planning for a design and optimization of a 1 liter pressurized hydrogen storage/tank

As the lightest, most common and most abundant element in the universe, is one of the most essential building blocks of the universe. It comprises about 75% of its elemental mass and 90% of its observable atoms.

When utilizing hydrogen as a source of vehicle fuel, they are usually manufactured in the form of fuel cells, rather than pure fuels such as gasoline and diesel fuels, due to the fact that a combustion engine using hydrogen as a source of fuel is extremely inefficient.

Below are the criteria needed to be fulfilled for a hydrogen tank design with a budget of only Rp. 500.000,00:

This design summary outlines an optimized storage system capable of safely handling an 8 bar pressure requirement while considering a budget limit of Rp 500.000. The system focuses on cost-effective solutions without compromising safety and functionality.

Key Considerations:

1. Storage Vessel: A cost-effective high-pressure vessel is chosen, considering material strength and compatibility with stored substances, while aiming for affordability. 2. Material: Economical materials like mild steel or reinforced plastics are selected, ensuring they meet the necessary strength and safety requirements.

3. Structural Design: The vessel is designed to meet the pressure requirement while minimizing material usage and fabrication costs. Simple shapes and standard sizes may be preferred.

4. Safety Measures: Essential safety features like pressure relief valves are incorporated, prioritizing affordable options that still meet regulatory standards. 5. Leakage Prevention: Cost-effective sealing mechanisms like gaskets or low-cost elastomers are implemented to prevent leaks, ensuring they are still reliable.

6. Pressure Control: Simple pressure regulation systems like manual valves or basic pressure regulators are used to meet the pressure control needs within the budget constraints.

7. Support Infrastructure: Basic instrumentation and monitoring equipment are chosen to facilitate system operation and maintenance without exceeding the budget.

8. Installation and Maintenance: Efficient installation practices are employed, and routine maintenance activities are planned to minimize costs while ensuring optimal performance.

9. Compliance and Standards: The system is designed to meet the necessary safety standards within the given budget, ensuring legal compliance and avoiding additional expenses.

What are the ways to utilize Hydrogen as a source of vehicle fuel and how:

Fuel Cells: Hydrogen fuel cells are a common method of using hydrogen as a vehicle fuel. In a fuel cell vehicle (FCV), hydrogen reacts with oxygen in the fuel cell, generating electricity to power an electric motor. This process only produces water vapor as a byproduct, making FCVs environmentally friendly. They offer high energy efficiency, longer driving ranges compared to electric vehicles, and quick hydrogen refueling.

Combustion: Hydrogen can be used in internal combustion engines, similar to gasoline or diesel engines. However, this method is less common and presents challenges. In a hydrogen internal combustion engine (HICE) vehicle, hydrogen is burned, creating mechanical power to propel the vehicle. Engine modifications are needed due to hydrogen's low density and ignition energy. Hydrogen combustion engines may produce nitrogen oxide emissions, although engine advancements can mitigate this issue.

Advantages and disadvantages of a hydrogen tank

ADVANTAGES

High Energy Density: Hydrogen has a high energy-to-weight ratio, making it a suitable fuel for applications that require energy storage with minimal weight.

Rapid Refueling: Hydrogen tanks can be refueled quickly compared to electric vehicle batteries, which can significantly reduce downtime and allow for longer driving ranges.

Versatility: Hydrogen tanks can be used in various applications, including transportation (such as fuel cell vehicles), stationary power generation, and industrial processes.

Low Environmental Impact: When hydrogen is used in a fuel cell, the only byproduct is water, making it a clean energy source with zero greenhouse gas emissions.

DISADVANTAGES

Storage Challenges: Hydrogen has low energy density by volume, requiring high-pressure or cryogenic storage systems to achieve sufficient energy storage. This can present challenges in terms of tank size, weight, and safety.

Cost: Hydrogen storage tanks, especially those designed to handle high-pressure or cryogenic conditions, can be expensive to manufacture, adding to the overall cost of hydrogen-based systems.

Safety Concerns: Hydrogen is highly flammable and can pose safety risks if not handled properly. Special precautions and safety measures are necessary to ensure the safe storage and handling of hydrogen tanks.

Limited Infrastructure: The infrastructure for hydrogen storage and refueling is still developing and not as widespread as conventional gasoline or electric charging stations. Limited availability of refueling stations can restrict the widespread adoption of hydrogen-powered vehicles.

Hydrogen Mass calculation

To calculate the mass of hydrogen in its liquid state, the following properties of hydrogen at liquified state are as stated below:

V = 1 liter = 0.001 m³ T = -253.16° Celcius P = 8 bar = 0.8 MPa

Hence; ρ = 65.91 kg/m³

Hence, to obtain the total mass, calculate with the equation below as follows:

M = ρV M = (65.91)(0.001) M = 0.06591 kg = 65.91 g

Therefore, the mass of hydrogen in its liquid state, at a pressure of 8 bar, volume of 1 liter, and boiling temperature of -253.16 degrees Celsius, is approximately 65.91 grams.

Tank Dimensions calculation

To calculate the dimensions of a cylindrical hydrogen tank with a volume of 1 liter, we can use the formula for the volume of a cylinder:

Volume = π * r^2 * h

where:

Volume is given as 1 liter = 1000 cm^3, π is a mathematical constant approximately equal to 3.14159, r is the radius of the cylinder, h is the height of the cylinder.

Let's solve for the dimensions:

Convert the volume to cubic centimeters:

Volume = 1 liter = 1000 cm^3

Rearrange the formula to solve for the height (h):

h = Volume / (π * r^2)

Choose a radius (r) value. For simplicity, let's assume a radius of 5 centimeters.

Calculate the height (h) using the formula:

h = 1000 / (3.14159 * 5^2) ≈ 12.732 cm

Therefore, for a cylindrical hydrogen tank with a volume of 1 liter, assuming a radius of 5 centimeters, the dimensions would be approximately:

Diameter: 10 centimeters (2 times the radius)

Height: 12.732 centimeters

Please note that these dimensions are approximate and can vary depending on design specifications, safety considerations, and manufacturing constraints.

Final dimensions: 5 x 5 x 12.732 (cm)

Alternative calculation for tank dimensions with python

import math from scipy.optimize import minimize

def calculate_tank_properties(diameter, height):

#Perhitungan volume tangki volume_m3 = (math.pi * (diameter**2) * height) / 4

#Perhitungan luas permukaan tangki radius = diameter / 2 surface_area = 2 * math.pi * radius * (radius + height)

#Konversi diameter, tinggi, dan luas permukaan ke dalam satuan cm diameter_cm = diameter * 100 height_cm = height * 100 surface_area_cm2 = surface_area * 10000

return diameter_cm, height_cm, surface_area_cm2

def cost_function(x):

diameter = x[0] height = x[1]

#Menghitung luas permukaan tangki _, _, surface_area_cm2 = calculate_tank_properties(diameter, height)

#Menghitung biaya berdasarkan luas permukaan #Anggap harga material adalah Rp 100 per cm^2 cost = surface_area_cm2 * 100

return cost

- Mendefinisikan batasan ukuran tangki

diameter_bounds = (0.1, 100) # batasan diameter antara 0.1 cm dan 100 cm height_bounds = (0.1, 100) # batasan tinggi antara 0.1 cm dan 100 cm

- Mendefinisikan nilai awal diameter dan tinggi

x0 = [1, 1] # nilai awal diameter 1 cm, tinggi 1 cm

- Melakukan optimisasi dengan menggunakan metode minimize dari library scipy

result = minimize(cost_function, x0, bounds=(diameter_bounds, height_bounds))

- Mengambil nilai diameter dan tinggi yang dioptimasi

diameter_opt = result.x[0] height_opt = result.x[1]

- Menghitung luas permukaan tangki yang dioptimasi

diameter_cm, height_cm, surface_area_cm2 = calculate_tank_properties(diameter_opt, height_opt)

print("Diameter tangki oksigen (cm):", diameter_cm) print("Tinggi tangki oksigen (cm):", height_cm) print("Luas permukaan tangki oksigen (cm^2):", surface_area_cm2)

With this code, we obtain the following dimensions:

Tank Diameter (cm): 10.0 Tank height (cm): 10.0 Tank Surface area (cm^2): 471.238898038469

A noteable thing that we can observe from the result of the calculation with the program above is that while having the exact same diameter size (10 cm), the program calculates the height of the tank as being less than the manual calculation above. And because having the same diameter but less in height, it is crucial to stick to the result of the manual calculation above as 1

Material Selection: Stainless steel 316L

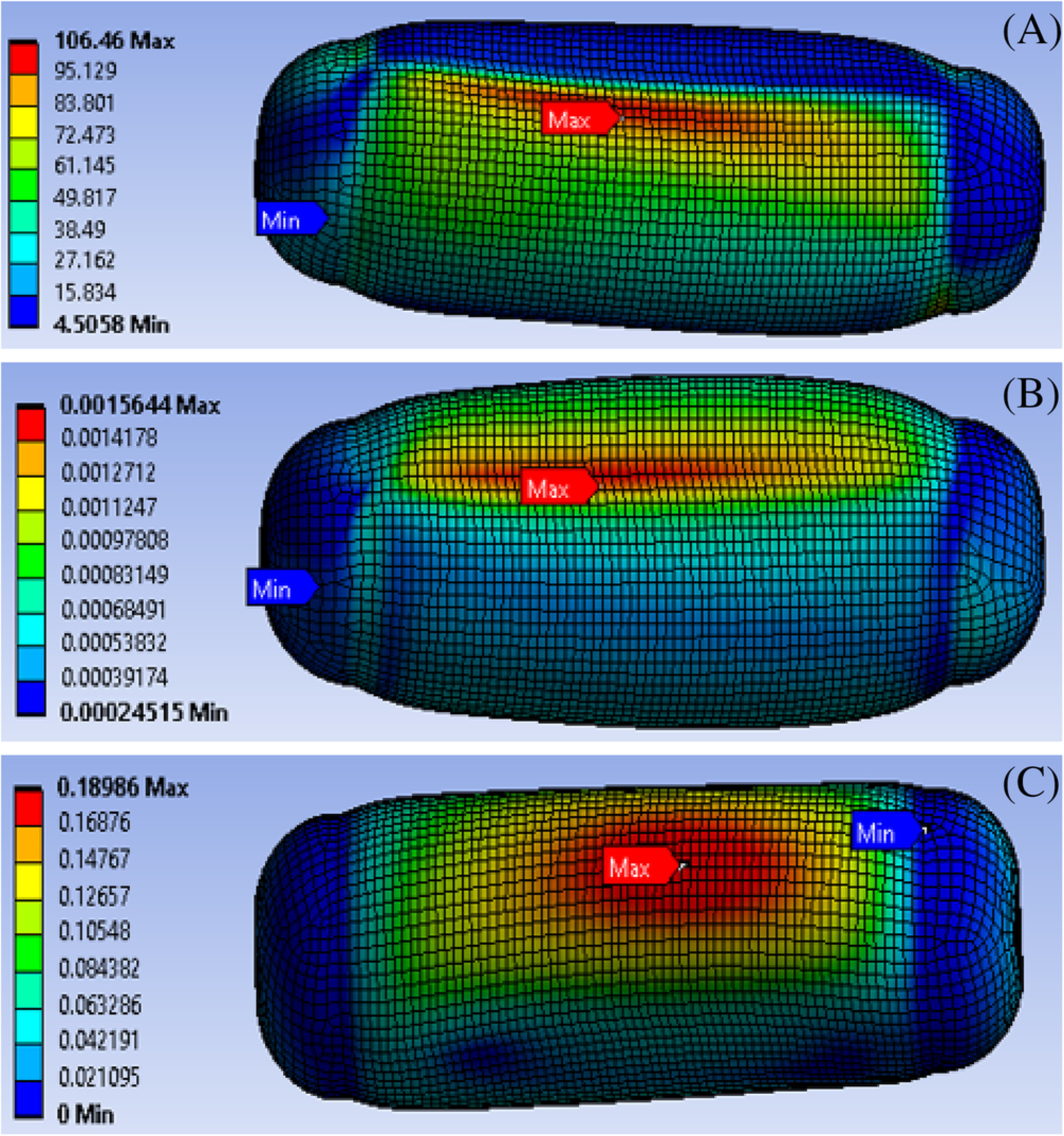

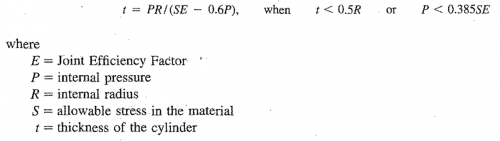

Thickness formula for circumferential stress direction:

Thickness formula for longitudinal stress direction:

E = 0.70 (For welded shells without radiography examination)

P = 8 bar = 116 psi

R = 50mm = 1.9685 in

S = 20000 Psi

Corrosion allowance = 1.5 mm = 0.06 in

t circumferential = 116 x (1,9685 + 0,06) / ((20000 x 0,7) - (0,7 x 116)) = 0.016905 in. (With corrosion allowance = 0.0769 in = 1.95mm)

t longitudinal = 116 x (1,9685 + 0,06) / ((2 x 20000 x 0,7) + (0,4 x 116)) = 0.00839 in. (With corrosion allowance = 0.06839 in = 1.74mm)

Hence, the minimum thickness for the material of the tank is 1.95mm

Why Aluminium 6061?

Lightness: Aluminium is a lightweight material, making it advantageous for applications where weight reduction is important. The use of aluminium 6061 allows for the construction of lightweight hydrogen tanks, which is crucial for applications like automotive and aerospace industries, where weight savings are critical for efficiency.

High strength: Aluminium 6061 has a high strength-to-weight ratio, meaning it offers good strength while maintaining a relatively low weight. This property is beneficial for ensuring the structural integrity of the hydrogen tank and providing safety during storage and transportation.

Corrosion resistance: Aluminium 6061 exhibits good resistance to corrosion, including resistance to hydrogen embrittlement. Hydrogen gas can cause embrittlement in certain materials, leading to reduced strength and potential failure. The corrosion resistance of aluminium 6061 makes it suitable for prolonged exposure to hydrogen without significant degradation.

Formability: Aluminium 6061 can be easily formed into different shapes and sizes using various manufacturing techniques, such as extrusion, casting, and machining. This formability allows for the production of hydrogen tanks with complex geometries, enabling optimal use of available space in vehicles or storage systems.

Cost-effectiveness: Aluminium is a widely available and relatively low-cost material compared to some other alternatives. This makes aluminium 6061 an economically viable option for hydrogen storage tanks, particularly for applications where cost considerations are important.

Calculation of the production cost

To calculate the production cost, first and foremost, it is a must that we consider and calculate the material cost.

Material volume = Outer radius cylinder volume - Inner radius cylinder volume

Outer radius volume = π(r+t)²(h+2t)

t = thickness = 12.732 cm (the t is multiplied by two because the thickness 'thickens' in both directions for height.

Calculation:

Out. radius vol. = π(5+(1.95))²(12.732+2(1.95)) = 2523.852431 cm³

Inner radius volume = πr²h

In. radius vol. = π(5)²(12.732) = 999.9689416 cm³

Material volume = Outer radius cylinder volume - Inner radius cylinder volume = 2523.852431 - 999.9689416 = 1523.883489 cm³ = 0.001523883489 m³

After calculating the volume, proceed to calculate the mass:

M = ρV

The density of Aluminium 6061 is 2720 kg/m³

M = 2720 x 0.001523883489

M = 4.14496309 kg ~ 4.14 kg

The cost for aluminium 6061 is around $2.75 per kg or IDR 41,000

Total material cost for hydrogen tank:

41,000 * 4.14 = IDR 169,740

With the material cost now calculated, we can now have an estimate in which material cost make up to 40%-70% of the total production cost. Let's estimate for the most expensive outcome, in which the material cost is only 40%, hence the total production cost would be IDR 424,350. It is quite expensive, but it is still below the client's requirement of being below IDR 500,000 in total production cost.