Difference between revisions of "Michael Geraldo Nabasa"

| Line 57: | Line 57: | ||

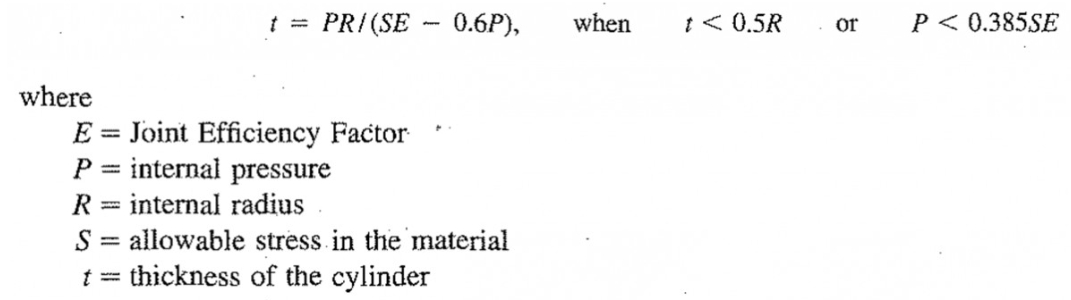

4. Ketebalan Minimum | 4. Ketebalan Minimum | ||

| + | |||

| + | [[File:Rumus ikel.jpg]] | ||

Revision as of 09:06, 5 June 2023

Introduction

Hi, my name is Michael Geraldo Nabasa (2106732872), and I am currently pursuing a Bachelor's degree in Mechanical Engineering, University of Indonesia.

Consciousness

By substituting x=1 into the equation, the expression evaluates to 0/0, which is undefined in basic mathematics due to division by zero. To resolve this, we can factorize (X^2 - 1) as (X+1)(X-1), transforming the equation into a well-defined form.

hydrogen Storage

To effectively design and enhance a pressurized hydrogen tank, I have gathered several key considerations that need to be addressed. These include:

1. To enhance the valve and fitting system's design, it is crucial to optimize them for compatibility with high-pressure hydrogen gas. This optimization is essential in order to mitigate the risk of leaks or any other potential safety concerns.

2. To ensure safety, a pressure relief device should be employed to allow the container to safely release excess pressure during emergency situations. This safety feature guarantees that the container does not burst in the event of over-pressurization.

3. To reduce weight and ensure the container's ability to withstand pressure, it is important to design the storage container using lightweight and durable materials that are both strong and cost-effective. Suitable materials may include carbon fiber, aluminum, or other composite materials.

4. To guarantee the reliability and performance of the storage system, it is imperative to subject it to suitable testing and certification procedures to ensure compliance with applicable safety standards. This step ensures that the system meets the necessary requirements and can be relied upon for its intended purpose.

5. To stay within the designated budget, it is beneficial to investigate cost-effective manufacturing techniques for the pressure vessel, such as extrusion or casting. Utilizing these methods can assist in managing production costs efficiently while maintaining the desired quality and functionality of the vessel.

Hydrogen Storage Design

Data Operasional:

1. Kapasitas : 1 Liter

2. Tekanan : 8 Bar

3. Cost : Rp 500.000,00

4. Temp Operational : 30 - 40 Deg Celcius

5. Instrument Control : Pressure Regulator range 1 - 15 Bar

A. Perhitungan tinggi tabung

Rumusnya adalah

V : πr²h

1. V diketahui 1 Liter

2. Diameternya asumsikan 10 cm sehingga jari jarinya adalah 5 cm

1000 : 3,14 x (5)² x h

1000 : 78,5h

h : 12,73 cm

3. Pemilihan Material

Material yang digunakan adalah sheet metal ASTM A36 dengan yield strength 248 MPa, sehingga didapatkan allowable stress adalah 165,3 Mpa

4. Ketebalan Minimum