Difference between revisions of "Ahmad Naufal 'Alim Arrasyid"

(→Compatibality for Motorcycle Usage) |

(→Compatibality for Motorcycle Usage) |

||

| Line 181: | Line 181: | ||

It's worth noting that hydrogen fuel cell motorcycles are still in the developmental stages, and the commercial availability and practicality of using hydrogen as a fuel for motorcycles may vary depending on the region and technological advancements. Therefore, it is essential to consult with experts in the field and consider the specific requirements and challenges associated with integrating hydrogen fuel systems into motorcycles. | It's worth noting that hydrogen fuel cell motorcycles are still in the developmental stages, and the commercial availability and practicality of using hydrogen as a fuel for motorcycles may vary depending on the region and technological advancements. Therefore, it is essential to consult with experts in the field and consider the specific requirements and challenges associated with integrating hydrogen fuel systems into motorcycles. | ||

| + | |||

| + | |||

| + | [[File:Kawasaki-hydrogen1.jpeg|300px|]] | ||

Revision as of 08:27, 5 June 2023

Contents

[hide]Intro

Halo, perkenalkan saya Ahmad Naufal 'Alim Arrasyid mahasiswa departemen teknik mesin paralel 2021 dengan NM 2106653205. Saat ini saya sedang menimba ilmu di kelas Metode Numerik - 03 dengan Bapak DAI.

Progress Update Week One

What is a Hydrogen Storage? A hydrogen storage tank is a specialized container designed to store and hold hydrogen gas safely and efficiently. Hydrogen, being the lightest and most abundant element in the universe, is increasingly being considered as a potential energy carrier for various applications, including transportation, energy storage, and industrial processes.

Hydrogen storage tanks are crucial for enabling the practical use and transportation of hydrogen gas. They need to meet specific requirements to ensure the safety and integrity of the stored hydrogen. Here are some key aspects of hydrogen storage tanks:

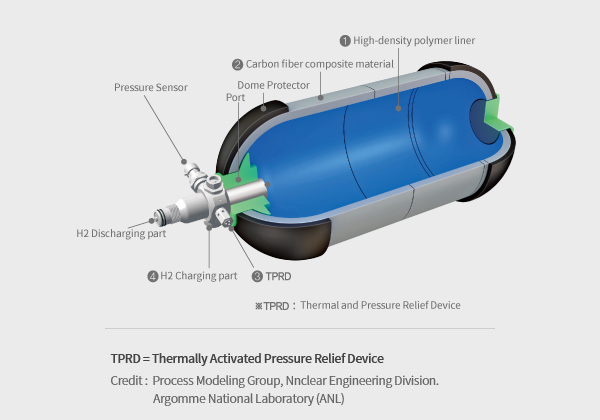

1. Material: Hydrogen storage tanks are typically constructed using high-strength materials capable of containing the high-pressure hydrogen gas. Common materials include steel, carbon fiber composites, aluminum, or a combination of these materials. The chosen material must exhibit suitable strength, durability, and resistance to hydrogen embrittlement.

2. Pressure: Hydrogen is often stored under high pressure to maximize its energy density. Hydrogen storage tanks can be categorized into three main types based on pressure levels: high-pressure tanks (350-700 bar), medium-pressure tanks (100-350 bar), and low-pressure tanks (up to 100 bar). The pressure rating depends on the application and the amount of hydrogen to be stored.

3. Tank Design: Hydrogen storage tanks come in various designs, including cylindrical, spherical, or prismatic shapes. Each design offers specific advantages in terms of storage capacity, weight, and structural integrity. For example, spherical tanks are known for their high volumetric capacity, while cylindrical tanks are relatively easier to manufacture.

4. Safety Measures: Safety is of paramount importance in hydrogen storage. Tanks are equipped with safety features such as pressure relief devices, rupture discs, and thermal management systems to prevent overpressure situations, manage temperature variations, and minimize the risk of explosion or leakage.

5. Insulation: To minimize hydrogen losses and maintain the desired temperature, storage tanks may be insulated. Insulation helps reduce heat transfer, prevents hydrogen boil-off, and improves overall energy efficiency.

It's worth noting that the development of advanced hydrogen storage technologies is an active area of research. Researchers are exploring alternative methods for hydrogen storage, such as solid-state materials, metal hydrides, chemical storage systems, and cryogenic storage, to enhance storage capacity, safety, and cost-effectiveness.

Overall, hydrogen storage tanks play a crucial role in the practical utilization and distribution of hydrogen as an energy carrier, providing a means to store and transport this versatile gas for a wide range of applications.

Hydrogen Tank Design and Optimization

For designing and optimizating of a 1-liter pressurized hydrogen with a maximum of an 8-bar pressure storage tank capability:

Pressure Rating:

Design the tank to withstand a pressure of 8 bar (800 kPa) with a safety margin to accommodate pressure fluctuations and ensure long-term reliability.

Volume and Dimensions:

Total storage volume: 1 liter (1000 cm³). Optimize the tank dimensions to maximize volumetric efficiency while considering factors like weight, structural integrity, and space constraints.

Material Selection:

Conduct an in-depth material analysis considering multiple factors, including hydrogen compatibility, permeation rates, fatigue resistance, embrittlement, and long-term durability. Explore advanced materials, such as high-strength alloys, composite materials, or novel nanostructured materials, to enhance strength-to-weight ratio and improve performance.

Safety Features:

Pressure Relief Device: Implement an advanced pressure relief system with multiple redundant valves and an electronic monitoring system for precise pressure control and rapid response. Fail-Safe Mechanism: Incorporate a fail-safe mechanism that automatically activates in the event of a critical failure, ensuring safe containment and preventing catastrophic incidents. Integrated Fire Suppression System: Integrate an automatic fire suppression system that can detect and extinguish hydrogen fires in and around the storage tank, enhancing safety in case of accidents.

Structural Considerations:

Advanced Stress Analysis: Utilize advanced simulation techniques, such as finite element analysis (FEA), to analyze stress distribution, fatigue life, and failure modes under various operating conditions. Composite Reinforcement: Investigate the use of advanced composite materials, such as carbon fiber reinforced polymers (CFRP), with tailored fiber orientations to optimize strength, weight, and resistance to fatigue and impact. Multi-Layered Design: Explore multi-layered tank configurations with optimized material combinations, such as an inner liner for hydrogen containment, a middle layer for structural strength, and an outer layer for thermal insulation and protection.

Testing and Certification:

Perform extensive testing and validation, including burst tests, cyclic loading tests, impact resistance tests, and thermal cycling tests, to ensure the tank meets or exceeds industry standards and safety requirements. Obtain certifications from recognized regulatory bodies, such as ISO 11439 or ASME Boiler and Pressure Vessel Code, demonstrating compliance with relevant safety standards for hydrogen storage.

Optimization Considerations:

Advanced Optimization Algorithms: Employ advanced optimization algorithms, such as genetic algorithms or machine learning-based algorithms, to optimize the tank's shape, dimensions, material distribution, and reinforcement patterns for improved performance and reduced weight. Integrated Sensors and Controls: Implement an intelligent control system that utilizes real-time sensor data to dynamically adjust pressure, temperature, and other parameters to optimize hydrogen storage conditions and enhance system efficiency. Active Thermal Management: Incorporate an active cooling system, such as a liquid cooling loop or phase-change materials, to manage temperature fluctuations and prevent hydrogen overheating during charging and discharging.

This expanded design and optimization approach encompasses a range of complex considerations to ensure the safety, performance, and efficiency of the 1-liter pressurized hydrogen storage tank with an 8-bar pressure capability.

Manufacturing Process

And for manufacturing steps for a 1-liter pressurized hydrogen storage tank with 8-bar pressure capability:

Design and Optimization:

- Define Requirements and Constraints:

Determine the desired specifications, including storage volume (1 liter) and pressure rating (8 bar). Consider space constraints, weight limitations, safety regulations, and applicable standards.

- Material Selection and Analysis:

Conduct an in-depth analysis of materials suitable for hydrogen storage, considering factors like compatibility, permeation rates, fatigue resistance, and long-term durability. Explore advanced materials, such as high-strength alloys or carbon fiber composites, to optimize strength-to-weight ratio and performance.

- Tank Design:

Select the tank shape (cylindrical or spherical) based on space constraints, structural considerations, and manufacturing feasibility. Determine the tank dimensions, optimizing for volumetric efficiency while considering weight, structural integrity, and safety factors. Perform stress analysis using advanced simulation techniques to ensure the tank can withstand the desired pressure and operational conditions.

- Safety Features:

Integrate safety mechanisms such as pressure relief devices, rupture discs, and fail-safe mechanisms to prevent overpressure situations, contain leaks, and manage critical failures. Incorporate an advanced fire suppression system to detect and extinguish hydrogen fires.

- Optimization:

Utilize advanced optimization algorithms, such as genetic algorithms or machine learning-based approaches, to optimize the tank's shape, dimensions, material distribution, and reinforcement patterns for improved performance, weight reduction, and structural integrity. Consider factors such as stress distribution, fatigue life, and thermal management during the optimization process.

-Testing and Validation:

Conduct comprehensive testing and validation of the design, including burst tests, cyclic loading tests, impact resistance tests, and thermal cycling tests, to ensure compliance with safety standards and performance requirements. Adjust the design if necessary based on the test results.

Manufacturing Process:

- Material Procurement:

Source the selected materials, considering quality, availability, and compliance with specifications and regulations.

- Tank Fabrication:

Prepare the material by cutting it into appropriate shapes and sizes based on the tank design. Utilize specialized manufacturing techniques such as welding, bonding, or filament winding to join the material components together, ensuring high-quality seams and joints. Implement quality control measures to verify the integrity of the manufacturing process.

- Surface Treatment:

Apply surface treatments, such as coatings or finishes, to enhance corrosion resistance, protect against environmental factors, and improve overall durability.

- Installation of Safety Features:

Integrate safety devices, including pressure relief valves, rupture discs, and fail-safe mechanisms, into the tank structure according to the design specifications.

- Quality Assurance:

Implement rigorous quality assurance processes to ensure the manufactured tanks meet the required standards and specifications. Conduct non-destructive testing, such as ultrasound or X-ray inspections, to verify the integrity of welds and detect potential defects. Testing and Certification:

Perform final testing, including pressure and leakage tests, to verify the tank's performance and safety. Obtain necessary certifications and approvals from regulatory bodies, demonstrating compliance with relevant standards for hydrogen storage. By following these steps, the design and optimization process can be seamlessly integrated with the manufacturing process, resulting in a 1-liter pressurized hydrogen storage tank with 8-bar pressure capability that meets safety, performance, and quality requirements.

Compatibality for Motorcycle Usage

It is possible to use a 1-liter pressurized hydrogen storage tank for a motorcycle, provided that the necessary infrastructure and components are in place to support the use of hydrogen as a fuel source. However, there are several important considerations to keep in mind:

Integration with Motorcycle Systems:

The motorcycle's engine and fuel delivery system need to be modified or specifically designed to accommodate hydrogen as a fuel source. The hydrogen storage tank should be securely and safely integrated into the motorcycle's frame or structure, considering factors such as weight distribution, stability, and vibration damping.

Safety Measures:

Ensure the motorcycle is equipped with necessary safety features, such as hydrogen leak detection systems, thermal management systems, and fire suppression systems. Adhere to safety regulations and guidelines specific to hydrogen fuel systems and transportation.

Infrastructure and Refueling:

Consider the availability of hydrogen refueling stations or other means of refueling the motorcycle's hydrogen storage tank. Evaluate the feasibility of establishing a hydrogen refueling infrastructure in the areas where you plan to use the motorcycle.

Regulations and Approvals:

Comply with local regulations and obtain necessary approvals for using hydrogen as a fuel source for a motorcycle. Ensure the motorcycle and its hydrogen fuel system meet applicable safety standards and certifications.

It's worth noting that hydrogen fuel cell motorcycles are still in the developmental stages, and the commercial availability and practicality of using hydrogen as a fuel for motorcycles may vary depending on the region and technological advancements. Therefore, it is essential to consult with experts in the field and consider the specific requirements and challenges associated with integrating hydrogen fuel systems into motorcycles.