Difference between revisions of "Faiq Nurzaman"

(→Hydrogen Engine on OM; Result) |

(→Hydrogen the Greener Energy) |

||

| Line 421: | Line 421: | ||

[[File:Result222.jpeg|400px|thumb|center]] | [[File:Result222.jpeg|400px|thumb|center]] | ||

| + | |||

| + | I also have made the explanation video for my progress report; https://youtu.be/hUp7OF3M52M | ||

Revision as of 21:44, 24 March 2023

Contents

- 1 Hello, everyone!

- 2 Oil Crisis, True or Not?

- 3 Greener Energy Plants for a Better Indonesia

- 4 Simulating Engines?

- 5 Optimizing Fuel Usage in the Middle of Sky-Rocketing Fuel Prices

- 6 Vibrations; The Beginning of Everything?

- 7 Energy Conversion; Pyrolisis vs Others

- 8 From Pyrolysis, to Desalination?

- 9 CCIT House Visit!!

- 10 QUIZ

- 11 Hydrogen the Greener Energy

Hello, everyone!

Whoever you are, I appreciate you for coming by here. My name is Faiq (1906422905), and I am a fourth-year student in Mechanical Engineering Universitas Indonesia.

This is my own page for Energy Conversion System 2 study with Mr. DAI and Prof. Adi. I will write and summarize anything I learned during the study.

I hope you enjoy it! Thank you

Oil Crisis, True or Not?

I was having my first Energy Conversion System class on Tuesday, 14 February 2023. The class was led by Mr. DAI and Prof. Adi.

I got some interesting sights from the class. During the class, Prof. Adi engages us to gain our consciousness on our daily life problems related with energy conversion. This time, one of the interesting problem was 'is it true that the world starts to run out of oil?'

We might have heard the oil crisis propaganda in every corner since long time ago. The question is, when does the world will totally run out of oil? We always heard that the world starts to run out of oil, but we still have them today.

Greener Energy Plants for a Better Indonesia

It was Friday on February 17th when I was in the class at around 1 PM. I opened ChatGPT to kill my time and explore my curiousities regarding Thermal Energy Conversion.

ChatGPT told me that there are currently some sources of thermal energy used for conversions worldwide, based on the specific application and technologies; fossil fuels, nuclear, solar, geothermal, biomass, and waste heat recovery.

I was curious about the most-common thermal energy source used for conversion in Indonesia, since Indonesia seems to have a positive trend in using electrified vehicles in recent years.

It turns out that the most used energy source in Indonesia is from coal-fired power plants due to the country's abundant amount of coal reserves. As of 2021, around 60% of the country's electricity sources are still based on them.

I also found that coal-fired power plants are actually advantageous in some ways; high reliability, affordable cost, and increasing the energy security by making the country independent from imported fuel.

Nevertheless, as the future engineers, we must also learn that coal-fired power plants have some bad impacts for the sustainability; significant emissions, dangerous pollutants for respiratory health, and hardly-disposable ash. Coal is also a non-renewable source whose extraction could also make a bad impact for the environment.

I was quite concerned with those disadvantages of coal-fired power plants, so that I asked ChatGPT about the preventive way taken by those power plants in Indonesia. It turns out that some power plants have been retrofitted with advanced pollution control technologies such as; Flue Gas Desulfurization (FGD), Selective Catalytic Reduction (SCR), Electrostatic Precipicators (ESP), Low NOx burners, and coal-washing. Though not every power plants have been retrofitted with those technologies, at least the major ones have been retrofitted.

However, Indonesia has targeted to have renewable energy sources to generate up to 23% of the country's electricity by 2025, and 31% by 2050. The renewable energies targeted includes; wind, solar, hydro, and geothermal sources. The country have also been having researches regarding some cleaner energies such as natural gas or nuclear energies.

Let's support the cleaner energy plants for a better Indonesia!

| Faiq Nurzaman: thermal energy conversion

Thermal energy conversion refers to the process of converting thermal energy, which is the energy that comes from the temperature difference between two objects or substances, into other forms of energy, such as mechanical or electrical energy. There are several methods for thermal energy conversion, including: Steam turbines: Steam turbines are commonly used in power plants to convert thermal energy from steam into mechanical energy, which is then used to generate electricity. Internal combustion engines: Internal combustion engines, such as those found in automobiles, convert thermal energy from burning fuel into mechanical energy to power the vehicle. Thermoelectric generators: Thermoelectric generators convert thermal energy into electrical energy directly, by using a temperature difference to generate a voltage across a material. Stirling engines: Stirling engines use temperature differences to drive a piston and generate mechanical energy. Organic Rankine cycles: Organic Rankine cycles use a working fluid with a lower boiling point than water to convert thermal energy into mechanical energy. These methods of thermal energy conversion are used in a variety of applications, including power generation, transportation, and waste heat recovery. Additionally, there are several technologies that are being developed to improve thermal energy conversion, such as advanced materials for thermoelectric generators, high-temperature materials for gas turbines, and improved heat exchangers for heat recovery systems. These advancements can help increase the efficiency of thermal energy conversion and reduce energy waste, contributing to a more sustainable and efficient energy system.

The source of thermal energy used for conversion depends on the specific application and technology being used. Here are some examples of common sources of thermal energy: Fossil fuels: Coal, natural gas, and oil are commonly used as a source of thermal energy in power plants and other industrial processes. The fossil fuels are burned to produce high-temperature gases, which are used to generate steam to drive a turbine and produce electricity. Nuclear energy: In nuclear power plants, the heat generated by nuclear reactions is used to produce steam, which drives a turbine to produce electricity. Solar energy: Concentrated solar power plants use mirrors or lenses to concentrate sunlight onto a heat-absorbing material, which produces high-temperature steam to drive a turbine and generate electricity. Geothermal energy: In geothermal power plants, the heat from the Earth's interior is used to produce steam, which drives a turbine to generate electricity. Biomass: Biomass, such as wood, agricultural waste, and municipal solid waste, can be burned to produce heat, which can be used to generate steam and produce electricity. Waste heat recovery: Waste heat from industrial processes or power generation can be captured and used to produce electricity, reducing energy waste. Overall, the choice of thermal energy source depends on the availability, cost, and environmental impact of the energy source, as well as the technology used for thermal energy conversion. Faiq Nurzaman: what thermal conversion system is commonly used in Indonesia? In Indonesia, the most common thermal energy conversion system is coal-fired power plants. Indonesia has abundant coal reserves and has been heavily dependent on coal for electricity generation. According to the Indonesia National Energy Policy, the target is to have 23% of the country's electricity generated from renewable energy sources by 2025. However, as of 2021, coal still accounts for around 60% of the country's electricity generation. Besides coal-fired power plants, other thermal energy conversion systems are also used in Indonesia, including natural gas-fired power plants, geothermal power plants, and biomass power plants. Indonesia has significant potential for geothermal energy due to its location in the Ring of Fire, but its development has been relatively slow compared to other countries. Additionally, the government has been promoting the development of renewable energy, including solar and wind, to diversify the country's energy mix and reduce reliance on fossil fuels. It's worth noting that as the country is situated in a highly active seismic zone, the design and construction of thermal energy conversion systems in Indonesia, including power plants, must take into account the potential risk of earthquakes and other natural hazards.

Coal-fired power plants have been widely used for electricity generation for many years. However, they also have some advantages and disadvantages that are worth considering: Advantages of coal-fired power plants: Reliability: Coal-fired power plants are known for their high reliability and can operate continuously for extended periods, making them suitable for base load power generation. Affordability: Coal is a relatively cheap and abundant fuel source, which makes it an affordable option for electricity generation, especially in countries with significant coal reserves. Energy security: Using domestic coal reserves for electricity generation can increase a country's energy security by reducing dependence on imported fuel. Disadvantages of coal-fired power plants: Environmental impact: Coal-fired power plants are significant sources of greenhouse gas emissions, which contribute to climate change. They also release other pollutants, such as sulfur dioxide, nitrogen oxides, and particulate matter, which can cause health problems and environmental damage. Resource depletion: Coal is a non-renewable resource, and its extraction can have negative environmental impacts, such as habitat destruction, water pollution, and soil degradation. Health impacts: Coal-fired power plants can release pollutants that can cause respiratory and other health problems in nearby communities, especially if they are located in densely populated areas. Coal ash disposal: Coal-fired power plants produce large amounts of ash and other waste products, which can be difficult and expensive to dispose of safely. Overall, while coal-fired power plants have some advantages, the negative environmental and health impacts associated with coal combustion make it necessary to consider transitioning to cleaner and more sustainable energy sources.

There are several solutions to address the negative environmental and health impacts of coal-fired power plants: Retrofitting existing power plants: One solution is to retrofit existing coal-fired power plants with advanced pollution control technologies, such as scrubbers, selective catalytic reduction, and fabric filters. These technologies can reduce emissions of sulfur dioxide, nitrogen oxides, and particulate matter. Carbon capture, utilization, and storage (CCUS): Another solution is to capture carbon dioxide emissions from coal-fired power plants and either store it underground or use it for enhanced oil recovery or other industrial processes. Transition to cleaner energy sources: A more fundamental solution is to transition away from coal and towards cleaner and more sustainable energy sources, such as renewable energy (solar, wind, hydro, and geothermal), natural gas, and nuclear energy. This transition would require a combination of policy incentives, regulatory measures, and technological advancements. Energy efficiency and conservation: Reducing energy demand through energy efficiency and conservation measures can help reduce the need for new coal-fired power plants and their associated negative impacts. Community engagement and public education: Engaging communities and educating the public about the risks and impacts of coal-fired power plants can help raise awareness and drive demand for cleaner energy sources. Overall, a combination of these solutions is needed to address the negative impacts of coal-fired power plants, protect human health and the environment, and support the transition to a more sustainable and low-carbon energy system.

Faiq Nurzaman: are the existing power plants in Indonesia have been retrofitted with those advanced pollution control technologies? what are those technologies that have been applied? In Indonesia, some existing coal-fired power plants have been retrofitted with advanced pollution control technologies. However, the extent of retrofitting and the types of technologies used vary among power plants. Here are some examples of pollution control technologies that have been applied in Indonesia: Flue gas desulfurization (FGD): FGD is a technology used to remove sulfur dioxide (SO2) from flue gas emissions. Some of Indonesia's newer coal-fired power plants, such as the 660 MW Cirebon Unit 1 and 2, and the 1000 MW Tanjung Jati B Unit 5 and 6, have installed FGD systems to reduce SO2 emissions. Selective catalytic reduction (SCR): SCR is a technology used to reduce nitrogen oxide (NOx) emissions. The 800 MW Indramayu coal-fired power plant has installed an SCR system to reduce NOx emissions. Electrostatic precipitators (ESP): ESP is a technology used to remove particulate matter (PM) from flue gas emissions. Some of Indonesia's coal-fired power plants, such as the 660 MW Cirebon Unit 1 and 2, have installed ESPs to reduce PM emissions. Low NOx burners: Low NOx burners are designed to reduce the formation of NOx during combustion. The 750 MW Suralaya coal-fired power plant has installed low NOx burners to reduce NOx emissions. Coal washing: Coal washing is a process that removes impurities from coal before it is burned. Some Indonesian power plants, such as the 660 MW Cirebon Unit 1 and 2, use washed coal to reduce emissions of sulfur dioxide and particulate matter. However, it's important to note that not all existing coal-fired power plants in Indonesia have been retrofitted with advanced pollution control technologies. As of 2021, many older power plants continue to operate without such technologies, and their emissions can have negative impacts on public health and the environment. Additionally, the effectiveness of these technologies can be impacted by factors such as the quality of coal being burned and the maintenance of the equipment. Therefore, there is a need for continued efforts to improve the environmental performance of coal-fired power plants in Indonesia.

Faiq Nurzaman: that’s all about the advanced pollution control technologies. about the transition to cleaner energy sources, is there any plan of it in Indonesia? what are the cleaner energy sources that have been planned in Indonesia? Yes, Indonesia has plans to transition to cleaner energy sources, as part of its efforts to reduce greenhouse gas emissions, improve energy security, and promote sustainable economic growth. Here are some examples of cleaner energy sources that have been planned or are being developed in Indonesia: Renewable energy: Indonesia has significant renewable energy potential, particularly in the areas of solar, wind, hydro, and geothermal power. The country aims to increase the share of renewable energy in its energy mix to 23% by 2025, and 31% by 2050. To achieve this target, the government has implemented a range of policies and incentives to promote renewable energy development, such as feed-in tariffs, tax incentives, and land use permits. Natural gas: Natural gas is a cleaner-burning fossil fuel that emits less greenhouse gases than coal. Indonesia is a major producer of natural gas, and the government has plans to expand the use of natural gas in power generation and other sectors. Nuclear energy: Indonesia is exploring the potential of nuclear energy as a clean and reliable energy source. The government has established the National Nuclear Energy Agency (BATAN) to oversee the development of nuclear energy infrastructure and regulations. Energy efficiency and conservation: Indonesia is also focusing on improving energy efficiency and conservation, in order to reduce energy demand and promote sustainable development. The government has launched various programs and initiatives to promote energy efficiency, such as the national energy labeling program for appliances and the green building program. Overall, the transition to cleaner energy sources in Indonesia is an important priority, and the government is taking steps to promote the development and deployment of these technologies. However, there are still challenges to be addressed, such as regulatory barriers, financing constraints, and infrastructure limitations.

Internal energy can be thought of as the sum of the kinetic and potential energies of all the particles within a system. These energies can take many forms, such as thermal energy, chemical energy, nuclear energy, and so on. Internal energy is an extensive property, meaning that it depends on the size and amount of matter in the system. It can also change due to heat transfer or work done on or by the system, but the change in internal energy depends only on the initial and final states of the system and is independent of the process used to get from one state to the other. Internal energy is often symbolized as U and is typically measured in units of joules (J) or kilojoules (kJ) in the International System of Units (SI).

During pyrolysis, organic materials such as biomass, waste plastics, or rubber are heated to high temperatures ranging from 300°C to 900°C, causing them to break down into smaller molecules. The process occurs in the absence of oxygen, preventing the materials from burning and producing harmful emissions. The byproducts of pyrolysis depend on the type of feedstock used and the specific conditions of the pyrolysis process. Solid byproducts can include biochar or activated carbon, which can be used as a soil amendment or a source of fuel. Liquid byproducts can include bio-oil or pyrolysis oil, which can be further refined into transportation fuels or other chemicals. Gaseous byproducts can include syngas, which can be used as a fuel or a feedstock for the production of chemicals. Pyrolysis is considered a promising technology for the conversion of waste materials into valuable products and for the production of renewable energy. It offers advantages over traditional combustion processes, such as lower emissions, higher energy efficiency, and greater flexibility in terms of feedstock. However, there are still challenges to be addressed, such as the high capital costs of pyrolysis plants, the need for consistent feedstock quality, and the need for appropriate environmental regulations to ensure safe and sustainable use of the technology.

Visual inspection: You can visually inspect the engine compartment to check for any obvious signs of damage or wear, such as cracks, leaks, or loose parts. Sounds and vibrations: You can listen for any unusual sounds or vibrations coming from the engine when it is running, such as knocking, rattling, or grinding noises, which could indicate problems with the engine components. Exhaust smoke: You can observe the color and smell of the exhaust smoke to determine if the engine is running properly. Black smoke may indicate fuel system problems, while blue or white smoke may indicate oil consumption or coolant leaks. Fluid levels: You can check the fluid levels of the engine, such as oil, coolant, and transmission fluid, to ensure they are at the proper levels. Dashboard warning lights: You can pay attention to any warning lights on the dashboard, such as the check engine light, which can indicate problems with the engine or other components. By observing these things, you can often identify potential problems with the engine before they become more serious and require more extensive repairs. Regular inspections and maintenance can help ensure the engine performs at its best and lasts as long as possible. |

Simulating Engines?

I finally reopened OpenModelica again on Friday, February 24th, to simulate Internal Combustion Engine. To simulate the engine, i regained my memories regarding the principles of internal combustion engine.

We all might have learned about internal combustion engines, how they works, etc. But, when it's coming to simulation, how do we supposed to simulate internal combustion engines? This time, I started to learn how to simulate the internal combustion engine using OpenModelica.

The first part is to create the OpenModelica class and import the OpenModelica library needed for internal combustion engines. The library needed is ThermoSysPro 3.2 if I'm not mistaken (p.s sorry for not attaching the screenshot for the initial steps, I forgot to do it).

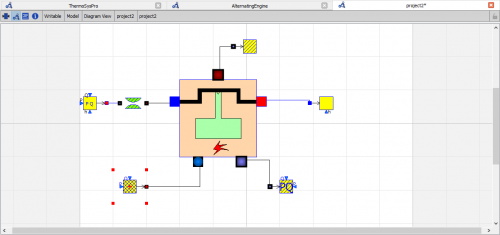

After that, we could make the diagram of the internal combustion engine. We all know that Internal combustion engine have input and output parameters. This is important to be considered in making the diagram.

From the figure above, we have some inlet and outlet parameters. There is the FuelSourcePQ as the fuel inlet, and also the SourccePQ on the kleft side for the engine cooling system. As we know, internal combustion engines do also have the output of fue gas and heated water/air from the cooling system.

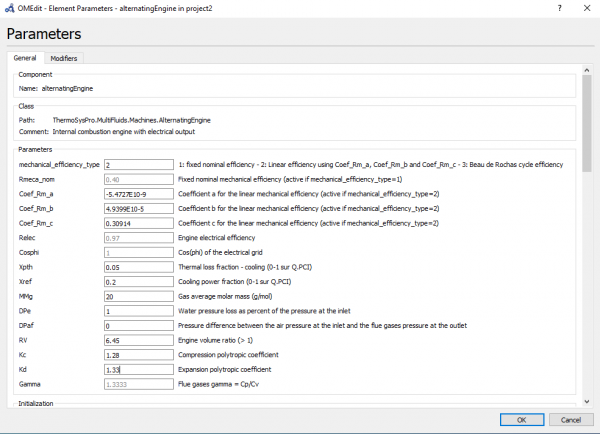

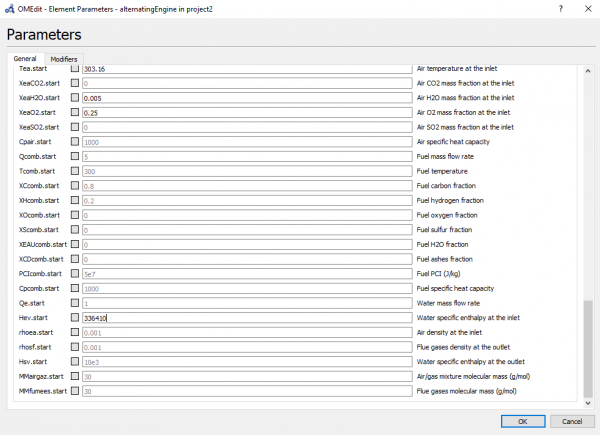

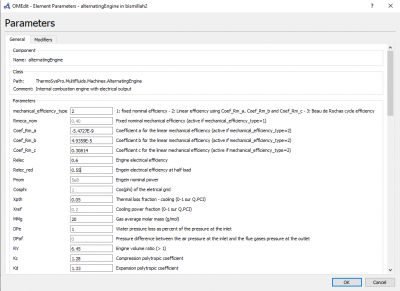

After visualizing the engine by making the diagram, the next step is to set the engine parameters.

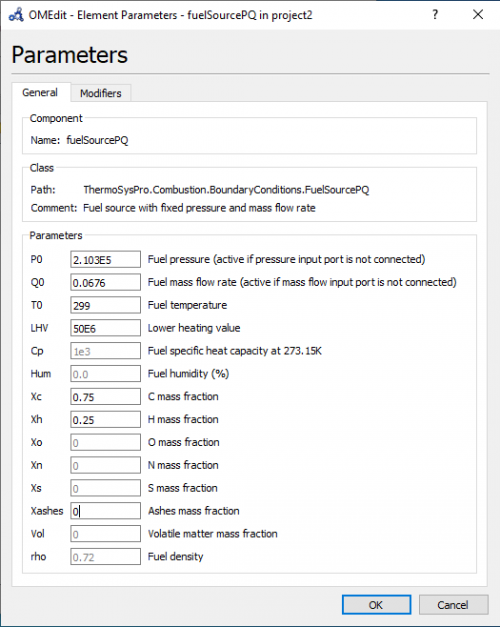

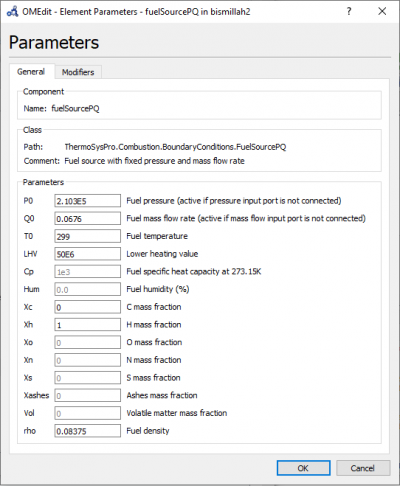

Aside from the engine parameters, we should also set the parameters for the fuel source. Here are the fuel parameters set in my previous ECS 2 class with Bang Tanwir

The steps are actually not finished yet. But, that's what i learned in the ECS class on 24 February 2023. It's not over yet, I'll continue writing again after I learned more about the simulation.

Stay tuned!

Optimizing Fuel Usage in the Middle of Sky-Rocketing Fuel Prices

|

"After weeks of tensions, Russian President Vladimir Putin ordered Russian troops to invade Ukraine, prompting an international sanctions response targeting Russia’s economy but not directly its oil supplies or energy payments. But as sanctions on Russia intensified and as financial institutions started to refuse financing Russia-related transactions, including opening letters of credit or clearing payments and as some companies became reluctant to purchase Russian crude, Brent on March 2 (the time of writing) was trading above $110 for the first time since 2014." from oxfordenergy.org |

The rise in world oil prices due to Russia-Ukraine war impacts the whole world, including Indonesia. One of the biggest affect of this phenomenon is the rise in fuel prices. I think the peak fuel price that I experienced is in the last quarter of 2022, where I bought Pertamina Dex for almost Rp18.800,00 per litres.

Although the world oil inflation has been subsided, the fuel price in Indonesia haven't been as stable as it was. As of February 2023, the national oil company (Pertamina) sells Pertamax for Rp12.800,00 and the diesel fuel Pertamina Dex for Rp16.850,00. These numbers are relatively high compared to how much they were sold for in December 2021. In December 2021, Pertamax was sold for Rp9000,00 and Pertamina Dex was sold for Rp11.150,00.

From those rise of price, we can conclude that diesel fuels got a bigger price rise compared to gasoline fuels. According to Gaikindo, Diesel-engined vehicles got 59,39% market of the 1500-2500cc engine car in 2020. From those percentage, Toyota takes 12.577 units of Diesel-engined cars in form of Toyota Innova and Toyota Fortuner. Both cars shared the same 2GD-FTV Diesel engine with the capacity of 2.4 litres.

From those data, I would like to start my Energy Conversion 2 project with the fuel consumption observation of Toyota Fortuner 2016, whose engine got 12.577 units sold in 2020. I actually have been observing its fuel consumption for my own usage in the last two quarters of 2022.

From my own usage, I got 620 kilometres reached by 61.42 litres of fuel. This means that I achieved 10.09 kilometres per litres for my own usage.

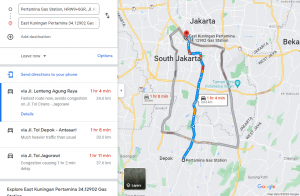

I admit that the fuel consumption of my own usage are not that accurate to define the engine's fuel consumption ability for inner-city routes, since I didn't always use it in rush hours. To get the actual fuel consumption in rush hours, I'd like to have the testing route from suburb areas (Depok) to the city central areas (Jakarta) in the morning.

My testing route would be from gas station (SPBU) near my home in Depok to a gas station in the prime area of Jakarta.

YouTube video for project explanation:

Vibrations; The Beginning of Everything?

If you want to understand the nature, then think of energy, vibrations, and frequency - Nikola Tesla |

Everything starts from vibration.

Well, at least that was the basic yet biggest thing that I discovered from Prof. Adi in today's class.

We were talking about our project; about the internal combustion engine, pyrolysis, and electric vehicles. We learned from the most basic things; the difference between them. One of them is that Internal Combustion Engines uses liquid fuel, while pyrolysis engines uses solid fuels.

Then, here is where the mind-blowing part of today's class started. Prof. Adi demonstrate the basic of combustion by burning a paper with lighter. Once the oxidation starts, the paper starts to burn itself down.

But, what is actually happened when the energy is transferred to the paper in form of heat??

The class started to think until Rafly stands up and shares his knowledge. According to him, every particle that heated up would be vibrating. And that is exactly what Prof. Adi meant.

Everything starts with vibration. Even if we knocked a table and made a sound, it is the result of vibration between our hand and the table itself. The cell phone we're currently using, they have 2G 3G 4G or even 5G connections. Those 'G' stands for 'Generation,' in which every generation have their own frequency ranges. frequency is basically a form of vibration. Vibration is one of the basic form of energy.

Beside the theory of vibration, we also talked about plastics, how they are made of, and how to utilize them properly. Nowadays, especially in Indonesia, we can see plastic wastes everywhere. The question is, are they actually useful? how to use them properly, so that we could get beneficial?

All these days, the plastic wastes are just disasters for us. Flooding, water quality issues, waste issues, landfill issues, etc. Plastic are actually made up from crude oil, can we convert them into energy?

Then, some of us that have done our exchange shares our experiences regarding how the country we lived manages waste, especially plastic wastes. Sintha shares her experience regarding waste management in South Korea. According to her, South Koreans are mostly conscious about sorting kinds of wastes independently. Everyone would sort their own waste before putting them away into the garbage, so that the waste management would be done easier.

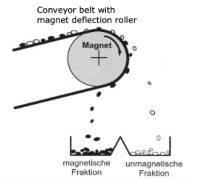

Beside Sintha, Kevin also gave his opinion about waste management in Germany. Talking about wastes, we also took a course about wastes too in Germany, named as 'Mechanical Biological Waste Treatment.' In that course, we talked about sorting wastes according to their materials (organic, non-organic, hazard wastes). Wastes are also sorted automatically depending on its size, density, and magnetic characteristics.

It's quite reminiscing me to the moments when we were making our final projects together in Germany. My group were designing a waste treatment plant for a small Indonesian urban area.

Back to our energy conversion topic, we discussed a lot in the class. Then, the class ended and we were given time to do more research and considerations regarding our own personal project.

Energy Conversion; Pyrolisis vs Others

If we listen well in the previous classes and the previous chapter of this page, we might have reas/heard about an energy conversion method named pyrolisis. But, what is actually pyrolisis? what makes it different from the other energy conversion method?

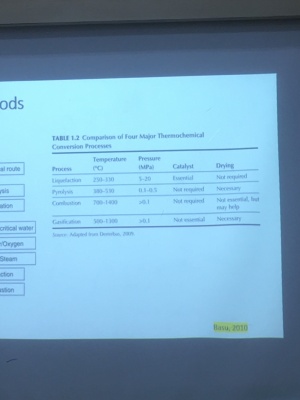

Pyrolisis is a type of biomass conversion. In general, therare two types of biomass conversion; biochemical route and thermochemical route. Pyrolisis is considered as the second one.

Well, does it ends here? The answer is, no. There are several types of thermocemical biomass conversion; Pyrolisis, Gasification, Combustion, and Liquifaction. Gasification results in the form of gas, while liquifaction indeed results in liquid. Combustion could result in both liquid and gas.

So, what differs pyrolisis with the others? Pyrolisis could result in gas, liquid, and even biochar. The incredible thing is that we could control the percentage of each form in pyrolisis. For example, we might want more biochar rather than liquid, or more gases rather than biochar. We can control those in Pyrolisis.

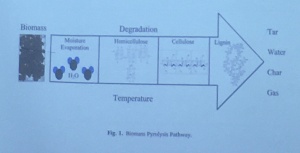

The other thing about pyrolisis is that the whole process uses close to zero oxygen. Pyrolysis degrades the biomass with multiple complex chemical reactions, and coverts them into liquid, solid, and gas product.

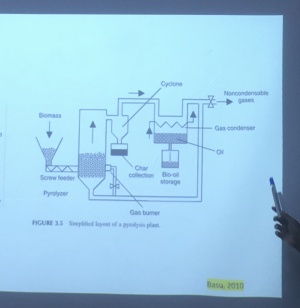

Here is the proses of pyrolysis. First of all, biomass is heated up in a burner. After that, the gas goes straight up into a condenser. In the condenser, the moisture content of the gas (which is oil) would be condensed and separated from the gas itself. Here is the separation between the oil and gas product. The condensed oil would be contained in bio-oil storage, and the gas would be stored later.

Pyrolysis is affected by some factors; technology, types of feedstock, feedstock size, residence time, and heating time.

From Pyrolysis, to Desalination?

If we talk about pyrolysis, we might think about a renewable energy source. But, what about desalination? is this thing even related to pyrolysis?

Basically, desalination is the purifying process of sea water to remove salt contents, so that the water would be safe to drink. Desalination have been massively applied recently in some countries. In one of my Energy Conversion class, Prof. Adi stated that China is one of the countries that got a massive planning on desalination.

Aside from the salt content, seawater also contains some contents that needs to be purified. These debris could come from wastes thrown into sea.

To remove the salt content from water, there are two methods. The first method is by using a conventional filter, while the newer method is by using graphene. What makes graphene more special compared to conventional filter is that it needs thinner layer to filter the water.

The goal of desalination is actually to make the water drinkable, for either public or industrial use. To remove the amount of salt, it indeed needs energy. Here is where pyrolysis takes its role here. Pyrolysis method would provide energy that could be used for desalination.

CCIT House Visit!!

On Friday, March 10th, we were given the chance to visit Pak DAI’s CCIT House in Kukusan, Depok. It was around 13.30 when I got arrived with Regina. We were then welcomed by Bu Illa. In a short time, we were then given a chance for a short walkaround in the house, along with Kevin that comes several minutes after us.

The main thing that stole my attention were EVIA and MRPP. I was always impressed with EVIA, even though I only see it through CCITOnline all this time. So, I decide to take a picture with EVIA.

MRPP is actually the thing that we learned all this time, Pyrolysis engine! It was my first time seeing Pyrolysis engine with my own eyes.

After we have a short walkaround and quick tour around EVIA and MRPP, Bang Tanwir and Bu Illa gives explanation about the principles of both equipments, with more focus to MRPP.

There are basically three equipments in MRPP; Generator, Pyrolysis, and FCC (Fluid Catalytic Cracking). The first step comes from the generator, powered by LPG. Generator produces 5000 watt of electricity and flue gasses. Then, the second and main step is pyrolysis.

The main energy source of Pak DAI’s pyrolysis engine is Azolla and Kohe (animal waste). These materials are then heated up to 300-400 degree celsius using flue gasses from generator. After that, gasses would flow up from the pyrolysis tank to condenser.

Condenser is used to condensate the gas to separate moisture contents (this time, crude bio oil) from the gas. Four condensers were used in Pak DAI’s MRPP to ensure that the moisture contents are separated as well as possible. the moisture content would be crude bio oil, while the gas would be bio singas

The next step is Fluid Catalytic Cracking. This is the refinery process for the crude bio oil to become a consumable bio oil.

QUIZ

The ECS 2 class on Friday, March 17th, was only attended by less than 10 people. We were having a quiz.

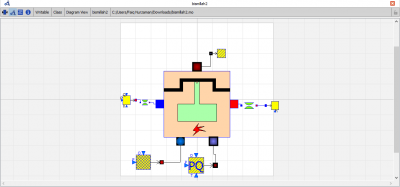

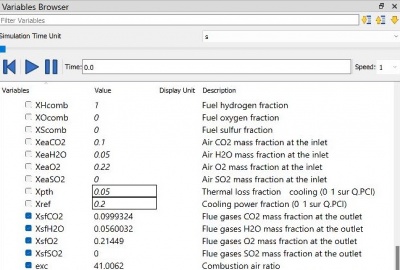

The quiz was about modelling an IC Engine using OpenModelica. We have the book as the reference, but Mr. DAI told us to change the fuel inlet with full hydrogen.

It was basically the same as what I have learned before with Bang Tanwir, with the difference in the fuel source (100% hydrogen). Hence i put 1 on the H mass fraction of the fuel parameter. I also put the fuel density to 0.08375 based on Google

For the engine parameters, its almost all the same with the tutorial from the book. However, I put some different things, one of them is the efficiency. According to my literature reviews on Google, the average efficiency for hydrogen engine is 0.6

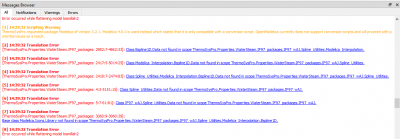

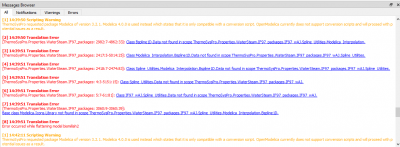

Unfortunately, there was an error with my OpenModelica software so that I couldn't simulate the IC engine.

I'm pretty sure that the error was 100% the software error since I have crosschecked the parameters and diagram several times, and found no fault in those parameters and diagram.

I also tried to solve the error by doing the task from OpenModelica. But, everytime I solve one problem, another problem occures immediately.

Hydrogen the Greener Energy

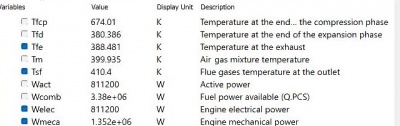

I finally solved the problem from my previous OpenModelica. From the parameters that I entered, I gained some result parameters.

I also have made the explanation video for my progress report; https://youtu.be/hUp7OF3M52M