Difference between revisions of "Mohammad Rafi"

| Line 32: | Line 32: | ||

[[File:Rafi2.png|1100px|thumb|center]] | [[File:Rafi2.png|1100px|thumb|center]] | ||

| + | |||

| + | |||

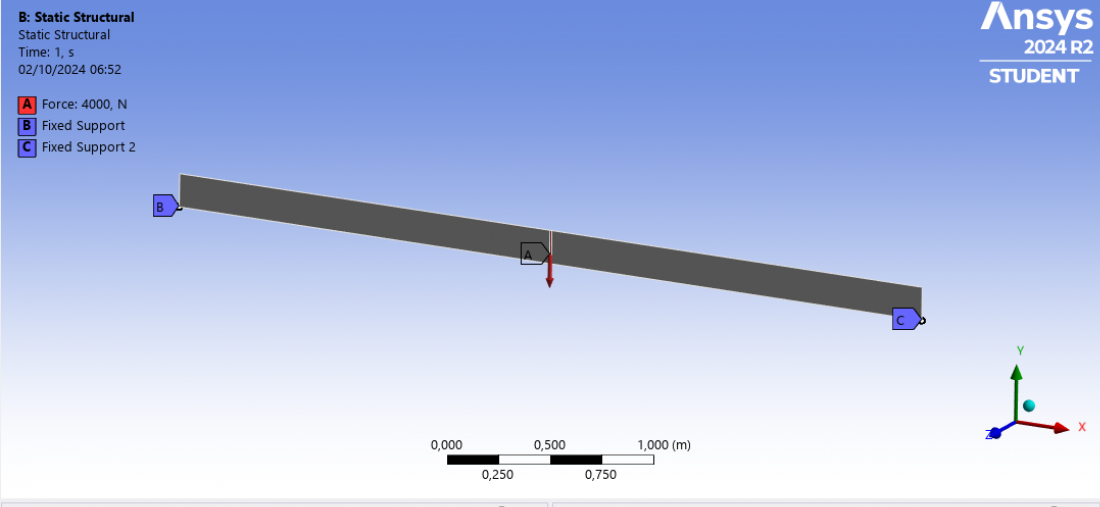

| + | The pipe analyzed in this simulation is modeled with fixed supports at both lower ends, ensuring that these points remain stationary under loading conditions. Additionally, a 4000 N load has been applied at the center of the pipe, representing the primary source of deformation observed in the simulation. This loading scenario is designed to simulate real-world conditions where pipes might experience concentrated forces at midspan, causing significant bending. The fixed supports provide resistance at the ends, preventing movement, while the central load introduces a bending moment that results in the observed deformation distribution. | ||

[[File:Rafi4.png|1100px|thumb|center]] | [[File:Rafi4.png|1100px|thumb|center]] | ||

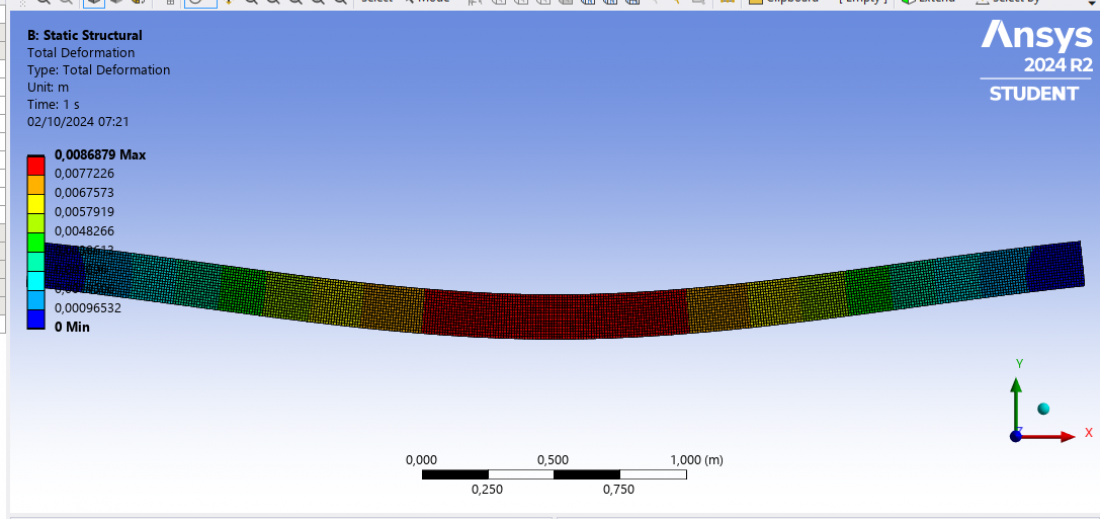

The simulation results indicate that the pipe experiences a maximum deformation of 8.69 mm in the middle section, represented by the red color, with minimal deformation at the ends, where no significant change occurs. This variation in deformation distribution suggests that the pipe is subjected to a load or pressure causing bending along its structure, with the greatest deformation occurring at the center. These simulation results are important for understanding the pipe's response to the applied load, which can affect the design and stability of the pipe structure. | The simulation results indicate that the pipe experiences a maximum deformation of 8.69 mm in the middle section, represented by the red color, with minimal deformation at the ends, where no significant change occurs. This variation in deformation distribution suggests that the pipe is subjected to a load or pressure causing bending along its structure, with the greatest deformation occurring at the center. These simulation results are important for understanding the pipe's response to the applied load, which can affect the design and stability of the pipe structure. | ||

Revision as of 07:18, 2 October 2024

Hello, I am Mohammad Rafi, currently pursuing a master's degree in Maritime Technology and Resources. My research focuses on optimizing fishing vessel structures, aiming to improve their efficiency and sustainability.

1. Initiator (Dr. Ahmad Indra): Dr. Ahmad Indra introduces the framework with the philosophy, "I am My Consciousness," highlighting the connection between self-awareness and identity. His role brings ethical, psychological, and philosophical dimensions, encouraging reflective thinking and emphasizing self-awareness as key to conscious actions.

2. Intention: In the DAI5 framework, intention shapes the purpose and direction of thought. By understanding one's intention, individuals gain clarity, focus, and alignment with their values, ensuring purposeful and intentional thinking throughout the process.

3. Initial Thinking: This phase involves brainstorming and exploring ideas without judgment, allowing for free association and intuition. It encourages diverse perspectives and reflections, setting the stage for more focused solutions.

4. Idealization: Idealization is the creative envisioning of the best possible solutions, inspiring individuals to think beyond current limitations. It fosters aspiration and hope, motivating deeper engagement with potential solutions while keeping a realistic perspective.

5. Instruction Set: This step converts idealized solutions into actionable steps, grounding aspirations in reality. Clear, practical instructions help ensure progress, reinforcing the importance of intentionality and reflection throughout the process.

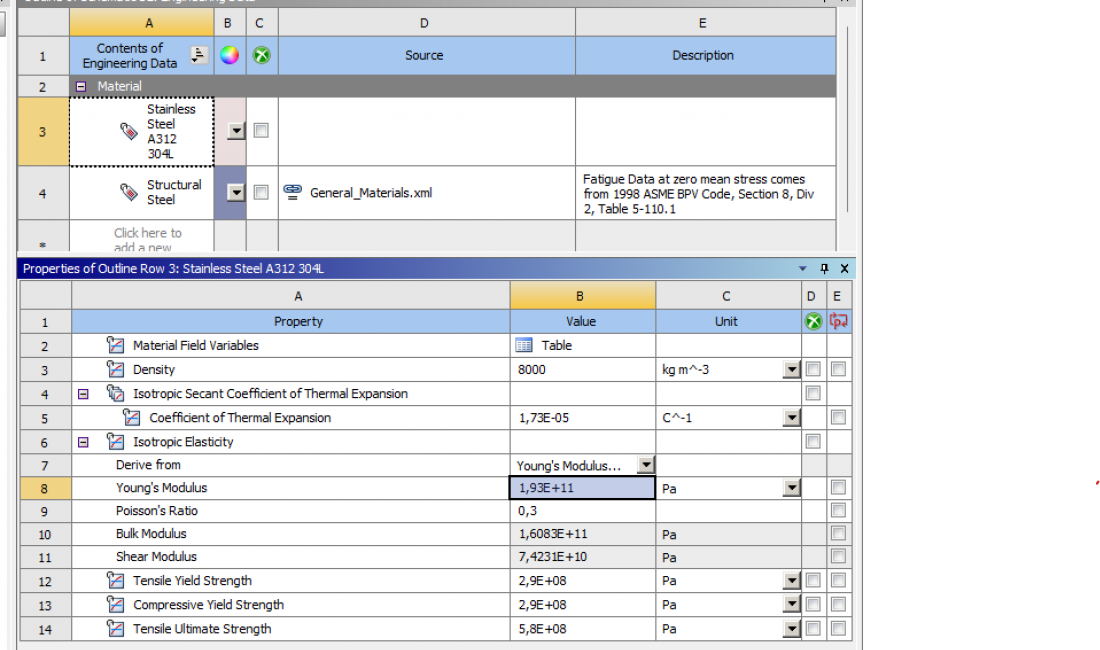

PIPE 2D

This analysis focuses on evaluating plane stress and plane strain conditions in a 2D model using ANSYS for a stainless steel pipe made of A312 304L.

Length : 4 m

Outside Diameter :168.275mm

Inside Diameter :162.175mm

The pipe analyzed in this simulation is modeled with fixed supports at both lower ends, ensuring that these points remain stationary under loading conditions. Additionally, a 4000 N load has been applied at the center of the pipe, representing the primary source of deformation observed in the simulation. This loading scenario is designed to simulate real-world conditions where pipes might experience concentrated forces at midspan, causing significant bending. The fixed supports provide resistance at the ends, preventing movement, while the central load introduces a bending moment that results in the observed deformation distribution.

The simulation results indicate that the pipe experiences a maximum deformation of 8.69 mm in the middle section, represented by the red color, with minimal deformation at the ends, where no significant change occurs. This variation in deformation distribution suggests that the pipe is subjected to a load or pressure causing bending along its structure, with the greatest deformation occurring at the center. These simulation results are important for understanding the pipe's response to the applied load, which can affect the design and stability of the pipe structure.