Difference between revisions of "Hazimi Hamar"

Hazimihamar (talk | contribs) |

Hazimihamar (talk | contribs) |

||

| Line 32: | Line 32: | ||

[[File:Stress Summary 1.png]] | [[File:Stress Summary 1.png]] | ||

| + | [[File:Stress Summary 2.png]] | ||

| + | |||

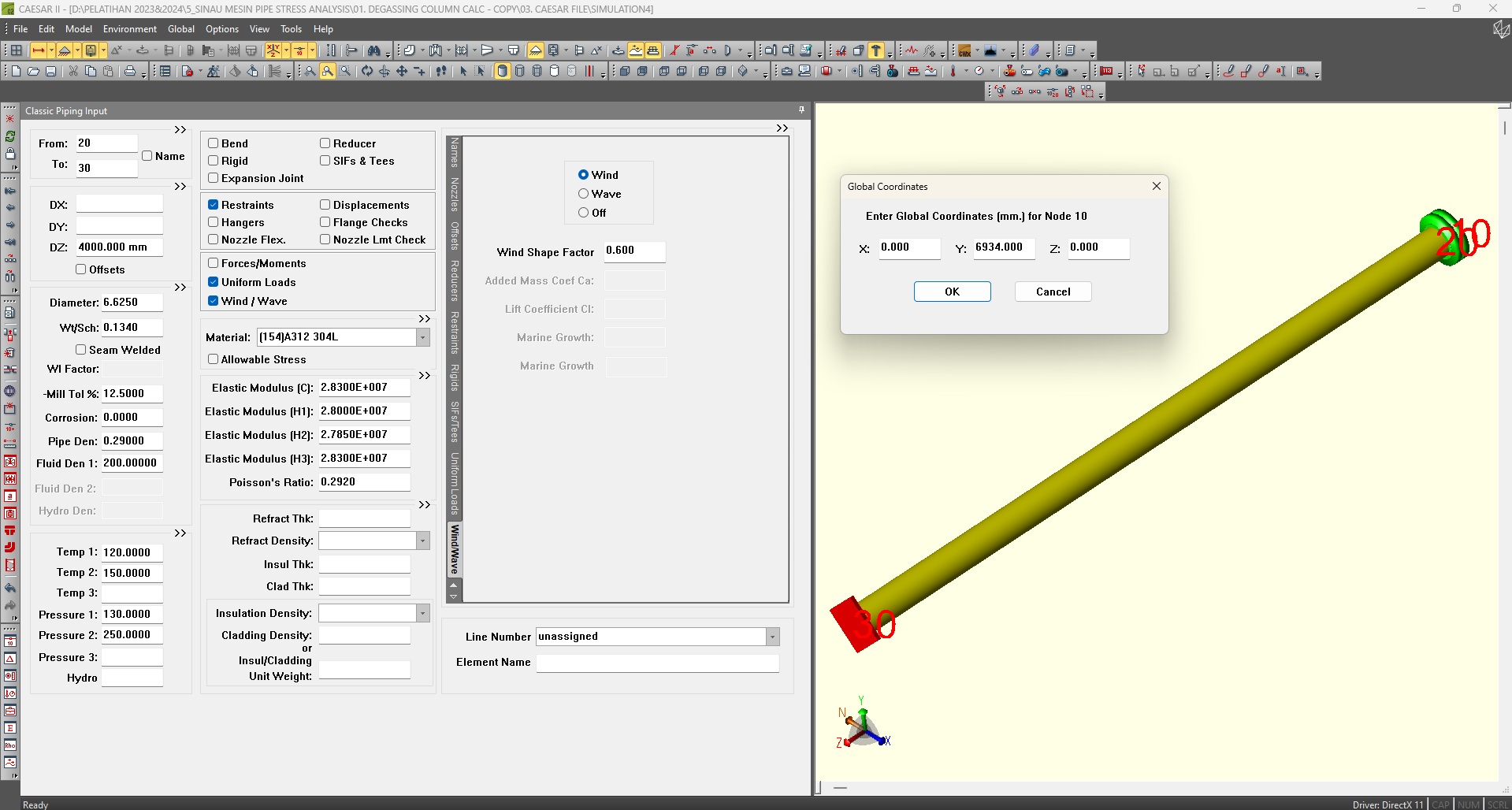

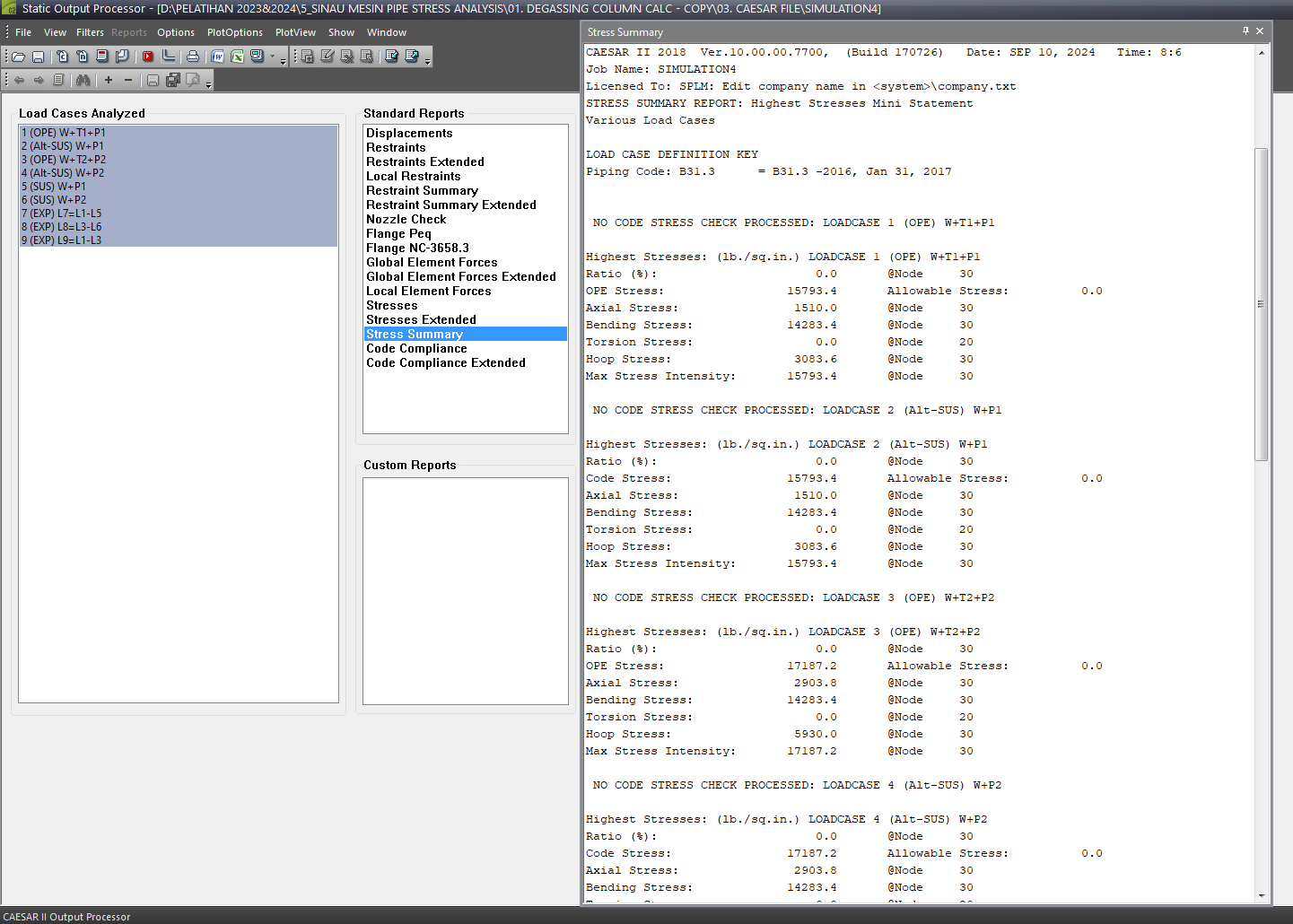

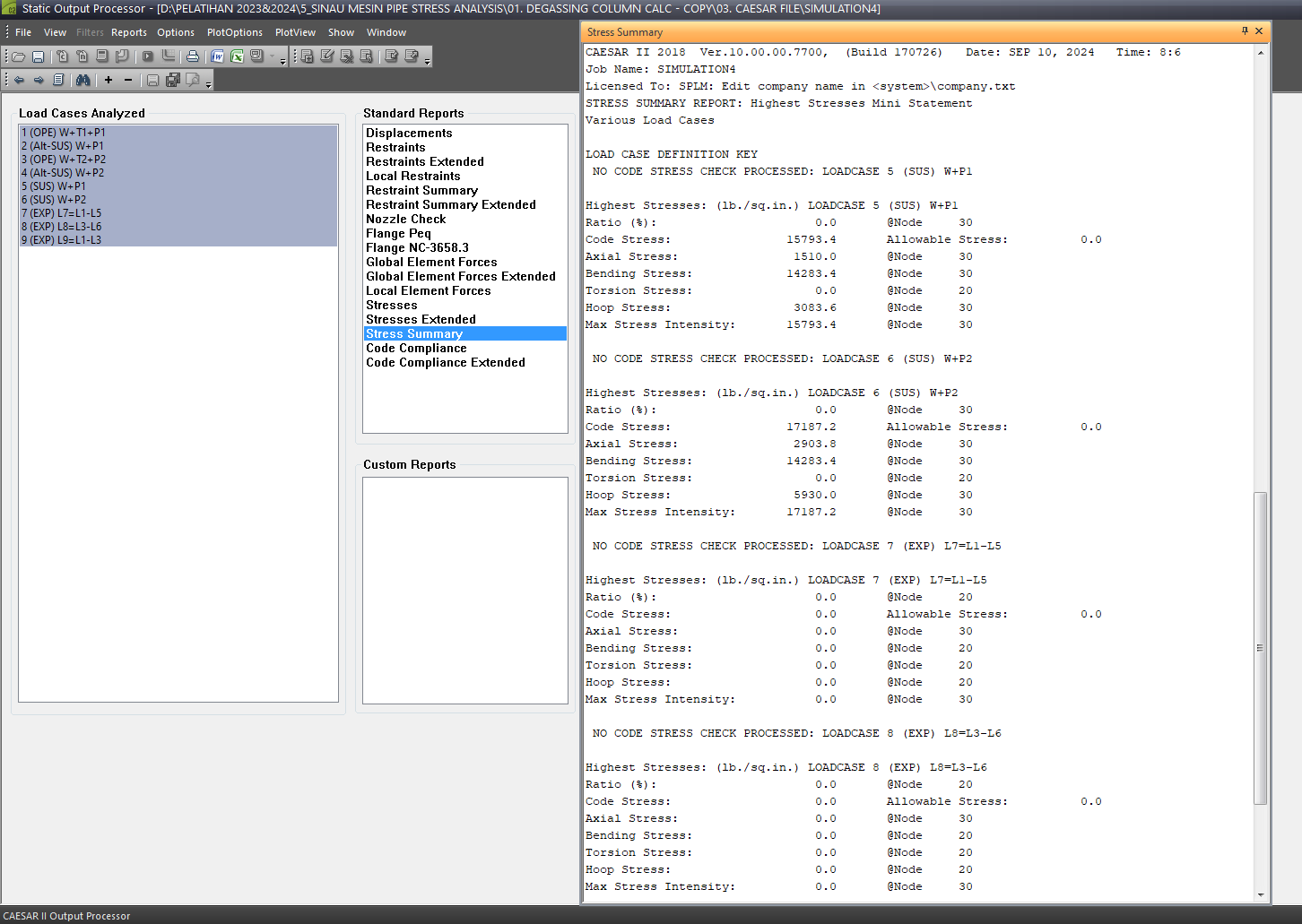

| + | In the Caesar II software from the modeling input we can see the results of the Load Case Analyzed obtained from the modeling that we input are Temperature Design and Operation, Pressure Design and Operation, Alternate SUSTAIN, SUSTAIN and Expansion. | ||

| + | |||

| + | For example, stress summary images 1 & 2 provide information on the results in the form of Axial Stress, Bending Stress, Torsion Stress, Hoop Stress and Max Stress Intensity. | ||

Revision as of 11:28, 10 September 2024

1. Hello, Welcome my first Home Page, in the form of assignment for meeting 1 in the Finite Element & Multhiphysics (27/08/2024)

At the 4th meeting the Finite Element & Multhiphysics (4/9/2024)

We do simple pipe design using Caesar II with classic piping input >> we make pipe models according to standard code B31.3 and set the layout of the pipe model including pipe length, pipe diameter, pipe wall thickness or sch, pipe fluid density, temperature and pressure are also set.

Material = A312 304L (stainless steel)

Pipe length = 4m

Diameter = 6in

Wallthicknes = 10s

Temp Operation = 120F Temp Design = 150F

Pressure Operation = 130lb./sq.in.

Pressure design = 270lb./sq.in.

3. Examples of the description above are modeling inputs that form the results of Displacement, Restraint Summary, Stress Summary and Global Element Forces.

In the Caesar II software from the modeling input we can see the results of the Load Case Analyzed obtained from the modeling that we input are Temperature Design and Operation, Pressure Design and Operation, Alternate SUSTAIN, SUSTAIN and Expansion.

For example, stress summary images 1 & 2 provide information on the results in the form of Axial Stress, Bending Stress, Torsion Stress, Hoop Stress and Max Stress Intensity.