Difference between revisions of "Setiawan Edy Prayogo"

| Line 150: | Line 150: | ||

The manufacturing of hydrogen cylinders, implemented through a concept design illustration using DWG drawings in Inventor software, involves a systematic series of steps. The initial stage is to design the concept of the hydrogen cylinder using Inventor software. Attention is given to precise dimensions, including diameter, height, and thickness of the cylinder, as well as the placement of components such as valves and sensors. | The manufacturing of hydrogen cylinders, implemented through a concept design illustration using DWG drawings in Inventor software, involves a systematic series of steps. The initial stage is to design the concept of the hydrogen cylinder using Inventor software. Attention is given to precise dimensions, including diameter, height, and thickness of the cylinder, as well as the placement of components such as valves and sensors. | ||

| + | |||

Once the concept design is complete, the next step is to prepare the detailed DWG drawings that outline each component and construction detail of the hydrogen cylinder. These DWG drawings include information on dimensions, tolerances, and material specifications. This process allows designers and engineers to collaborate and ensure that the hydrogen cylinder can be produced according to the desired design. | Once the concept design is complete, the next step is to prepare the detailed DWG drawings that outline each component and construction detail of the hydrogen cylinder. These DWG drawings include information on dimensions, tolerances, and material specifications. This process allows designers and engineers to collaborate and ensure that the hydrogen cylinder can be produced according to the desired design. | ||

| + | |||

After the DWG drawings are prepared, the next stage is the manufacturing process of the hydrogen cylinder. This involves selecting suitable materials, in this case, ASME SA36 carbon steel, which possesses corrosion resistance properties and sufficient strength to withstand hydrogen pressure. The chosen material is then processed and formed according to the DWG drawings using techniques such as welding or specialized forming machines. | After the DWG drawings are prepared, the next stage is the manufacturing process of the hydrogen cylinder. This involves selecting suitable materials, in this case, ASME SA36 carbon steel, which possesses corrosion resistance properties and sufficient strength to withstand hydrogen pressure. The chosen material is then processed and formed according to the DWG drawings using techniques such as welding or specialized forming machines. | ||

Revision as of 01:52, 7 June 2023

Introduction

Halo semua, saya Setiawan Edy Prayogo. Saya Mahasiswa Teknik Mesin UI angkatan 2021 dengan NPM 2106732960.

Saya bagian dari Kelas METODE NUMERIK-03.

Hydrogen Storage Optimization Project

• User Requirnments

• Capacity : 1 ltr

• Prasure : 8 bar

• Cost : Rp.500.000

A.Safety in Hydrogen Cylinder Manufacturing:

• Potential risks and hazards of hydrogen

Hydrogen possesses several potential risks and hazards that need to be considered in the manufacturing of hydrogen cylinders. Hydrogen is a highly flammable gas and can form explosive mixtures with air within a wide concentration range. These hazardous properties require proper safety measures to prevent potential fire or explosion incidents.

• Factors to consider in ensuring cylinder safety

In the manufacturing of hydrogen cylinders, several factors need to be considered to ensure safety:

a. Proper design: The cylinder design should consider adequate structural strength to withstand internal pressure and external loads. The design should also consider proper temperature control and ventilation to prevent the accumulation of hazardous hydrogen.

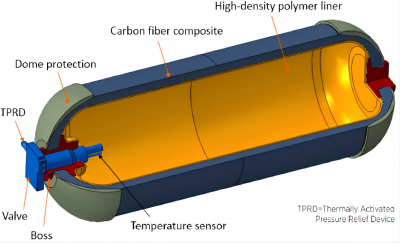

b. Selection of appropriate materials: The materials used for hydrogen cylinders should be corrosion-resistant and possess sufficient strength. Commonly used materials include stainless steel or carbon fiber reinforced with epoxy resin.

c. Testing and inspection: Hydrogen cylinders should undergo strict testing and regular inspections to ensure structural strength, pressure resistance, and prevention of unwanted leaks. Testing includes pressure tests, leak tests, and non-destructive testing.

d. Training and awareness: Adequate training should be provided to workers involved in the production and handling of hydrogen cylinders. Awareness of potential hazards and proper safety practices should be instilled to prevent accidents and unwanted incidents.

• Applicable safety standards and requirements

In the manufacturing of hydrogen cylinders, various safety standards and requirements should be considered. Some applicable standards include ISO 11114-4 for the compatibility of cylinder and valve materials with gas contents, ISO 9809-1 for the design and construction of quenched and tempered steel cylinders with a tensile strength less than 1,100 MPa, and ISO 15869 which specifies product requirements for compressed hydrogen. Additionally, national and regional regulations such as Title 49 of the Code of Federal Regulations (49 CFR) in the United States also regulate safety requirements in the production and handling of hydrogen cylinders.

B.Hydrogen Cylinder Design

• Concepts and design principles of hydrogen cylinders

The design of hydrogen cylinders should consider several key principles, including adequate structural strength to withstand internal pressure and external loads, the use of suitable materials to prevent corrosion and leakage, and a design that allows for efficient and safe filling and emptying.

• Ideal design types for pressurized hydrogen cylinders

Cylindrical cylinders with convex ends are one of the commonly used design types for pressurized hydrogen cylinders. This design provides good structural strength and enables efficient space utilization. When using a pressurized hydrogen cylinder with a capacity of 1 liter and pressure of 8 bar, it is important to consider a design that meets the prescribed strength and capacity requirements with a maximum production cost of 500k.

C.Suitable Materials for Hydrogen Cylinders

Suitable materials for an 8-bar pressurized hydrogen cylinder with a capacity of 1 liter and a maximum production cost of 500k include Carbon Steel (ASME SA36 Carbon Steel Sheet Metal) and stainless steel. Carbon Steel has the advantage of being lightweight yet having high strength. This makes it suitable for use in hydrogen cylinders that require good structural strength. Carbon Steel also exhibits good corrosion resistance and is commonly used in aerospace and automotive industries. However, the drawback of this material is its relatively high production cost.

Stainless steel is another commonly used material for hydrogen cylinders. It has the advantage of good corrosion resistance and lower production costs compared to carbon fiber. Stainless steel also possesses adequate strength and can fulfill the requirements of hydrogen cylinders. However, stainless steel tends to be heavier than carbon fiber. When selecting a suitable material for hydrogen cylinders, cost considerations should also be taken into account. Carbon Steel has higher production costs compared to stainless steel. Therefore, decision-making should consider cost efficiency alongside meeting the requirements for strength and safety.

• Technical Design

• Dimensions:

To minimize manufacturing costs, the hydrogen storage tank will have a basic cylindrical shape with curved edges for safety reasons. If we choose an approximate diameter of 8 cm (r = 4) and aim for an internal volume of around 1 liter (1000 cm^3), we can calculate the height of the tank using the formula:

h = 1000 / (π x r^2) = 1000 / (3.14 x 4^2) = 1000 / 50.24 = 19.90 cm

Therefore, the general dimensions of the storage tank would be approximately a diameter of 8 cm and a height of around 20 cm.

• Sheet Metal Thickness:

For the material, we plan to use ASME SA36 Carbon Steel Sheet Metal with a yield strength (Sy) of 250 MPa or 36,300 psi. The allowable stress (S) is calculated as 2/3 of the yield strength: 2/3 x 36,300 = 24,200 psi. To determine the minimum thickness (t) of the tank, we use the formula:

t = PR / (2SE + 0.4P)

Where:

E = 0.85 (for a double welded butt joint)

P = 20 bar = 290 psi

R = 40 mm = 1.57 inches

S = 24.200 psi

Plugging in the values, we have:

t = 290 x 1.57 / (2 x 24200 x 0.85) + (0.4 x 290)

t = 0.0110 inch = 2.7 mm

Therefore, the minimum thickness of the tank should be around 2.7 mm.

• Attachment

• Regulator Design:

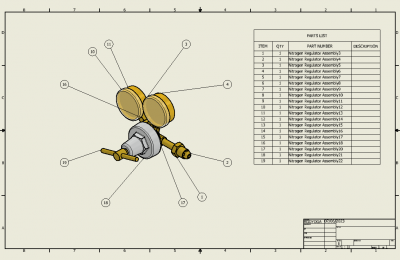

The manufacturing of hydrogen storage regulators involves a systematic and coordinated series of processes. In the initial stage, I am involved in designing a specialized regulator that takes into account the physical properties of hydrogen and regulatory requirements. As part of this process, I have designed an illustration of the regulator using Inventor software. Careful selection of materials and components that are resistant to hydrogen is then carried out. The manufacturing process can utilize modern technologies and methods such as CNC and precision processing to ensure accuracy and consistency. The regulators undergo rigorous testing and calibration to ensure proper functioning, precise pressure regulation, and reliability. After successful testing, the regulators are installed in various hydrogen storage systems.

The manufacturing of hydrogen storage regulators has been successfully implemented through a concept design illustration created using DWG drawings in Inventor software. This design concept represents a meticulous collaboration between designers and engineers to create regulators that meet the unique requirements of hydrogen storage. The illustration showcases regulators composed of various components, such as valves, pressure regulators, and sensors, designed with high precision to ensure optimal performance.

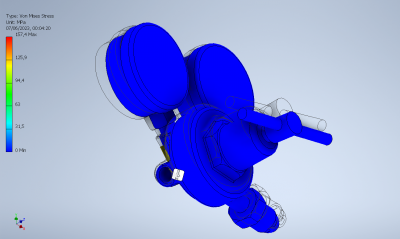

Furthermore, the manufacturing of regulators for hydrogen storage has also been successfully implemented through a safety design concept illustration that utilizes stress analysis in Inventor software. In this design concept, regulators have been thoroughly analyzed using finite element method to estimate stress, deformation, and critical points in the regulator's structure. The stress analysis ensures that regulators can withstand and operate safely under the encountered hydrogen pressure.

In both design concepts, safety, reliability, and efficiency in hydrogen pressure regulation are prioritized. Careful selection of hydrogen-resistant materials and proper structural placement are considered to withstand the generated stress from hydrogen pressure. The use of Inventor software allows for accurate detailed representation, enabling the production of regulators that meet high-quality standards.

Through the implementation of these design concept illustrations, the manufacturing of regulators for hydrogen storage can produce products that not only meet stringent safety standards but also support the development of sustainable hydrogen technology. With collaboration between designers, engineers, and the application of stress analysis, these regulators can be produced with confidence in their ability to withstand extreme conditions and maintain the integrity of the hydrogen storage systems.

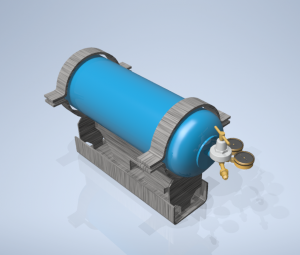

• Hydrogen Storage Design:

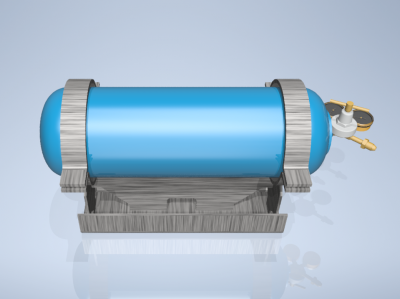

The manufacturing of a hydrogen cylinder with a capacity of 1 liter and a pressure rating of 8 bar using ASME SA36 carbon steel material involves a meticulous and coordinated process. The initial stage involves designing a conceptual illustration using Inventor software, with reference to dimensions of 8 cm in diameter, 20 cm in height, and a material thickness of 2.7 mm. Subsequently, the ASME SA36 material is prepared to the appropriate size and thickness, followed by shaping and heat treatment. The cylinder undergoes rigorous testing, including pressure and leakage tests, to ensure its safety and reliability. Upon successfully passing the tests, the hydrogen cylinder is ready for use in various storage and transportation applications. Safety, quality, and reliability are the primary concerns in this manufacturing process to meet industry standards and user requirements.

The manufacturing of hydrogen cylinders, implemented through a concept design illustration using DWG drawings in Inventor software, involves a systematic series of steps. The initial stage is to design the concept of the hydrogen cylinder using Inventor software. Attention is given to precise dimensions, including diameter, height, and thickness of the cylinder, as well as the placement of components such as valves and sensors.

Once the concept design is complete, the next step is to prepare the detailed DWG drawings that outline each component and construction detail of the hydrogen cylinder. These DWG drawings include information on dimensions, tolerances, and material specifications. This process allows designers and engineers to collaborate and ensure that the hydrogen cylinder can be produced according to the desired design.

After the DWG drawings are prepared, the next stage is the manufacturing process of the hydrogen cylinder. This involves selecting suitable materials, in this case, ASME SA36 carbon steel, which possesses corrosion resistance properties and sufficient strength to withstand hydrogen pressure. The chosen material is then processed and formed according to the DWG drawings using techniques such as welding or specialized forming machines.

Once the hydrogen cylinder is manufactured, the next step is rigorous testing and quality inspection. The cylinder undergoes pressure tests to verify its ability to withstand the specified hydrogen pressure, in this case, 8 bar. Additionally, leak tests are conducted to ensure that the cylinder does not experience gas leakage, which could compromise safety and hydrogen storage efficiency.

After successfully passing the tests and meeting the set quality standards, the hydrogen cylinder is ready for use in various hydrogen storage and transportation applications. Throughout the manufacturing process, primary attention is given to safety, reliability, and quality of the hydrogen cylinder. This is done to ensure that the cylinder functions well and safely when used in hydrogen storage and transportation environments.

The manufacturing of hydrogen cylinders has been implemented through a safety design concept illustration that utilizes stress analysis in Inventor software. This design places a strong emphasis on safety aspects to ensure safe and reliable performance when the cylinder is used in hydrogen storage and transportation.

The initial stage in this manufacturing process is to design a safety design concept illustration using Inventor software. In this stage, designers utilize stress analysis techniques to study how the cylinder will behave and withstand the given pressure and loads. This analysis provides in-depth insights into critical points, deformations, and stresses that may occur in the cylinder structure.

Subsequently, designers consider the results of the stress analysis in the manufacturing process. Suitable materials are chosen, and the dimensions and thickness of the cylinder are determined while considering safe stress limits. Welding techniques and cylinder forming processes are also taken into account to ensure structural integrity and optimal stress distribution.

After the hydrogen cylinder is produced, stringent testing and quality inspections are conducted. The cylinder undergoes a series of tests to verify its ability to withstand expected pressures and loads, as well as extreme conditions. These tests include pressure tests and non-destructive analysis to detect any leaks or defects in the cylinder.

Through the implementation of the safety design concept with stress analysis, the manufacturing of hydrogen cylinders ensures that the produced cylinders meet strict safety standards. By considering stress factors and material strength in the design and manufacturing process, hydrogen cylinders become more durable, reliable, and capable of maintaining structural integrity in various operational conditions. Safety and quality are the top priorities in this hydrogen cylinder manufacturing to maintain a safe and efficient environment for hydrogen storage and transportation.

D.Hydrogen Cylinder Manufacturing Methods

The manufacturing of hydrogen cylinders involves several steps, including material preparation, cylinder forming, hardening, and finishing. The first step is material preparation, where the selected materials such as carbon fiber or stainless steel are prepared in appropriate forms for cylinder manufacturing. Subsequently, the materials are shaped into cylinder form using techniques such as filament winding or molding. After forming, the cylinders undergo a hardening process. This involves the use of heat treatment or specific chemical processes to enhance the material's strength. Hardening is essential to ensure that the cylinders can safely withstand internal pressure and external loads. Lastly, the cylinders undergo a finishing process, which includes cleaning, surface smoothing, and surface treatment as required. This aims to ensure that the cylinders have a good appearance and are ready for use.

The production process of hydrogen cylinders should be accompanied by periodic testing and inspections. Testing such as pressure tests and leak tests should be conducted to ensure cylinder safety and reliability. Regular inspections are also crucial for detecting any damage or wear that may occur over time.

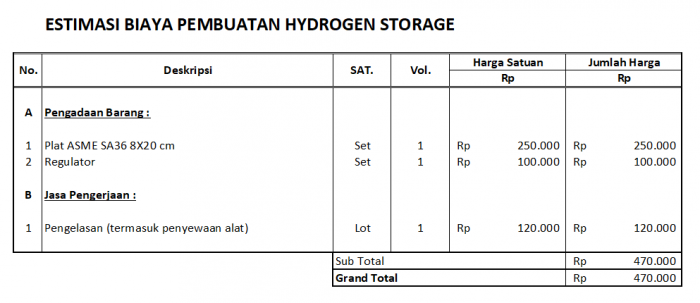

• Cost

• Price Reference Tokopedia Indonesia

Referensi:

Haynes, W.M. (Ed.). (2014). CRC Handbook of Chemistry and Physics (95th ed.). CRC Press.

International Organization for Standardization (ISO). ISO 11114-4: Gas cylinders -- Compatibility of cylinder and valve materials with gas contents -- Part 4: Test methods for selecting metallic materials resistant to hydrogen embrittlement.

International Organization for Standardization (ISO). ISO 9809-1: Gas cylinders -- Refillable seamless steel gas cylinders -- Design, construction and testing -- Part 1: Quenched and tempered steel cylinders with tensile strength less than 1,100 MPa.

International Organization for Standardization (ISO). ISO 15869: Gas cylinders -- Seamless steel and aluminium-alloy gas cylinders evaluation of the regulatory framework. United States Department of Transportation. Title 49 of the Code of Federal Regulations (49 CFR) -- Transportation of hazardous materials