Difference between revisions of "Shafira herdiyan maritza salsabila"

(→Efektivitas Biaya) |

|||

| Line 211: | Line 211: | ||

==Efektivitas Biaya== | ==Efektivitas Biaya== | ||

[[File:MessageImage 1686003418270.jpg|300px|Left]] | [[File:MessageImage 1686003418270.jpg|300px|Left]] | ||

| + | Berdasarkan tabel harga plat aluminium dan setelah hasil perhitungan iterasi | ||

Revision as of 05:06, 6 June 2023

Contents

INTRODUCTION

Nama : Shafira Herdiyan Maritza Salsabila

NPM : 2006574080

Jurusan : Teknik Mesin Reguler

METODE NUMERIK 02

Tugas Designing Hydrogen Storage

Hydrogen storage optimization involves determining the most efficient and effective methods for storing hydrogen gas. There are various factors to consider, such as storage capacity, energy density, safety, cost, and practicality. The optimization process typically involves evaluating different storage technologies and their performance characteristics.

To calculate hydrogen storage optimization, you would need to consider the specific requirements and constraints of the application or system where hydrogen is being stored. This could include factors like available space, desired storage duration, required release rates, and any specific safety considerations.

Several storage technologies are commonly used for hydrogen, including compressed gas storage, liquid hydrogen storage, metal hydride storage, and carbon-based materials such as activated carbon or carbon nanotubes. Each technology has its own advantages and limitations in terms of storage capacity, energy density, release rates, and safety.

The calculation process involves assessing the performance parameters of each storage technology and comparing them based on the application requirements. This can include evaluating factors such as the gravimetric and volumetric storage densities, the efficiency of hydrogen uptake and release, the cycling stability, and the overall cost.

Designing hydrogen storage systems requires careful consideration of various aspects to ensure safety, efficiency, and practicality. Here are some key aspects to consider:

1. Storage Method: There are several methods to store hydrogen, including compressed gas, liquefied hydrogen, metal hydrides, chemical storage, and solid-state storage. Each method has its advantages and disadvantages in terms of storage capacity, energy density, safety, and cost. The chosen storage method will depend on the specific application and requirements.

2. Safety: Safety is paramount when designing hydrogen storage systems. Hydrogen is highly flammable and has a wide flammability range, requiring stringent safety measures. The storage system should be designed to prevent leaks, minimize the risk of ignition, and handle any potential releases safely. Safety features such as pressure relief devices, venting systems, and leak detection mechanisms should be incorporated.

3. Storage Capacity and Energy Density: Hydrogen storage systems need to provide sufficient storage capacity and energy density to meet the intended application's requirements. High storage capacity allows for longer operation times, while high energy density enables compact and lightweight storage systems. Balancing these factors with safety considerations is crucial.

4. Efficiency: Efficient storage systems minimize energy losses during storage and retrieval. Consider factors such as heat management, thermal insulation, and energy losses associated with the chosen storage method. Minimizing energy losses ensures that stored hydrogen can be effectively utilized when needed.

5. Scalability: The design should consider scalability to accommodate different storage capacities and application requirements. This is particularly important for applications such as energy storage systems, where the demand may vary over time.

6. Infrastructure and Compatibility: Designing hydrogen storage systems also involves considering the infrastructure and compatibility with existing or planned infrastructure. For example, if the system is intended for transportation, it should be compatible with refueling infrastructure and vehicles. Compatibility with existing hydrogen production and distribution methods is also important.

7. Material Selection: Selecting appropriate materials for the storage system is crucial. The materials should have high strength, durability, and resistance to hydrogen embrittlement. Compatibility with hydrogen gas is essential to prevent material degradation or contamination.

8. Environmental Impact: Consider the environmental impact of the storage system throughout its lifecycle. Assess factors such as energy requirements for manufacturing, recyclability or reusability of materials, and any potential emissions or waste associated with the system.

9. Cost: The cost of designing and implementing the storage system should be considered. Evaluate the costs associated with materials, manufacturing processes, maintenance, and any necessary safety measures. Cost-effectiveness is important for the widespread adoption of hydrogen storage systems.

10. Regulations and Standards: Keep in mind the relevant regulations and standards for hydrogen storage systems. Compliance with safety standards and industry regulations is essential to ensure legal and safe operation.

11. Cost: Evaluate the cost implications of different storage options, including initial investment, maintenance, and operational expenses. Consider the total cost of ownership over the system's lifespan.

Remember that designing hydrogen storage systems can be complex and often requires expertise in various engineering disciplines. Engaging professionals with experience in hydrogen technologies is highly recommended to ensure optimal design and safe operation.

Final Project Designing Hydrogen Storage

Persyaratan: Mendesain penyimpanan hidrogen pada tekanan 8 bar dengan kapasitas 1 liter dan anggaran sebesar Rp 500.000.

Variabel desain: Geometri, pemilihan material dan kekuatan.

Harga: Di bawah Rp 500.000.

Tujuan: Luas permukaan terkecil, material paling tipis, dan dapat menahan tekanan 8 bar.

Geometri

Untuk menemukan geometri optimal pada desain Hydrogen Tank digunakan iterasi dengan bantuan software python sehingga bisa didapatkan ukuran radius dan tinggi tanki optimal dengan luas daerah yang minimum untuk volume 1 liter

import math

from scipy.optimize import minimize

def Luas_Permukaan(radius_height):

r, h = radius_height

return 2 * math.pi * r * (r + h)

target_volume = 1000 # Volume dalam cm^3 (1 liter = 1000 cm^3)

x0 = [1, 1] # Tebakan awal (radius, height)

bounds = [(0, None), (0, None)] # Batas untuk radius dan height

# Optimasi menggunakan metode minimize dari scipy

result = minimize(Luas_Permukaan, x0, method='SLSQP', bounds=bounds,

constraints={'type': 'eq', 'fun': lambda x: math.pi * (x[0]**2) * x[1] - target_volume})

# Cetak hasil optimasi

print("Radius:", result.x[0])

print("Tinggi:", result.x[1])

print("Luas Permukaan:", result.fun)Radius: 5.41926305506462

Tinggi: 10.838511985088449

Luas Permukaan: 553.5810444905989Maka radius dan tinggi yang akan digunakan pada perancangan tanki hidrogen kali ini adalah Radius: 5.41926305506462 Tinggi: 10.838511985088449

Material

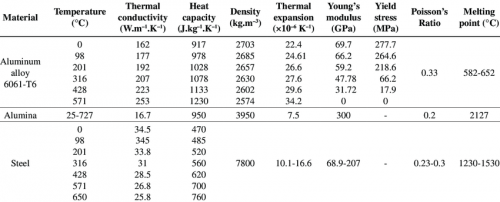

Pada studi kasus kali ini saya memilih Alumunium Alloy 6061 untuk menjadi material dasar perancanganan hydrogen tank dengan alasan:

Kekuatan dan Kekakuan: Alumunium Alloy 6061 memiliki rasio kekuatan-berat yang sangat baik, sehingga menjadi pilihan yang diinginkan untuk tangki hidrogen bertekanan.

Ketahanan Korosi: Alumunium Alloy 6061 memiliki lapisan oksida alami yang memberikan ketahanan korosi inheren. Lapisan oksida ini dapat ditingkatkan melalui perlakuan permukaan atau lapisan pelindung untuk meningkatkan ketahanan material terhadap kerapuhan hidrogen.

Ringan: Alumunnium Alloy 6061 adalah material yang ringan, yang berkontribusi pada pengurangan berat keseluruhan tangki hidrogen.

Efektivitas Biaya: Alumunium Alloy 6061 relatif ekonomis dibandingkan dengan material kinerja tinggi lainnya, seperti komposit serat karbon atau paduan titanium.

Untuk menghitung kekuatan material pada desain hydrogen tank kembali digunakan iterasi dengan bantuan software python

r = 5.419e-2

p = 800000

t = 2.8e-3

while t < 11e-3:

hoop = (r * p)/(t)

print('for thickness', t, 'hoop stress =', hoop, "Pa")

t += 0.1e-3

if hoop > 264e9:

breakHasil iterasi didapatkan

for thickness 0.0028 hoop stress = 15482857.142857144 Pa

for thickness 0.0029 hoop stress = 14948965.517241381 Pa

for thickness 0.0029999999999999996 hoop stress = 14450666.666666668 Pa

for thickness 0.0030999999999999995 hoop stress = 13984516.12903226 Pa

for thickness 0.0031999999999999993 hoop stress = 13547500.000000004 Pa

for thickness 0.003299999999999999 hoop stress = 13136969.696969701 Pa

for thickness 0.003399999999999999 hoop stress = 12750588.235294122 Pa

for thickness 0.0034999999999999988 hoop stress = 12386285.714285718 Pa

for thickness 0.0035999999999999986 hoop stress = 12042222.222222228 Pa

for thickness 0.0036999999999999984 hoop stress = 11716756.756756762 Pa

for thickness 0.0037999999999999983 hoop stress = 11408421.052631585 Pa

for thickness 0.003899999999999998 hoop stress = 11115897.435897442 Pa

for thickness 0.003999999999999998 hoop stress = 10838000.000000004 Pa

for thickness 0.004099999999999999 hoop stress = 10573658.53658537 Pa

for thickness 0.004199999999999999 hoop stress = 10321904.761904765 Pa

for thickness 0.004299999999999999 hoop stress = 10081860.465116281 Pa

for thickness 0.004399999999999999 hoop stress = 9852727.272727273 Pa

for thickness 0.0045 hoop stress = 9633777.777777778 Pa

for thickness 0.0046 hoop stress = 9424347.826086957 Pa

for thickness 0.0047 hoop stress = 9223829.787234042 Pa

for thickness 0.0048000000000000004 hoop stress = 9031666.666666666 Pa

for thickness 0.004900000000000001 hoop stress = 8847346.93877551 Pa

for thickness 0.005000000000000001 hoop stress = 8670399.999999998 Pa

for thickness 0.005100000000000001 hoop stress = 8500392.156862743 Pa

for thickness 0.0052000000000000015 hoop stress = 8336923.076923074 Pa

for thickness 0.005300000000000002 hoop stress = 8179622.641509431 Pa

for thickness 0.005400000000000002 hoop stress = 8028148.1481481455 Pa

for thickness 0.005500000000000002 hoop stress = 7882181.818181815 Pa

for thickness 0.0056000000000000025 hoop stress = 7741428.571428568 Pa

for thickness 0.005700000000000003 hoop stress = 7605614.035087716 Pa

for thickness 0.005800000000000003 hoop stress = 7474482.758620686 Pa

for thickness 0.005900000000000003 hoop stress = 7347796.610169487 Pa

for thickness 0.006000000000000004 hoop stress = 7225333.333333329 Pa

for thickness 0.006100000000000004 hoop stress = 7106885.245901635 Pa

for thickness 0.006200000000000004 hoop stress = 6992258.064516124 Pa

for thickness 0.006300000000000004 hoop stress = 6881269.841269837 Pa

for thickness 0.006400000000000005 hoop stress = 6773749.999999995 Pa

for thickness 0.006500000000000005 hoop stress = 6669538.461538456 Pa

for thickness 0.006600000000000005 hoop stress = 6568484.848484843 Pa

for thickness 0.006700000000000005 hoop stress = 6470447.761194024 Pa

for thickness 0.006800000000000006 hoop stress = 6375294.117647054 Pa

for thickness 0.006900000000000006 hoop stress = 6282898.550724632 Pa

for thickness 0.007000000000000006 hoop stress = 6193142.857142852 Pa

for thickness 0.0071000000000000065 hoop stress = 6105915.492957741 Pa

for thickness 0.007200000000000007 hoop stress = 6021111.111111105 Pa

for thickness 0.007300000000000007 hoop stress = 5938630.136986296 Pa

for thickness 0.007400000000000007 hoop stress = 5858378.378378373 Pa

for thickness 0.0075000000000000075 hoop stress = 5780266.66666666 Pa

for thickness 0.007600000000000008 hoop stress = 5704210.526315784 Pa

for thickness 0.007700000000000008 hoop stress = 5630129.870129865 Pa

for thickness 0.007800000000000008 hoop stress = 5557948.717948712 Pa

for thickness 0.007900000000000008 hoop stress = 5487594.936708855 Pa

for thickness 0.008000000000000007 hoop stress = 5418999.999999995 Pa

for thickness 0.008100000000000007 hoop stress = 5352098.765432094 Pa

for thickness 0.008200000000000006 hoop stress = 5286829.268292679 Pa

for thickness 0.008300000000000005 hoop stress = 5223132.530120479 Pa

for thickness 0.008400000000000005 hoop stress = 5160952.380952378 Pa

for thickness 0.008500000000000004 hoop stress = 5100235.294117644 Pa

for thickness 0.008600000000000003 hoop stress = 5040930.232558138 Pa

for thickness 0.008700000000000003 hoop stress = 4982988.505747125 Pa

for thickness 0.008800000000000002 hoop stress = 4926363.636363635 Pa

for thickness 0.008900000000000002 hoop stress = 4871011.235955055 Pa

for thickness 0.009000000000000001 hoop stress = 4816888.888888888 Pa

for thickness 0.0091 hoop stress = 4763956.043956044 Pa

for thickness 0.0092 hoop stress = 4712173.9130434785 Pa

for thickness 0.0093 hoop stress = 4661505.376344087 Pa

for thickness 0.009399999999999999 hoop stress = 4611914.893617022 Pa

for thickness 0.009499999999999998 hoop stress = 4563368.421052633 Pa

for thickness 0.009599999999999997 hoop stress = 4515833.333333335 Pa

for thickness 0.009699999999999997 hoop stress = 4469278.350515465 Pa

for thickness 0.009799999999999996 hoop stress = 4423673.469387757 Pa

for thickness 0.009899999999999996 hoop stress = 4378989.898989901 Pa

for thickness 0.009999999999999995 hoop stress = 4335200.000000002 Pa

for thickness 0.010099999999999994 hoop stress = 4292277.227722774 Pa

for thickness 0.010199999999999994 hoop stress = 4250196.078431375 Pa

for thickness 0.010299999999999993 hoop stress = 4208932.038834955 Pa

for thickness 0.010399999999999993 hoop stress = 4168461.5384615413 Pa

for thickness 0.010499999999999992 hoop stress = 4128761.904761908 Pa

for thickness 0.010599999999999991 hoop stress = 4089811.3207547204 Pa

for thickness 0.01069999999999999 hoop stress = 4051588.7850467325 Pa

for thickness 0.01079999999999999 hoop stress = 4014074.074074078 Pa

for thickness 0.01089999999999999 hoop stress = 3977247.706422022 Pa

for thickness 0.010999999999999989 hoop stress = 3941090.909090913 PaEfektivitas Biaya

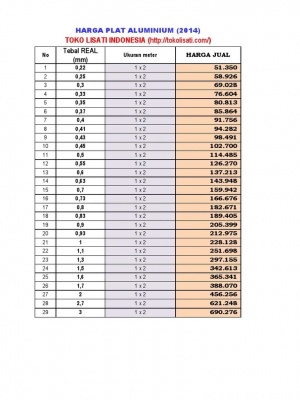

Berdasarkan tabel harga plat aluminium dan setelah hasil perhitungan iterasi

Berdasarkan tabel harga plat aluminium dan setelah hasil perhitungan iterasi